A method for manufacturing an electrode assembly for an automotive metal halide lamp

A technology of electrode assembly and manufacturing method, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of long welding time, unstable welding strength, and falling off of solder joints, and achieve stable laser energy and welding consistency Good, guarantee the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

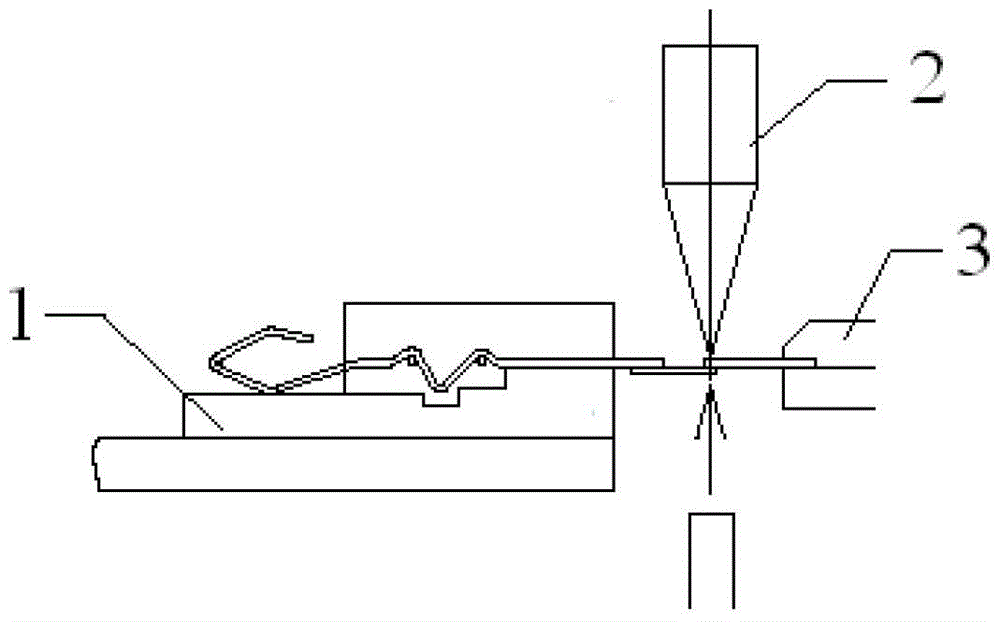

[0032] A manufacturing method of electrode assembly for automobile metal halide lamp, the manufacturing device is as figure 1 As shown, a tungsten wire jig 1 is used to clamp the tungsten wire to be processed, and a molybdenum sheet clamp 3 is used to fix the molybdenum sheet to be processed. After the position of the tungsten wire to be processed is precisely controlled, the laser light generated by the laser generator 2 passes through The laser output head outputs, welding and connecting the tungsten wire and the molybdenum sheet. During the manufacturing process, the precise tungsten wire fixture and the molybdenum sheet fixture are configured to ensure that the welding position is at the center of the tungsten wire (diameter 0.25mm); laser generator Equipped with ultra-fine optical fiber to meet the requirements of micro electrode welding; the equipment is equipped with an output energy control system to ensure the stability of the welding energy. The power of the laser gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com