Patents

Literature

56results about How to "Improve engraving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

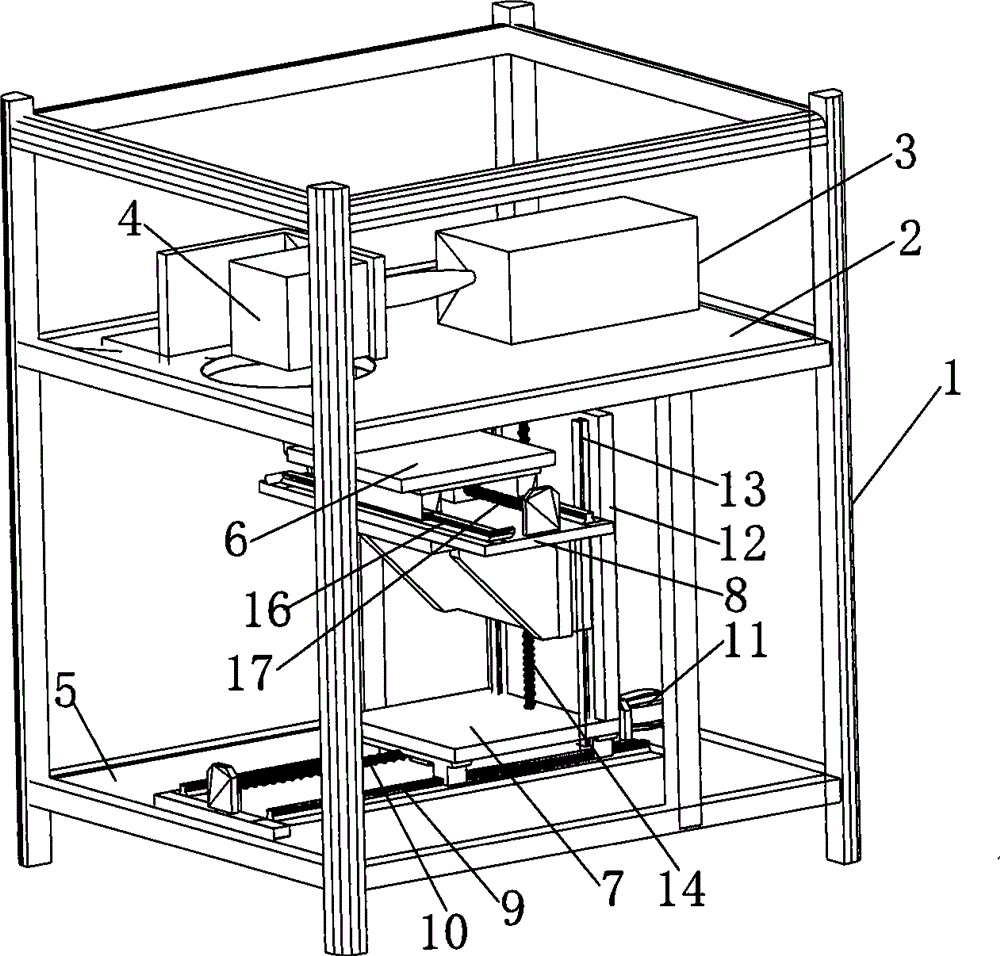

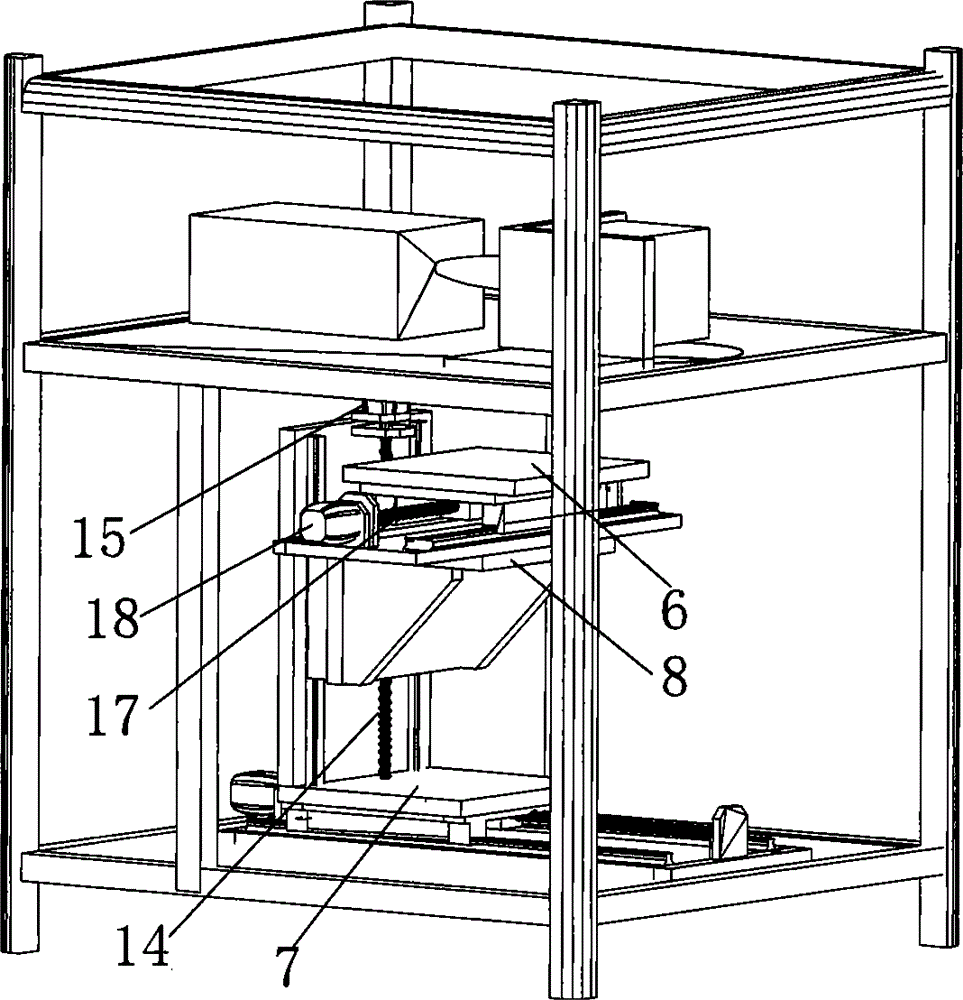

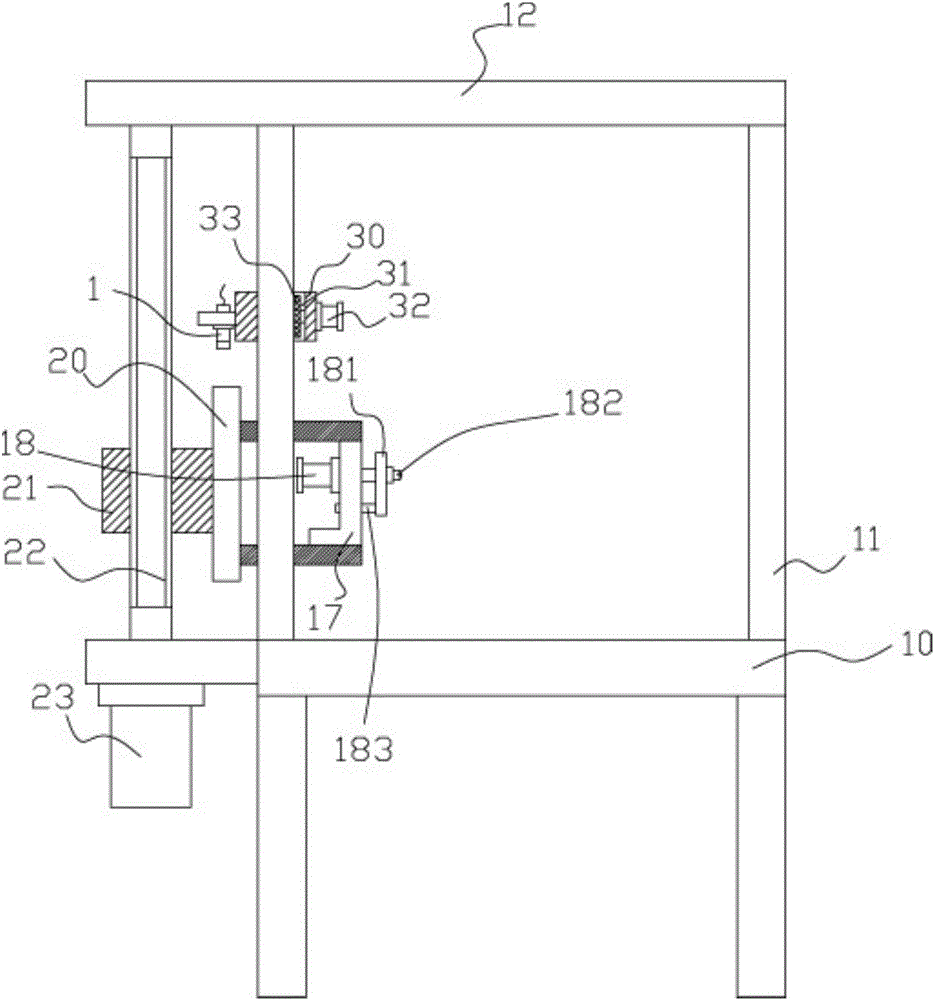

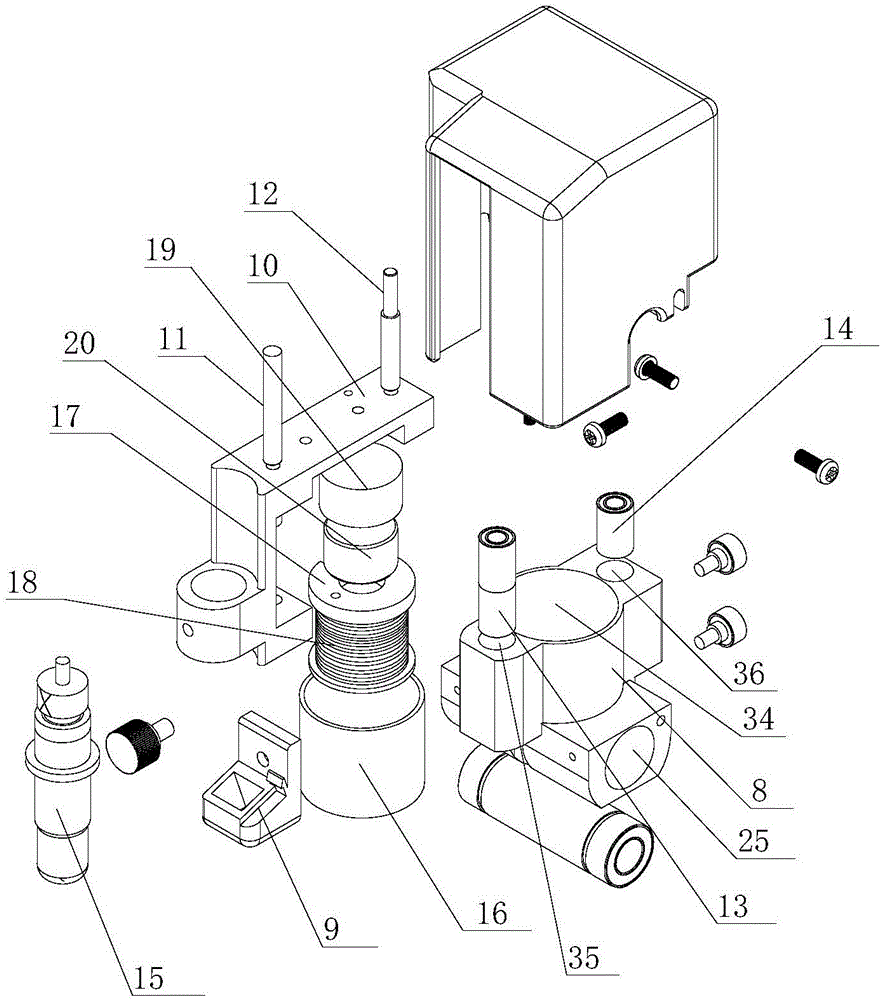

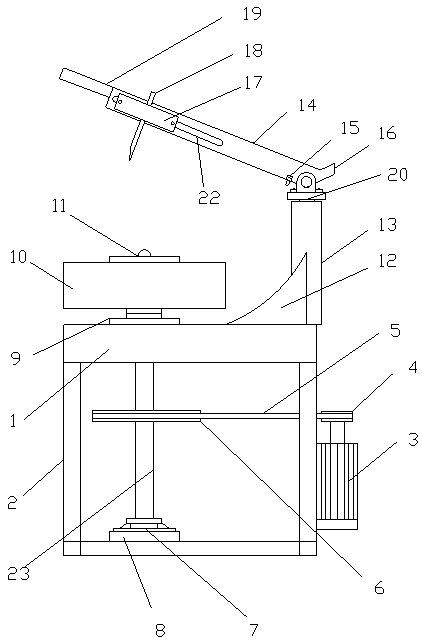

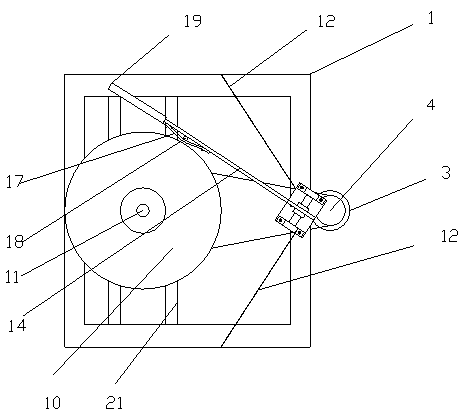

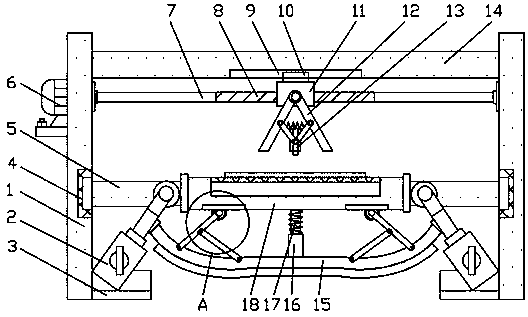

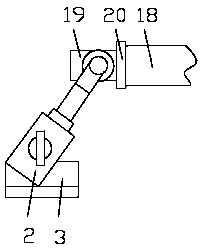

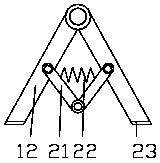

Plastic cylinder ring-shaped engraving device with up-down adjustable cutter

InactiveCN105922804AImprove engraving effectImprove efficiencyOther artistic work equipmentsEngravingEngineering

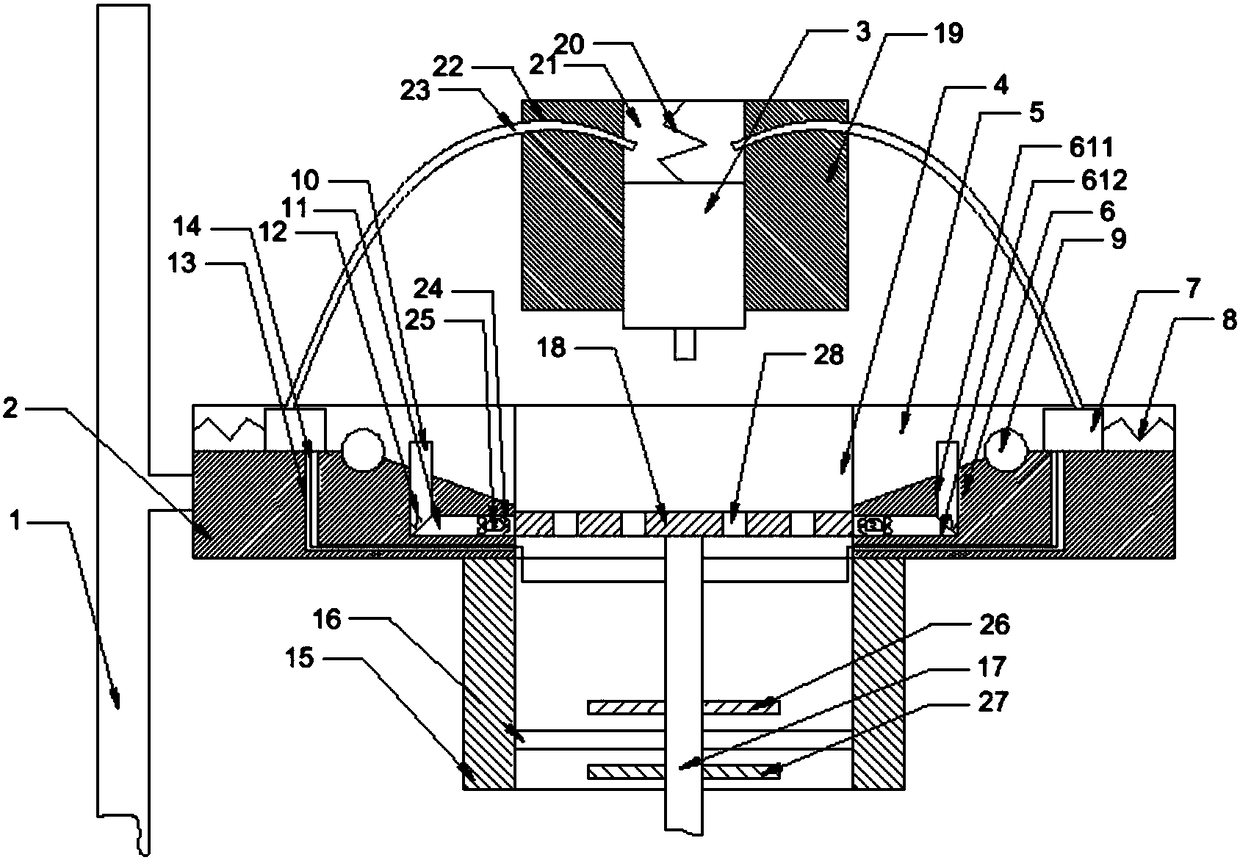

The invention discloses a plastic cylinder ring-shaped engraving device with an up-down adjustable cutter. The ring-shaped engraving device comprises a rack, wherein two supporting columns are fixed on the top surface of a top plate of the rack; the top ends of the two supporting columns are fixed on the bottom surfaces of the two ends of an upper top plate; a compaction cylinder is fixed on the top surface at the middle of the upper top plate; a cutter connecting frame is inserted into one supporting column of the rack in a sleeving manner; a push cylinder is fixed on a supporting plate of the cutter connecting plate; a push rod of the push cylinder penetrates through the supporting plate; a graver connecting plate is fixed on the push rod; a cutter is fixed on the graver connecting plate and faces the outer side wall of a plastic cylinder; an adjusting block is fixed on the cutter connecting frame; the upper end of a vertical adjusting screw rod is hinged onto the upper top plate; the lower end of the vertical adjusting screw rod is hinged onto the top plate of the rack; and an adjusting motor is fixed on the top plate of the rack. By adoption of the ring-shaped engraving device, the outer wall of the plastic cylinder can be subjected to ring-shaped engraving after the plastic cylinder is fixed; the cutter of the ring-shaped engraving device can be adjusted up and down as required; and the ring-shaped engraving device is good in engraving effect and efficient.

Owner:贵州三圆瑞通科技有限公司

Digital printing method of woodgrained paper

ActiveCN105383199AEasy to controlPromote reductionDuplicating/marking methodsOther printing apparatusPulp and paper industryDigital printing

