An automated system for producing toothed plate structures in car seats

An automation system and a technology for car seats, which are applied in the field of automated production systems, can solve the problem that the welding process requirements of the toothed plate connecting plate and the rack are quite high, and achieve easy welding quality, improved yield, better firmness and precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

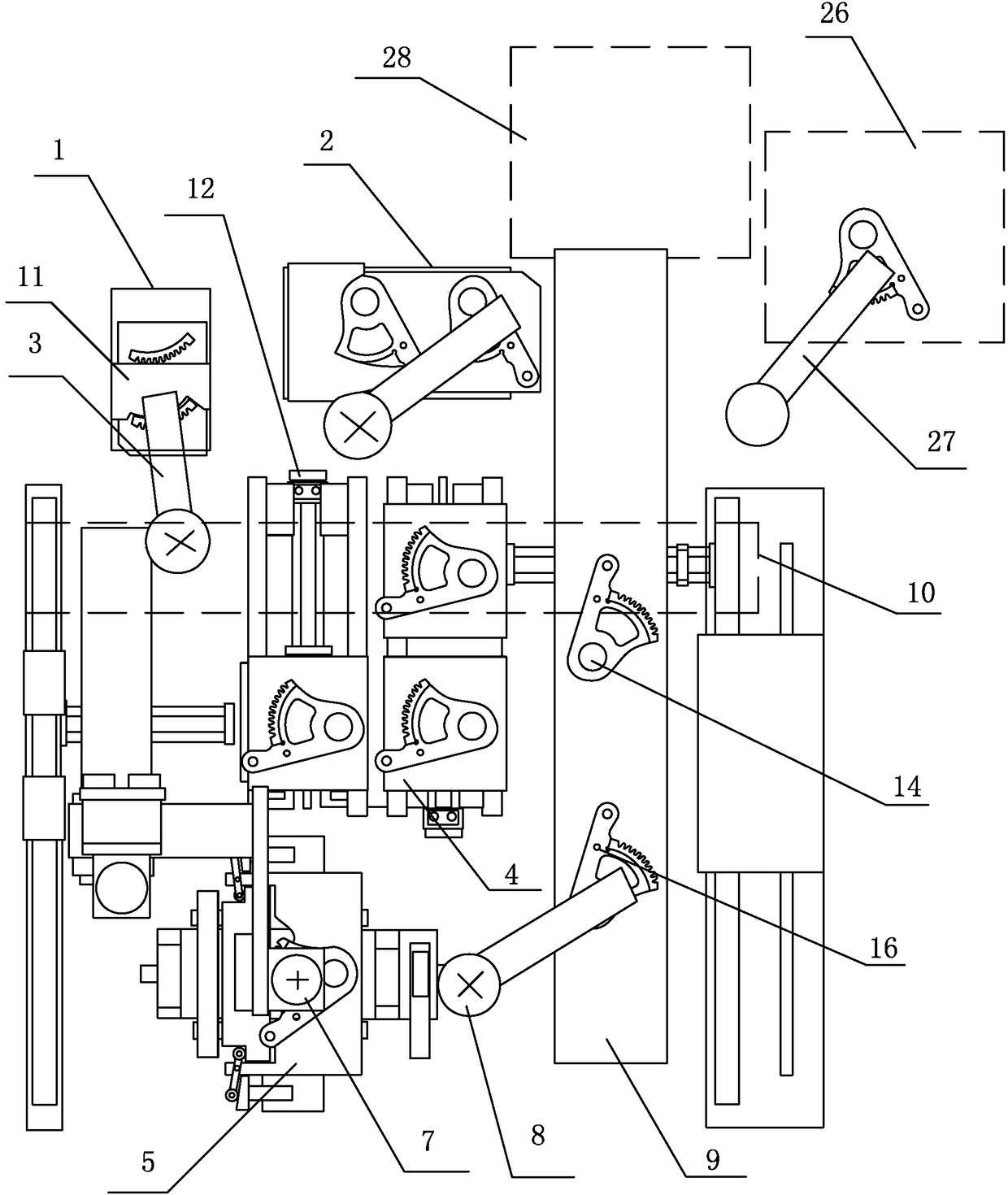

[0031] Embodiment one: see Figure 1~3 As shown, an automatic system for producing tooth plate structures in automobile seats includes a feeding mechanism, a pre-positioning mechanism, a welding mechanism, a material discharging mechanism and a visual inspection mechanism 10, wherein:

