Outside-furnace welding device and method for auxiliary electrodes of vacuum arc furnace

A vacuum electric arc furnace and auxiliary electrode technology, which is applied in auxiliary devices, auxiliary welding equipment, arc welding equipment, etc., can solve the problems of difficult to control the centering accuracy of consumable electrodes, high welding quality, and deformation of mold bases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

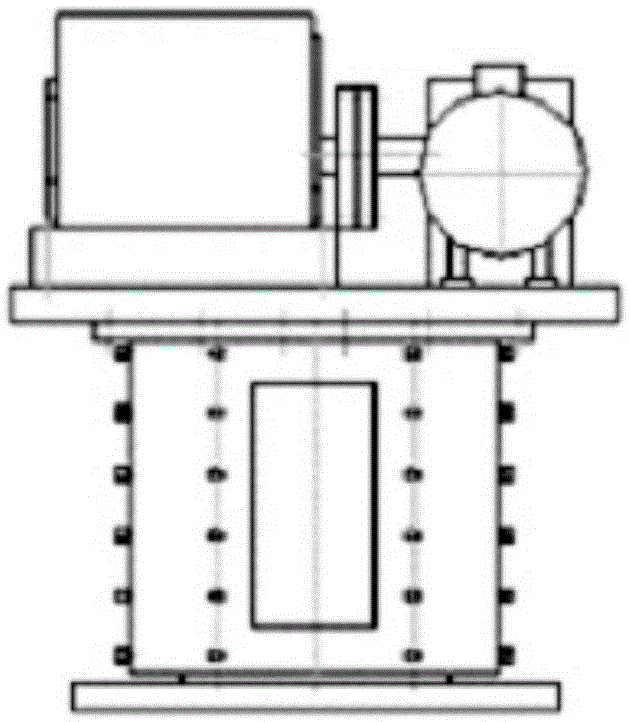

[0168] Vacuum arc furnace auxiliary electrode welding device outside the furnace, such as figure 1 As shown, the vacuum electric arc furnace auxiliary electrode welding device outside the furnace is composed of a consumable electrode positioning device, an auxiliary electrode positioning device, and an electrode lifting and rotating drive device.

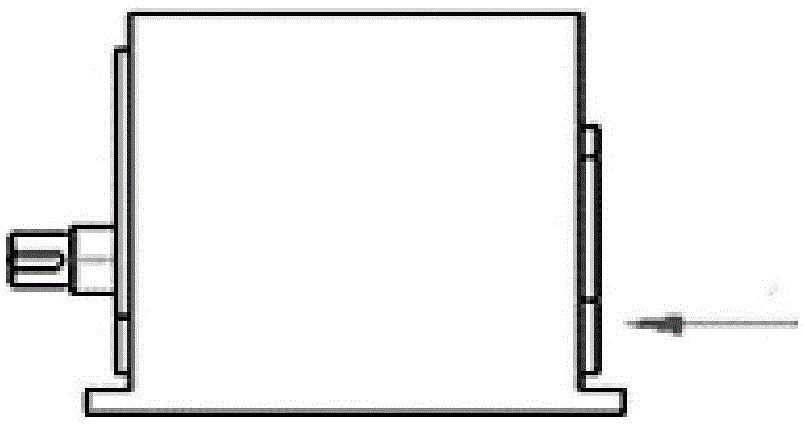

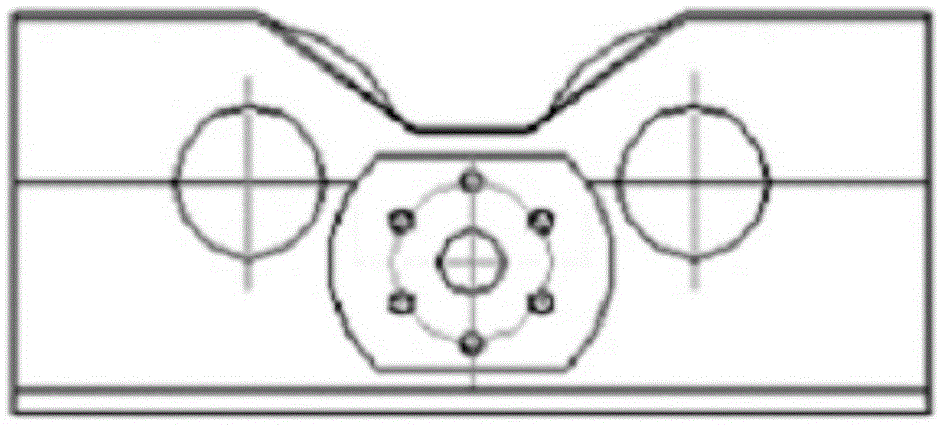

[0169] Consumable electrode positioning devices such as figure 1 As shown, in order to meet the spatial positioning of consumable electrodes of different lengths, it is mainly composed of a first center frame adjustment device, a second center frame adjustment device and a third center frame adjustment device arranged at a certain distance and with the same structure. As shown in Figure 2, the first center frame adjustment device is mainly composed of a base, a center frame, an adjustment mechanism and the like. Among them, the center frame is shown in Figure 3, which is mainly composed of a center frame cover, a center frame seat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com