The invention relates to the technical field of gravure plate making, in particular to a digital printing method of woodgrained paper. The digital printing method comprises the steps of: (1) manuscript scanning; (2) manufacturing and color separation; (3) digital sample printing: files, after the color separation, are directly output and subjected to sample printing through a printer; printed objects adopt 80 g woodgrained paper; the sample products and manuscripts are compared to check if the color separation structure is reasonable and if the sample printing effect can satisfy the demands; if the sample printing effect cannot satisfy the demands, the color separation processing is performed again by returning to the last step; and if the sampling effect satisfies the demands, the next step is performed; (4) plate making through carving; and (5) printing. The digital printing method enables sample paper printed by a digital sampling system to be very approximate to actual printing sample paper through controlling a color management system and adjusting a process, preferably achieves actual gravure effects, improves the plate making quality, and reduces the rework rate.

Owner:DONGGUAN YUNCHENG PLATE MAKING

Method and device for engraving three-dimensional patterns in glass

InactiveCN104924825AReduce vibrationSolve vibration instabilityDecorative surface effectsLaser beam welding apparatusEngravingMovable type

The invention discloses a method and device for engraving three-dimensional patterns in glass. An area to be engraved is divided into one or two or more parallel engraving divided areas; firstly, the glass is moved to enable the first engraving divided area to reach the position below a laser focusing point, and the glass motion is controlled to enable the laser focusing point to engrave the portion, between 1percent to 100percent of a pattern in the first engraving divided area; then the glass is moved in a parallel manner to enable the engraving divided area close to the first engraving divided area to reach the position below the laser focusing point, and the glass motion is controlled to enable the laser focusing point to engrave the portion, between 1percent to 100percent of the pattern in the engraving divided area close to the first engraving divided area; then, the glass is moved to enable the next divided area to each the position below the laser focusing point, and the engraving steps are repeated until the complete pattern is engraved. A laser source and a galvanometer are arranged to be in fixed state, and a working table carrying the glass is arranged to be in a movable type, so that laser vibration is reduced; and the laser focusing point is more stable, and the engraving effect is improved.

