Horizontal positioning drive apparatus for tab positioning

A driving device and horizontal positioning technology, applied in auxiliary devices, gas flame welding equipment, conductors, etc., can solve problems such as increased energy consumption, increased costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

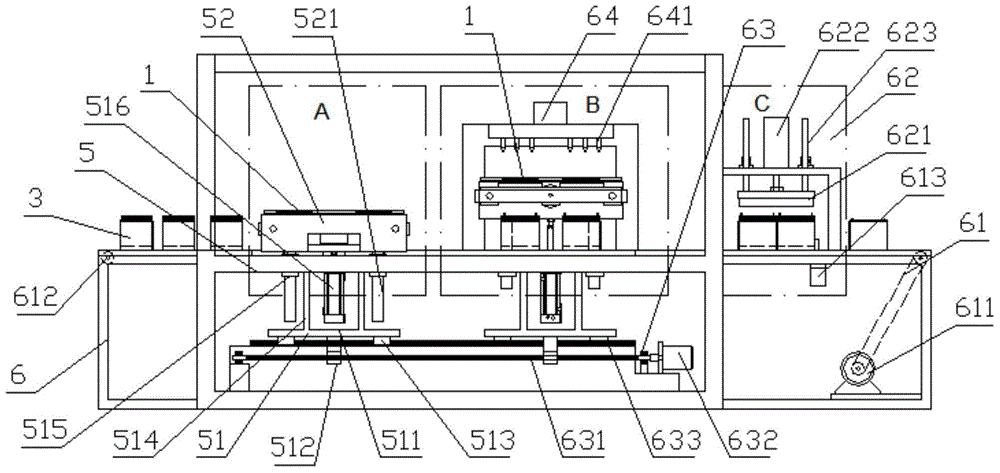

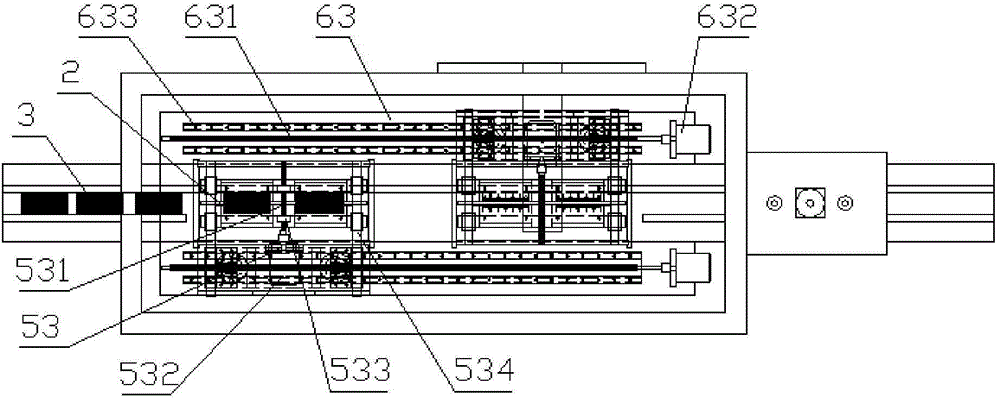

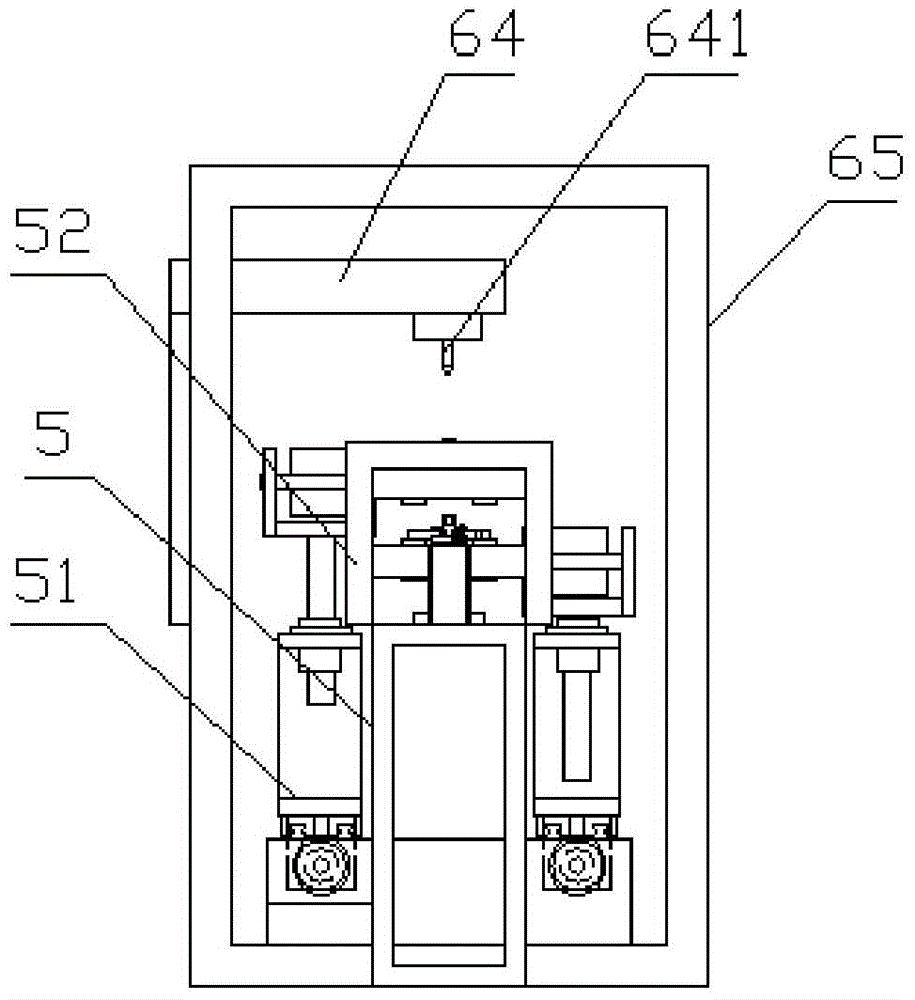

[0021] Such as Figure 1 to Figure 3 As shown, the lead-acid battery electrode group welding machine includes a frame 6, and an electrode group horizontal conveying device 61 is provided between the head and the tail of the frame 6, and the lead-acid battery electrode group to be welded is transported from the electrode group horizontal conveying device The head of 61 is input, and extremely group level conveying device 61 comprises conveying chain, is provided with conveying sprocket wheel 612 at frame head and afterbody, and wherein afterbody is driving sprocket wheel, and head is driven sprocket wheel, between driving sprocket wheel and A tensioning sprocket is also arranged between the driven sprockets, and an extreme group conveying motor 611 is arranged under the tail of the frame, and the extreme group conveying motor 611 drives the driving sprocket to rotate through a transmission chain.

[0022] The pole group welding device is provided in the middle of the frame 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com