Preparing method for high-temperature and high-humidity resisting golden film

A high-temperature-resistant, gold-colored technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve discoloration and other problems, achieve the effect of improving compactness, dense film structure, and improvement of discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

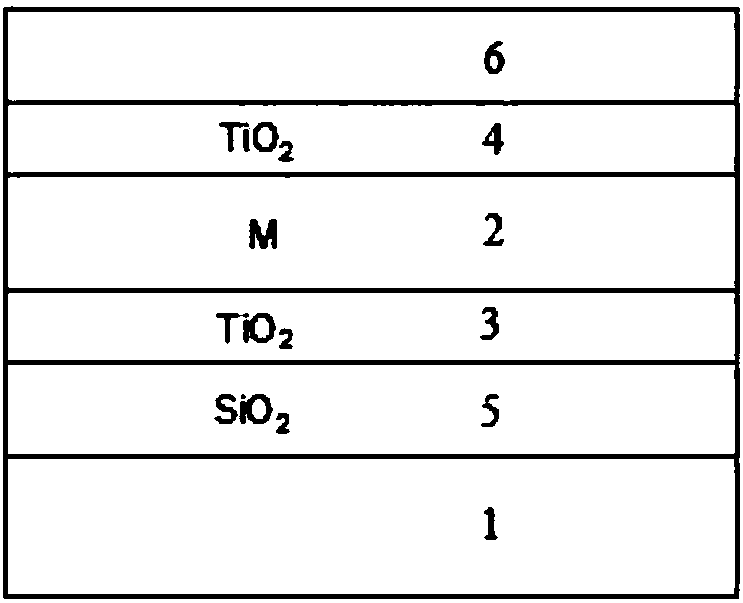

Method used

Image

Examples

Embodiment 1

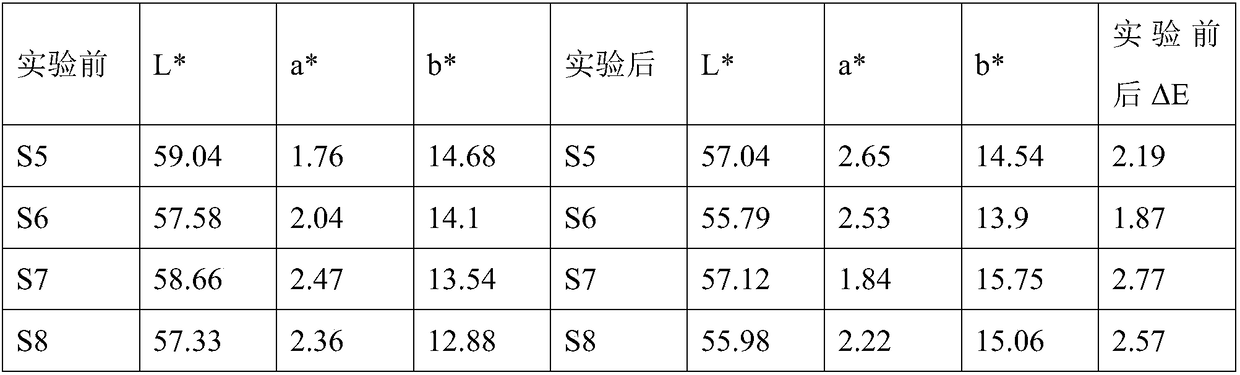

[0034]The film system structure and film system thickness used in embodiment 1 are the same as those of comparative example 1. Argon ions are added to assist deposition during the indium plating process. The flow of argon gas is 50 sccm. After the indium layer is plated, oxygen ions are added to bombard the indium layer for 10 minutes. The oxygen flow rate that feeds is 50sccm, and other technological processes are identical with comparative example 1. The prepared samples are marked as S9, S10, S11, and S12. The L*, a*, and b* values of the samples before and after the high temperature and high humidity (85° C., 85% RH) test are shown in Table 3.

[0035] table 3

[0036]

[0037] Table 3 shows the results of L*, a*, b* values and ΔE values of the samples before and after the high temperature and high humidity test in Example 1. It can be seen from Table 3 that the ΔE value is between 1 and 1.5, and compared with Comparative Examples 1 and 2, the high-temperature an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com