Polyimide film externally coated with metal conductive layer and preparation method thereof

A polyimide film, metal conductive layer technology, applied in metal layered products, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem that the PI insulating layer cannot withstand decomposition, etc. Industrialized production, low production cost, improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

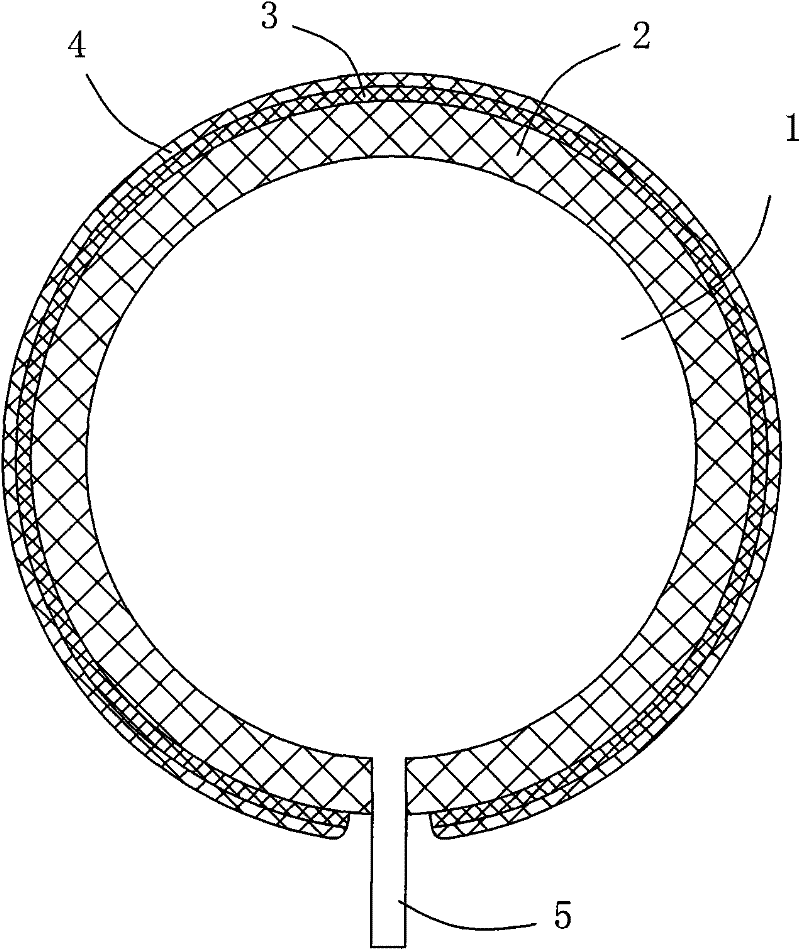

Image

Examples

Embodiment 1

[0064] Polyamic acid with a molecular weight of 250,000 to 350,000 (solid content 15wt%) synthesized from pyromellitic anhydride and diamine is coated on the On a 146mm stainless steel ball, after obtaining a uniform adhesive layer, put it into a heating furnace for imidization. The initial temperature is 60°C, and the temperature is gradually raised to 250°C. After cooling, a polyimide insulating layer is obtained, and the thickness is measured to be 80 microns. , no breakdown under DC voltage 10.8kv (insulation layer immersed in water test), with 15wt% solid content of polyamic acid 100 grams, add 4.5 grams of graphite, 4.5 grams of carbon black, 0.5 grams of silane coupling agent A1100, 3.5 grams Solid nickel silver agent JSW, 5 grams of conductivity enhancer 522, 3 grams of SA910 leveling agent, 6 grams of polyvinylpyrrolidone, 30 grams of solvent dimethylacetamide, mixed and ground evenly to form an intermediate adhesive layer coating, sprayed on the insulation The surfa...

Embodiment 2

[0066] Coat the same polyamic acid with the method of dipping with implementing 1 on On a 77mm stainless steel ball, put it into a heating furnace for imidization after a uniform adhesive layer is obtained. The initial temperature is 60°C, and the temperature is gradually raised to 250°C. After cooling, an insulating layer with a thickness of 80 microns is obtained. After a DC voltage of 10.5 The kv withstand voltage test does not break down. Then use the same two-way adhesive as in Example 1 to spray on the surface of the insulating layer, with a thickness of 5 microns. After natural drying, Ag and Ni ultrafine powder are evenly coated on the bonding layer in a closed powder sprayer, shaking Fall and blow lightly into adhered metal powder, move into a heating furnace at a heating rate of 5°C / min, and finally solidify and form at 340°C, take it out to cool, and polish it with a cloth wheel to obtain a smooth, bright metal conductive layer, thickness 15 microns, for measuring...

Embodiment 3

[0068] Coat the same polyamic acid with the method of dipping with implementing 1 on On a 146mm stainless steel ball, put it into a heating furnace for imidization after a uniform adhesive layer is obtained. The initial temperature is 60°C, and the temperature is gradually raised to 250°C. After cooling, an insulating layer with a thickness of 20 microns is obtained. After a DC voltage of 10.5 The kv withstand voltage test does not break down.

[0069] Use 85.3 grams of polyamic acid with a solid content of 15 wt%, add 4.5 grams of graphite, 4.5 grams of carbon black, 1.3 grams of silane coupling agent A1100, 3.6 grams of solid nickel silver agent JSW, 5.7 grams of conductivity enhancer 522, and 3.6 grams of SA910 fluid Leveling agent, 3.6 grams of polyvinylpyrrolidone, 26 grams of solvent dimethylacetamide, mixed and ground evenly to form an intermediate adhesive layer coating, sprayed on the surface of the insulating layer, with a thickness of 5 microns, and obtained an int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com