Method for manufacturing holographic moulded plate

A manufacturing method and technology of embossing plates, applied in the directions of plate preparation and printing, can solve the problems of high development cost and equipment dependence, achieve strong anti-counterfeiting function, reduce plate-making costs, and achieve the effect of three-dimensional printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The manufacturing method of this holographic embossed plate, the manufacturing method of this holographic embossed plate, comprises the following steps:

[0037] (1) Electroforming is used to form a molded nickel plate;

[0038] (2) Set a fine adjustment area on the molded nickel plate, divide each pixel in the fine adjustment area into multiple sub-pixels, and each sub-pixel contains multiple segments of molded stripes;

[0039] (3) Using laser ablation to reduce the height of some or all of the embossed stripes in the sub-pixels to form the shape of patterns or characters.

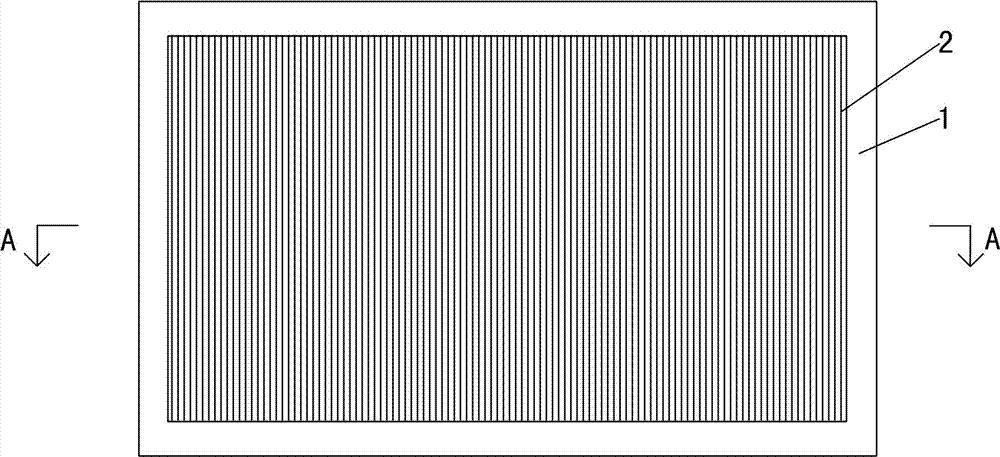

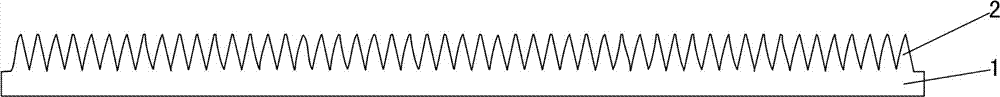

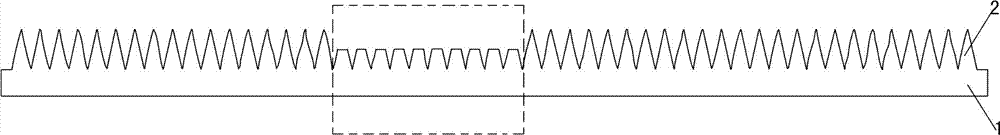

[0040] Through the above manufacturing method, forming such as Figures 1 to 8 Holographic stamped version shown.

[0041] like figure 1 and figure 2 As shown, this holographic molded plate includes a molded nickel plate 1, and a plurality of molded stripes 2 are arranged on the molded nickel plate 1, and the height of the molded stripes 2 is 0.01 mm; image 3 As shown, the molded nickel pla...

Embodiment 2

[0048] The manufacturing method of this holographic embossed plate comprises the following steps:

[0049] (1) Electroforming is used to form a molded nickel plate;

[0050] (2) First coat the photosensitive resin layer on the molded nickel plate, and then form a fine adjustment area by exposure and development;

[0051] (3) Reduce the height of some or all of the embossed stripes in the fine adjustment area by corrosion to form the shape of patterns or characters.

Embodiment 3

[0053] The manufacturing method of this holographic embossed plate comprises the following steps:

[0054] (1) Electroforming is used to form a molded substrate opposite to the pattern of the molded nickel plate;

[0055] (2) Coating a photosensitive resin layer on the molded substrate;

[0056] (3) On the photosensitive resin layer, a temporary adjustment area opposite to the grain of the fine adjustment area is formed by exposure and development;

[0057] (4) Perform the first electroforming on the temporary adjustment area to form a fine adjustment area;

[0058] (5) Cleaning off the photosensitive resin layer on the molded substrate;

[0059] (6) Perform the second electroforming on the molded substrate to form other parts of the molded nickel plate, and complete the production of the whole holographic molded plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com