Radial rotary sealing device for magnetic liquid

A magnetic liquid and rotary seal technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of higher processing and assembly precision, difficulty in adding or replacing magnetic liquid, etc., so as to reduce difficulty, avoid increase, The effect of avoiding collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described with accompanying drawing as specific embodiment:

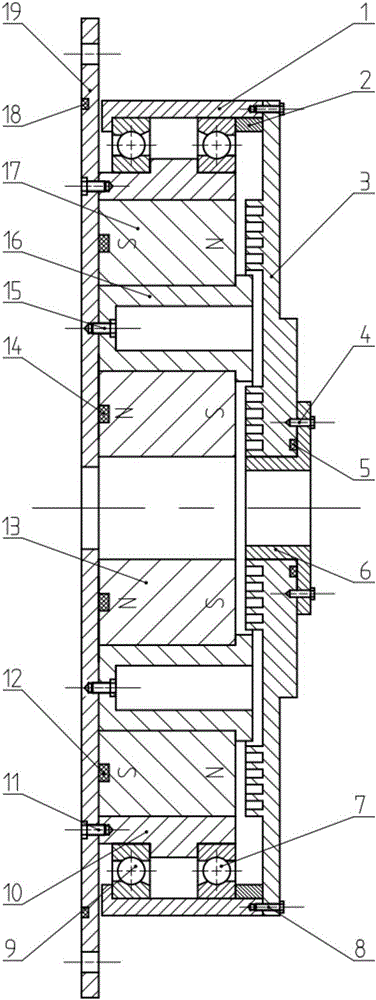

[0018] Radial magnetic liquid rotary seals, such as figure 1 , the sealing device includes: shell 1, adjusting gasket 2, first guiding disk 3, screw 4, third rubber sealing ring 5, bushing 6, right bearing 7, screw 8, left bearing 9, magnetic isolation sleeve 10, Screw 11, second rubber sealing ring 12, first annular permanent magnet 13, first rubber sealing ring 14, screw 15, magnetic isolation cover 16, second annular permanent magnet 17, second guide disk 19.

[0019] Connections between the parts making up the device:

[0020] The first rubber sealing ring 14 is installed in the groove of the end surface of the first annular permanent magnet 13 to form a first annular permanent magnet with a rubber sealing ring, and the second rubber sealing ring 12 is installed on the end surface of the second annular permanent magnet 17 In the groove, a second annular permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com