Laser welding method of high-strength gas discharge electrode

A gas discharge and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of uneven discharge on the electrode surface, large contact surface of welding electrodes, unstable welding strength, etc., and achieve wear and deformation joints. Low, good welding consistency, stable laser energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

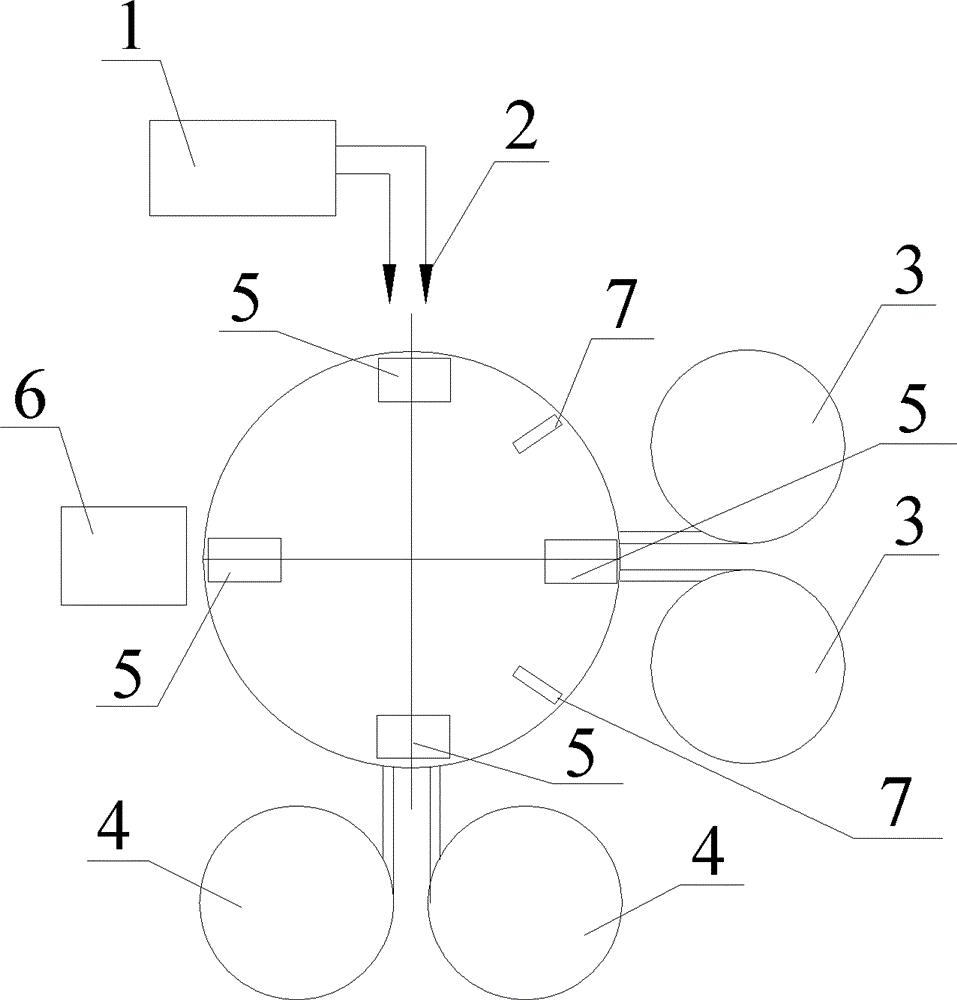

[0030] A laser welding method for a high-intensity gas discharge electrode, the welding device used is such as figure 1 As shown, the device includes a laser generator 1 , a laser emitting head 2 , a mandrel blanking mechanism 3 , an electrode blanking mechanism 4 , a clamping fixture 5 , a blanking mechanism 6 , and a detection mechanism 7 .

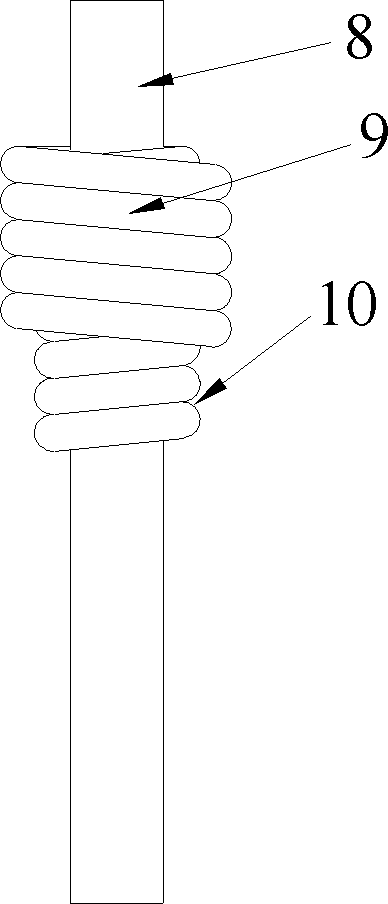

[0031] After the mandrel 8 and the electrode spring 9 are assembled into the clamping jig 5 through the mandrel blanking mechanism 3 and the electrode blanking mechanism 4 respectively, the electrode spring 9 is clamped on the mandrel 8, and then the mandrel 8 and the The electrode spring 9 is placed at the laser generator 1. The laser generator 1 uses neodymium (Nd) as the excitation element, and uses yttrium aluminum garnet crystal rods (Nd:YAG) to generate 1-8KW continuous single-wavelength laser light. The flexible optical fiber is connected to the laser emitting head 2, and the electrode spring 9 is welded and fixed on the mandrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com