Temperature control coolant oil cycle apparatus used for quenching

A technology of circulation device and cooling oil, applied in the field of quenching process, can solve the problems of waste of furnace temperature, increased cost, long time, etc., and achieve the effect of improving cooling efficiency and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

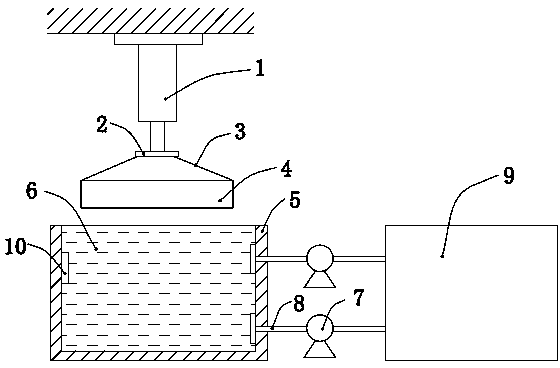

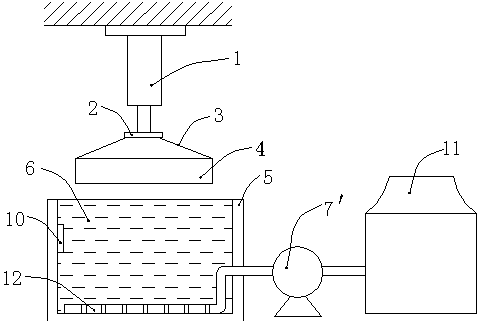

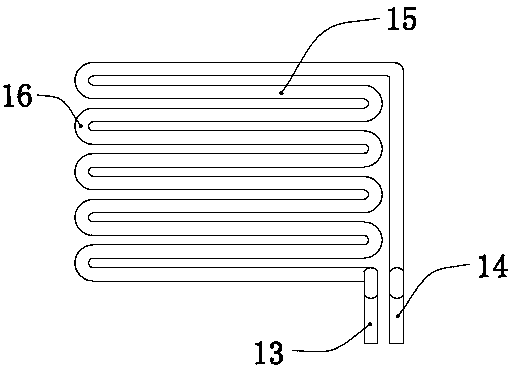

[0020] Such as figure 1 Shown is the connection diagram of the existing quenching equipment for steel balls used as abrasives, and the existing equipment will be described in detail below in conjunction with the accompanying drawings. There is a quenching oil pool 5 on the ground. The quenching oil pool 5 is filled with cooling oil 6. The cooling oil 6 is used to cool the steel balls heated to a certain temperature to improve the strength, hardness, wear resistance and Toughness etc. A vertically placed oil cylinder 1 is arranged above the quenching oil pool 5, and the cylinder barrel of the oil cylinder 1 is fixed on a support in the workshop; during work, the piston rod of the oil cylinder 1 performs telescopic movement in the vertical direction. A metal disc 2 is fixedly installed on the free end of the piston rod of the oil cylinder 1, and four through holes are evenly arranged on the disc 2 along the circumference, and a steel wire rope 3 is respectively fixed in the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com