Owner:ZHEJIANG HOLY LASER TECH CO LTD

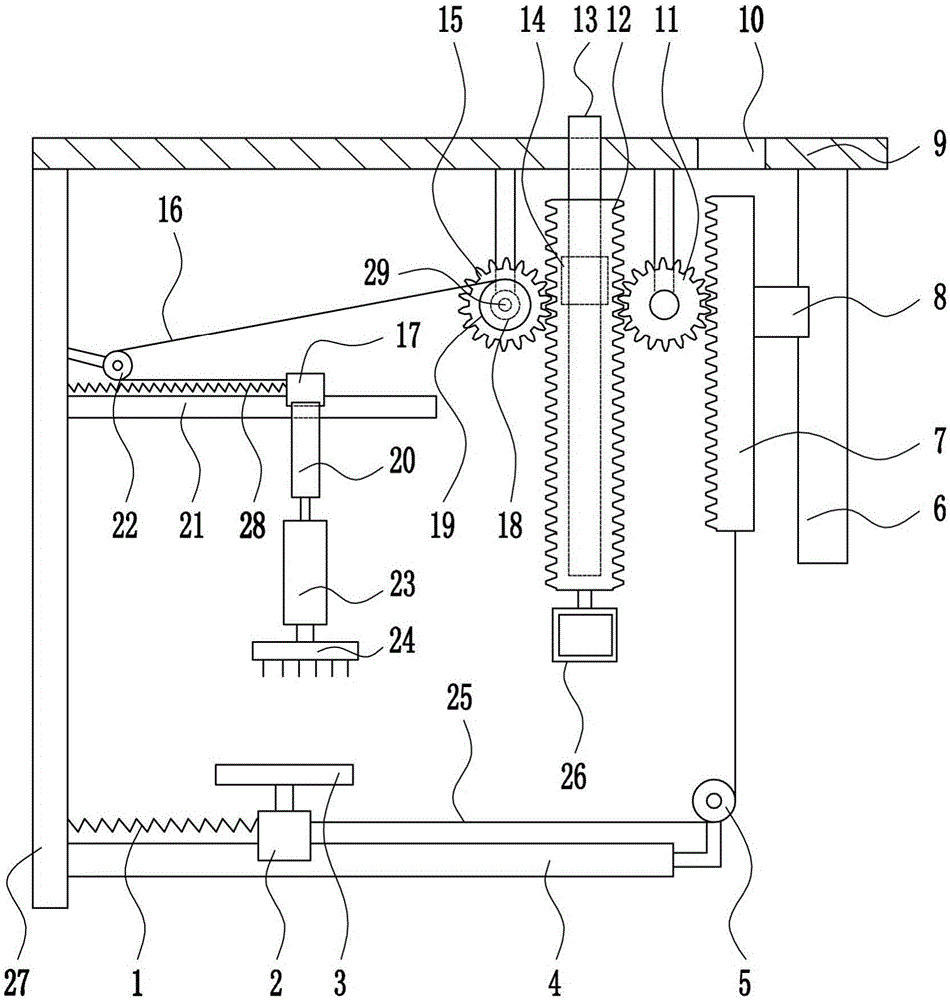

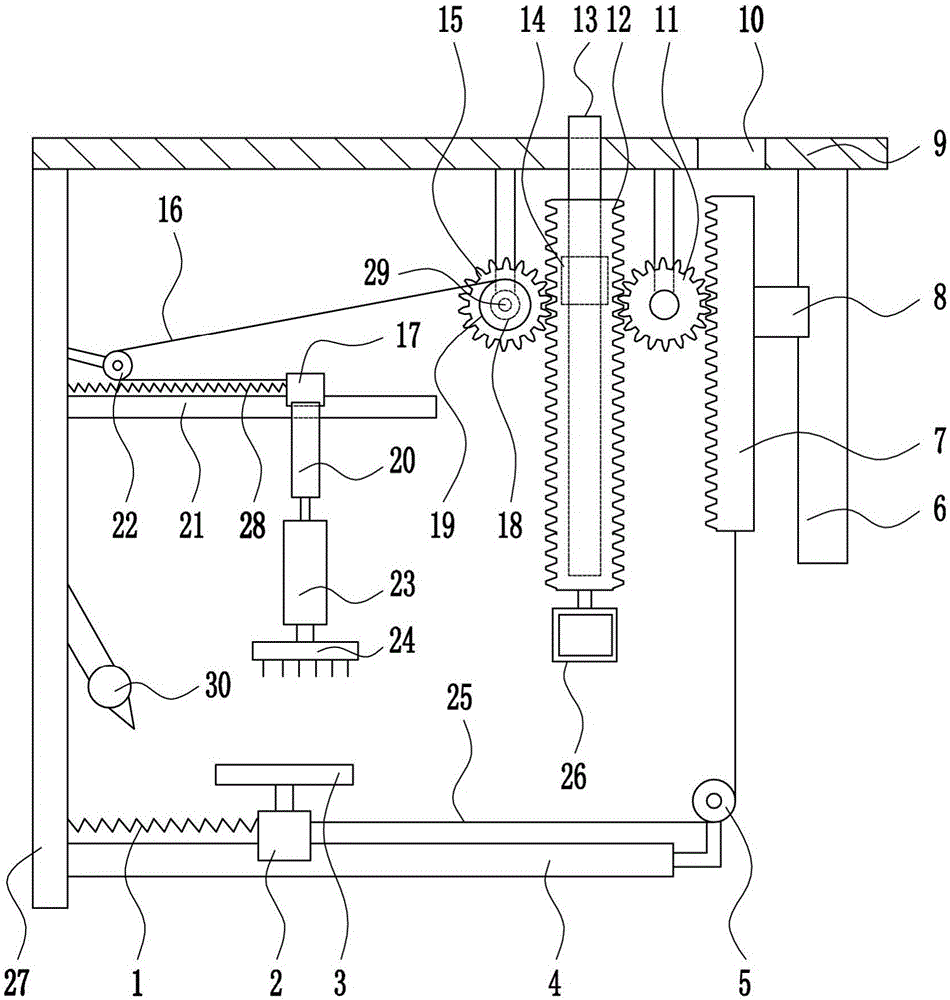

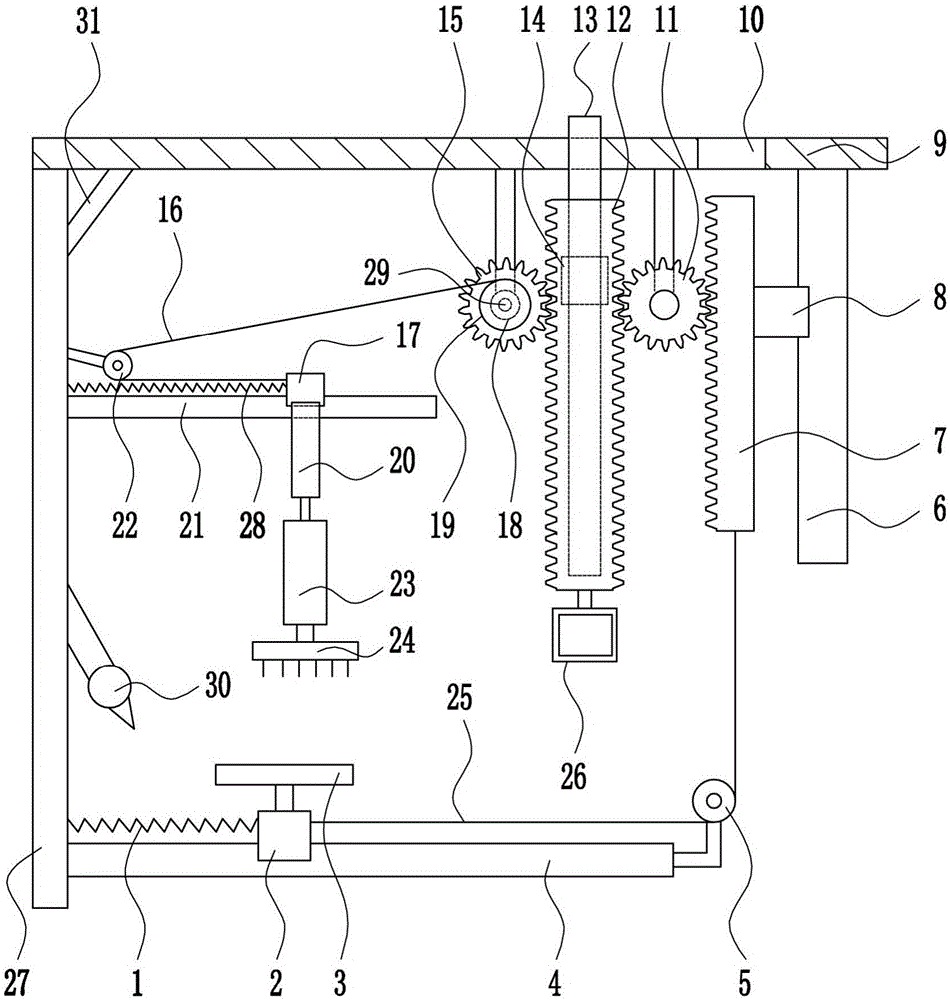

Lampholder trademark engraving-printing device for hardware manufacturing

The invention relates to a trademark engraving-printing device, in particular to a lampholder trademark engraving-printing device for hardware manufacturing. The technical problem to be solved by the invention is to provide the lampholder trademark engraving-printing device for hardware manufacturing, and trademark engraving-printing is clear through the lampholder trademark engraving-printing device. The lampholder trademark engraving-printing device for hardware manufacturing comprises a first spring, a third sliding block, a placing plate, a third sliding rail, a first fixed pulley, a first sliding rail, a second rack, a first sliding block, a top support, a second gear and the like. A second sliding rail is arranged on the front side of the top support and provided with a second sliding block. A first rack is arranged on the front side of the second sliding block. A grinding tool is connected to the bottom end of the first rack. Through the lampholder trademark engraving-printing device, the effects of clear trademark engraving-printing, saving of time and labor, ideal engraving-printing, resource saving and simple operation are achieved. A rotary motor is started to rotate forwards, a lampholder is driven to move rightwards, and the grinding tool is driven to move downwards.

Owner:平方米(徐州)科技发展有限公司

Laser engraving device

InactiveCN108098152ARealize limitImprove the limit effectWelding/cutting auxillary devicesAuxillary welding devicesTransverse grooveLaser engraving

The invention discloses a laser engraving device. The device comprises a machine base, a workbench, a laser engraving head and an adjustable mechanism are arranged on the machine base, and a round hole is formed in the middle of the workbench; first sliding grooves and auxiliary grooves are correspondingly and symmetrically formed in the workbench along the round hole, sliding blocks are slidablyconnected in the first sliding grooves, and first springs are arranged between the sliding blocks and the first sliding grooves; round shafts are rotationally connected in the first sliding grooves; the auxiliary grooves comprise vertical grooves and transverse grooves, first inclined wedge blocks are slidably connected in the vertical grooves, and second inclined wedge blocks are arranged in thetransverse grooves; second springs are arranged between the second inclined wedge blocks and the vertical grooves, and clamping mechanisms are arranged on the second inclined wedge blocks; through holes are formed in the bottoms of the transverse grooves, and steel wires are arranged on the sliding blocks; a sleeve pipe is arranged at the bottom of the workbench, an iron plate is fixedly connectedin the sleeve pipes, a threaded rod is connected to the iron plate in a threaded mode, and the steel wires are fixedly connected with the threaded rod; and a supporting plate is arranged on the threaded rod, and a positioning mechanism is arranged on the threaded rod. The laser engraving device mainly solves the problem that an existing laser engraving device is poor in workpiece engraving effect.

