Injection molding machine mould cooled by circulating water

A circulating water cooling and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of increased mechanical cost of molds, low product fit, uneven cooling, etc., and achieve the effect of improving heat exchange efficiency, simple structure, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

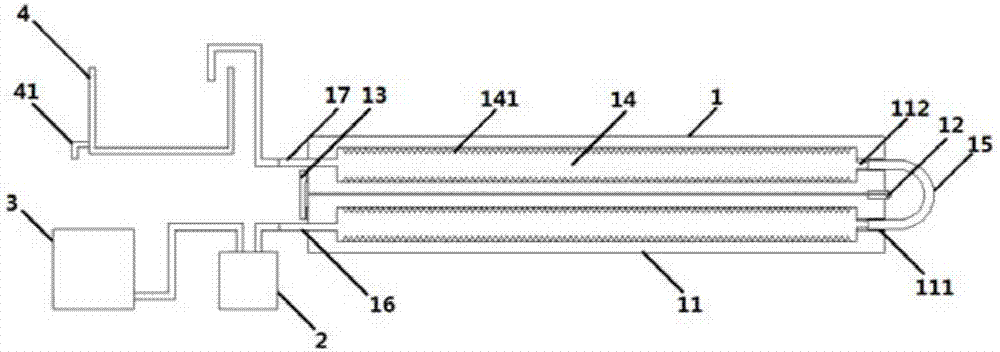

[0013] An injection molding machine mold cooled by circulating water, such as figure 1 As shown, the mold 1 is formed by splicing and combining two or more modules 11, each module 11 is connected in series by a hinge 12, and fixed by a buckle 13, each module 11 is provided with A hollow water chamber 14, the water chambers 14 of the two modules 11 connected by the hinge 12 are connected through a hose 15, a water inlet 16 is arranged on the module 11 at the head end, and a water outlet 17 is arranged on the module 11 at the end , the water inlet 16 is connected with a water pump 2, the water pump 2 is connected with the cold water tank 3, and the water outlet 17 is connected with the cooling pool 4.

[0014] Further, the module 11 is provided with a cylindrical groove 111, the bottom of the groove 111 is provided with a joint 112 communicating with the water chamber 14, the hose 15 extends into the groove 111 and is sleeved on the joint 112, The position of the groove 111 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com