Lead frame deoxidizer and preparation method and application thereof

A technology of lead frame and oxidant, which is applied in jewelry and other fields, can solve the problems of poor environmental protection and toxicity, and achieve the effect of good environmental protection and strong metallic luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. Preparation of lead frame to remove oxidant

[0035] In the embodiment of the present invention, the sum of the mass fractions of the components for removing the oxidizing agent is 100%.

[0036] In the examples of the present invention, the % in the table refers to the mass fraction content.

[0037] In the examples of the present invention, PVP refers to polyvinylpyrrolidone; OP-10 refers to alkylphenol polyoxyethylene ether-10.

[0038] In the embodiments of the present invention, unless otherwise specified, water refers to deionized water.

[0039] In the examples of the present invention, unless otherwise specified, the operating temperature refers to room temperature conditions.

[0040] In the embodiments of the present invention, unless otherwise specified, the deoxidizer refers to the deoxidizer of the lead frame.

[0041] In the embodiment of the present invention, the preparation method for removing the oxidizing agent of the lead frame is carried out i...

Embodiment 1-10

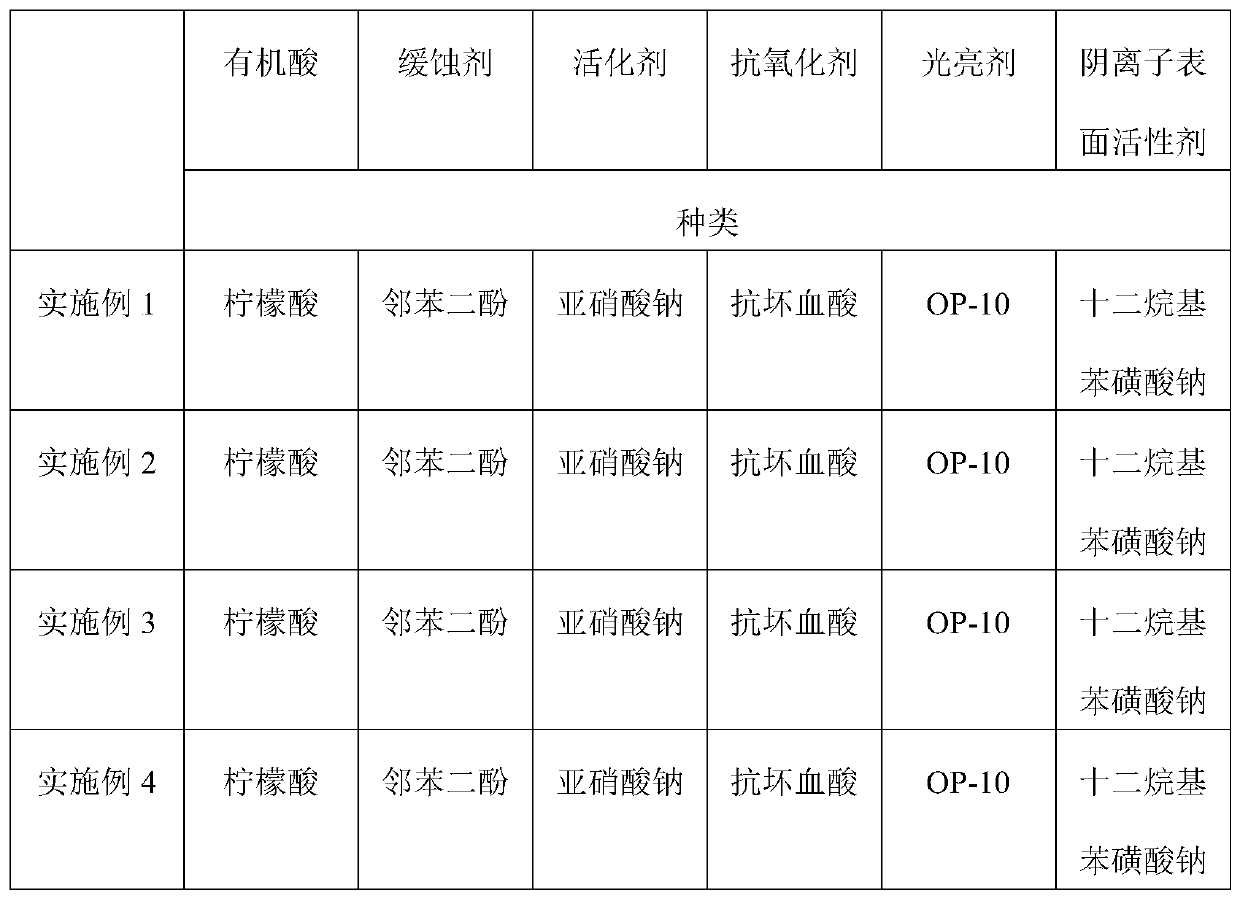

[0043] Table 1

[0044]

[0045]

