ZIFs derived metal nitride/carbon composite material and preparation method and application thereof

A carbon composite material and composite material technology, applied in the field of ZIFs-derived metal nitride/carbon composite material and its preparation, can solve the problems of poor electrical conductivity, limited amplification and industrialization, long preparation cycle, etc. The effect of improving the content and performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

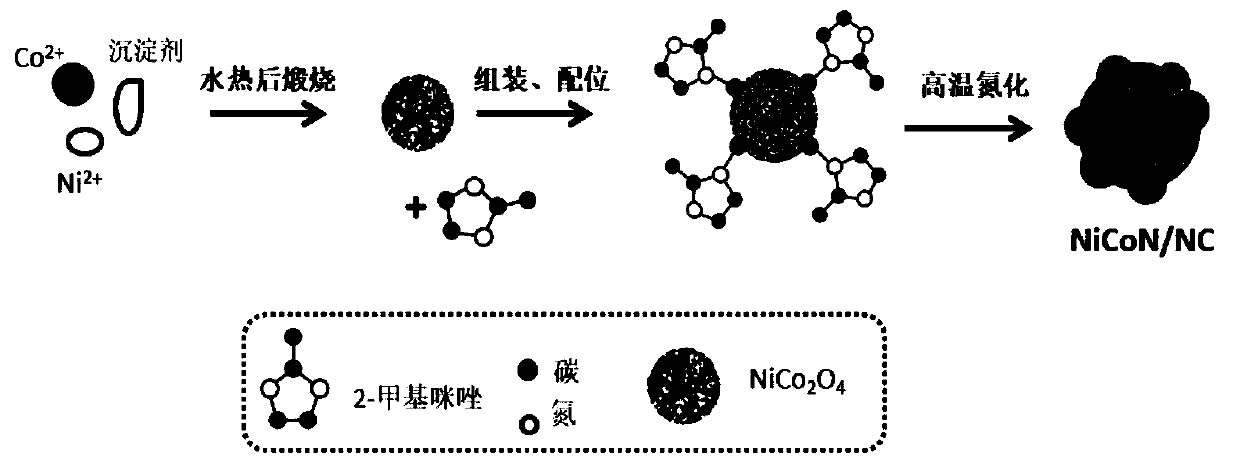

[0055] A kind of preparation method of ZIFs derived metal nitride / carbon composite material, such as figure 1 Shown is a schematic diagram of the synthesis of ZIFs-derived metal nitride / carbon composites prepared in Example 1 of the present invention, including: Synthetic NiCo 2 o 4 , then NiCo 2 o 4 Co in the high-temperature molten state is assembled with 2-methylimidazole to form ZIF-67, and then further nitrided, the specific steps are as follows:

[0056] (1) Weigh 248.84mg (1mM) of nickel acetate tetrahydrate, 498.12mg (2mM) of cobalt acetate tetrahydrate and 2.37g (30mM) of ammonium bicarbonate, respectively, and disperse them in a mixed solution of 15mL deionized water and 35mL ethylene glycol , add a stirrer, and use a magnetic stirrer to stir evenly for 30 minutes at room temperature;

[0057] (2) Put the uniformly mixed solution into a 50mL polytetrafluoroethylene reactor, set the oven parameters to 200°C, and conduct a hydrothermal reaction for 12 hours. After...

Embodiment 2

[0067] A kind of preparation method of ZIFs derived metal nitride / carbon composite material, such as Figure 4 As shown, it is a schematic diagram of the synthesis of ZIFs-derived metal nitride / carbon composite material (Ni-CoN / NC in the figure) prepared in Example 2 of the present invention, and the steps (1)-(3) to prepare NiCo 2 o 4 The same as the preparation process of Example 1, the difference is:

[0068] (4) Weigh 200mg NiCo 2 o 4 1. 5g polyvinylpyrrolidone (PVP), put into a beaker with 50mL methanol, add a stir bar, and stir at room temperature for 30min on a magnetic stirrer;

[0069] (5) Weigh 0.8924g of zinc nitrate hexahydrate and dissolve it in 10mL of methanol, weigh 4g of 2-methylimidazole and dissolve it in 30mL of methanol, and quickly pour the methanol solution of 2-methylimidazole into the methanol of zinc nitrate hexahydrate In the solution, stir at room temperature for 30 minutes and then let it stand for 3 hours, then pour it into the methanol soluti...

Embodiment 3

[0082] A method for preparing a ZIFs-derived metal nitride / carbon composite material is basically the same as in Example 2, except that in step (5), 1.7848 g of zinc nitrate hexahydrate and 8 g of 2-methylimidazole are used. The obtained ZIFs-derived metal nitride / carbon composite is designated as sample 3.

