Wind power generation steel ball thermal treatment and quenching combined device

A technology of wind power generation and combined devices, applied in quenching devices, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of steel ball surface damage, affecting processing efficiency and product performance, and achieve small impact, avoid collision damage, and large heat dissipation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

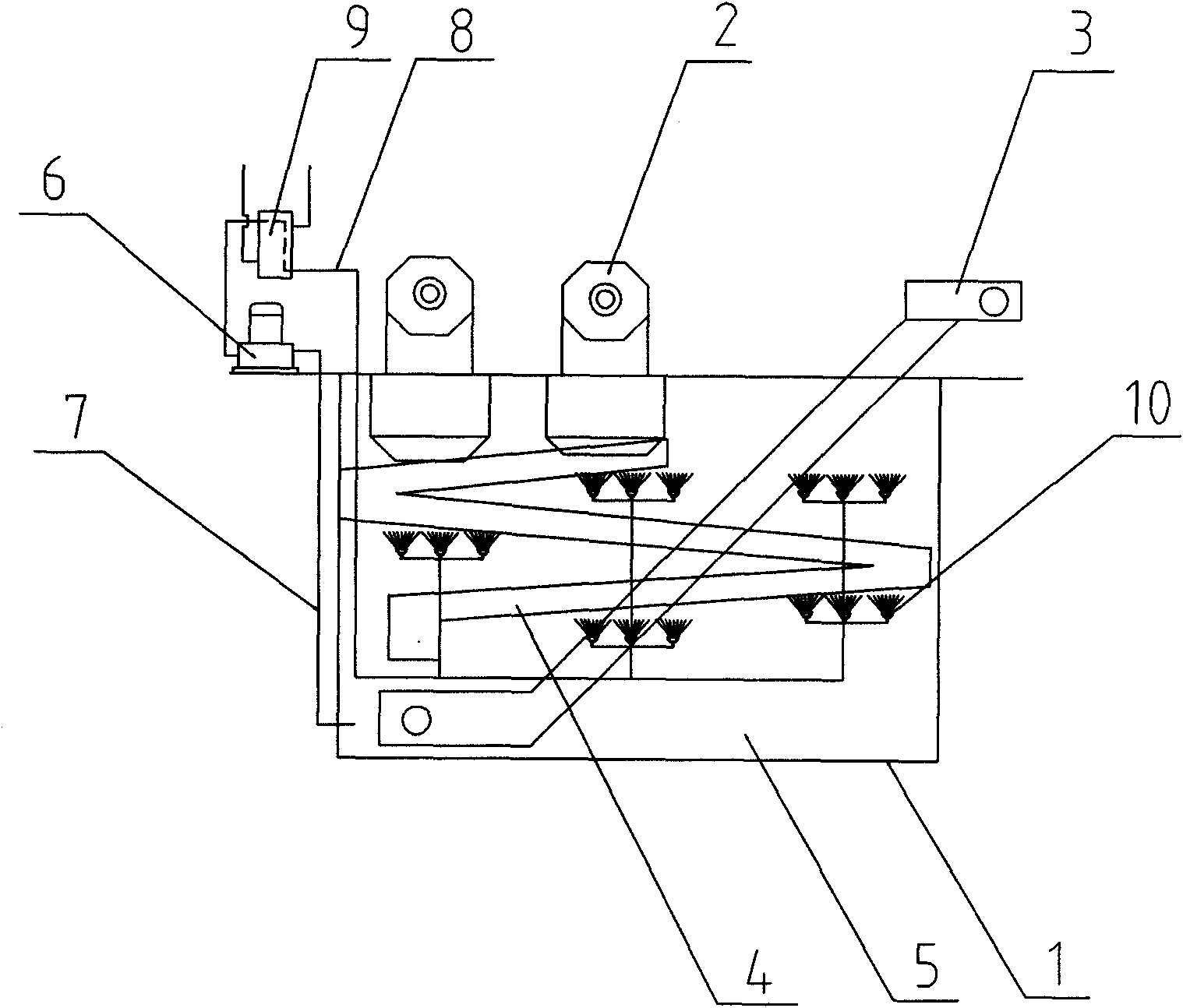

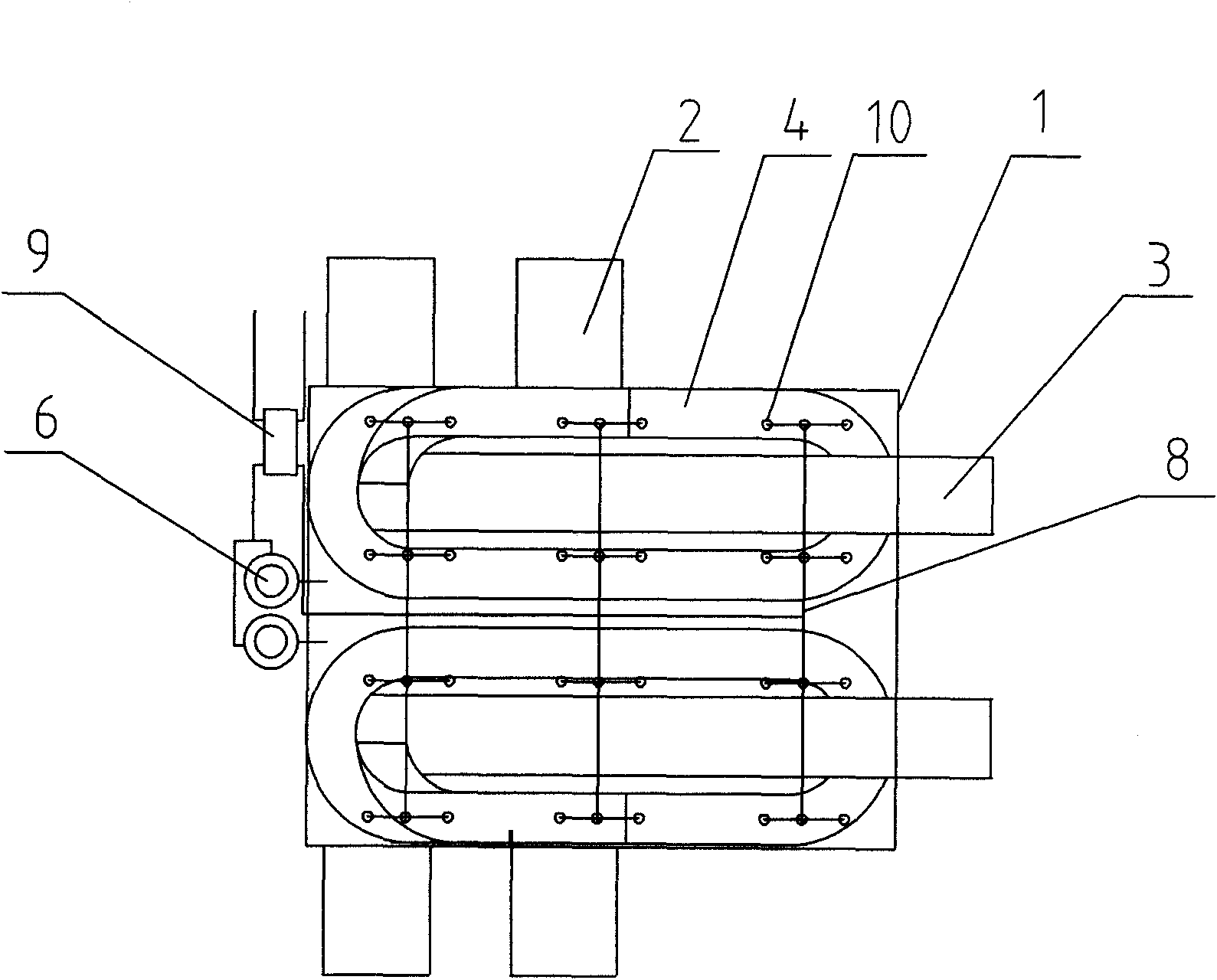

