Cantilever welding machine of fillet weld in narrow space

A space corner and welding machine technology, applied in the direction of welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of difficult control of weld quality, low efficiency of manual welding, and inability of automatic submerged arc welding machine to achieve simple operation, Effects that do not affect welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

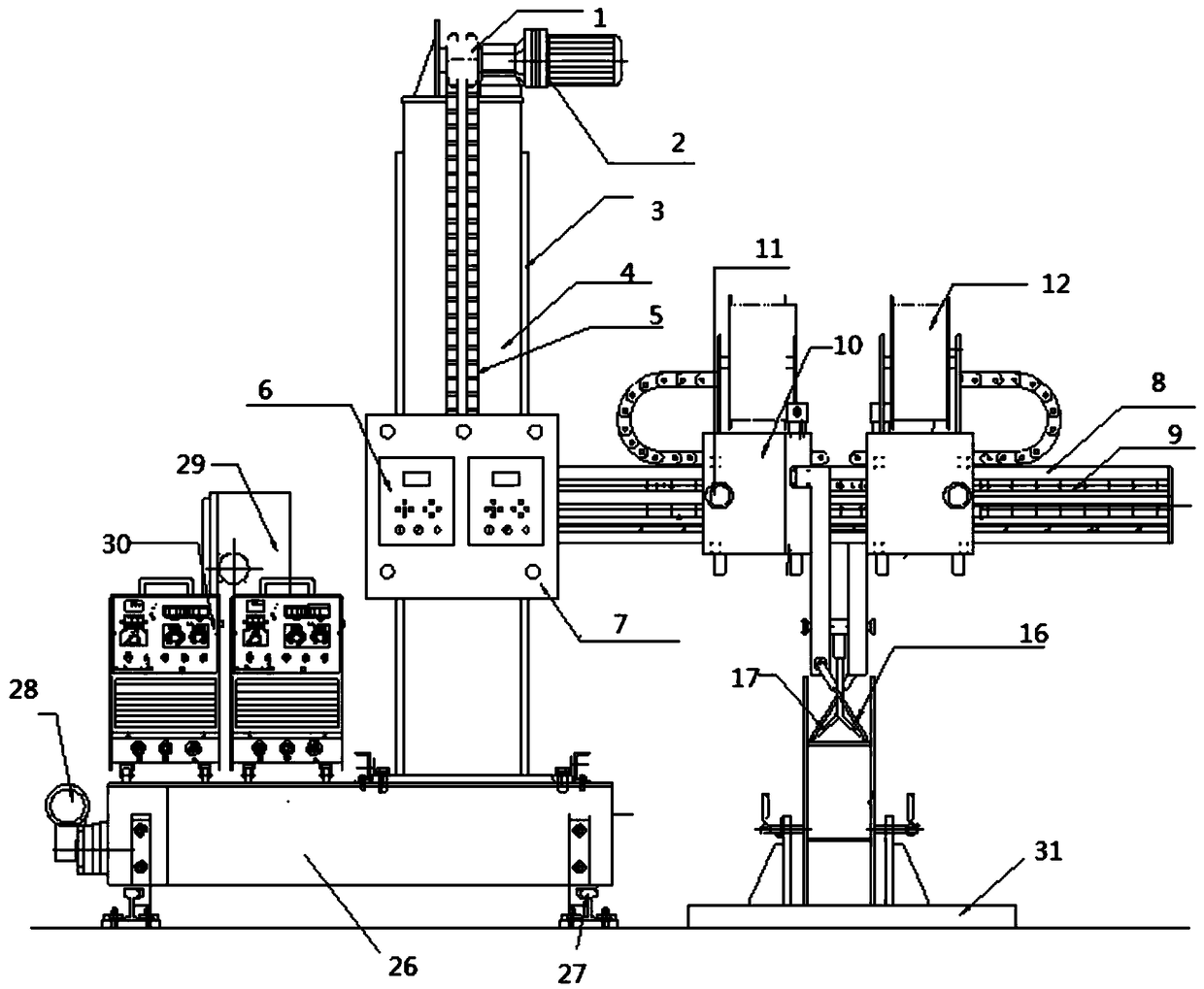

[0026] The present invention is further described below in conjunction with accompanying drawing:

