Automobile interior material being suitable for vacuum molding and achieving pearlescent appearance

An automotive interior and vacuum forming technology, applied in the field of automotive interior materials, can solve the problems of limited scratch resistance and damage to the TPO skin, and achieve the effect of enhancing the status symbol and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Disclosed in the embodiment 1 is a kind of automotive interior material with a pearlescent appearance suitable for vacuum forming, which includes a TPO skin and a water-based paint evenly coated on the above-mentioned TPO skin, in parts by weight,

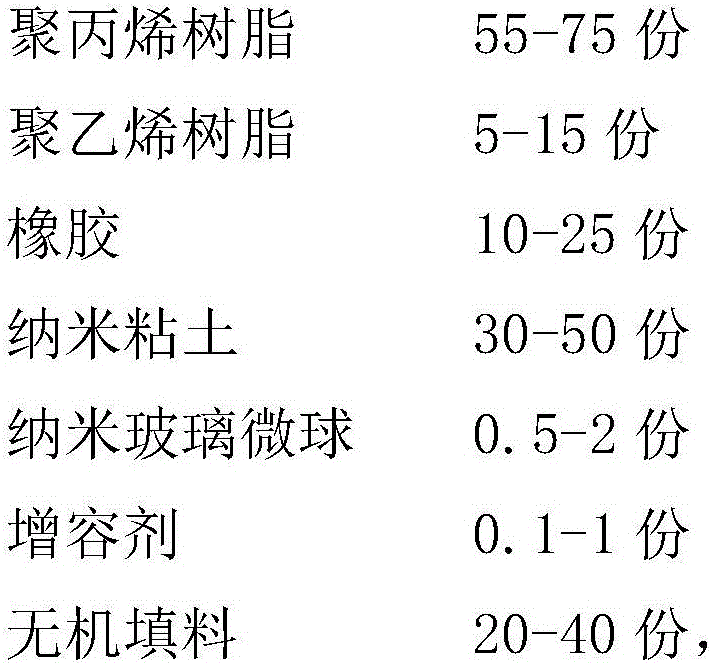

[0033] Among them, the above-mentioned TPO skin materials include:

[0034]

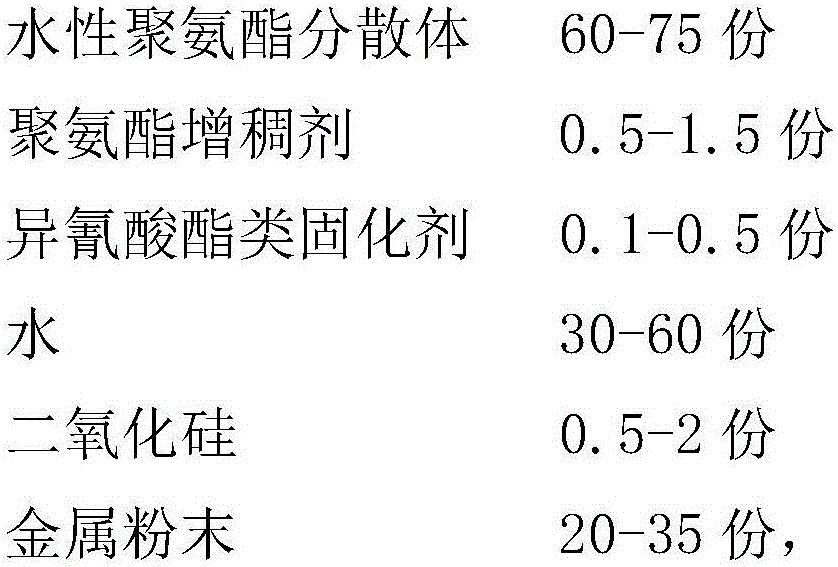

[0035] Above-mentioned water-based paint is water-based polyurethane paint, and above-mentioned water-based polyurethane paint comprises:

[0036]

[0037] Methods for preparing waterborne polyurethane paints with metal powders include:

[0038] S101 Mix and stir the water-based polyurethane dispersion, silicon dioxide and water evenly;

[0039] S102 Add the polyurethane thickener to the mixed solution in S101, and stir well;

[0040] S103 adding the isocyanate curing agent into the mixed solution in S102, fully stirring evenly;

[0041] In S104, the metal powder is mixed into the mixed solution in S103 to prepare a water-based polyurethan...

Embodiment 2

[0052] In terms of parts by weight, wherein the above-mentioned TPO skin material includes:

[0053]

[0054]

[0055] Above-mentioned water-based paint is water-based polyurethane paint, and above-mentioned water-based polyurethane paint comprises:

[0056]

[0057] Methods for preparing waterborne polyurethane paints with metal powders include:

[0058] S101 Mix and stir the water-based polyurethane dispersion, silicon dioxide and water evenly;

[0059] S102 Add the polyurethane thickener to the mixed solution in S101, and stir well;

[0060] S103 adding the isocyanate curing agent into the mixed solution in S102, fully stirring evenly;

[0061]In S104, the metal powder is mixed into the mixed solution in S103 to prepare a water-based polyurethane paint containing metal powder.

[0062] Adjust the pH value of the water-based polyurethane paint containing metal powder prepared in S104 to 6.5-8.5 with a pH regulator, and measure its viscosity to 30-40S under the co...

Embodiment 3

[0072] In terms of parts by weight, wherein the above-mentioned TPO skin material includes:

[0073]

[0074] Above-mentioned water-based paint is water-based polyurethane paint, and above-mentioned water-based polyurethane paint comprises:

[0075]

[0076] Methods for preparing waterborne polyurethane paints with metal powders include:

[0077] S101 Mix and stir the water-based polyurethane dispersion, silicon dioxide and water evenly;

[0078] S102 Add the polyurethane thickener to the mixed solution in S101, and stir well;

[0079] S103 adding the isocyanate curing agent into the mixed solution in S102, fully stirring evenly;

[0080] In S104, the metal powder is mixed into the mixed solution in S103 to prepare a water-based polyurethane paint containing metal powder.

[0081] Wherein, the water-based polyurethane paint containing metal powder prepared in S104 is adjusted to a pH value of 6.5-8.5 by using a pH regulator, and its viscosity is measured as 30-40S und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com