Equipment for riveting battery cover plate

A battery cover and riveting technology, which is applied in the direction of battery cover/end cover, battery box/coat, etc., can solve the problems of low riveting efficiency, low riveting efficiency, and inability to meet the needs of different types of products, so as to expand the scope of use and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

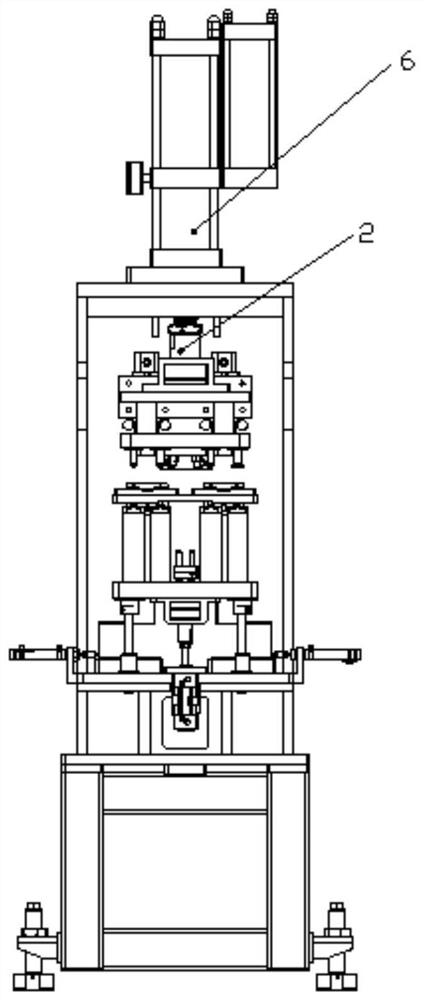

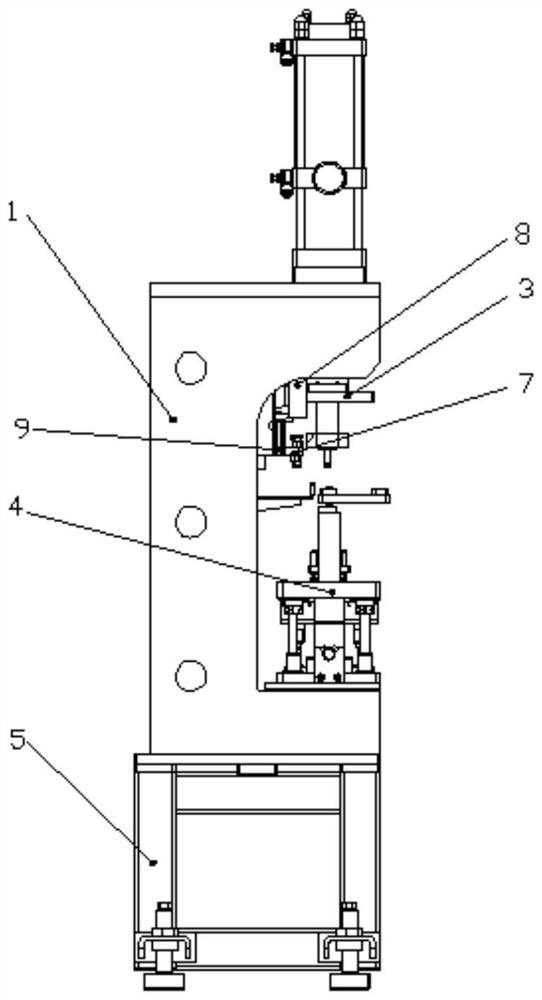

[0024] The invention is a device for riveting a battery cover plate, which includes a riveting support 1, a riveting frame platform 5, a riveting pressing part, and a riveting lifting part 4; the riveting support 1 is fixed on the top of the riveting frame platform 5, The pressing member is connected to the head of the riveting support 1 , and the riveting lifting member 4 is connected to the table surface of the riveting support 1 .

[0025] When the battery cover plate that has been preliminarily assembled is placed on the tooling plate and transported to the device of the present invention with the assembly line, it is located between the riveting jacking part and the riveting pressing part; during riveting, the riveting jacking part first bears against the battery The cover plate becomes a supporting surface, and then the pressing parts are riveted and pressed down, and the pressurizing force of the gas-liquid booster cylinder is used to realize riveting, so that the upper ...

