An eddy current resistance welding device and welding method for foil miniature parts

A technology of miniature parts and resistance welding, applied in resistance welding equipment, high-frequency current welding equipment, welding equipment, etc., can solve the problems of insufficient heat, unfused lap welding heads, etc., to achieve high production efficiency, low heat dissipation, easy to use effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

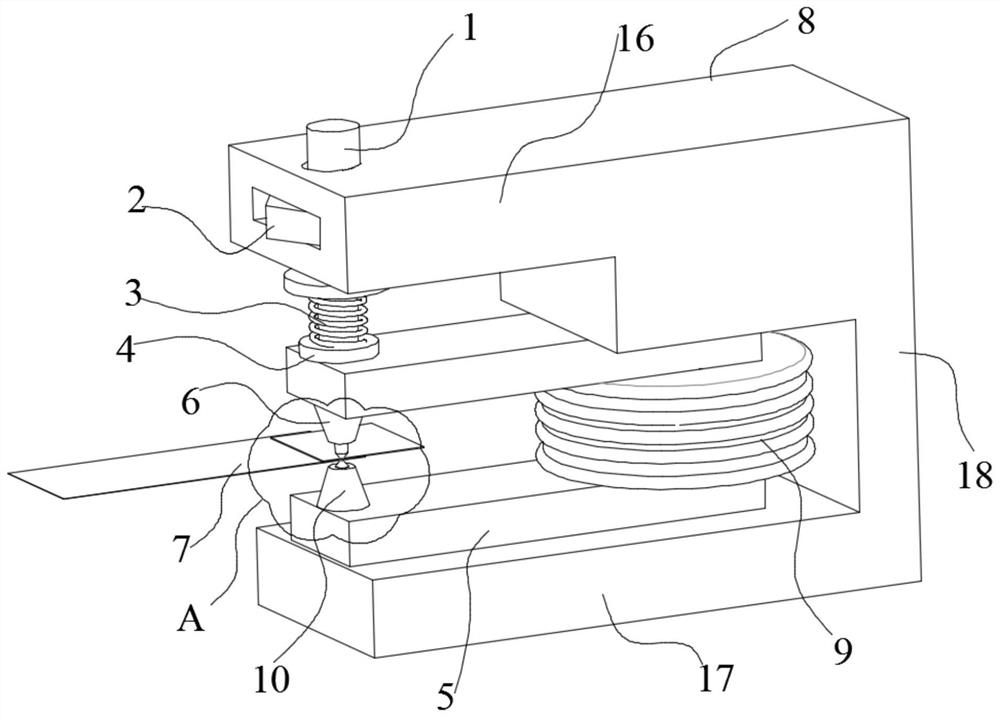

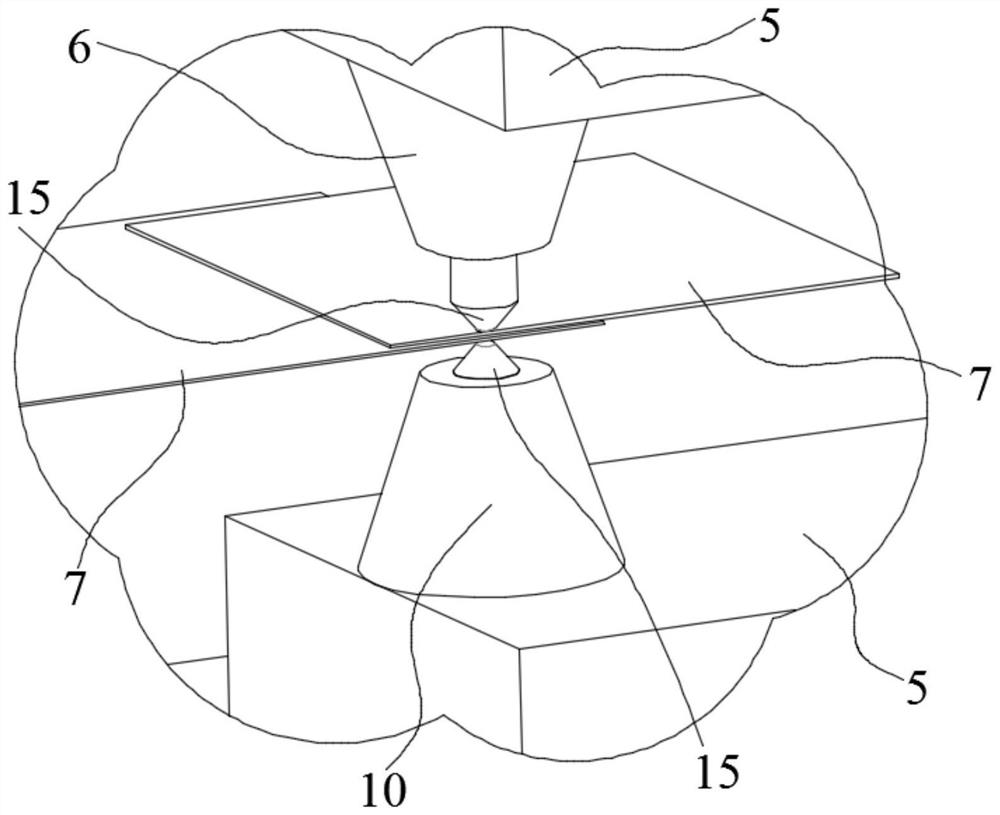

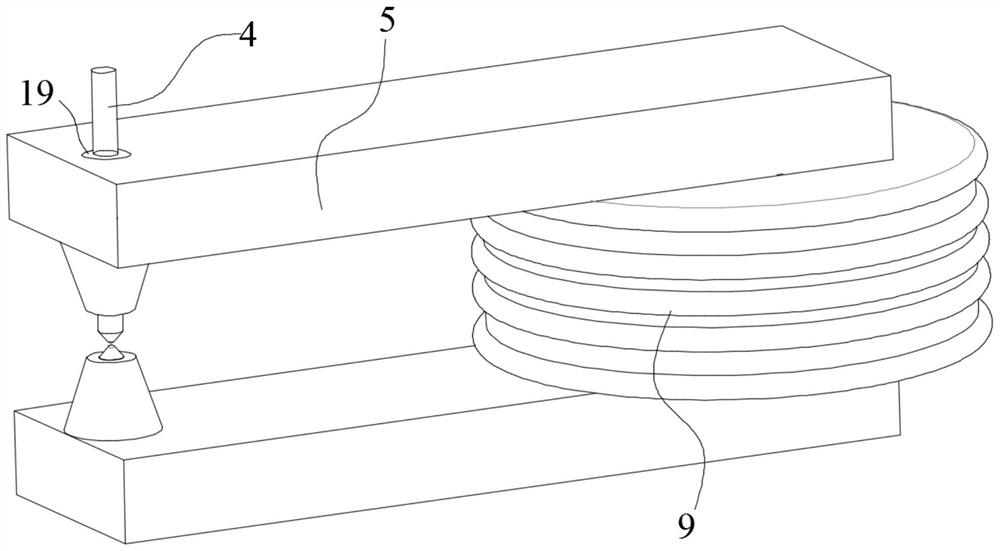

[0032] The present invention is illustrated below in conjunction with the accompanying drawings.

[0033] Such as Figure 1 to Figure 6 As shown, an eddy current resistance welding device for foil miniature parts includes a frame 8, a U-shaped magnetic core 5, an alternating magnetic field generator, an upper electrode 6 and a lower electrode 10; the frame 8 is U-shaped Frame 8 comprises frame upper limbs 16, frame lower limbs 17 and the vertical support 18 that upper and lower limbs are fixed.

[0034] The alternating magnetic field generating device is installed at the rear of the U-shaped magnetic core 5 for providing an alternating magnetic field for the U-shaped magnetic core 5;

[0035] The upper electrode 6 and the lower electrode 10 are oppositely installed on the inside of the front ends of the two limbs of the U-shaped magnetic core 5, and are used to clamp the soldered foil miniature parts 7;

[0036] The upper electrode 6 and the lower electrode 10 are made of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com