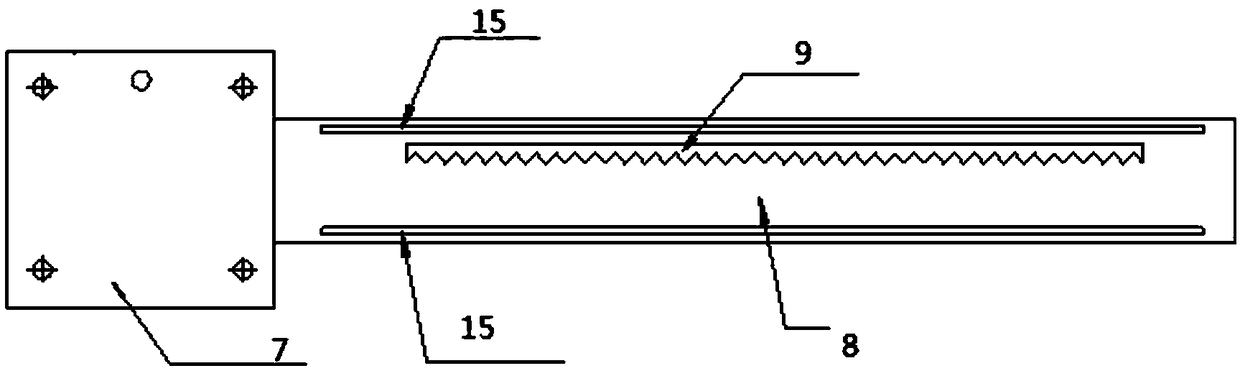

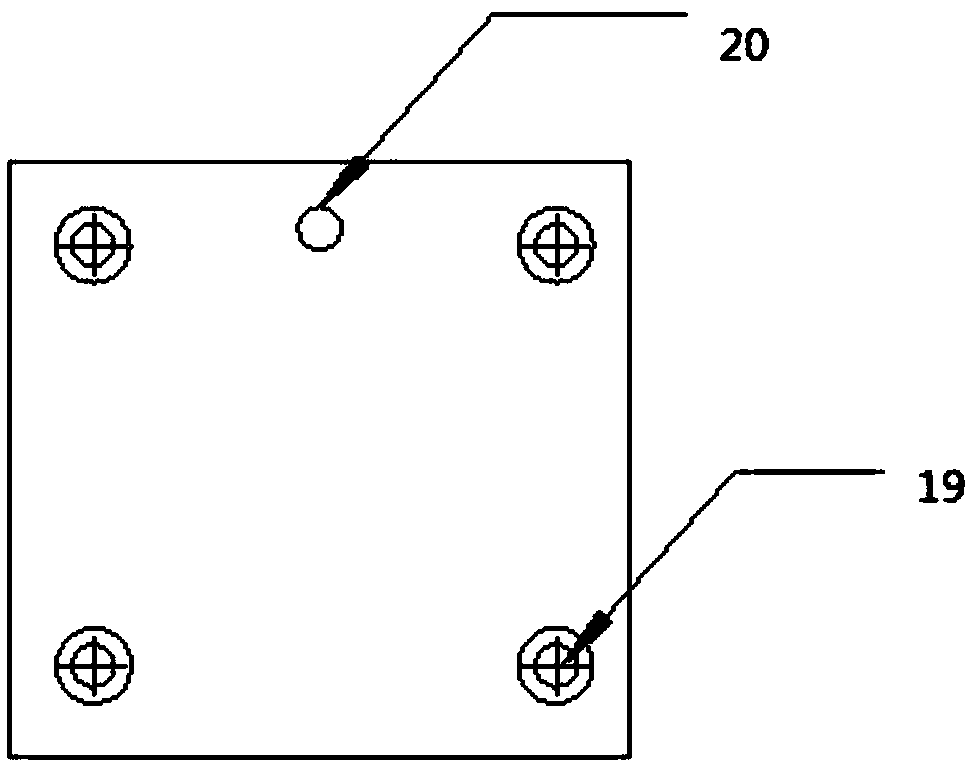

[0027] see Figure 1 to Figure 6 , a cantilever welding machine for fillet welds in narrow spaces, comprising a lifting mechanism, a lateral moving mechanism, a welding mechanism, an electric controller 29 and an electric welding machine 30; The lateral moving mechanism moves up and down; the welding mechanism is arranged on the lateral moving mechanism, and the welding mechanism can move on the lateral moving mechanism; the welding mechanism is connected to the electric welding machine 30, and the electric welding machine 30 is connected to the electric controller 29; the lifting mechanism and the lateral moving mechanism are all connected to The electrical controller 29 can control the movement of the lifting mechanism and the lateral movement mechanism; the model of the electrical controller 29 is SIEMENS S7-200CN.

[0028] The lifting mechanism comprises a lifting motor 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com