Embodiment 2

[0028] The invention is a device for riveting a battery cover plate: the riveting and pressing components include a gas-liquid booster cylinder 6, a cylinder pressure head 2, a riveting pressure head assembly 3, a slider 8, and a linear guide rail 9; the gas-liquid booster cylinder 6 is fixed on the On the top of the head of the riveting support 1, the cylinder head 2 connected with the rod end is connected with the lower riveting head assembly 3, and the riveting head assembly 3 is connected with the rear slider 8, and the slider 8 is fixed on the riveting rack table. 5 Connect the linear guide 9 on the support column.

[0029] When the gas-liquid booster cylinder 6 is working, the cylinder ram 2 drives the riveting ram assembly 3 to move up and down along the linear guide 9 through the slider 8, so as to realize the riveting of the battery cover plate. The sliding block 8 and the linear guide 9 ensure the stability of the up and down movement of the riveting indenter assembl...

Embodiment 3

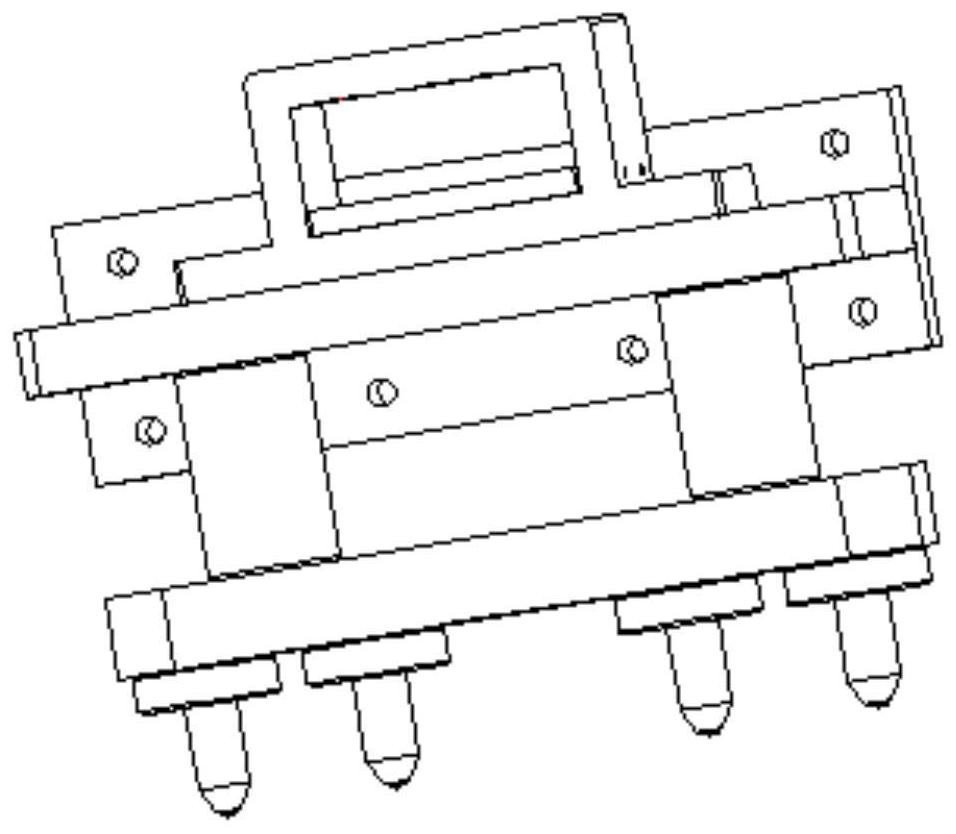

[0032] The present invention is a device for riveting a battery cover plate: the riveting indenter assembly 3 includes a sliding base 301, an indenter support 302, two indenter extension rods 304, an indenter mounting plate 305, four riveting heads 303, and a sliding base 301 It is formed by connecting two horizontal and vertical plates. The top of the horizontal plate is connected to the indenter support 302, and the indenter support 302 is connected to the cylinder indenter 2; the lower part of the horizontal plate of the sliding base 301 is connected to the indenter through two indenter extension rods 304. The mounting plate 305, four riveting heads 303 are connected below the indenter mounting plate 305; the sliding block 8 is connected to the rear of the vertical plate of the sliding base 301.

[0033] When the gas-liquid booster cylinder 6 works, the cylinder ram 2 drives the sliding base 301 to move up and down through the ram support 302, so that the riveting head 303 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com