Process method for assembling and welding pile leg of ocean platform

A technology of offshore platforms and process methods, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of low welding qualification rate, large welding deformation, and low welding efficiency, and achieve small welding stress, fast operation, and improved The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The process method for assembling and welding offshore platform pile legs according to the present invention,

[0034] a Preparations before assembly

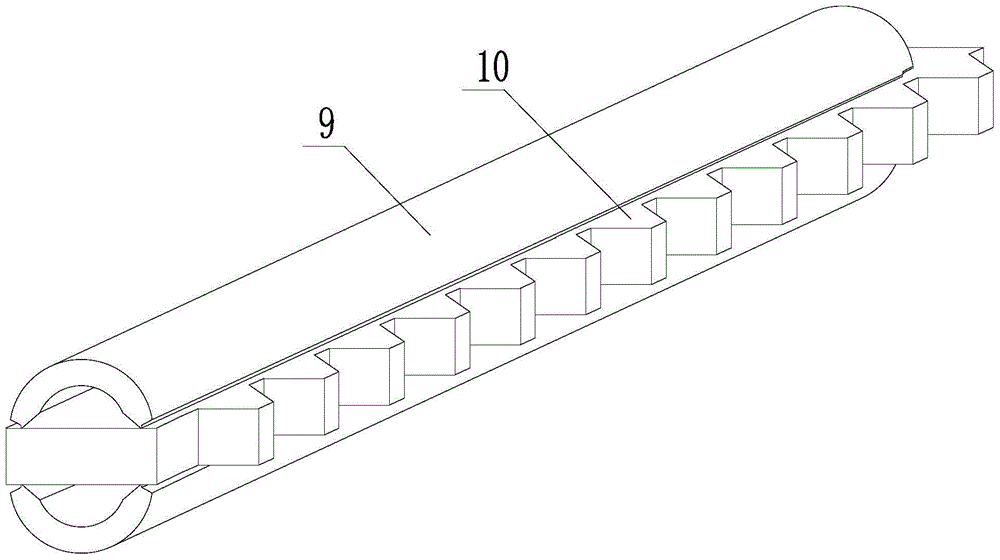

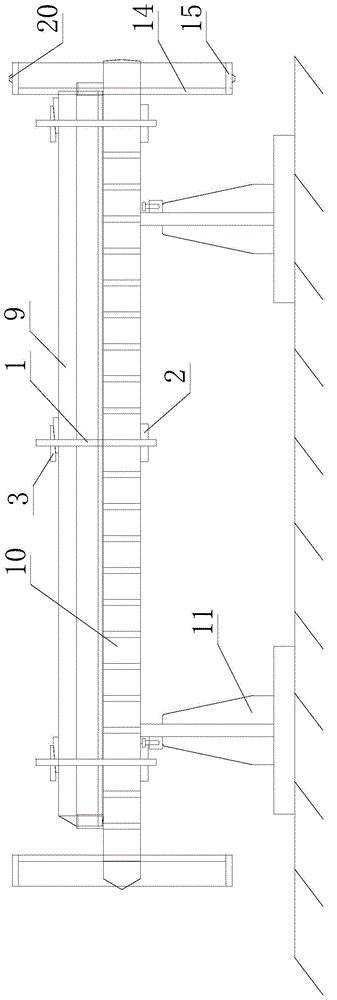

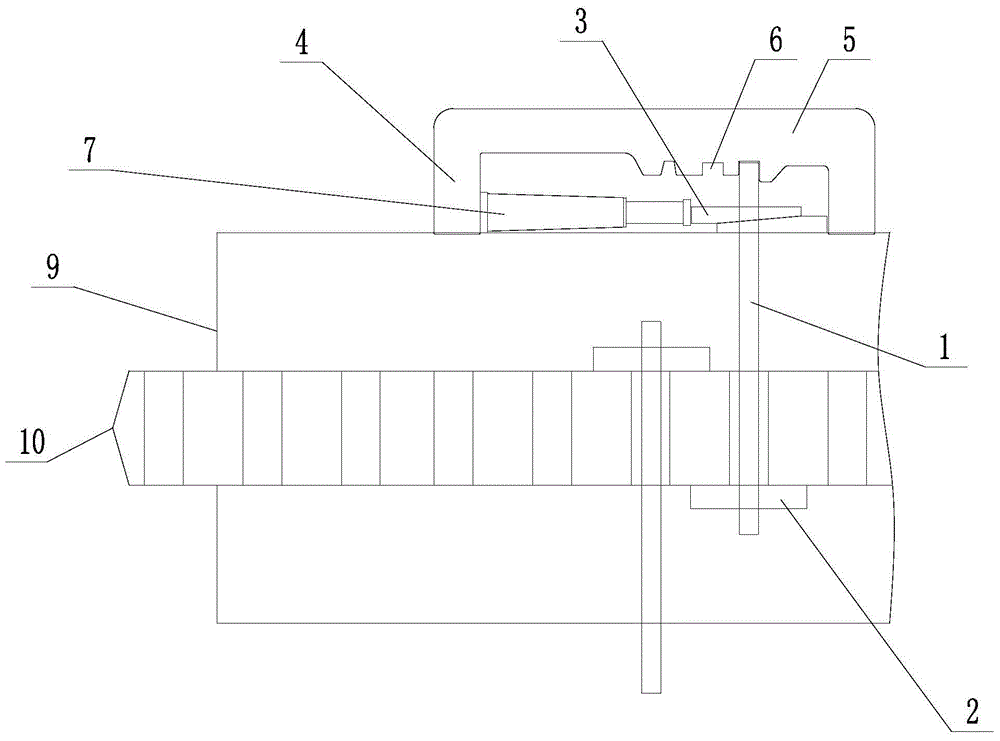

[0035] Such as figure 1 As shown, a pile leg assembly is composed of a rack 10 and two semicircular tubes 9. Before assembly, the rack 10 and semicircular tubes 9 should be carefully inspected to ensure that the products that flow into the next process are qualified products. Put the rack 10 flat on the ground, and completely remove the surface of the area to be welded on the upward side by grinding. After the requirements, install the welding steel liner, and immediately use the electric heating sheet for post-weld heat treatment and heat preservation after welding. After the weld has passed the non-destructive test, the longitudinal weld groove and the nearby 30mm area will be polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com