[0032] The feeding mechanism includes a rack loading level 1 and a connecting plate loading level 2, and the rack loading level 1 and the connecting plate loading level 2 are sent to the pre-positioning mechanism through the feeding mechanical arm 3 respectively ;

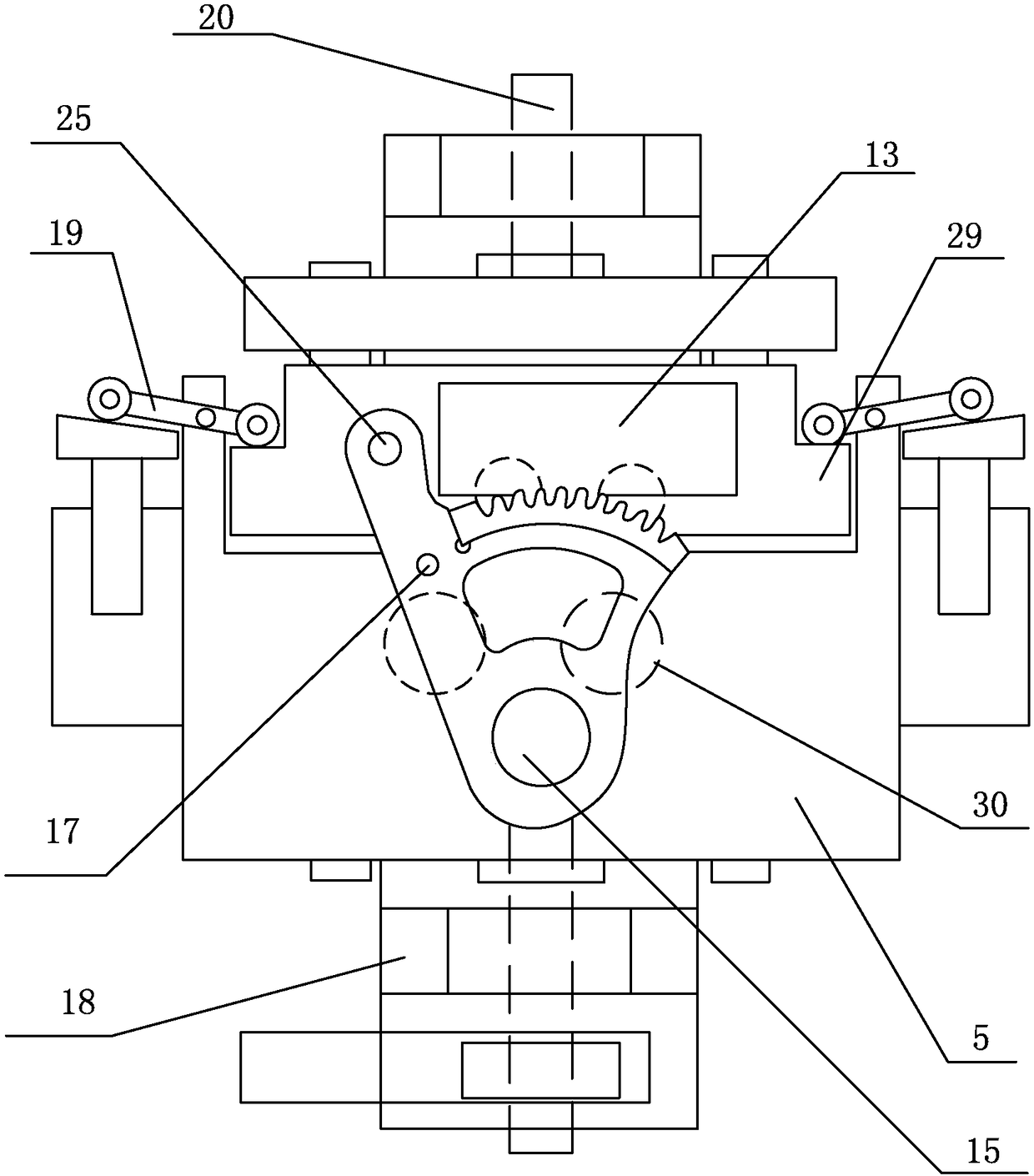

[0033] The pre-positioning mechanism includes at least one positioning platform 4, and the positioning platform 4 is provided with a connecting plate positioning pin matching the hole position of the tooth plate rotation center, and the positioning platform is sent to the welding mechanism through a transmission mechanism;

