Aerobic granular sludge reactor for treating low-temperature sewage and water treatment method thereof

An aerobic granular sludge and reactor technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor start-up and stable operation performance, low-temperature activated sludge bulking , poor performance of aerobic sludge, etc., to achieve the effects of stable operation, stable effluent quality and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

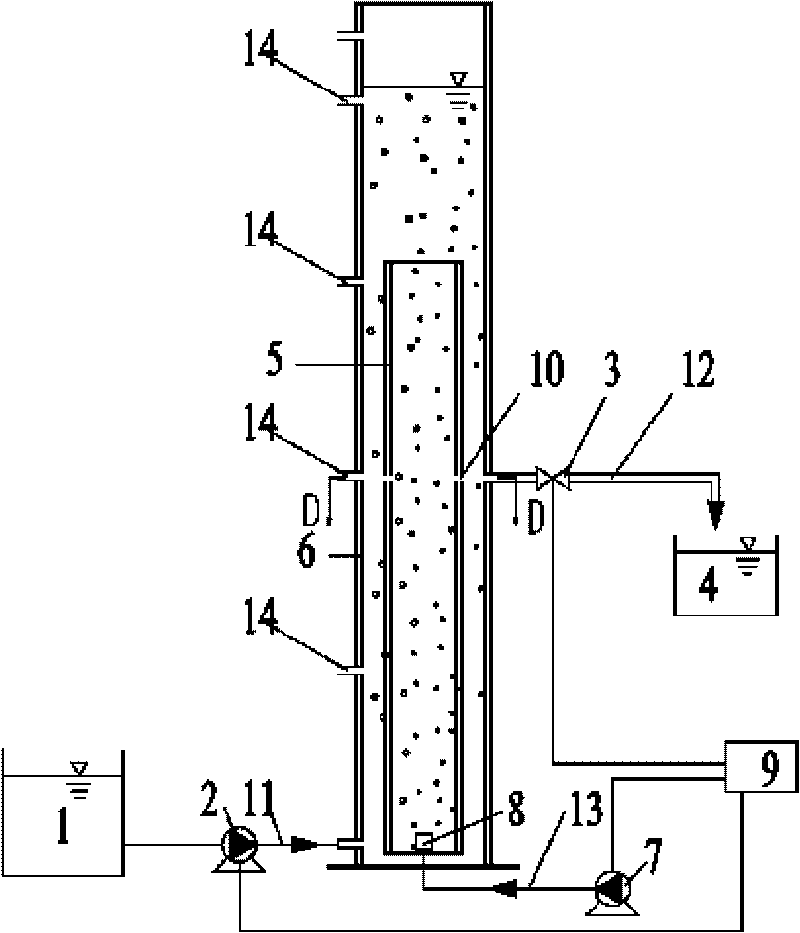

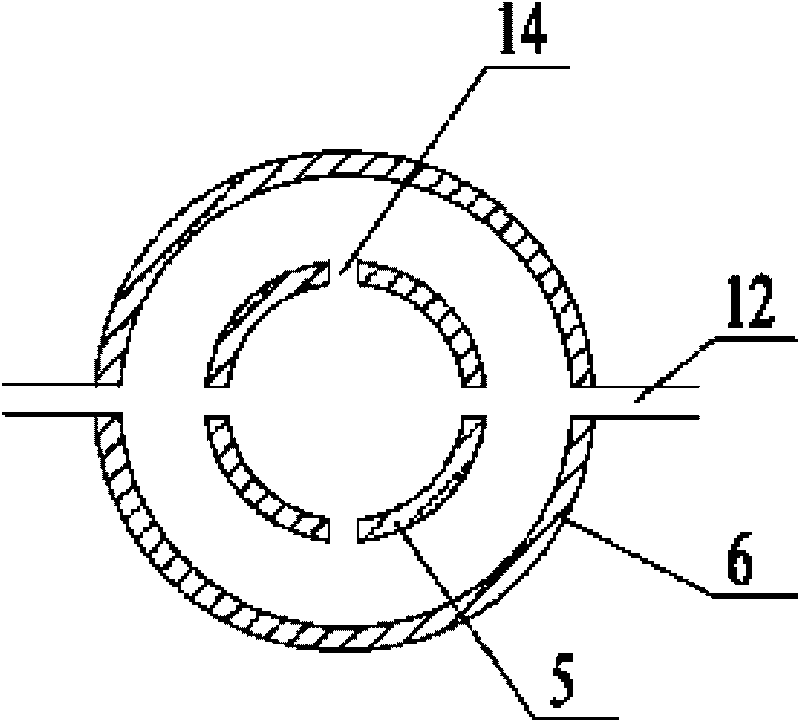

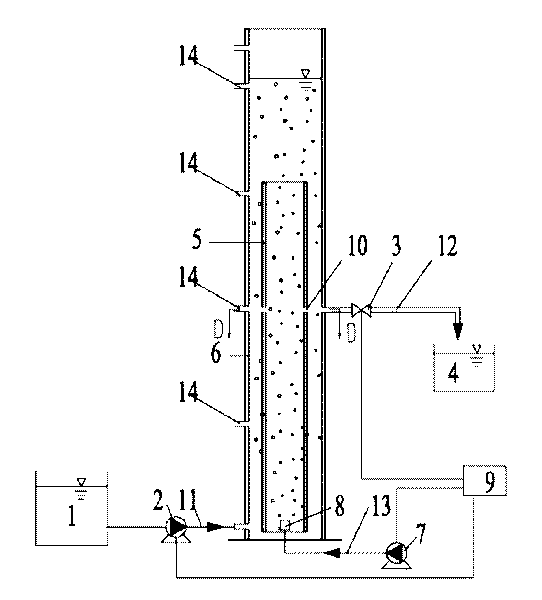

[0009] Specific implementation mode one: combine Figure 1 ~ Figure 2 Describe this embodiment, an aerobic granular sludge reactor for treating low-temperature sewage in this embodiment includes a water inlet tank 1, a water inlet pipe 11, a water inlet pump 2, an outlet solenoid valve 3, an outlet pipe 12, an outlet tank 4, a reaction The main body of the reactor, the air compressor 7, the aeration head 8 and the inlet pipe 13, the main body of the reactor is composed of the riser 5 and the downcomer 6, the riser 5 and the downcomer 6 are coaxially set from the inside to the outside, and the The bottom of the riser 5 is provided with an aeration head 8, and the aeration head 8 communicates with the air compressor 7 outside the reactor main body through the air inlet pipe 13, and the bottom of the downcomer 6 communicates with the bottom of the riser 5, The top of the descending pipe 6 communicates with the top of the ascending pipe 5, one end of the water inlet pipe 11 commun...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To describe this embodiment, a plurality of connection holes 10 in this embodiment are opened at 1 / 2 the height of the riser 5 from the bottom of the reactor main body. Such setting shortens the start-up time of the aerobic granular sludge reactor under low temperature conditions, and the granular sludge operates stably under low temperature conditions. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 The present embodiment will be described. In this embodiment, the ratio of the height of the riser pipe 5 to the inner diameter of the riser pipe 5 is 10, and the ratio of the height of the descender pipe 6 to the inner diameter of the descender pipe 6 is 10. Such setting increases the stability of the operation of the aerobic granular sludge reactor under low temperature conditions. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0012] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the aerobic granular sludge reactor of this embodiment is further provided with a programmable controller 9, and the programmable controller 9 is connected to the water outlet solenoid valve 3, the air compressor 7 and the water inlet pump 2 respectively. With such setting, the operation period of the reactor and the time of water inflow, aeration, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com