Preparation method for antiskid surgical suture

A surgical suture and anti-slip technology, which is applied in the field of surgical sutures, can solve problems such as difficult production and cannot completely replace knotting, and achieve the effects of low cost, not easy to slip, and pain relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0024] The invention provides a kind of preparation method of the anti-slip surgical suture, comprising the steps of:

[0025] Step (1) Melt spinning: Melt the polymer material for preparing surgical sutures, and prepare coarse denier silk threads by melt spinning;

[0026] Step (2) heating: uniformly heating the coarse denier yarn prepared in step (1), so that the coarse denier yarn becomes soft;

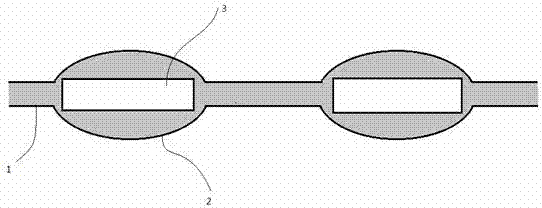

[0027] Step (3) Filament pressing: The heated coarse denier silk thread is intermittently extruded through the extruding device. The extruding device includes a pressure roller and a stressed groove. There are multiple ellipses evenly distributed intermittently along the axial direction on the pressure roller. Shaped protrusion, the minor axis direction of the elliptical protrusion is consistent with the axial direction of the pressure roller; the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com