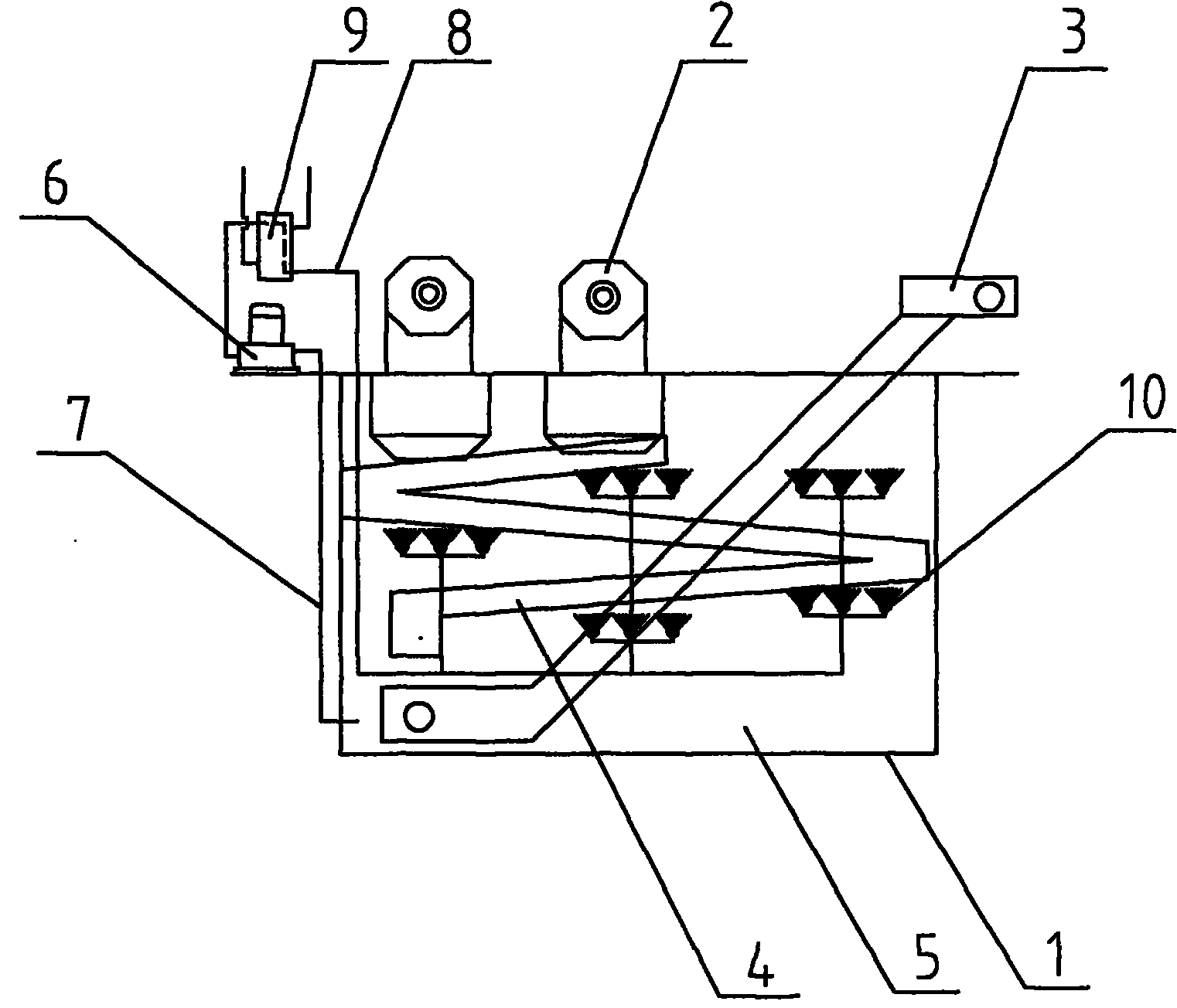

[0011] Such as figure 1 , 2 As shown, it includes a cooling pool 1, a feed port 2, a lifting mechanism 3, a spiral track 4, a coolant 5, a water pump 6, a liquid inlet pipe 7, a liquid outlet pipe 8, a heat exchanger 9, and a liquid injection port 10.

[0012] The top side of the above-mentioned cooling pool 1 is connected with a feed inlet 2, and the bottom is provided with a lifting mechanism 3, and a spiral track 4 is connected between the feed inlet 2 and the lifting mechanism 3, and the pool is filled with cooling liquid 5. The steel ball enters the spiral track 4 in the cooling pool 1 through the feed port 2. Due to the small slope of the spiral track 4 and the buoyancy of the cooling liquid 5, the steel ball slides down the spiral track 4 at a slower speed. The length of the spiral track 4 is longer, so the steel balls can fully contact with the cooling liquid 5 to dissipate heat during the sliding process to realize quenching, and the steel balls falling into the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com