Scissor type integrated tin welding gun

A scissors-type, integrated technology, applied in the direction of welding equipment, tin feeding device, manufacturing tools, etc., can solve the problems of extended cable reserve, easily damaged cables, unsightly welding, etc., to achieve convenient operation and ensure accuracy , The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below through specific embodiments.

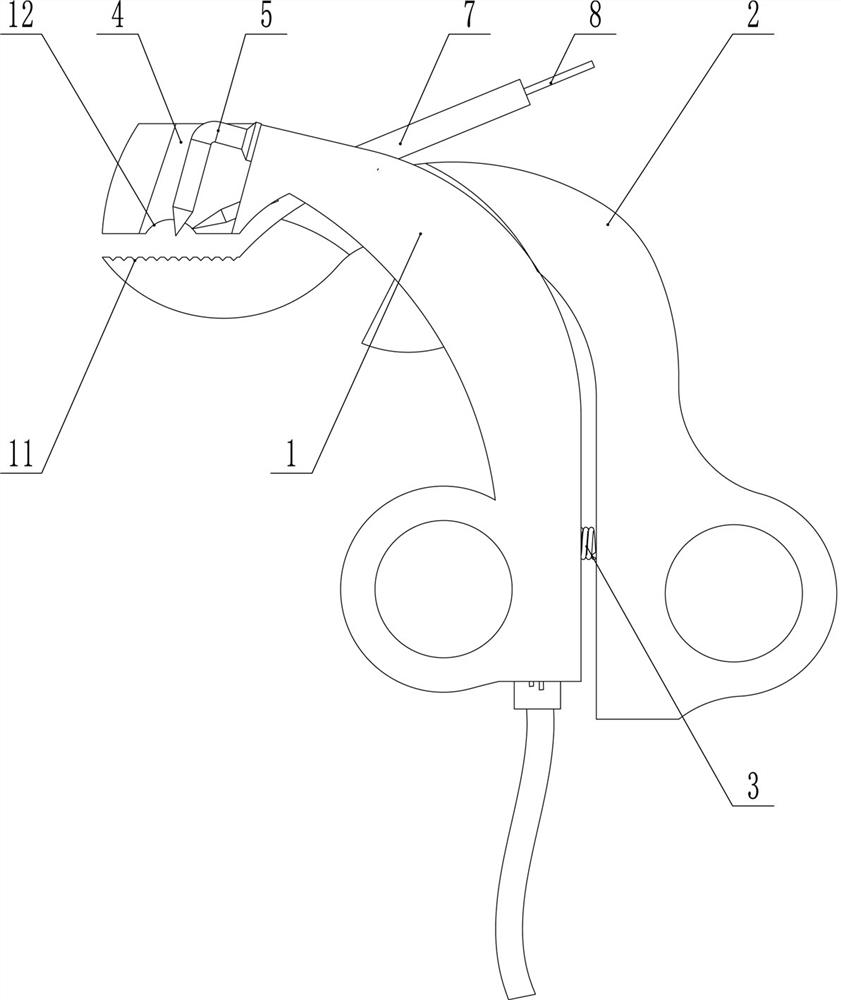

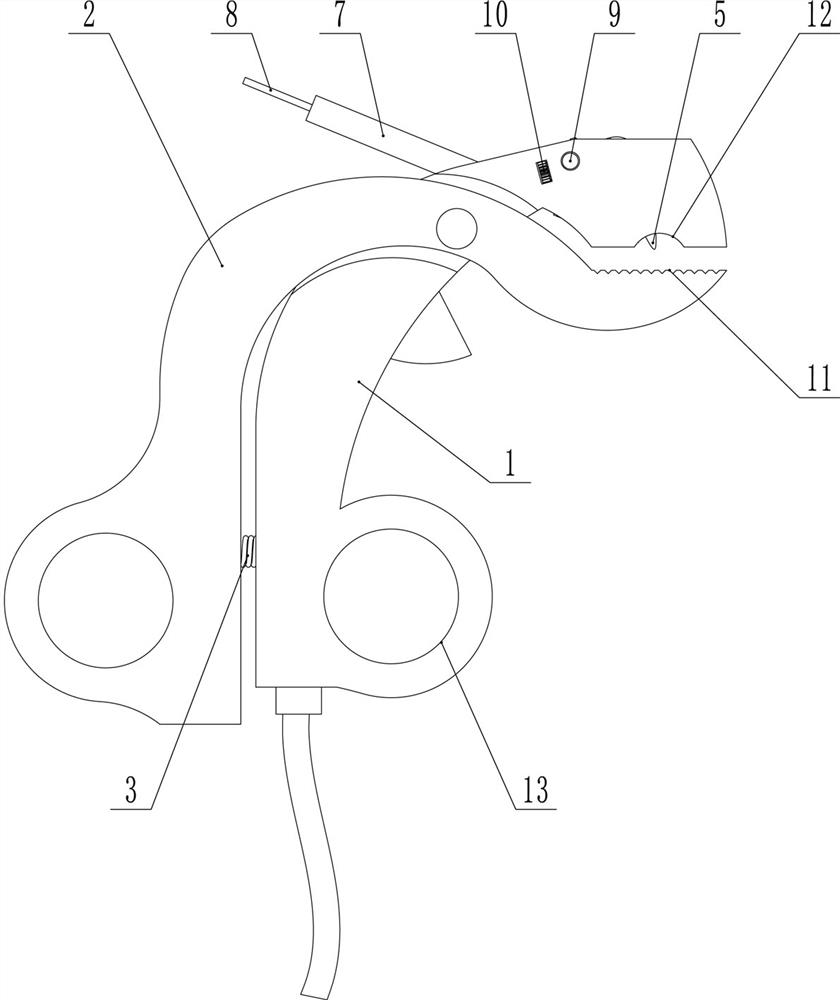

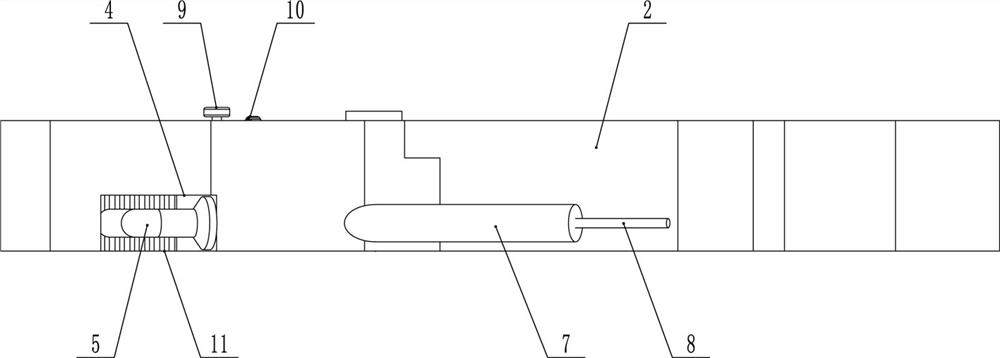

[0019] like Figure 1-5 As shown, a scissors-type integrated tin welding gun includes a scissors-type clamping mechanism, an electric iron mechanism and a tin feeding cavity, and the scissors-type clamping mechanism includes a first hinge 1 and a second hinge that are hinged together in the middle 2, the head of the first hinge 1 and the head of the second hinge 2 are provided with a wire clamping mechanism that cooperates with each other, and the tail of the first hinge 1 and the second hinge 2 A tension spring 3 is connected between the tails of the hinges, the first hinge 1 is provided with a mounting cavity and a head welding groove 4, the head welding groove 4 is arranged side by side with the wire clamping mechanism, and the head welding groove 4 is arranged side by side. The side opening of the welding tank 4 is provided; the electric ironin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com