Rotary body part automatic argon arc welding device

A technology of argon arc welding and welding device, which is applied in the field of automatic argon arc welding device for rotating body parts, can solve the problems of difficult quality assurance and low production efficiency, and achieves the effects of good welding consistency, improved automation and accurate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

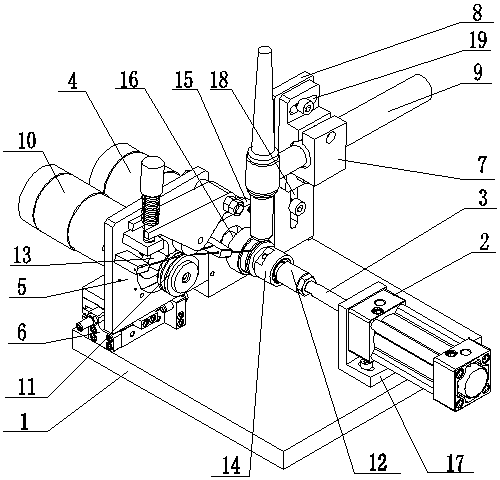

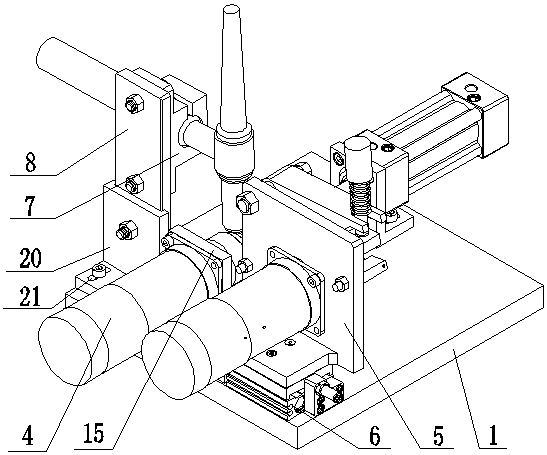

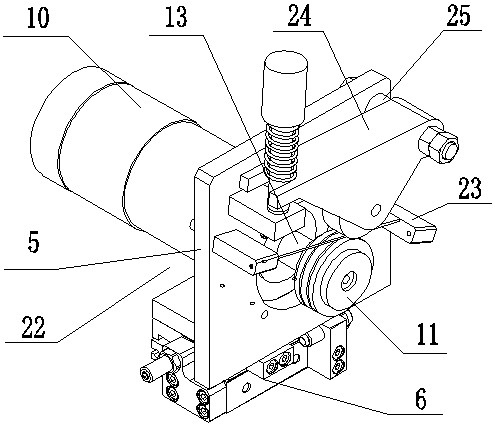

[0025] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0026] The material of the rotating parts to be welded in the present invention is 304 stainless steel; dimensions: outer diameter 34mm, total length after welding 41mm, hollow, and welding height 2mm.

[0027] in Figure 1-4 Among them, the automatic argon arc welding device for rotating parts is composed of mechanical devices, electric control devices and pneumatic control devices. The mechanical devices include: bottom plate 1, telescopic cylinder 2, rotary servo motor 4, sliding table cylinder 6, wire feeder 22 , Wire feeding servo motor 10 and argon arc welding machine. The telescopic cylinder 2 is fixedly installed on the right side of the base plate 1 through the cylinder connecting seat 17, the piston rod 3 of the telescopic cylinder 2 is connected to the rotary joint 14 through the cylinder connecting joint 12; the rotary servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com