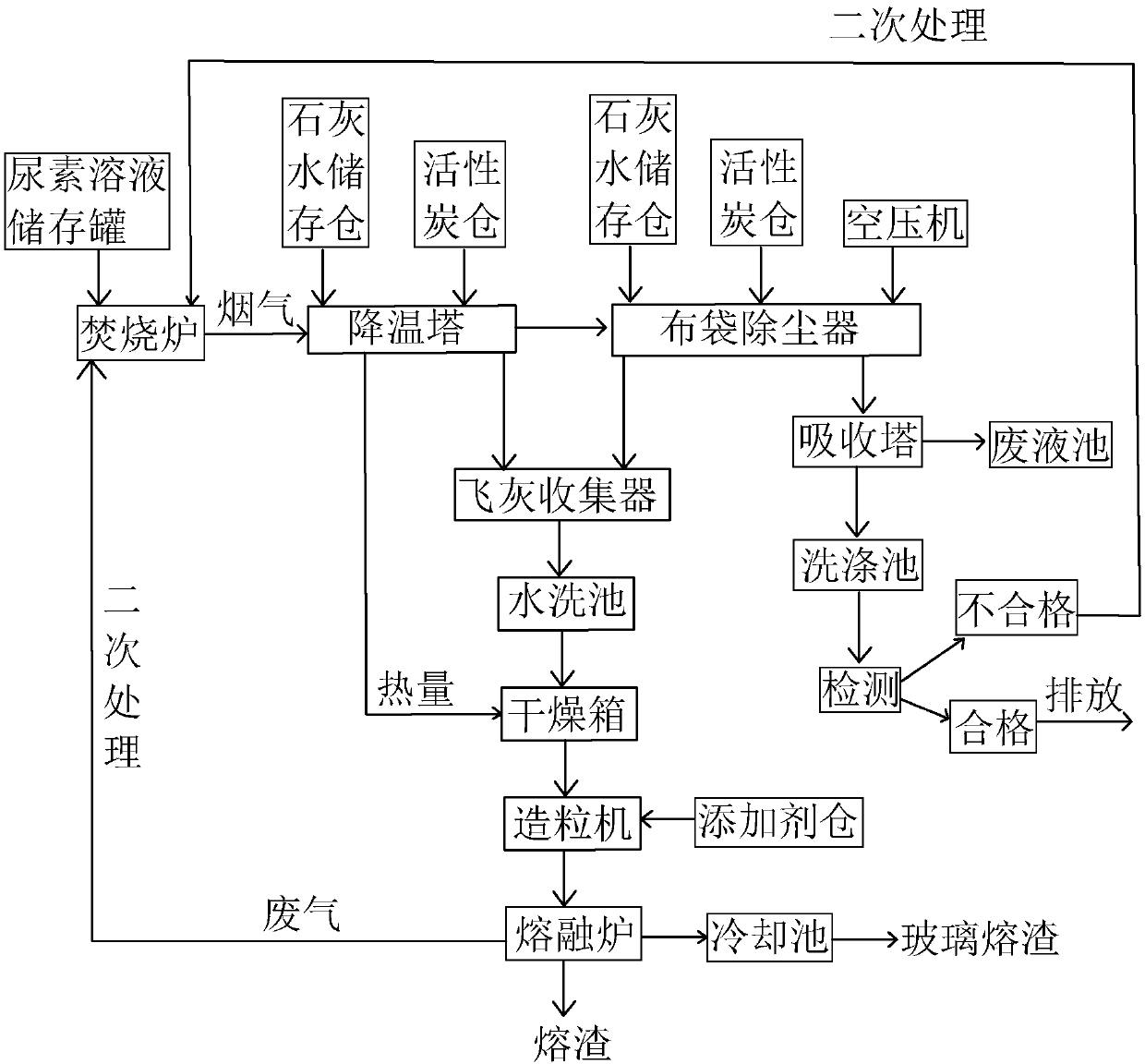

Garbage incineration waste gas and flying ash co-processing system

A technology of waste incineration and co-processing, which is applied in the direction of solid waste removal, incinerators, and combustion methods. Secondary pollution and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