Owner:重庆鑫盟精密模具有限公司

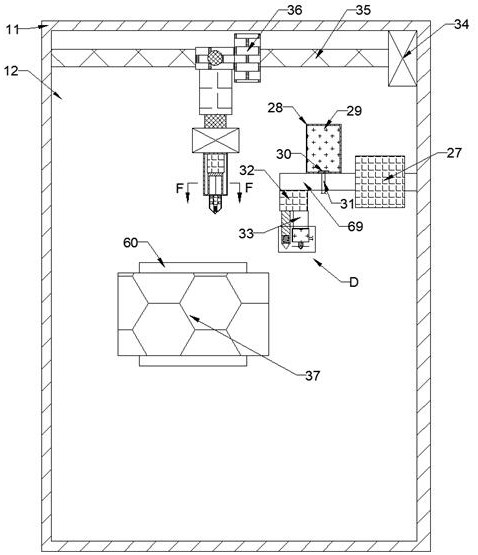

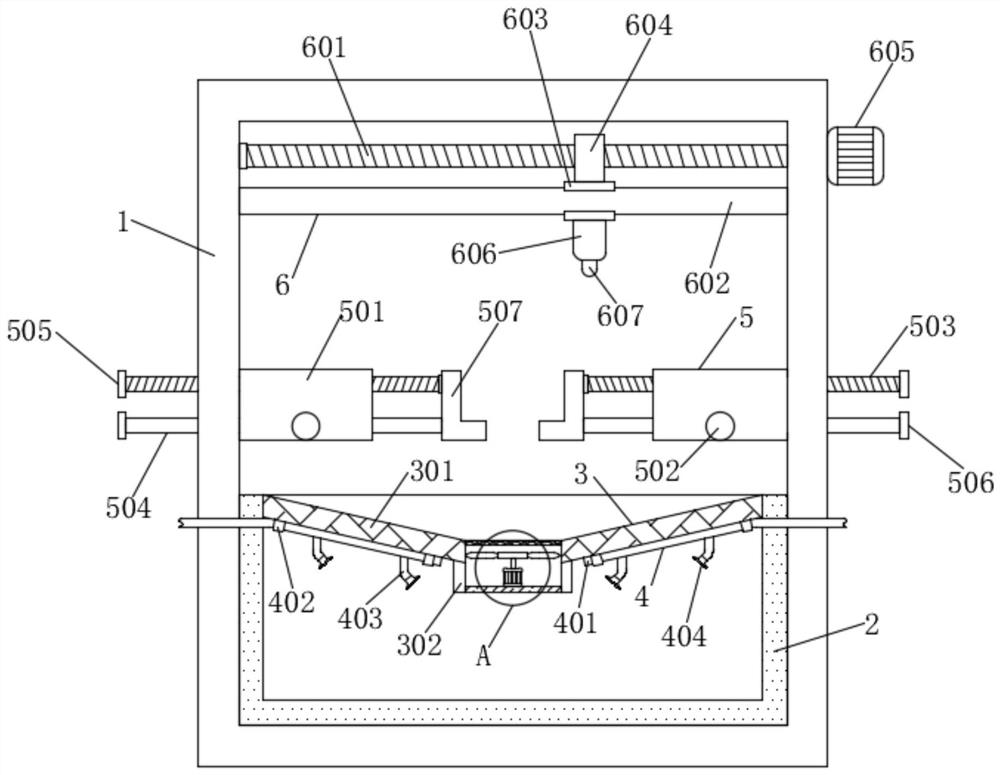

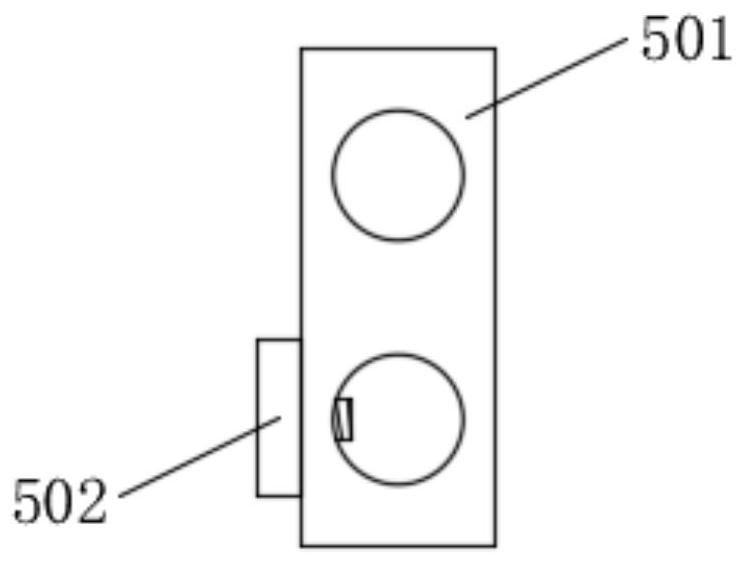

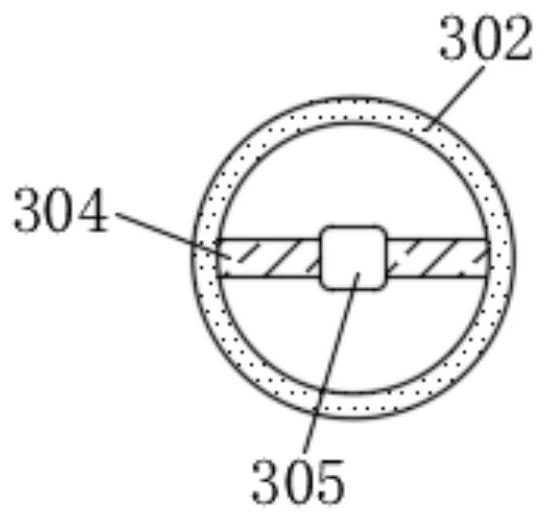

Engraving machine capable of changing size of drill bit according to lines and spraying

The invention discloses an engraving machine capable of changing the size of a drill bit according to lines and spraying. The engraving machine comprises an engraving box and an engraving cavity formed in the engraving box; a first moving motor is fixedly arranged on the upper cavity wall of the engraving cavity; and a first moving worm is arranged at the front end of the first moving motor. Afterthe engraving machine is used, when an irregular workpiece is clamped, the workpiece can be clamped more effectively, so that the workpiece is prevented from deviating during working; after the engraving is finished, the engraved lines can be polished, the engraving effect is improved, the size of the drill bit can be automatically adjusted without manual replacement when the drill bit needs to be replaced, and the working efficiency is improved; and during spraying, whether the position is engraved or not and the engraving depth are determined through the up-down displacement change of a sensor, then the position is sprayed, then dye possibly splashed out is blocked through a baffle to prevent from being splashed out to the surface of a workpiece, the workpiece is prevented from being wasted, and economic losses are reduced.

Owner:威海市周识工艺品有限公司

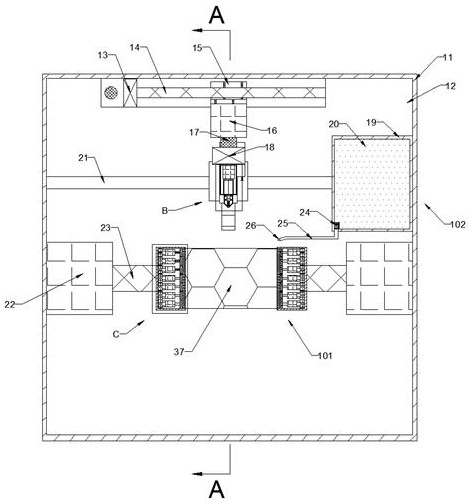

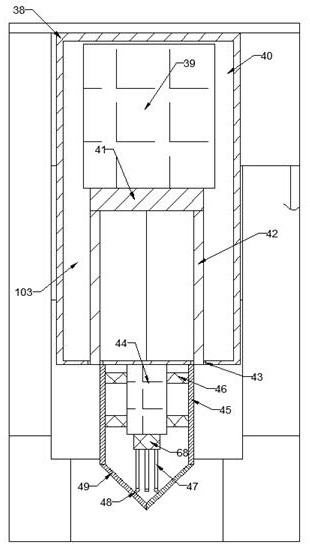

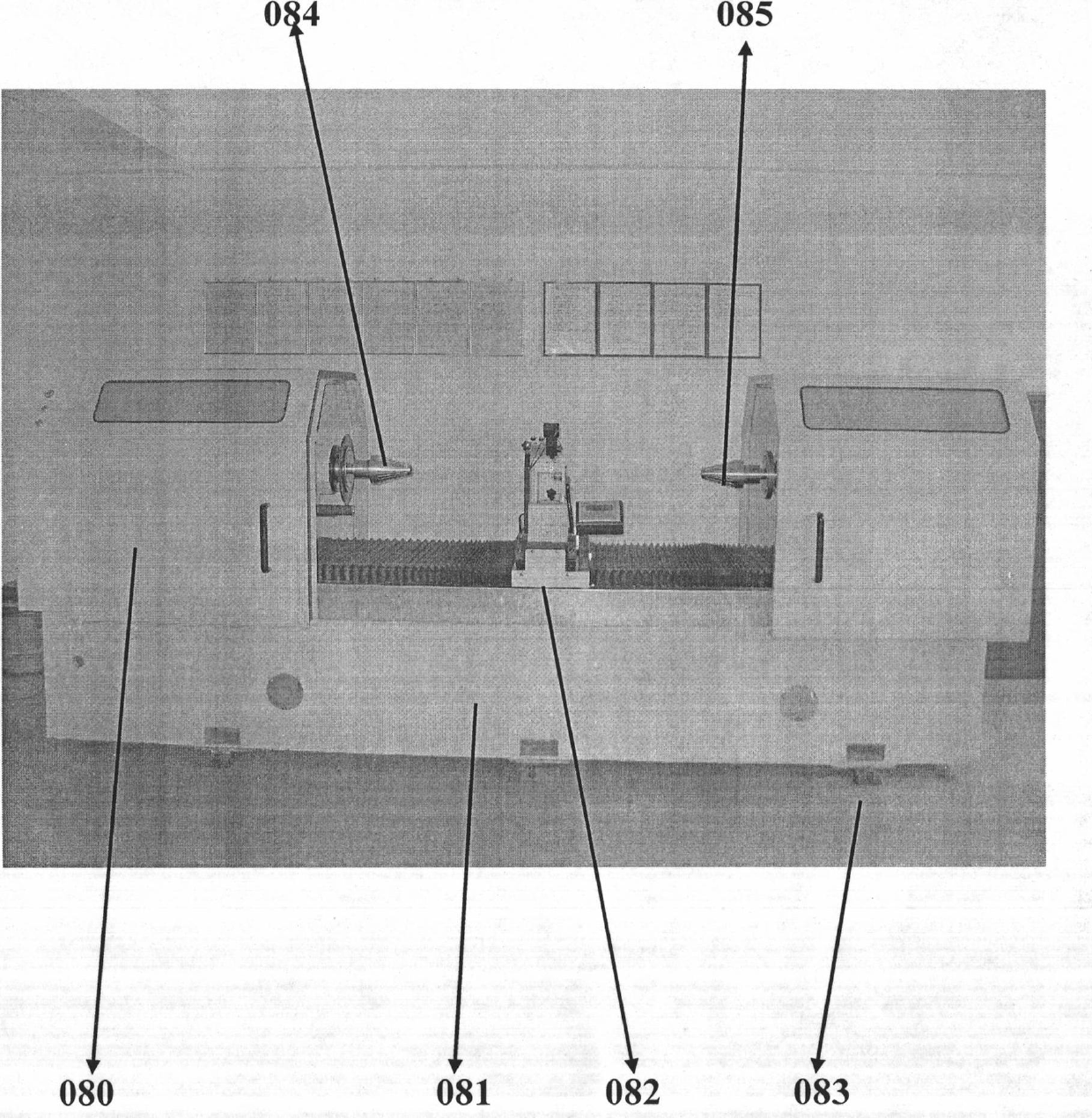

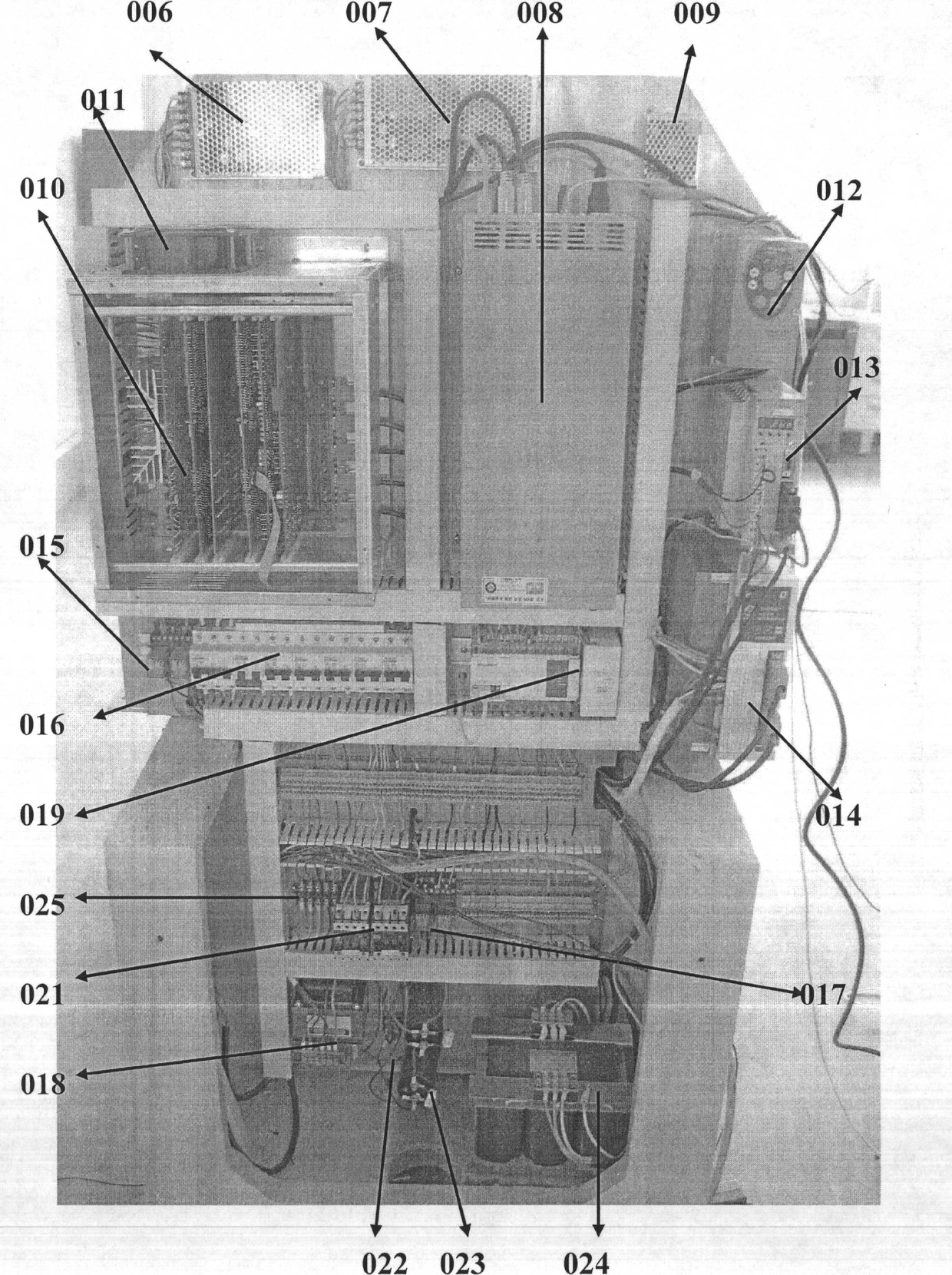

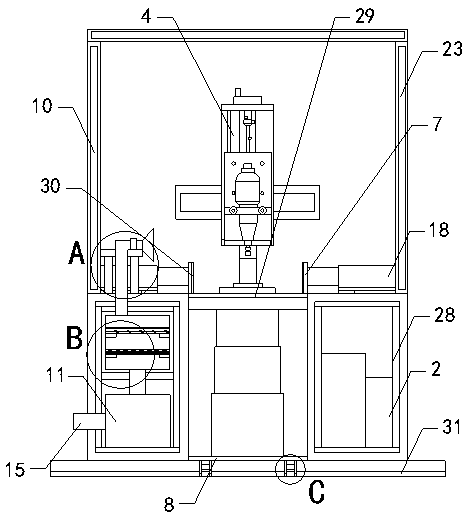

Electronic sculpturing machine

The present invention relates to an electronic sculpturing machine, comprising a machine body which comprises a working bench and a machine cover, wherein the working bench comprises front and back tips for supporting a processing cylinder, and a sculpturing car; a makeup work station which uses a brand new rip analyzer, can accept PS, EPS, PDF, TIFF makeup, and can realize integrated tension enlarging and reducing; a DTG control circuit board which comprising a 2050CPU board, a 7070 board, a 3010 board, a 8090 board, a FIFO card and a 7020 sculpturing head amplifier board; a DTG control software which comprises a preset menu, trail sculpturing menu, a sculpturing menu, a tool sculpturing menu and a website button; a PLC controller for overall control to realize fast forward raising, headresting, head backing and car driving and the like; a website tester for measuring sculpturing websites and correcting positions. The weight of the present invention is reduced, the whole machine is beautiful, and material expenses are reduced greatly; the national energy-conservation requirements are satisfied. The operations are simple and easy to be learned; the electronic sculpturing machine is humanized. A Chinese control interface and an English control interface can be transformed, which is in favour of popularizing the electronic sculpturing machine in international markets.

