System for advanced treatment and recycle of cold rolling wastewater

A technology for advanced treatment and waste water, applied in the field of water treatment, which can solve the problems of increased operating costs, increased pretreatment investment costs, high water quality requirements for influent water, etc., and achieves the effects of low production and operation costs, reduced load impact, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

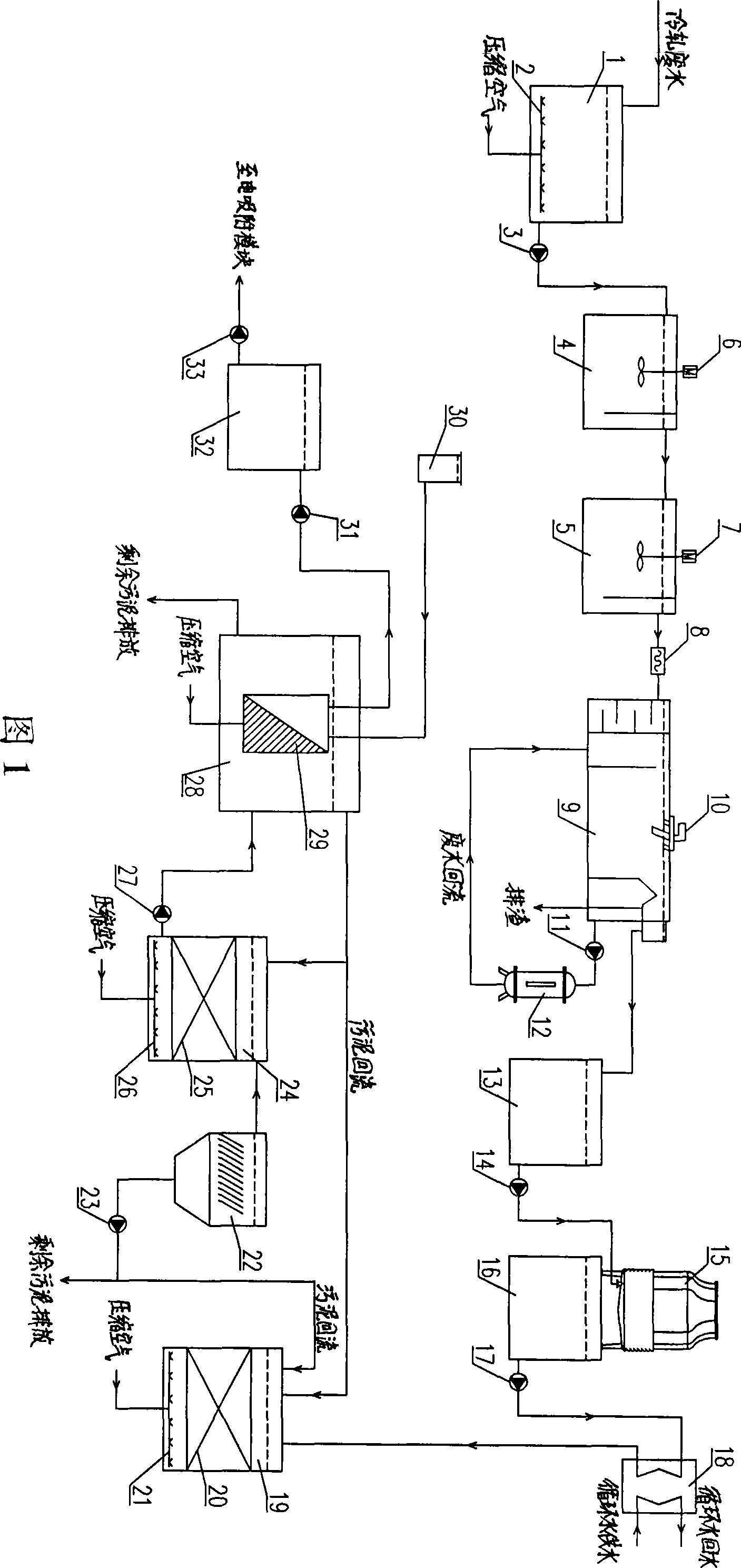

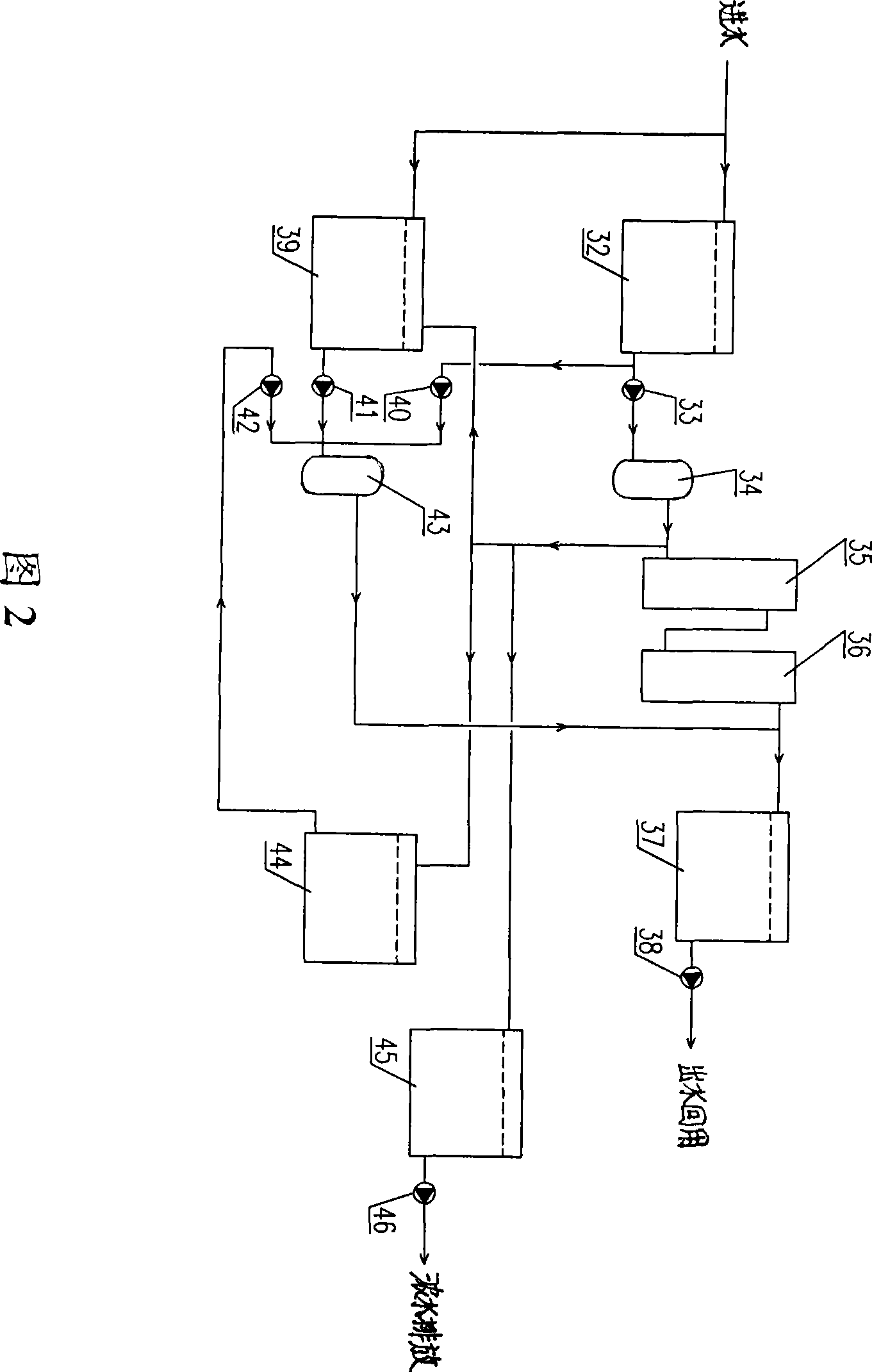

[0023] Referring to Fig. 1 and Fig. 2, the present invention is an advanced treatment and reuse system of cold rolling wastewater, which includes a pretreatment process, a biochemical secondary treatment process and an electro-adsorption desalination treatment process.

[0024] As shown in Figure 1, the pretreatment process includes a uniform aeration adjustment tank 1, an aeration device 2, a lift pump 3 in the adjustment tank, a first-stage pH adjustment tank 4, a second-stage pH adjustment tank 5, and mixers 6 and 7. , Dissolved air flotation 9, dissolved air pump 11, dissolved air tank 12, intermediate pool 13, intermediate pool lift pump 14, cooling tower 15, cooling pool 16, cooling pool lift pump 17, and plate heat exchanger 18. The pretreatment process also includes a slag scraper 10 and a pipeline mixer 8 .

[0025] An aeration device 2 is arranged in the homogeneous aeration regulating tank 1, and the aeration device 2 may be an aeration tube. The equalization and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com