Waste oil cracking, rectifying and regenerating system

A regeneration system and oil cracking technology, applied in the field of oil purifiers, can solve the problems of difficult production process control, catalyst replacement, difficult equipment adaptation, etc., and achieve the effects of reducing production costs, rational structure, and improving oil yield and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

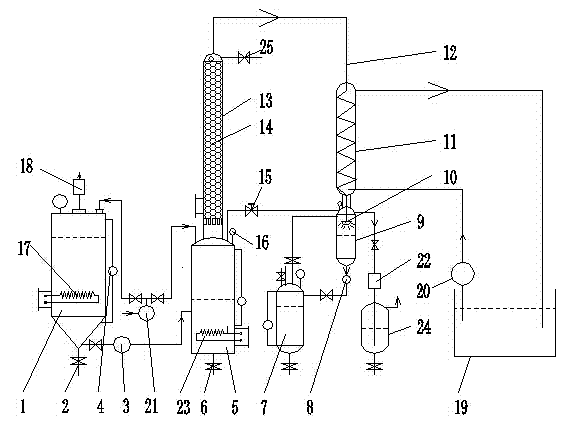

[0018] With reference to the accompanying drawings, a waste oil pyrolysis rectification regeneration system is mainly composed of a dehydration tank 1, a reaction kettle 5, a cooling tower 11, a rectification tower 13, a gas-liquid separation tower 9, an oil storage tank 7, and a waste gas separation tank 24 , a cooling pool 19, and a gas-liquid separation tower vacuum pump 22. The external waste oil is pumped into the dehydration tank 1 or the reactor 5 by the oil inlet pump 21, and the oil in the dehydration tank 1 enters the reactor 5 by the oil pump 3, and the liquid oil is in the reactor. Cracking occurs in 5 to form gaseous oil, and the gaseous oil is rectified in the rectification tower 13. The gaseous oil after rectification enters the cooling tower 11 through the oil and gas pipe 12 to be cooled into liquid oil. The liquid oil and a small amount of miscellaneous gas The liquid separation tower 9 separates, and the liquid oil in the gas-liquid separation tower 9 is tran...

Embodiment 2

[0020] With reference to the accompanying drawings, a waste oil pyrolysis rectification regeneration system is mainly composed of a dehydration tank 1, a reaction kettle 5, a cooling tower 11, a rectification tower 13, a gas-liquid separation tower 9, an oil storage tank 7, and a waste gas separation tank 24 , a cooling pool 19, and a gas-liquid separation tower vacuum pump 22. The external waste oil is pumped into the dehydration tank 1 or the reactor 5 by the oil inlet pump 21, and the oil in the dehydration tank 1 enters the reactor 5 by the oil pump 3, and the liquid oil is in the reactor. Cracking occurs in 5 to form gaseous oil, and the gaseous oil is rectified in the rectification tower 13. The gaseous oil after rectification enters the cooling tower 11 through the oil and gas pipe 12 to be cooled into liquid oil. The liquid oil and a small amount of miscellaneous gas The liquid separation tower 9 separates, and the liquid oil in the gas-liquid separation tower 9 is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com