Owner:东莞东运机械制造有限公司

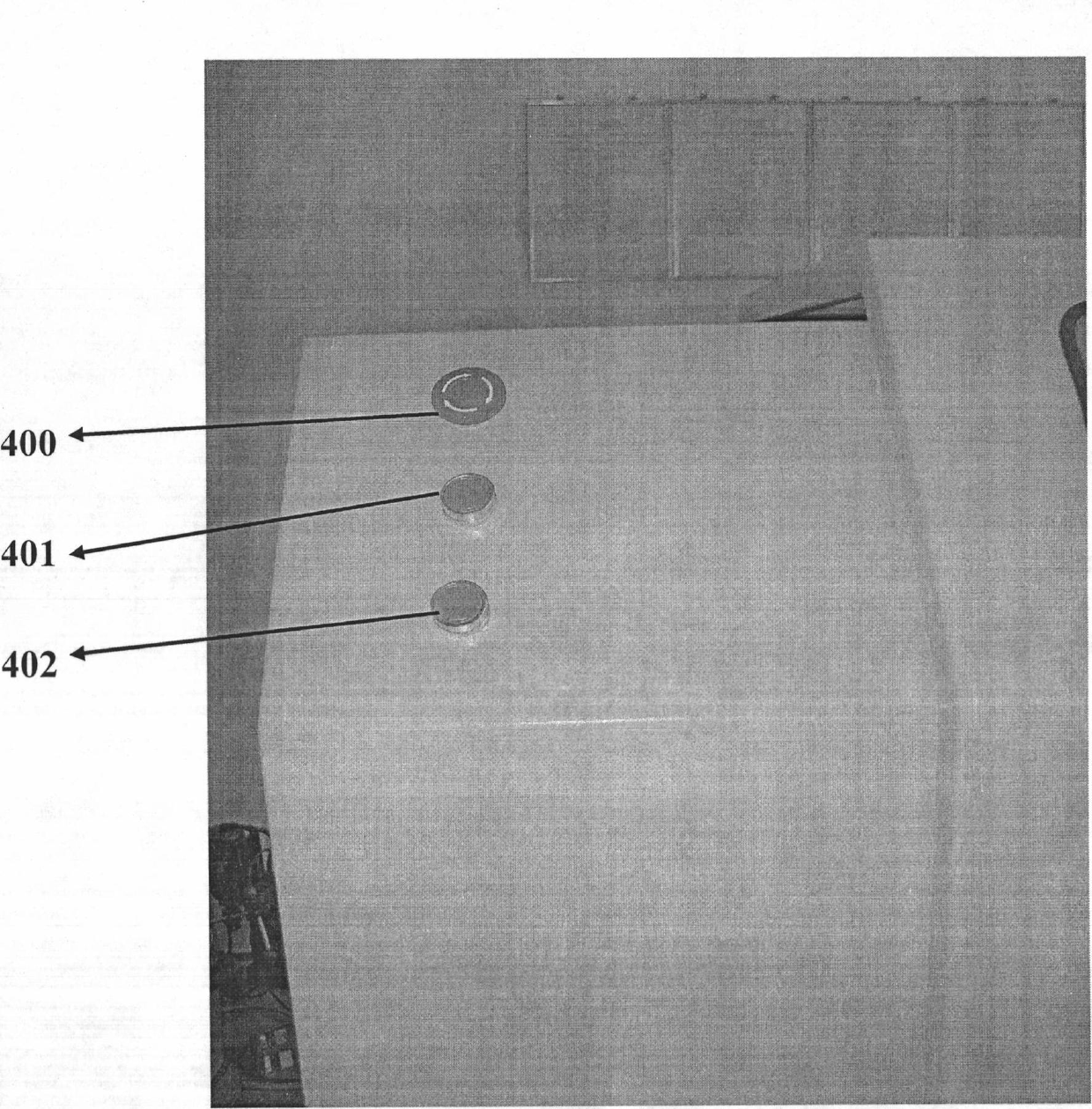

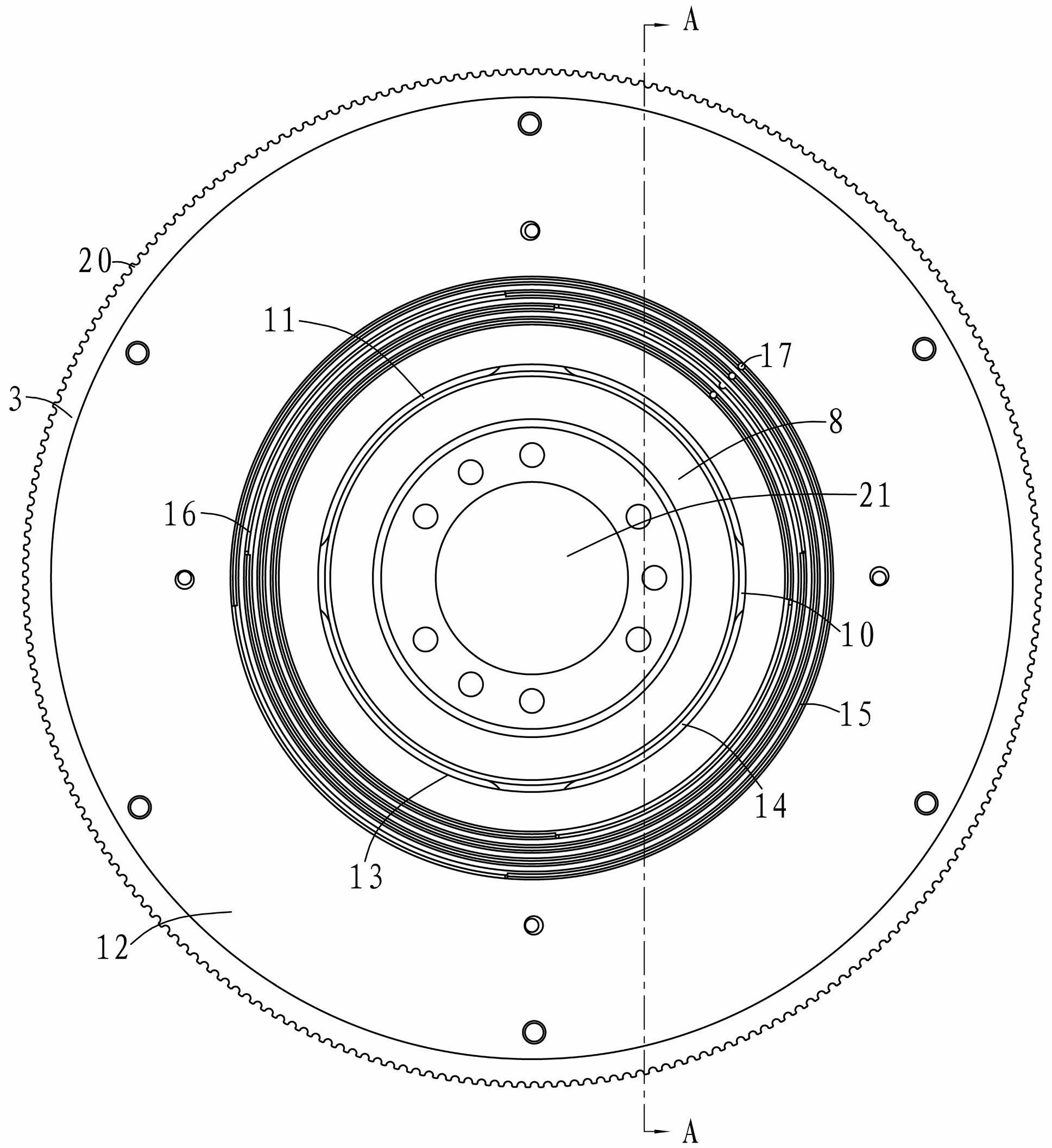

Water balance structure for machine tailstock

InactiveCN102091794AEnsure relative dynamic balanceGuaranteed service lifeTailstocks/centresMaintainance and safety accessoriesDynamic balanceEngineering

The invention relates to a water balance structure for a machine tailstock. A clamp arranged on the machine tailstock is fixedly connected with a synchronous belt pulley connection disc; a front end cover is connected to one side corresponding to the clamp; a mounting groove is arranged in the middle part of the synchronous belt pulley connection disc; a cavity formed by the mounting groove and the wall of the synchronous belt pulley connection disc is divided into more that two cavities by rib plates; the open end of the synchronous belt pulley connection disc is provided with a liquid injection disc; a water outlet is arranged between the center hole of the liquid injection disc and the mounting groove arranged on the synchronous belt pulley connection disc; more than two liquid guiding grooves are distributed concentrically on the outer side of the center hole; each liquid guide groove is internally provided with a liquid guide hole and a liquid injection hole; one side of the front end cover is provided with a liquid injection block; and one side of the liquid injection block, which corresponds to the liquid injection disc, is provided with more than two liquid spraying holes. Due to the adoption of the water balance structure for the machine tailstock, the relative dynamic balance between the clamp and a printing roller is ensured, the unbalanced load generated during the rotation of the printing roller is avoided, the matching errors are reduced, the processing precision is improved, the normal service life of a bearing is ensured, the sculpturing effect is improved, and the labor and the materials are saved.

Owner:DONGGUAN YUNCHENG PLATE MAKING

Stone carving machine with switching function

InactiveCN108656815AWith switching functionFlexible structureOther artistic work equipmentsModel makingStone carvingDrive shaft

The invention relates to a stone carving machine with a switching function. The stone carving machine with the switching function comprises a machine tool, a main machine body, an advancing mechanism,an advancing plate, a carving mechanism, four supporting legs and four fixing mechanisms. Each fixing mechanism comprises a first motor, a first drive shaft, a top plate, a telescopic assembly and anextension plate. Each telescopic assembly comprises a drive unit, a telescopic frame and two connection rods. The carving mechanism comprises a lifting assembly, a lifting plate, a rotary plate, a power assembly and a plurality of drill bits. Each power assembly comprises a horizontal movement unit, a rack, a first gear, a second gear, a concentric shaft and a supporting unit. According to the stone carving machine with the switching function, stone is fixed on the machine tool through the fixing mechanisms and prevented from shaking in the carving process so that the carving effect cannot beaffected, besides, the carving mechanism can flexibly switch the drill bits according to carving needs in the carving process, configuration is optimized, a good carving effect is ensured, and thus the practicability of the stone carving machine is improved.

Owner:南安市德力拉建材贸易有限公司

Surface decorating method for decorative art earthenware

The invention discloses a surface decorative method of the display art pottery which the surface of the pottery is decorated the carved gold. The process is: the whole or the local surface of the pottery is covered with the carved layer; the surface is grinded by the fine sandcloth after the carved layer dry; the need figure is carved in the carved layer by the nicking tool; cleaning the surface by the compressed air; the figure is colored by the normal ceramic paint when all of the metal sheet is plastered in the selected location by the water miscible adhesive; last to paint the surface of the pottery by the water miscible paint. So the invention has the good color and relief effect.

