Non-die hydraulic integrally forming ultra-thin spherical shell technology

A hydroforming and integral technology, applied in other household appliances, household appliances, applications, etc., can solve the problems of difficult welding, difficult control of welding quality, and high labor intensity, so as to achieve no damage to mechanical properties and easy control of welding quality. , the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

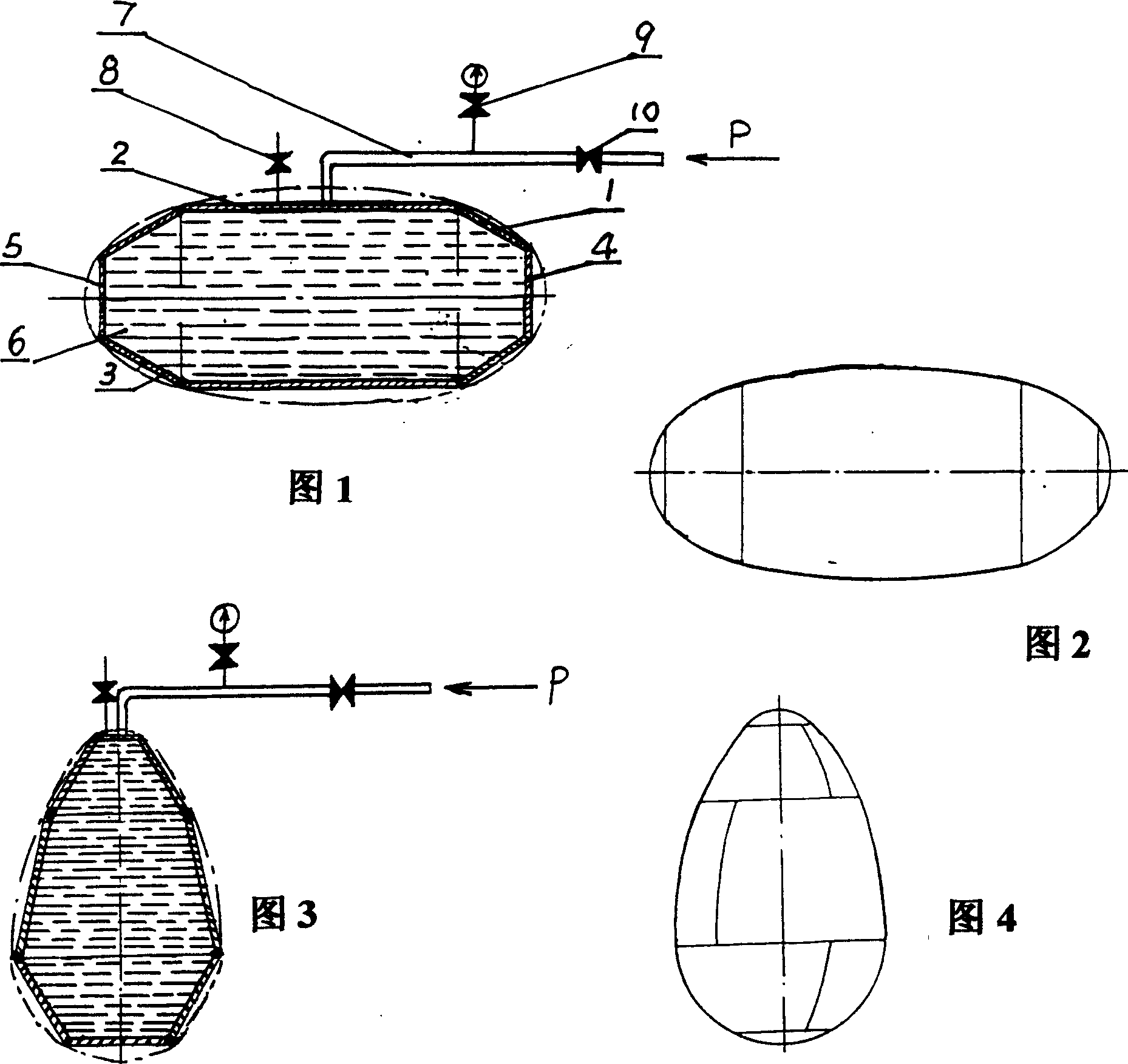

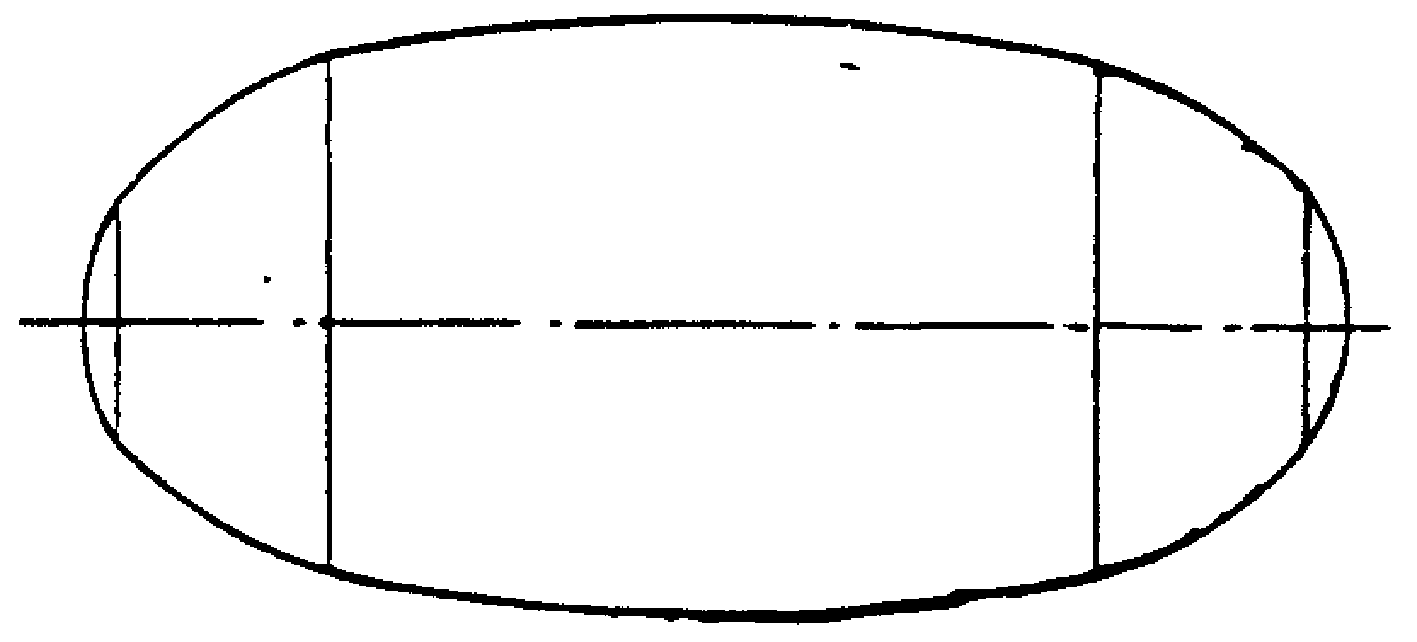

[0008] Taking the metal ultra-thin ellipsoid manufacturing process as an example, the present invention can be realized according to the following process: ①. The metal sheet is cut into the rectangular material required for rolling a section of cylinder and several pieces of rolling into frustum body through calculation. Fan-shaped material, (you can also cut all the metal plates into several pieces and roll them into fan-shaped materials required for the cone body), and then weld the rolled metal plates into ultra-thin elliptical balls according to the requirements of the design structure The housing is internally connected with a polyhedron, such as 1, 2, and 3 in attached drawing 1; A round hole is opened at the upper end of the elliptical spherical shell, and water is injected into the shell to fill it up as a pressure transmission medium, such as 6 in attached drawing 1; Connected, such as 7 in the accompanying drawing 1; ④. Connect a vent valve on the welded ultra-thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com