Automatic speed changer shell body and welding method thereof

A technology of automatic transmission and welding method, applied in welding equipment, transmission box, resistance welding equipment and other directions, can solve the problems of normal driving of automobiles, high labor intensity, reducing the service life of clutch assemblies, etc., and achieves easy control of welding quality, The effect of prolonging the service life and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

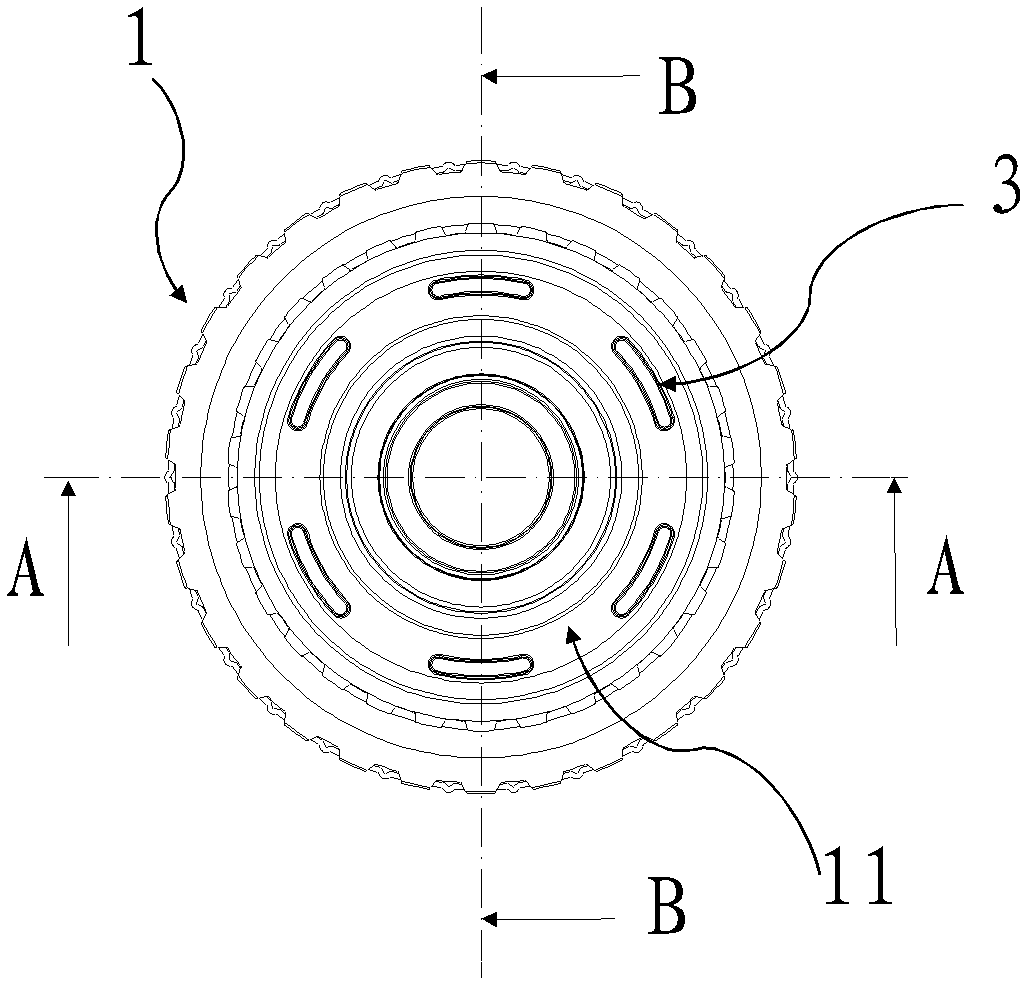

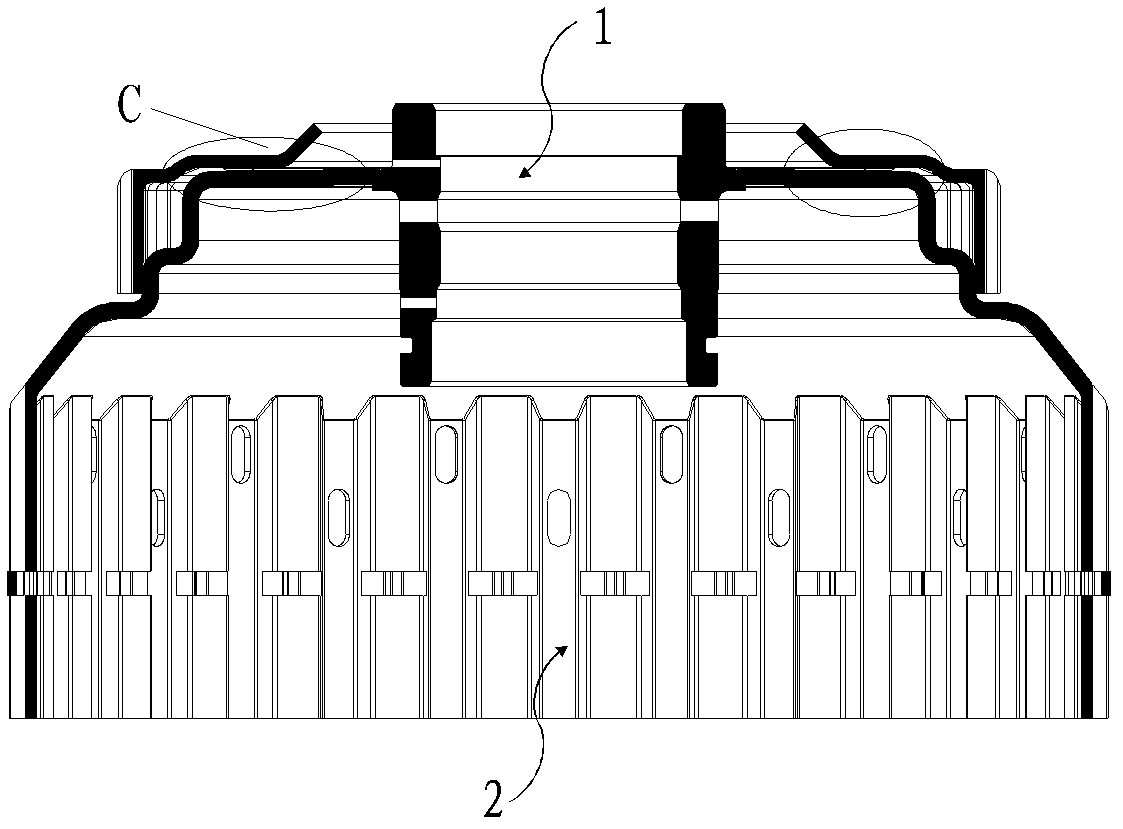

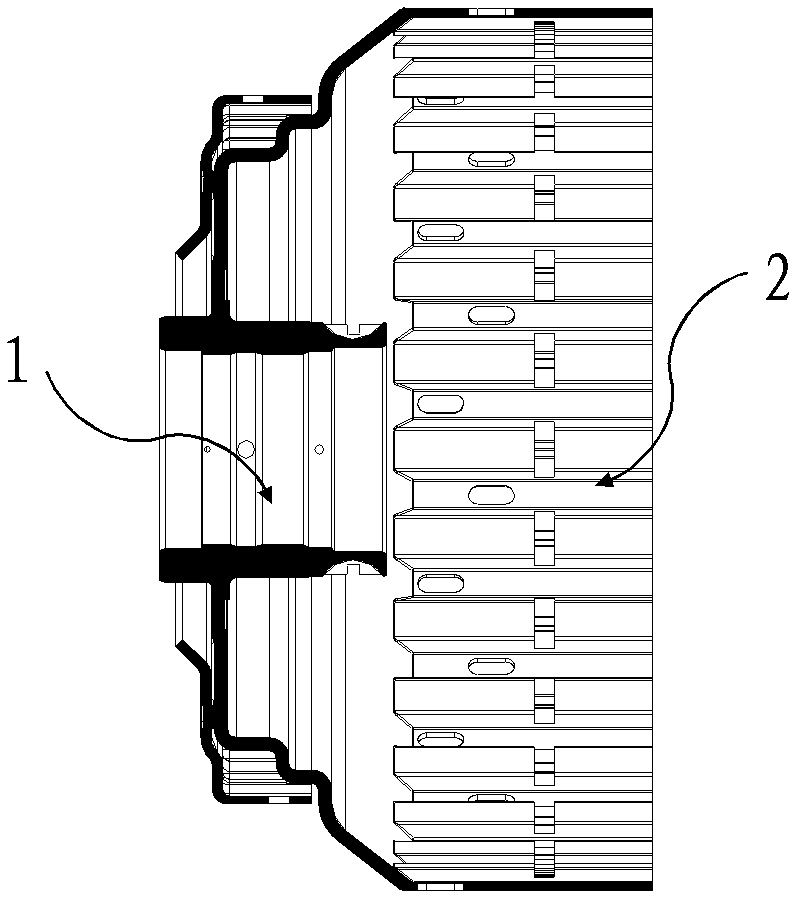

[0023] see figure 1 and FIG. 2 , in order to better understand the technical solution of the present invention, a detailed description will be given below through specific embodiments and in conjunction with the accompanying drawings.

[0024] see figure 1 , the automatic transmission housing of the present invention includes an inner hub 1 and an outer hub 2 ( figure 1 (not shown), the bottom of the inner hub 1 is provided with a first annular welding surface 11 . In this embodiment, six welding bosses 3 of equal height are evenly distributed along the first annular welding surface 11 . The welding boss 3 is processed by stamping.

[0025] see Figure 2a and Figure 2b , the table surface of the welding boss 3 is welded with the second annular welding surface at the top of the outer hub 2 to obtain the automatic transmission housing of the present invention. In this embodiment, the welding process used is a projection welding process. This is because one of the purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com