Owner:潮州市威成瓷艺有限公司

Laser engraver

InactiveUS20090045178A1Improve engraving effectLaser beam welding apparatusLaser engravingOptoelectronics

A laser engraver comprises a glass laser tube and a modulation mechanism. The glass laser tube is used for outputting laser beam utilized by the laser engraver. The modulation mechanism is provided on the optical path of the output laser beam from the glass laser tube for adjusting the frequency of the output laser beam to achieve optimal engraving effect.

Owner:XINGYUN COMP

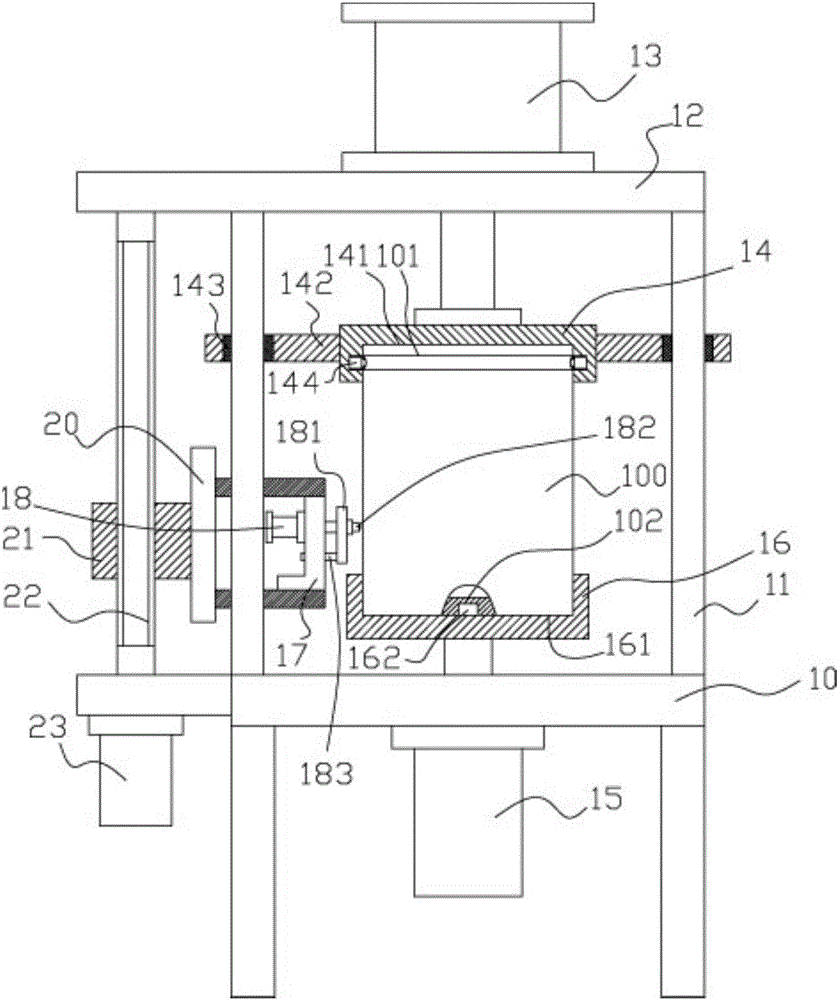

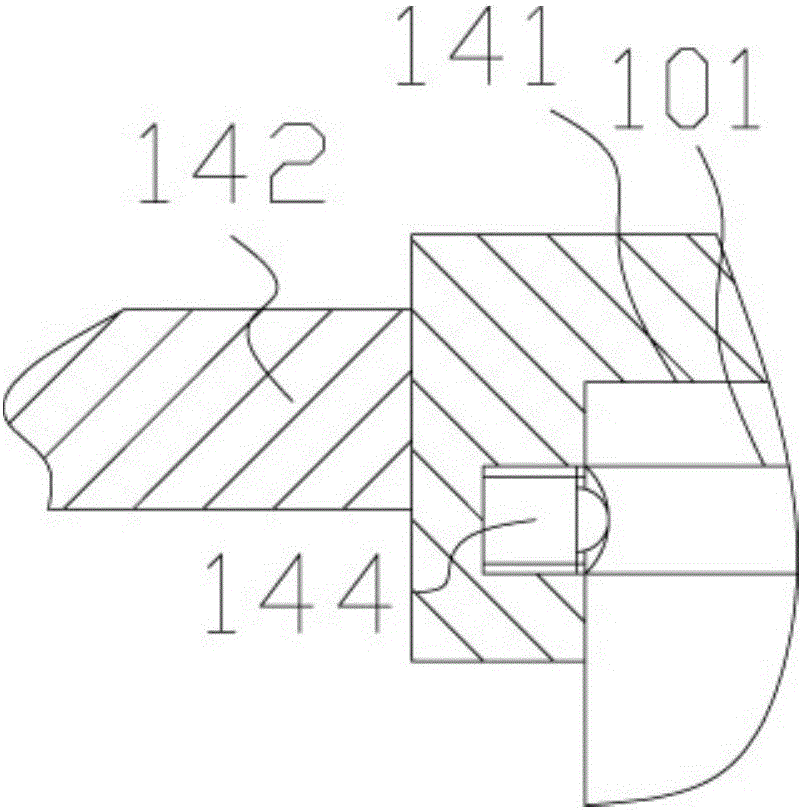

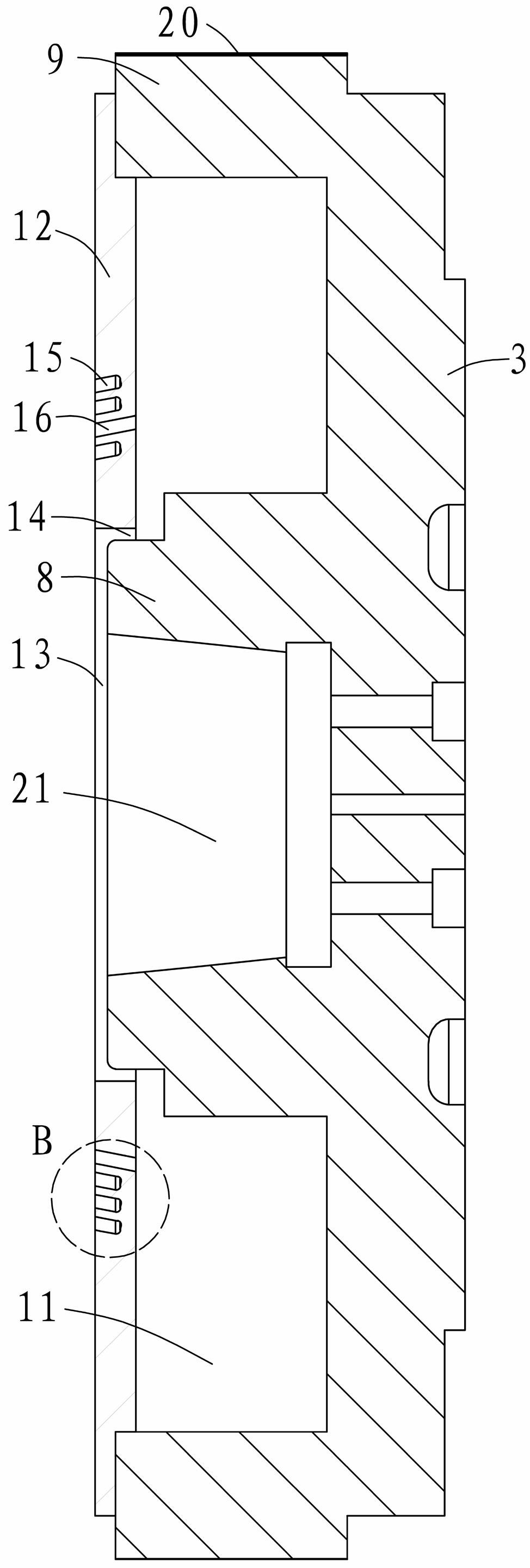

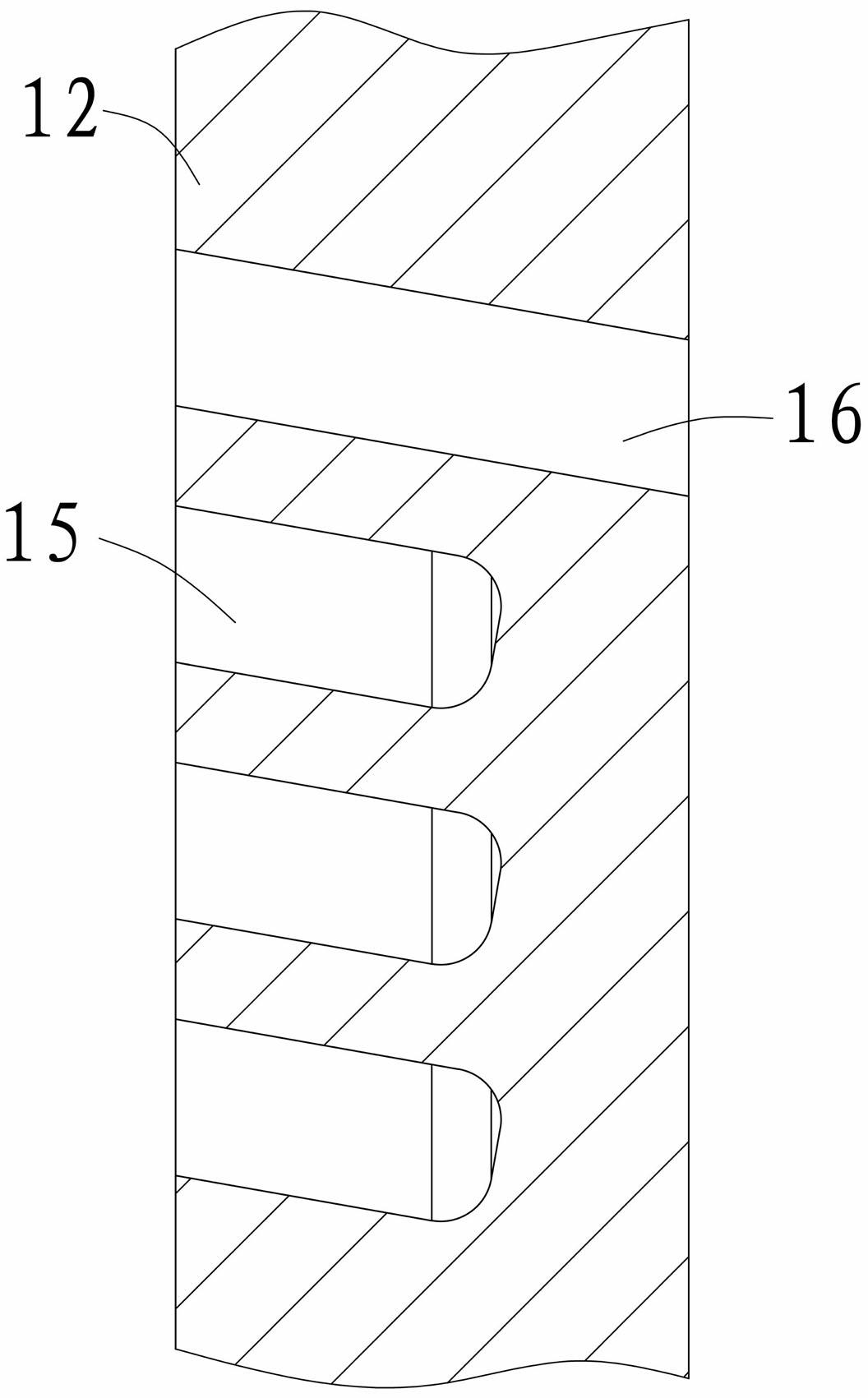

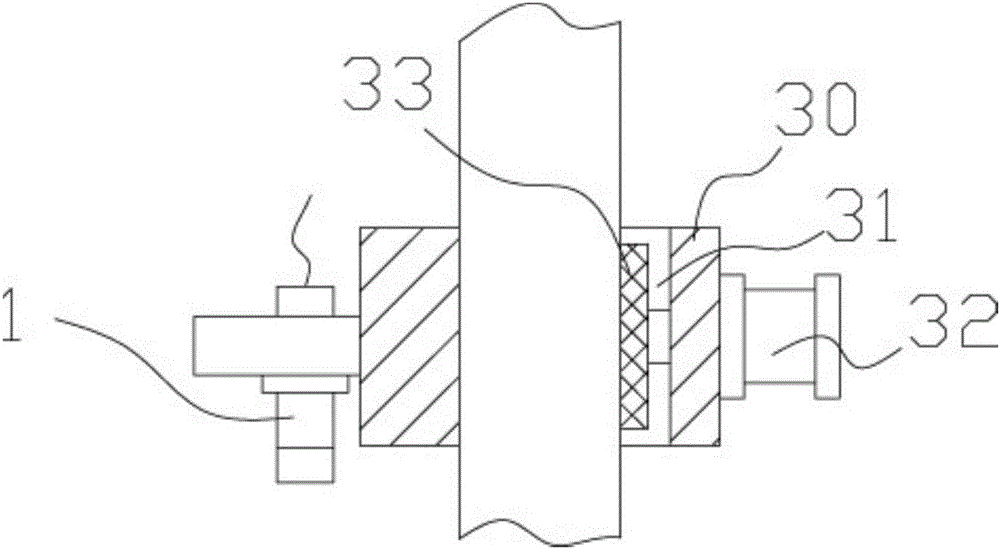

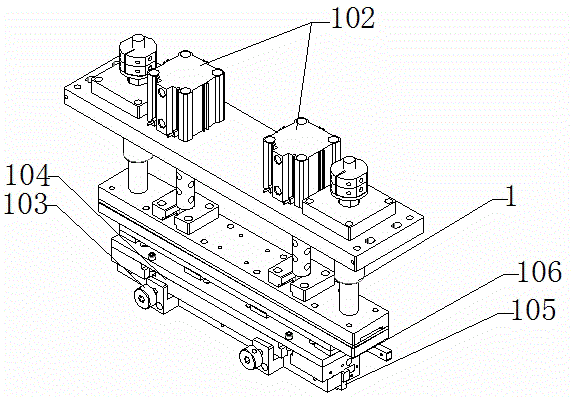

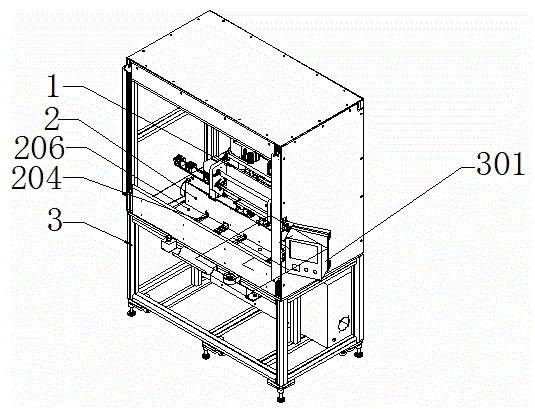

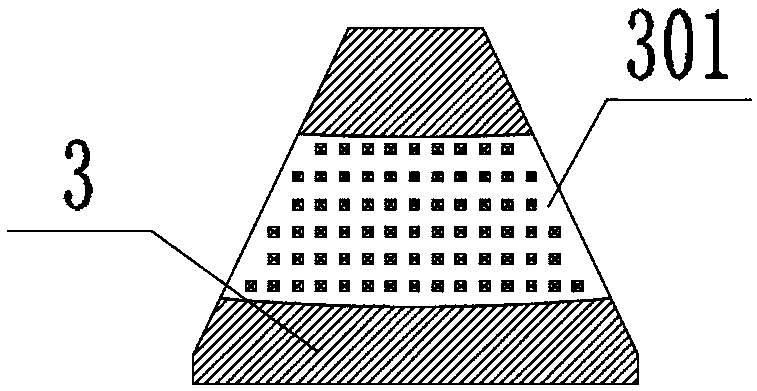

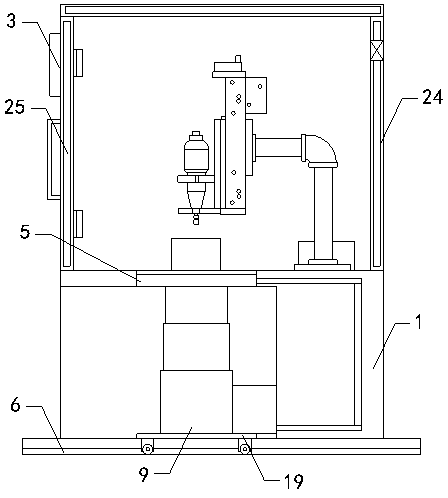

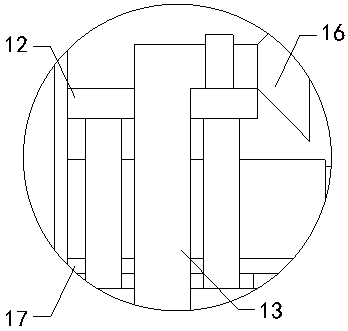

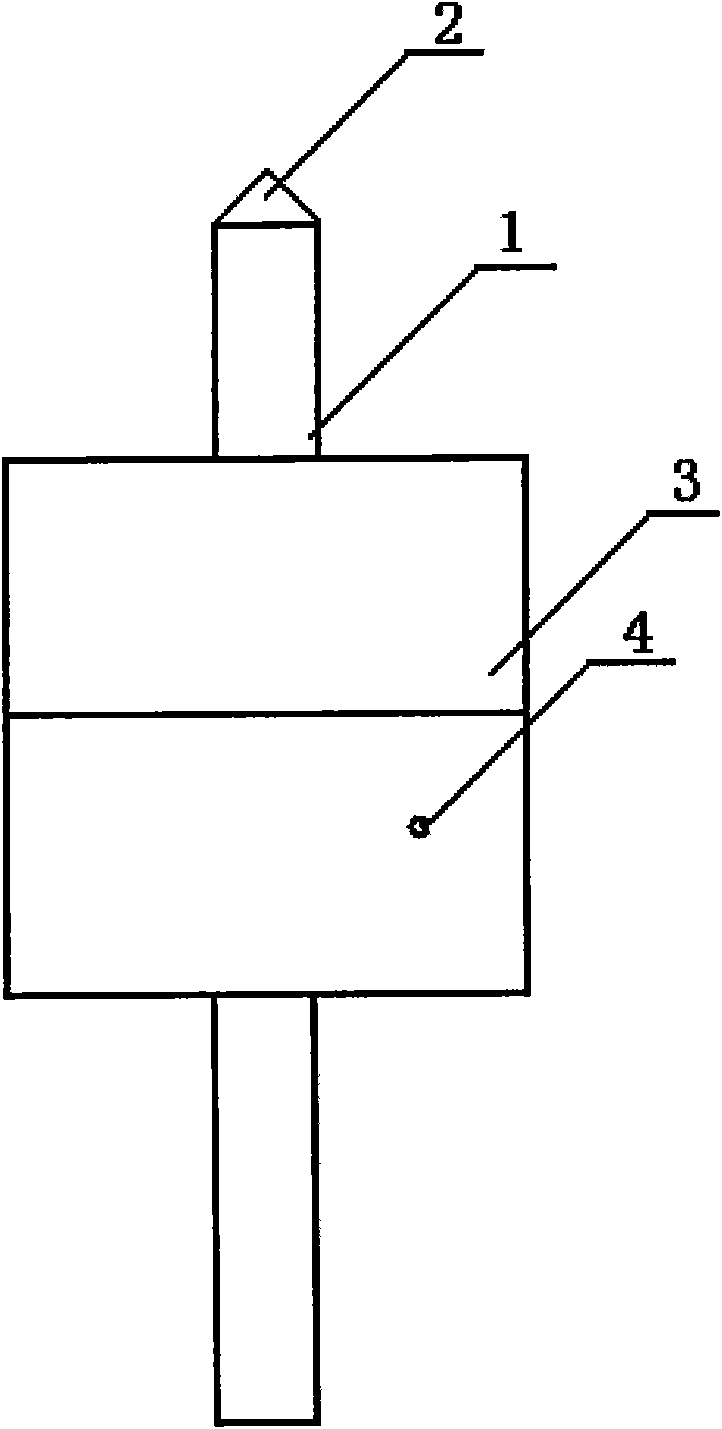

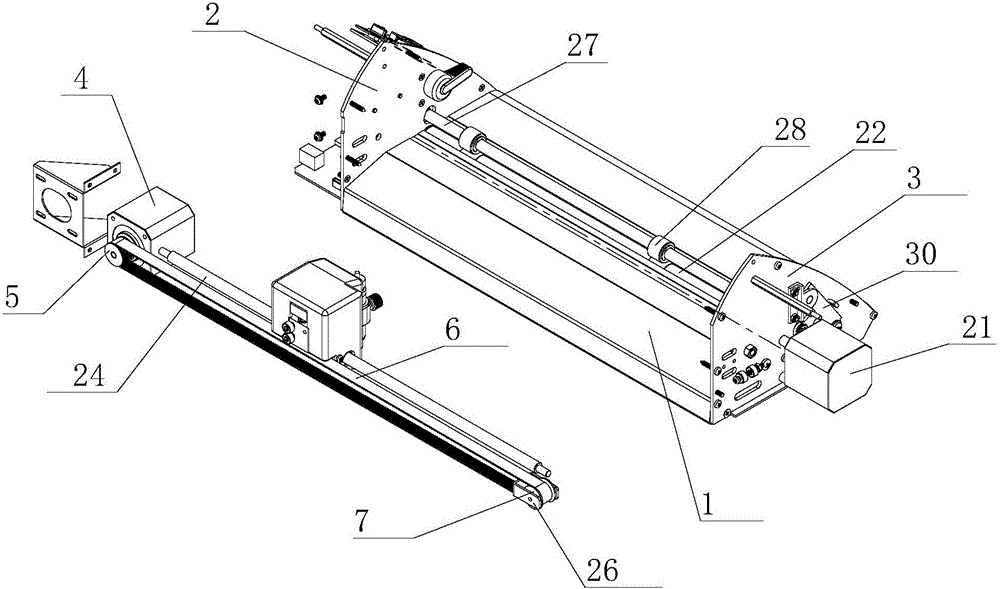

Up-down adjustable cutter device for plastic cylinder engraving

ActiveCN105922803AImprove engraving effectImprove efficiencyOther artistic work equipmentsEngravingEngineering

The invention discloses an up-down adjustable cutter device for plastic cylinder engraving. The cutter device comprises a rack, wherein two supporting columns are fixed on the top surface of a top plate of the rack; the top ends of the two supporting columns are fixed on the bottom surfaces of the two ends of an upper top plate; a cutter connecting frame is inserted into one supporting column in a sleeving manner; a push cylinder is fixed on a supporting plate of the cutter connecting plate; a push rod of the push cylinder penetrates through the supporting plate; a graver connecting plate is fixed on the push rod; a cutter is fixed on the graver connecting plate and faces the outer side wall of a plastic cylinder; an adjusting block is fixed on the cutter connecting frame; the upper end of a vertical adjusting screw rod is hinged onto the upper top plate; the lower end of the vertical adjusting screw rod is hinged onto the top plate of the rack; an adjusting motor is fixed on the top plate of the rack; and the vertical adjusting screw rod is driven by an output shaft of the adjusting motor to rotate. By adoption of the cutter device, a ring-shaped groove can be engraved in the outer side wall of the plastic cylinder mounted on the rack; the cutter of the cutter device can be adjusted up and down as required; and the cutter device is good in engraving effect and efficient.