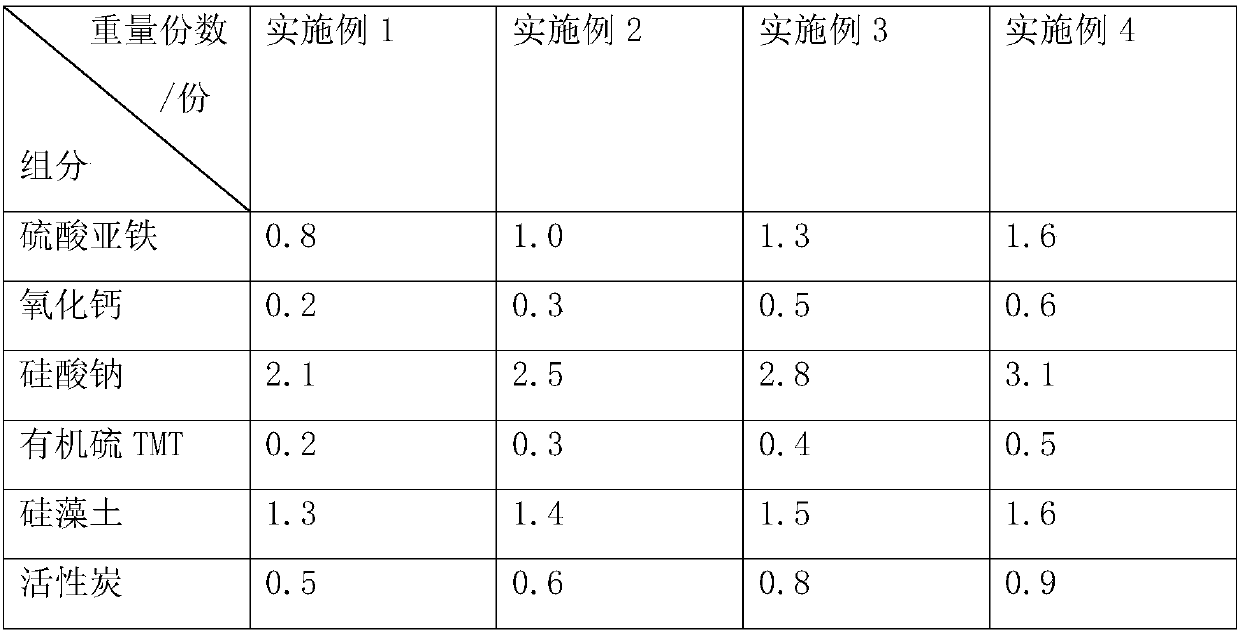

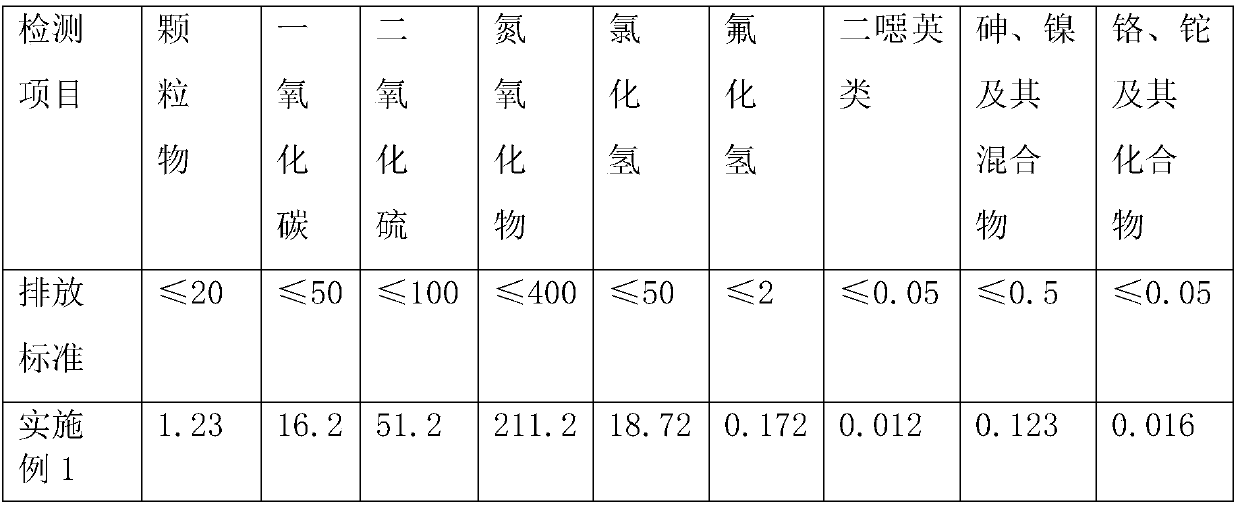

Examples

preparation example 1

[0036] Preparation example 1: 1.2 kilograms of sodium hypochlorite, 1.6 kilograms of sodium hydroxide and 26 kilograms of water are placed in a reactor, stirred and dissolved, then 1.5 kilograms of sodium bicarbonate and 2.1 kilograms of natural plant liquid deodorant are placed in the reactor, stirred Dissolve and mix evenly, and finally add 0.8 kg of trisodium phosphate and 0.9 kg of ethylenediaminetetraacetic acid into the reaction kettle, stir and mix evenly.

preparation example 2

[0037] Preparation example 2: 1.4 kilograms of sodium hypochlorite, 1.7 kilograms of sodium hydroxide and 32 kilograms of water are placed in the reactor, stirred and dissolved, then 1.9 kilograms of sodium bicarbonate and 2.4 kilograms of natural plant liquid deodorant are placed in the reactor, stirred Dissolve and mix evenly, and finally add 1.0 kg of trisodium phosphate and 1.2 kg of ethylenediaminetetraacetic acid into the reaction kettle, stir and mix evenly.

preparation example 3

[0038] Preparation example 3: 1.8 kilograms of sodium hypochlorite, 1.9 kilograms of sodium hydroxide and 38 kilograms of water are placed in the reactor, stirred and dissolved, then 2.2 kilograms of sodium bicarbonate and 2.6 kilograms of natural plant liquid deodorant are placed in the reactor, stirred Dissolve and mix evenly, and finally add 1.2 kg of trisodium phosphate and 1.5 kg of ethylenediaminetetraacetic acid into the reaction kettle, stir and mix evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com