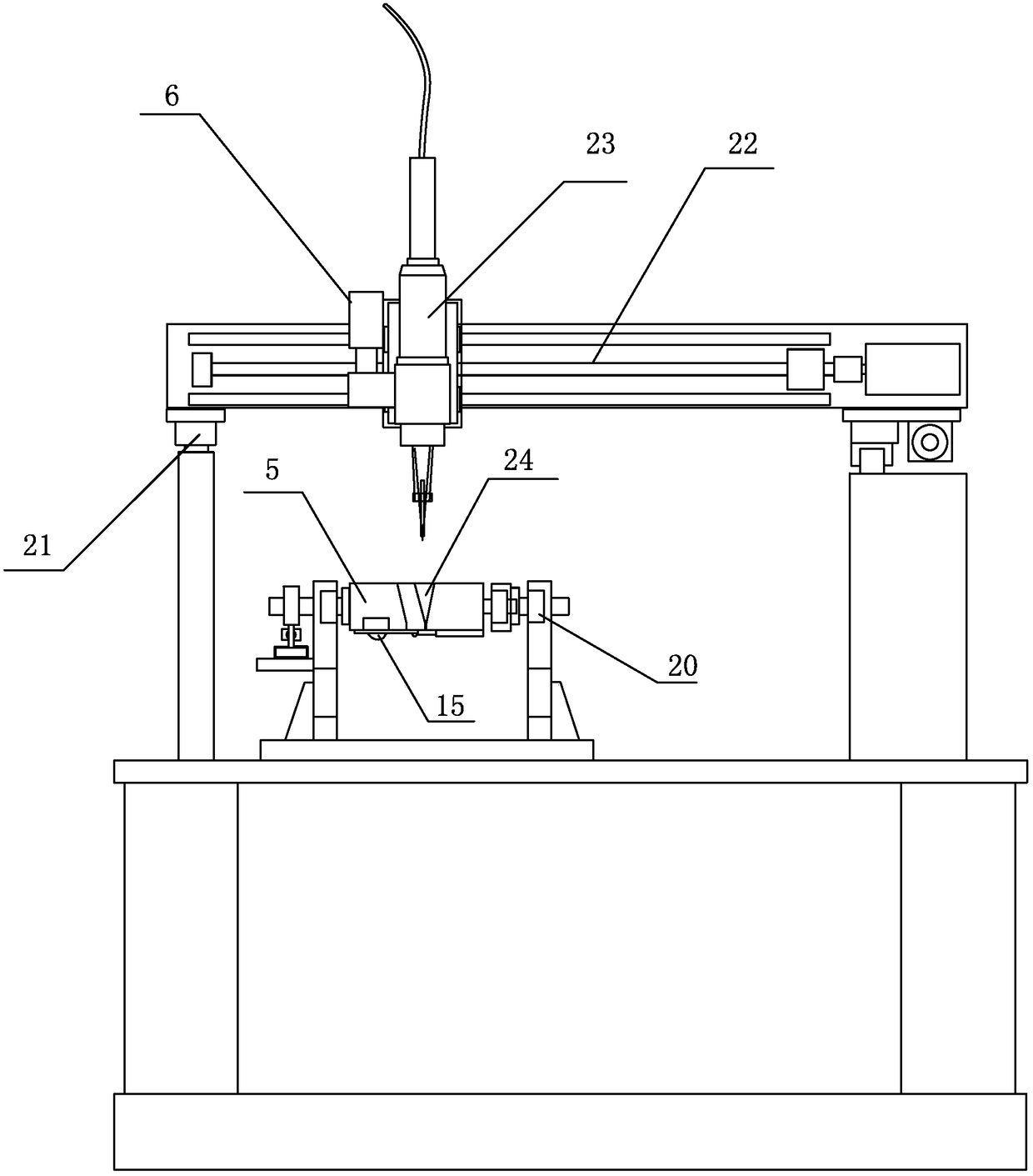

[0034] The welding mechanism includes a welding platform 5, a laser welding device 6 and a magnetic gripper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com