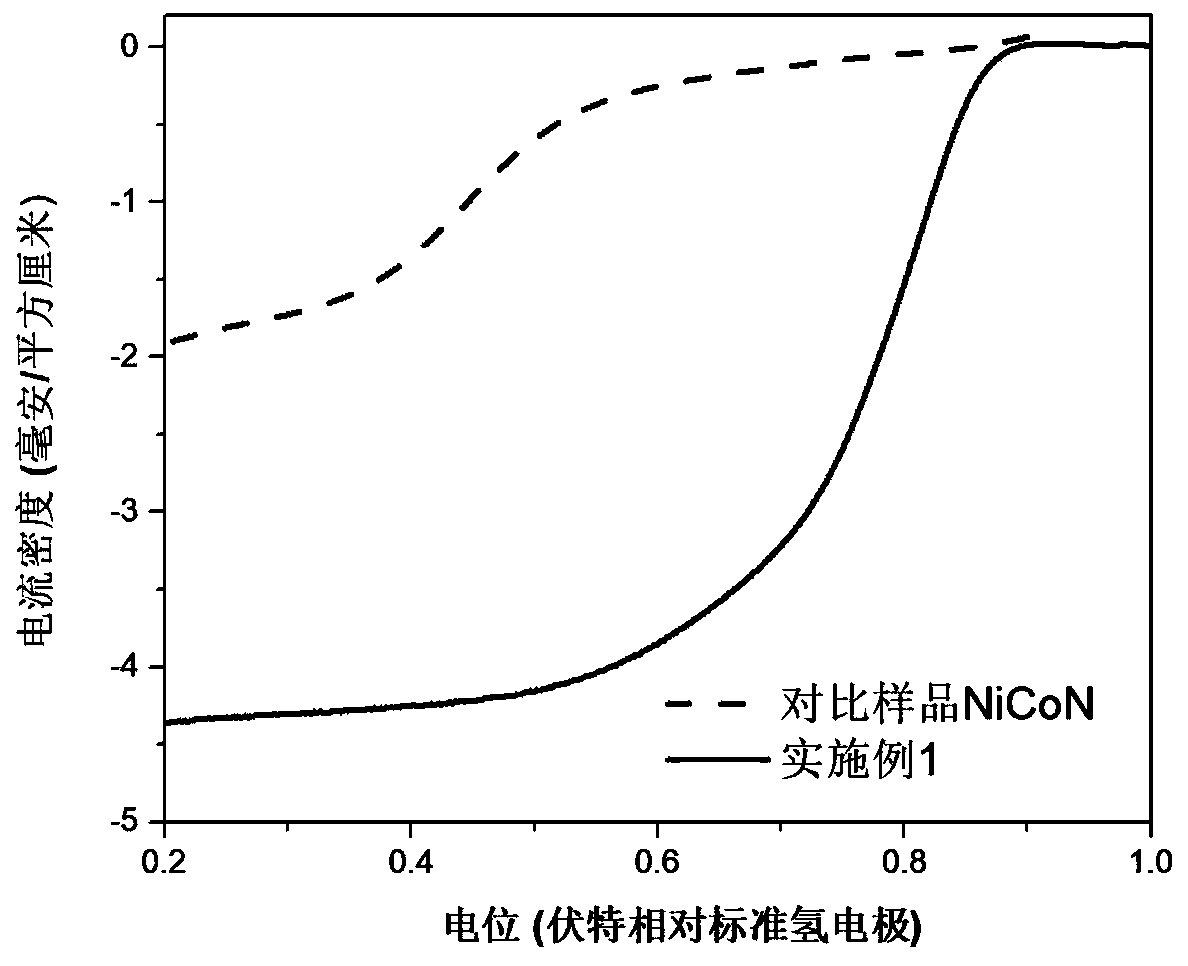

[0083] Such as Figure 15 Shown is the oxygen reduction performance comparison chart of the samples prepared in Example 1, Example 2 and Example 3. It can be seen from the figure that the onset potential of sample 2 is about 0.95V (vs.RHE), and the half-wave potential is 0.77 V(vs.RHE), the limiting current density is about 5.0mA cm -2 , showing optimal oxygen reduction activity, indicating that an appropriate proportion of nitrogen reacts with metals in this example to obtain metal nitrides, and adding an appropriate proportion of 2-methylimidazole forms nitrogen-doped carbon compounds with abundant pore structures. To a certain extent, the number of active sites is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com