Graphene modified polyaspartic acid ester zinc-containing coating and preparation method thereof

An aspartate and graphene modification technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of low construction efficiency, excessive VOC emissions, large solvent volatilization, etc. The effect of improved efficiency, strong covering ability and long corrosion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

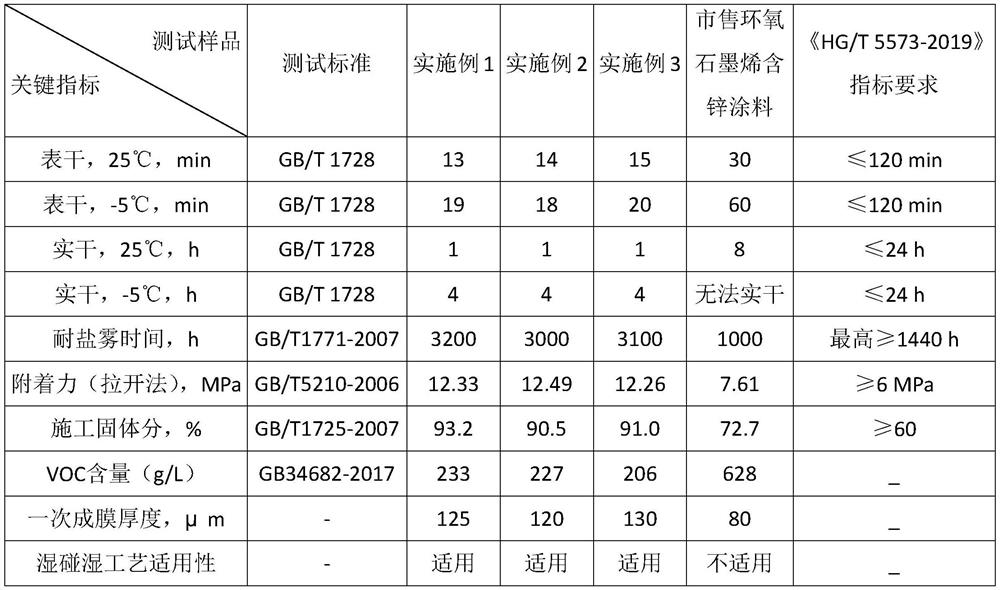

[0039] The parts by weight of each raw material are as shown in Table 1:

[0040] Table 1 Graphene-modified polyaspartic ester zinc-containing coating embodiment 1~3 weight part list of each raw material

[0041]

[0042]

[0043] Note: "-" in the table means not added.

Embodiment 1

[0045] (1) Preparation of Component A: According to the parts by weight of the raw materials described in Example 1 of Table 1, mix and stir the polyaspartic ester resin with an organic solvent and a dispersant evenly to form a clear solution, and add graphite in a stirring state olefin, at 800r / min, disperse for 15min, then add iron oxide red, spherical zinc powder, flake zinc powder, phosphorus iron powder, leveling agent, anti-settling agent, at 1500r / min, high-speed Disperse for 30 minutes until the fineness is ≤40μm, and it is ready;

[0046] (2) Preparation of component B: mix N3900 and N3600 evenly according to the weight parts of the raw materials described in Table 1, Example 1, and it is ready;

[0047] (3) When using, mix component A obtained in step (1) with component B obtained in step (2) according to the mass ratio of 11:1, and it is ready.

[0048] Preparation method embodiment 2

[0049] (1) Preparation of Component A: According to the parts by weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com