Drilling automatic clamping device of double-lug supporting plate nut

A technology of pallet nuts and clamping devices, applied in positioning devices, drilling/drilling equipment, clamping, etc., can solve the problem of inability to meet the requirements of mass automated production, inability to ensure accurate positioning of parts, inability to realize continuous processing, etc. problems, to achieve the effect of realizing large-scale automated production and processing, improving the consistency of product processing, and improving the drilling and processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

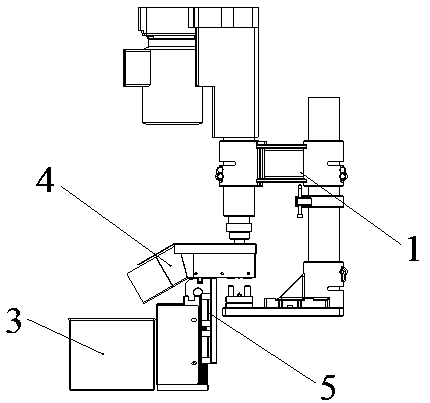

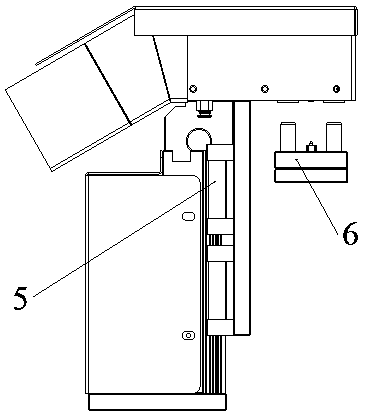

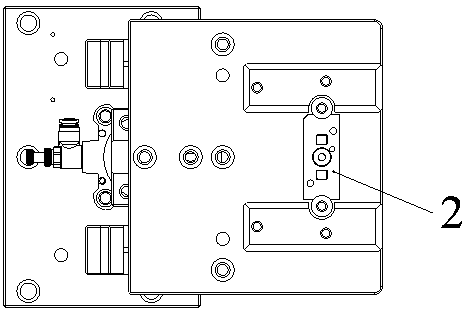

[0023] see Figure 1 to Figure 6 An automatic clamping device for double-ear pallet nut drilling, including double servo power head 1, clamping and positioning mechanism 2, drill cuttings collection box 3, waterproof sheet metal 4, cylinder pressing mechanism 5, and part positioning mechanism 6 , cylinder 7, installation bottom plate 8, vertical plate 9, guide rail slider 10, pressing plate 11, drilling insert 12, cover plate 13, connecting plate 14, drill sleeve 15, pressing column 16, fixing plate 17, positioning Plate 18, positioning insert 19, guide pin 20 and guide post 21; among them, the part positioning mechanism 6 for positioning the double-ear bracket nut is arranged under the double servo power head 1, and is used to guide the drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com