Dual-powder mixing printing system for 3D printing

A 3D printing and hybrid printing technology, which is applied in the field of 3D printing systems, can solve problems such as the difficulty of finding metal powder process parameters, and achieve the effect of improving metal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

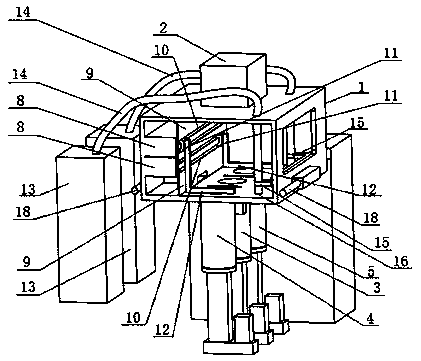

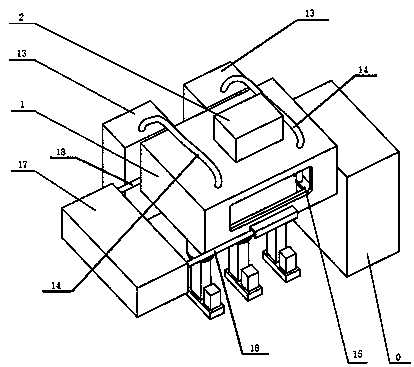

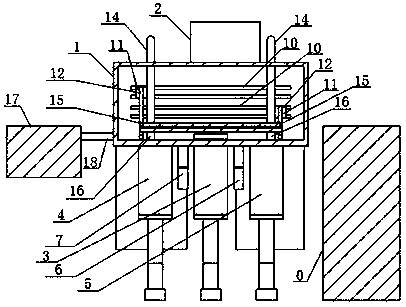

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] The present invention designs a dual-powder mixed printing system for 3D printing. In practical application, it specifically includes control module 0, sealed box 1, laser device 2, A scraper system, B scraper system, A adsorption system, B Adsorption system, air suction purification device 17, at least one air suction pipe 18, molding cylinder 3, A powder material cylinder 4, B powder material cylinder 5, A material collection cylinder 6, B material collection cylinder 7, and are respectively arranged in each Electric control lifting platform device inside the cylinder.

[0018] Among them, such as Figure 1 to Figure 3 As shown, the top surface of each cylinder is open, and each cylinder is located under the sealed box 1 in a vertical posture, A powder material cylinder 4, B material collection cylinder 7, form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com