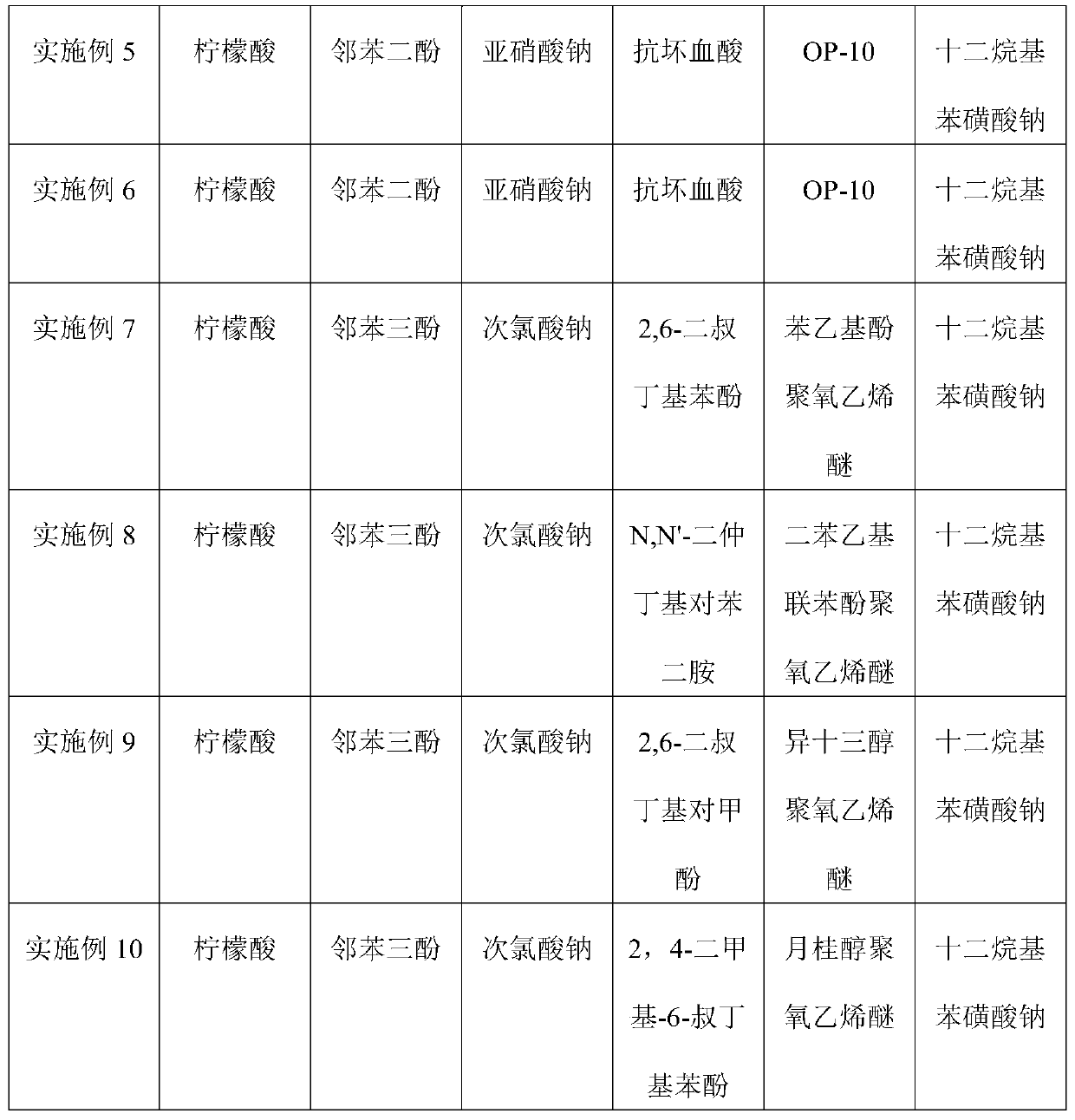

[0046] Table 2

[0047]

[0048]

Embodiment 11-24

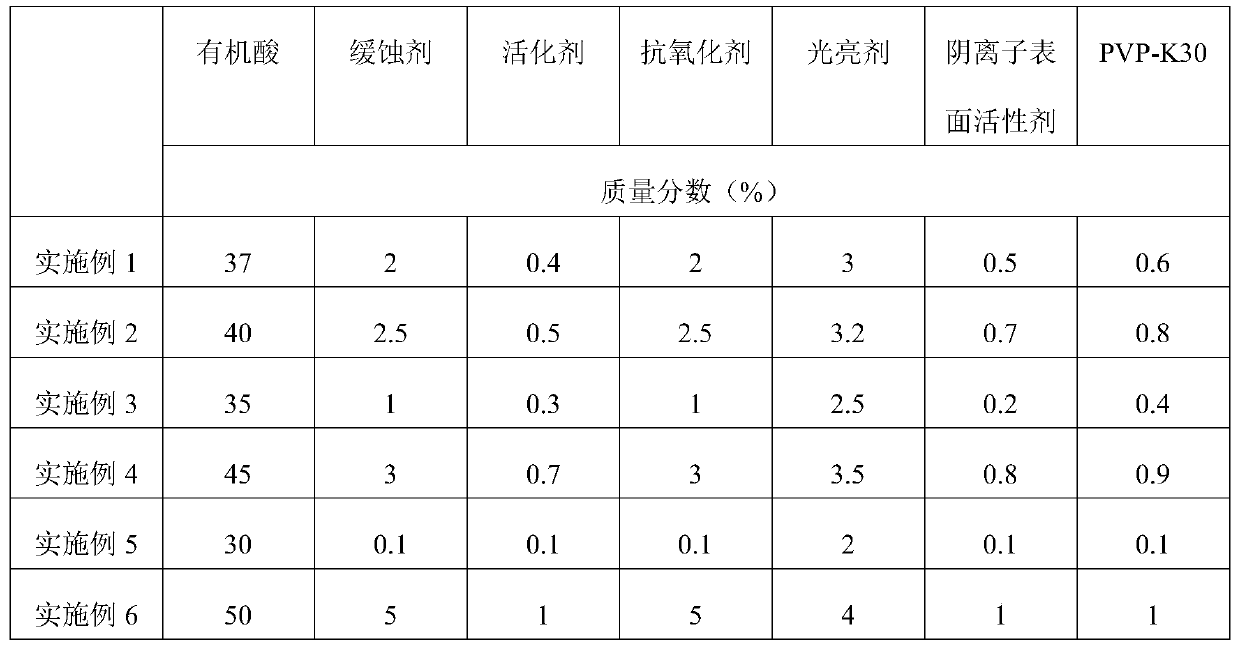

[0050] table 3

[0051]

[0052] Examples 11-24 are on the basis of Example 5, the content of each component in the oxidizing agent is changed higher or lower, and the amount of water is adjusted accordingly, so that the sum of the mass fractions of each component is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com