ABS-PMMA composite material as well as preparation method and application thereof

A technology of composite materials and materials, applied in the field of ABS-PMMA composite materials, can solve the problems of increasing material costs and labor costs, increasing process flow, human injury, etc., to avoid pollution and harm to the human body, with good mechanical properties, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

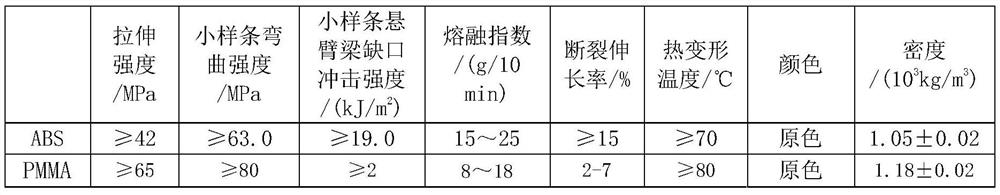

[0041] Step A, mix the ABS resin of 75 parts by weight, the PMMA resin of 15 parts by weight and the white oil of 0.4 parts by weight, and then with the antioxidant of 0.4 parts by weight, the lubricant of 5 parts by weight, the metal of 1.2 parts by weight The powder and 3 parts by weight of the pearlescent pigment were stirred in a mixer at room temperature for 2 minutes, and the mixed material was obtained after uniform mixing.

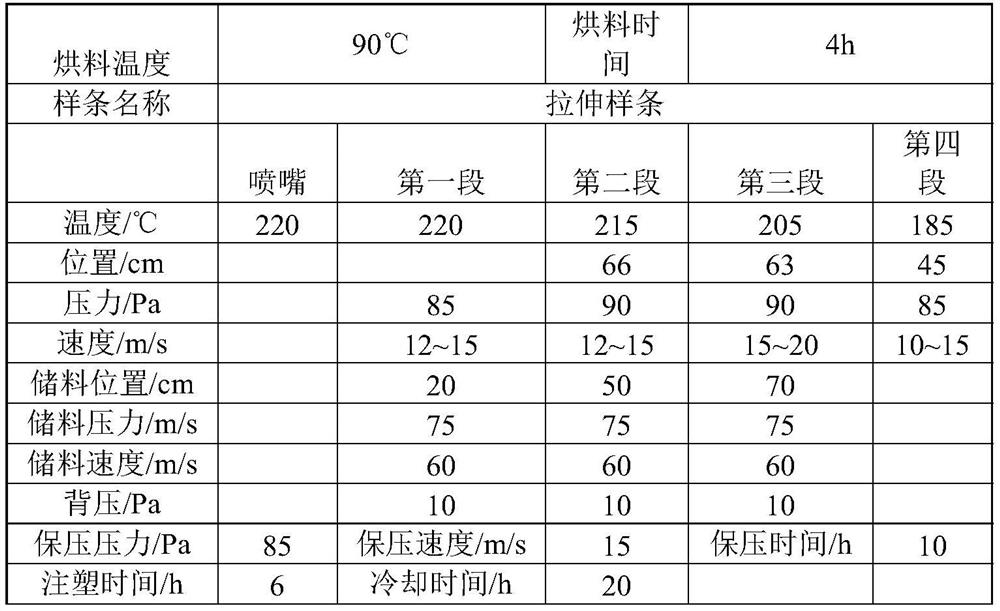

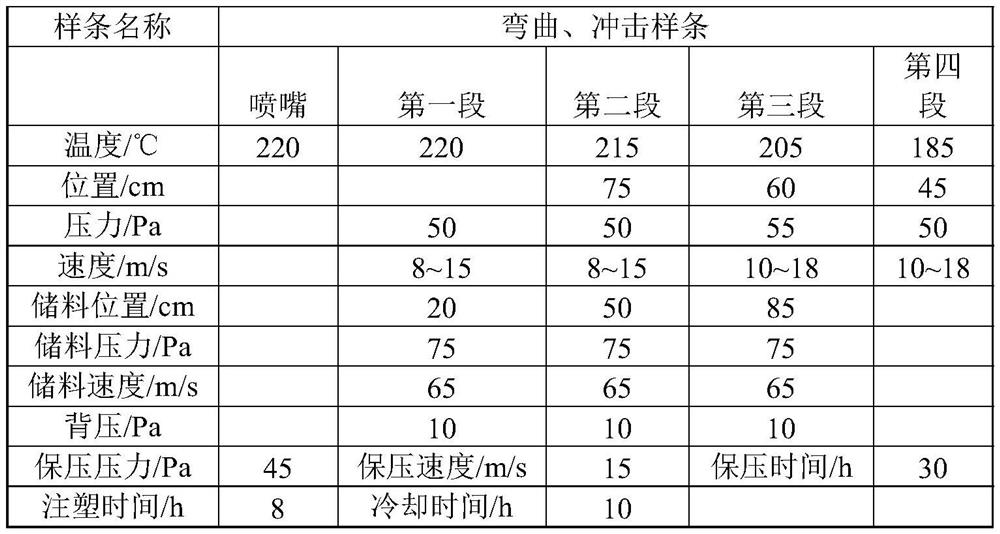

[0042] Step B. Put the mixed materials into a single-screw granulator, control the temperature at 210° C., feed at 9 r / min, screw at 150 r / min, and without shearing force. Take 3kg of plastic granules obtained through granulation treatment, and carry out injection molding proofing treatment. The process parameters of the injection molding process are shown in Table 2. The obtained product 1# is left for 48 hours for performance testing. The test results are shown in Table 3.

Embodiment 2

[0044] Carry out according to the method for embodiment 1, difference is: step A, the ABS resin of 70 parts by weight, the PMMA resin of 20 parts by weight and the white oil of 0.3 parts by weight are mixed, and then with the antioxidant of 0.5 parts by weight , 6 parts by weight of lubricant, 1 part by weight of metal powder, and 2.2 parts by weight of pearlescent pigment were stirred in a mixer for 5 minutes at room temperature, and mixed uniformly to obtain a mixed material. And after processing according to step B, the obtained product 2# was left for 48h and then subjected to a performance test. The test results are shown in Table 3.

Embodiment 3

[0046] Carry out according to the method for embodiment 1, difference is: step A, the ABS resin of 80 parts by weight, the PMMA resin of 10 parts by weight and the white oil of 0.3 parts by weight are mixed, and then with the antioxidant of 0.5 parts by weight , 6 parts by weight of lubricant, 1 part by weight of metal powder, and 2.2 parts by weight of pearlescent pigment were stirred in a mixer for 5 minutes at room temperature, and mixed uniformly to obtain a mixed material. And after processing according to step B, the obtained product 3# is placed for 48h and then subjected to a performance test. The test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com