Magnetic flocculation separation waste water treatment technology

A technology of wastewater treatment and process method, which is applied in the direction of flocculation/sedimentation water/sewage treatment, magnetic field/electric field water/sewage treatment, etc. It can solve the problems of inability to handle dispersed oil and emulsified oil, increased load on high-speed filters, and inability to decolorize, etc. problems, to achieve the effect of reducing investment and land occupation, reducing land occupation, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

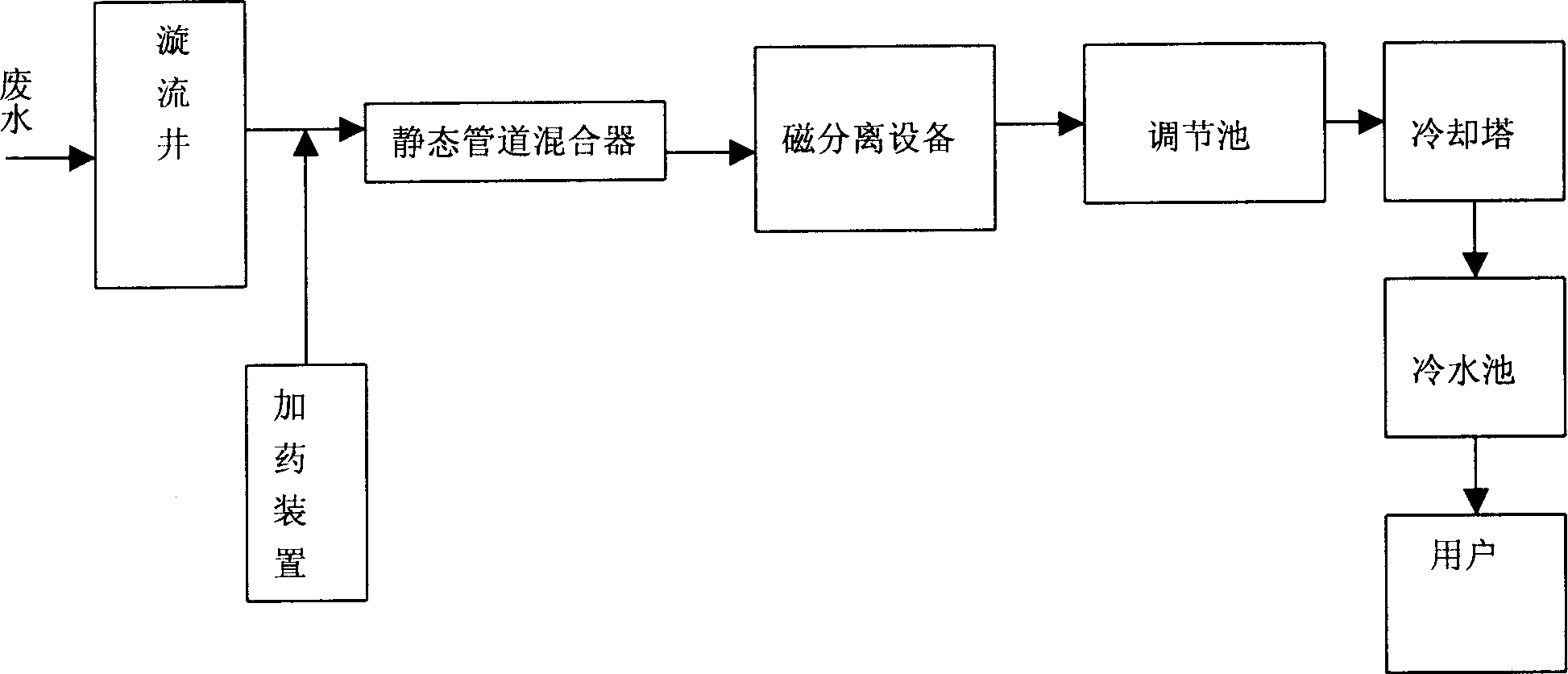

[0017] The process of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Firstly, the waste water enters the swirl well (1), where the coarse particles are removed by sedimentation and the slick oil recovery device, and then the waste water is pumped into the magnetic separation equipment (3); the waste water enters the pipeline before the magnetic separation device In the process, the inorganic polymer flocculant and the organic polymer coagulant or a composite flocculant of the two are added through the dosing device (8), and the static pipeline mixer (2) is used for thorough mixing to produce flocs. If the inorganic polymer flocculant and the organic polymer coagulant are added separately, the former dosing port is set in front of the pump, and the latter dosing port is set in front of the static pipeline mixer, and the time it takes for the wastewater to pass through the second dosing port 5 to 30 seconds; if the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com