Cable coupling component and method for jointing steel rail with cable using the cable coupling component

A cable connection and cable technology, which is applied to cable terminals, electrical connectors, railway car body parts, etc. Stable performance, not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

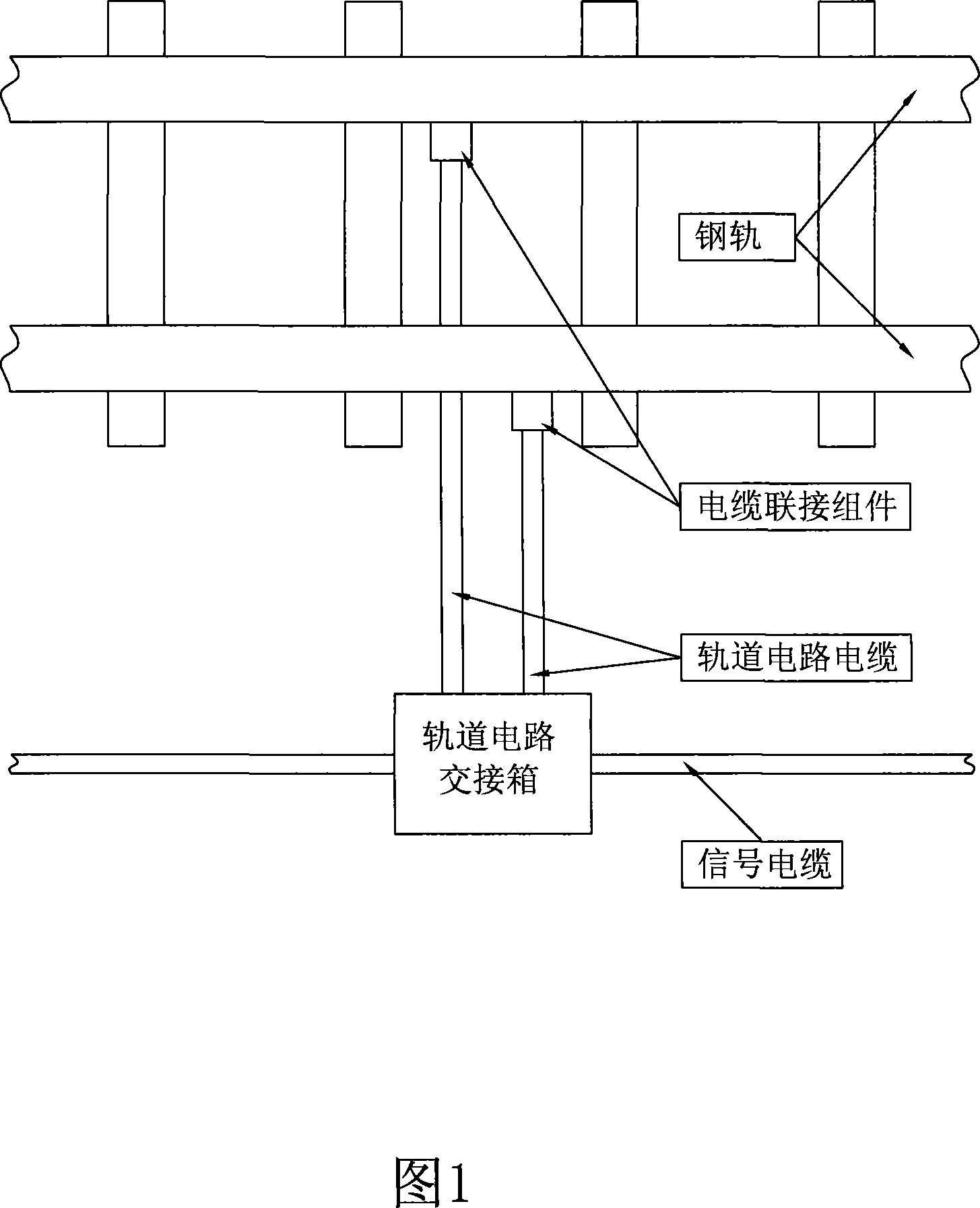

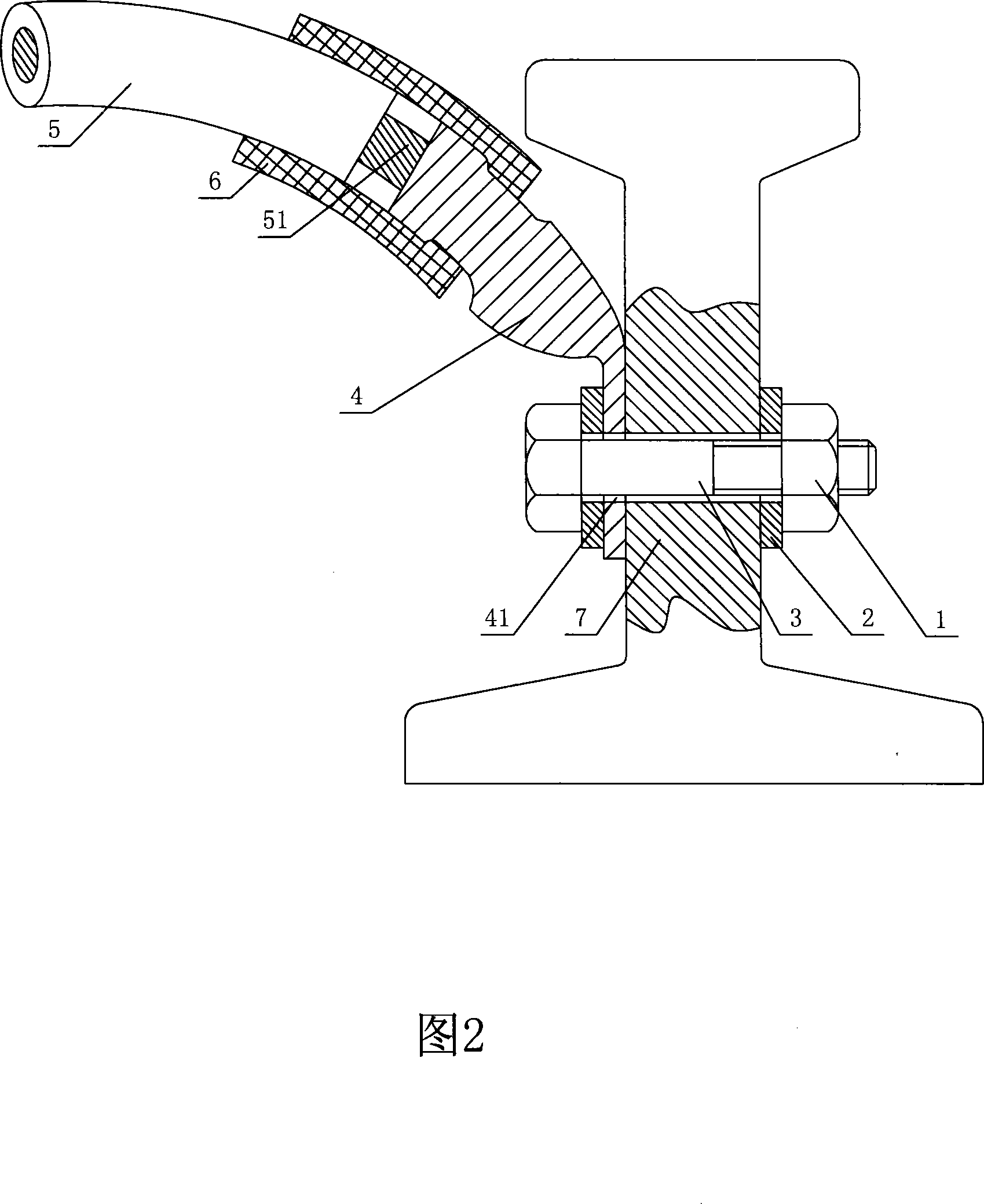

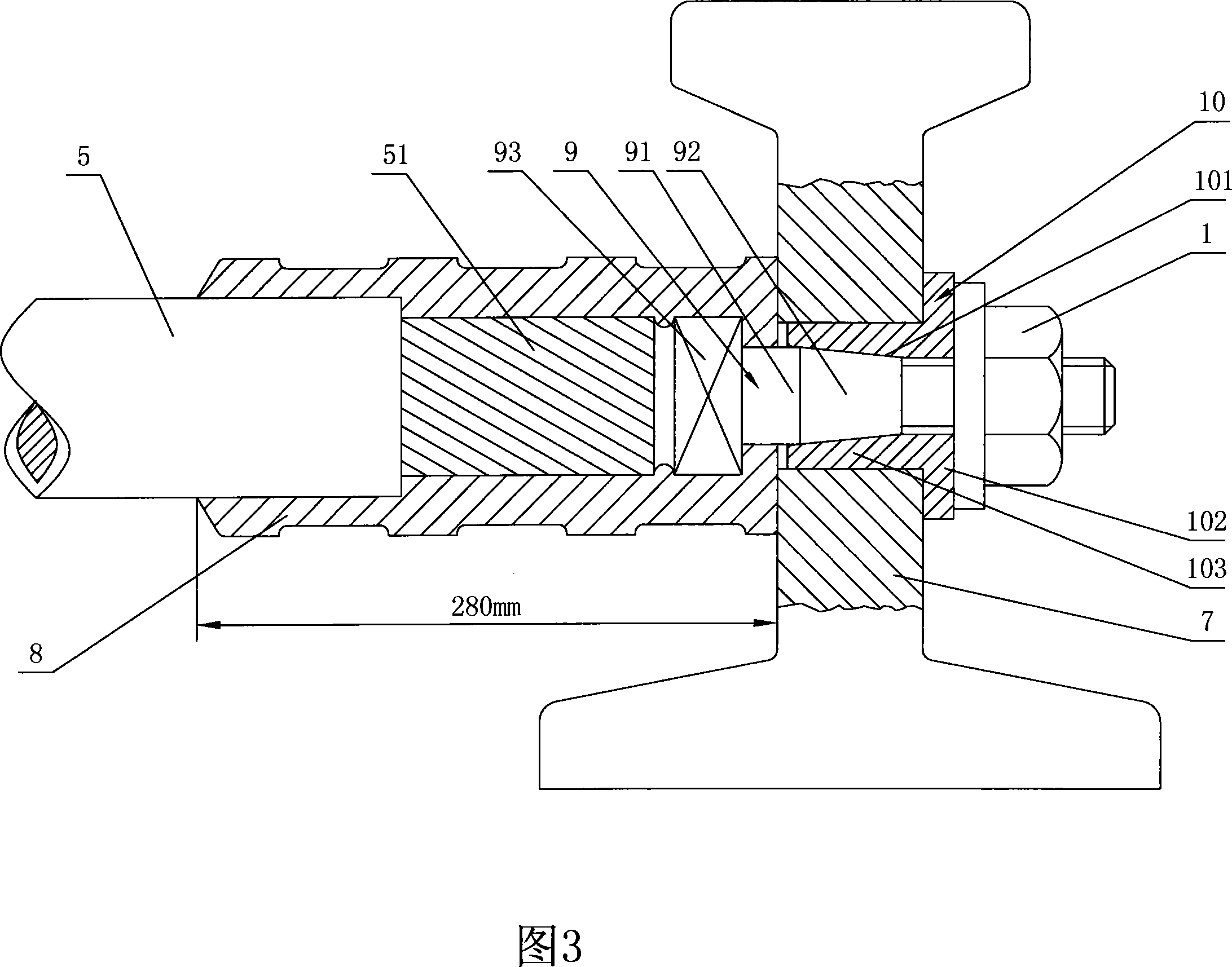

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] A cable coupling assembly applied to railway track circuit cables 5 and railway rails, which includes a tapered bolt 9 whose head 93 is connected to the track circuit cable 5, and the shaft of the tapered bolt 9 91 has the tapered part 92 that diameter gradually reduces from head 93 to shank 91 direction; It also comprises the elastic sleeve 10 that is inserted on the rail waist 7, and the inner wall of described elastic sleeve 10 is provided with can The tapered hole 101 of the tapered portion 92 is accommodated. When the cable connection assembly is in use, the end of the shaft 91 of the tapered bolt 9 away from the head 93 passes through the inner hole of the elastic sleeve 10, the The outer wall of the tapered portion 92 is in close contact with the inner wall of the tapered hole 101, and a nut 1 is provided at an end of the shaft 91...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com