Longitudinal supporting frame of automobile transverse stabilizing bar

A technology of horizontal stabilizer bar and longitudinal support, which is applied in the field of auto parts, can solve the problems of poor connection strength, weakened strength, and easy cracking of the weld seam of the horizontal stabilizer bar mounting plate, so as to facilitate load transmission, reduce stress concentration, The effect of avoiding weld cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

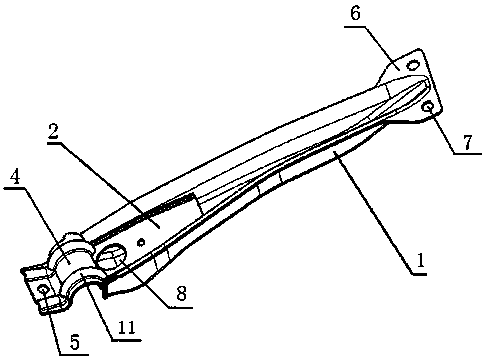

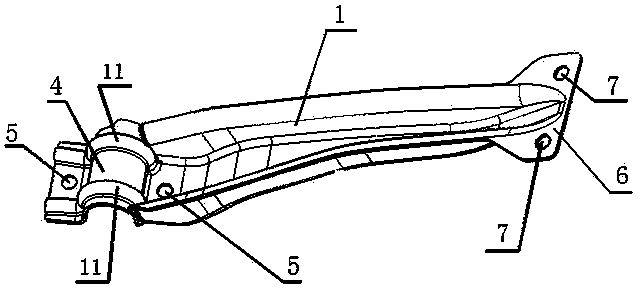

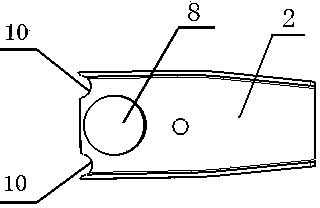

[0016] Such as Figure 1 to Figure 6 The shown longitudinal support frame of the automobile transverse stabilizer bar includes a longitudinal support frame body 1 with a U-shaped cross section. The bottom surface of the longitudinal support frame body 1 extends forward to form an Ω-shaped clamp 4. side of the front end with clamp 4 through the CO 2 Shielded welding, both sides of the clamp 4 are provided with ribs 11 for preventing the stabilizer bar bushing from moving laterally, and the front mounting surface of the front and rear ends of the clamp 4 is provided with the first for installation and fixing with the lower beam of the water tank. A mounting hole 5, the bottom surface of the longitudinal support frame body 1 is inclined upward from the rear part of the front mounting surface at the rear end of the clamp 4, and the rear end of the longitudinal support frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com