Owner:济南蓝象数控机械有限公司

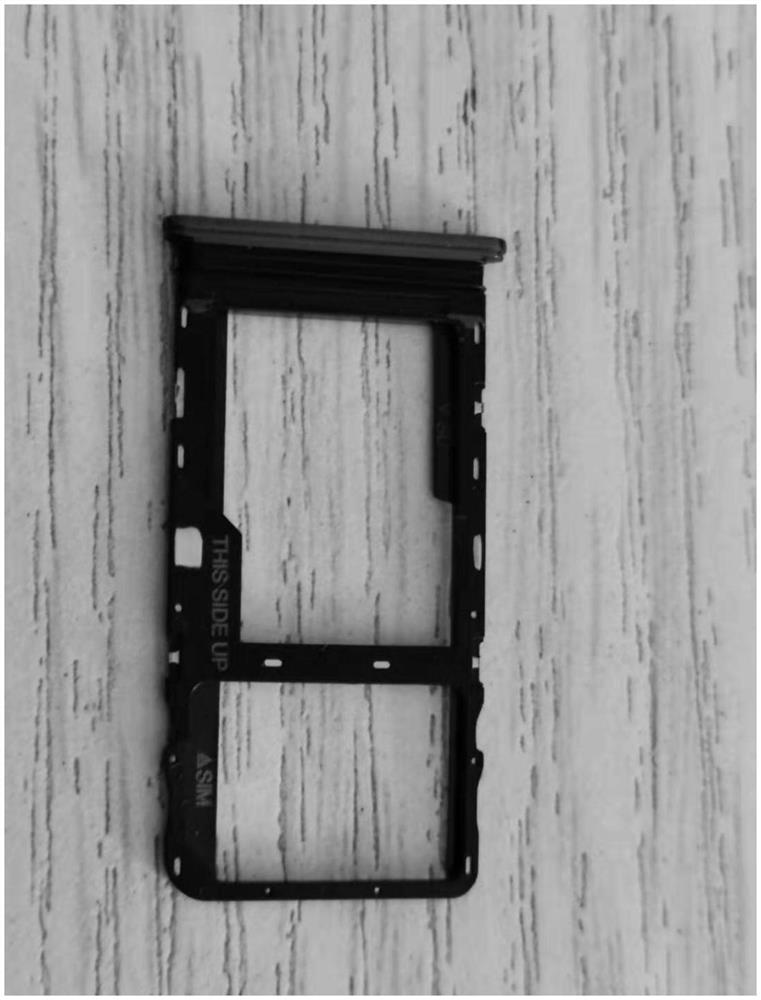

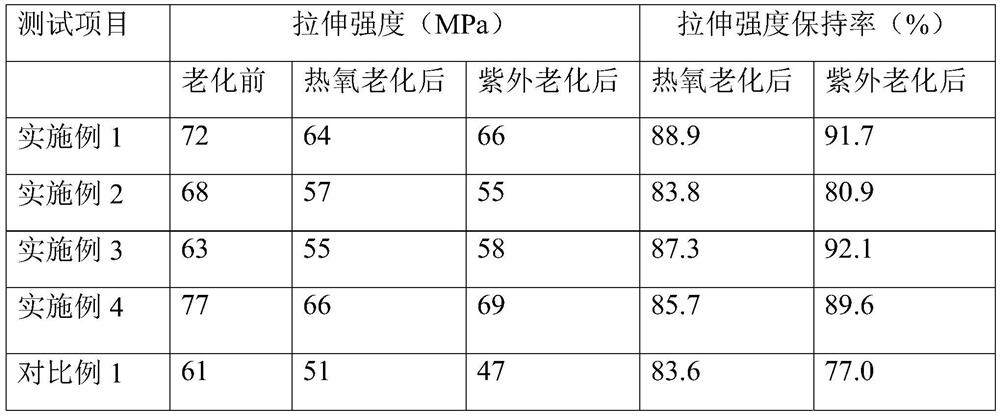

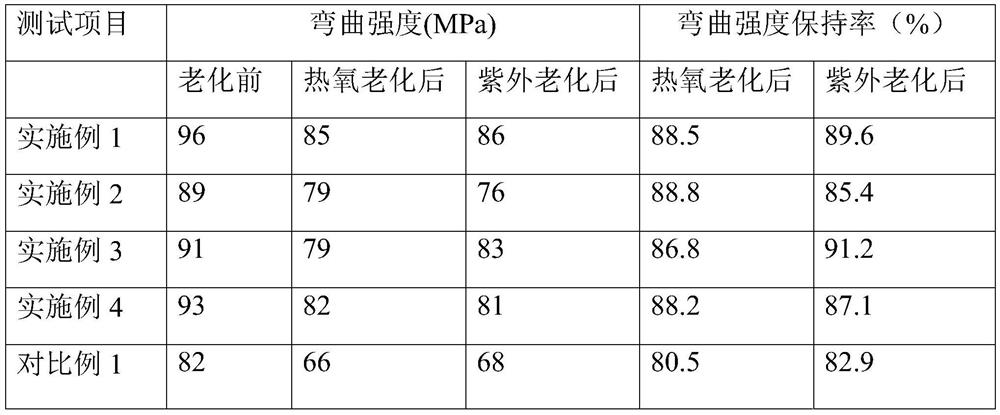

Material for laser etching and preparation method thereof

The invention relates to the technical field of laser etching, in particular to a material for laser etching and a preparation method thereof. The material for laser etching is prepared from the following raw materials in parts by weight: 80 to 90 parts of PC, 8 to 14 parts of glass fiber, 8 to 15 parts of ABS resin, 12 to 18 parts of inorganic filler, 1.5 to 3 parts of laser etching aid, 15 to 25 parts of compatilizer, 0.5 to 2 parts of antioxidant, 15 to 22 parts of synergistic aid and 3 to 7 parts of color master batch. The material for laser etching has the advantages of favorable mechanical properties, favorable aging resistance, favorable toughness, favorable engraving effect during laser etching, clear patterns and writings and long service life. The preparation method of the material is simple and convenient to operate, easy to control and high in production efficiency, the prepared product is stable in quality, and industrial mass production is facilitated.

Owner:GUANGDONG GERUI NEW MATERIALS CO LTD

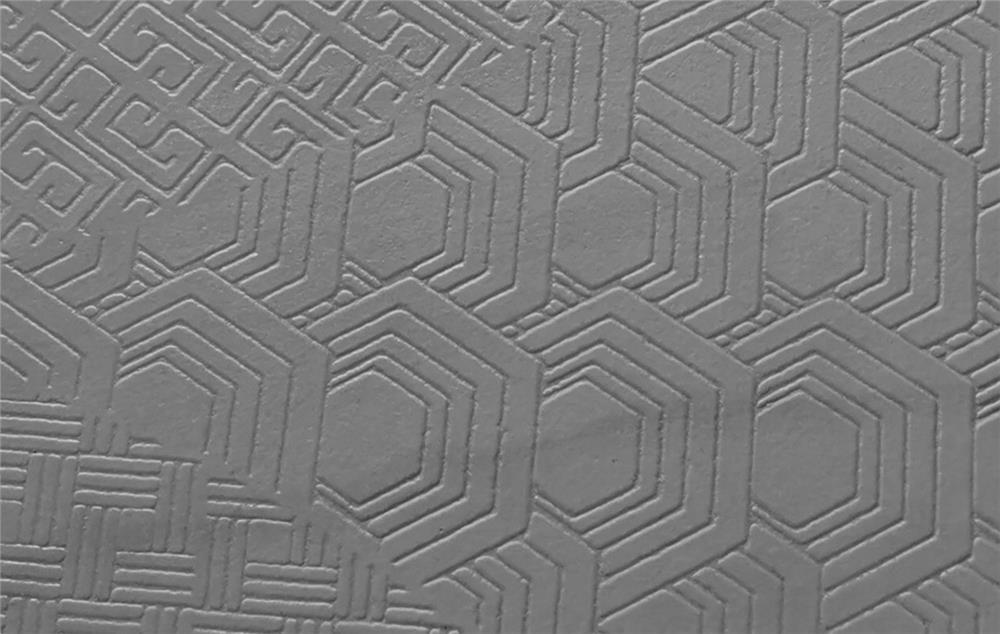

Ceramic digital ink with matte carving effect and application thereof

The invention belongs to the field of ceramics, and discloses ceramic digital ink with a matte carving effect and application thereof. The digital ink with the matte carving effect is composed of powder, a solvent and an auxiliary, and the powder is composed of albite, wollastonite, limestone, calcined zinc oxide, quartz, corundum and high-calcium zinc-containing frit. The ceramic digital ink of some examples is particularly suitable for preparing digital mold tiles, the mold effect is good, the mold depth can reach 0.1-0.3 mm, lines are clear, particularly turning positions are also clear, and the obvious matte carving effect is achieved. The ceramic digital ink of some examples is simple in preparation method, low in production cost and suitable for large-scale production.

Owner:GUANGDONG DOWSTONE TECH

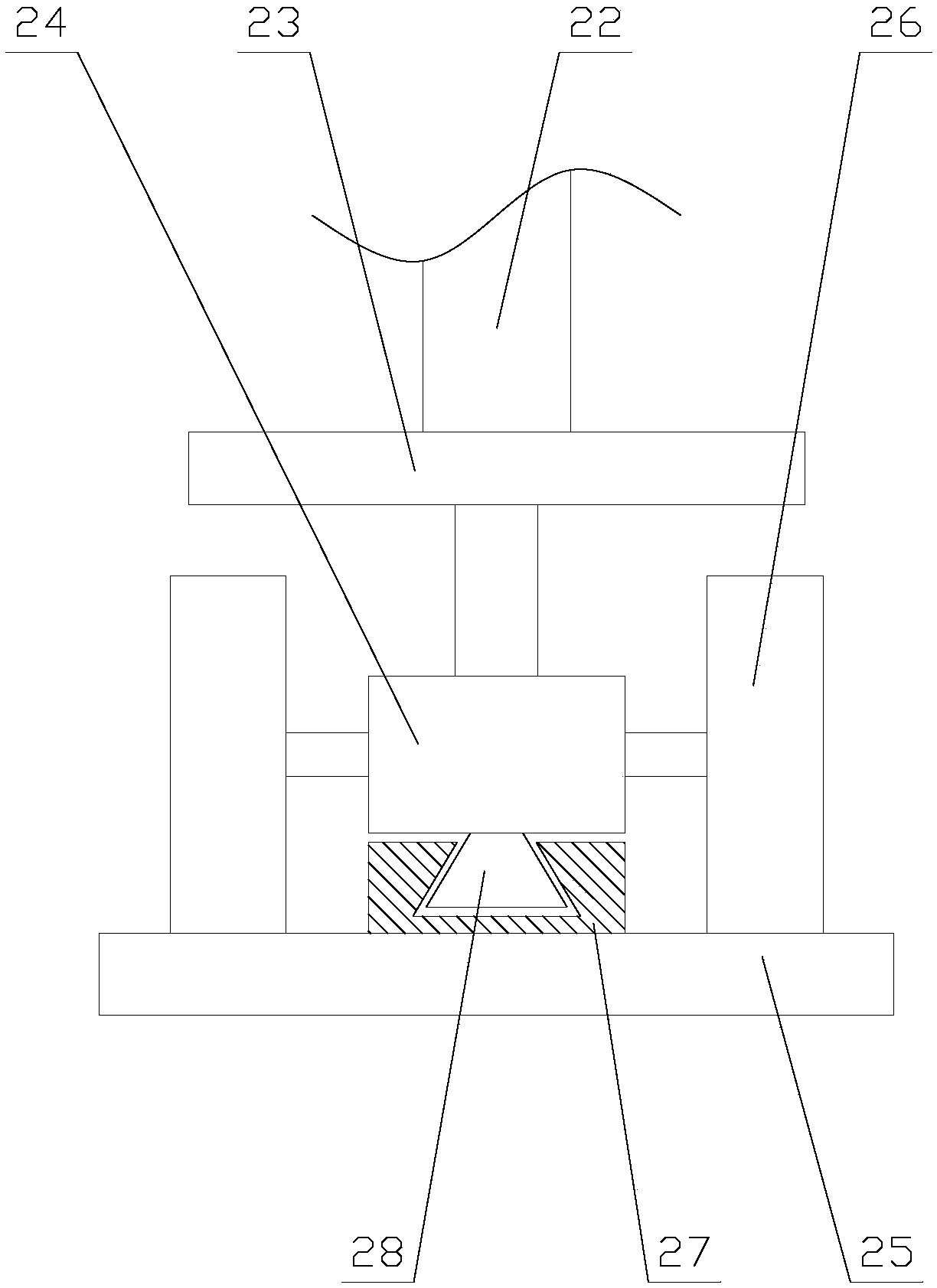

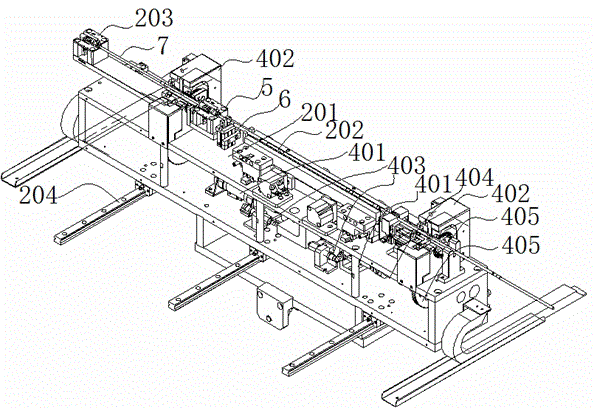

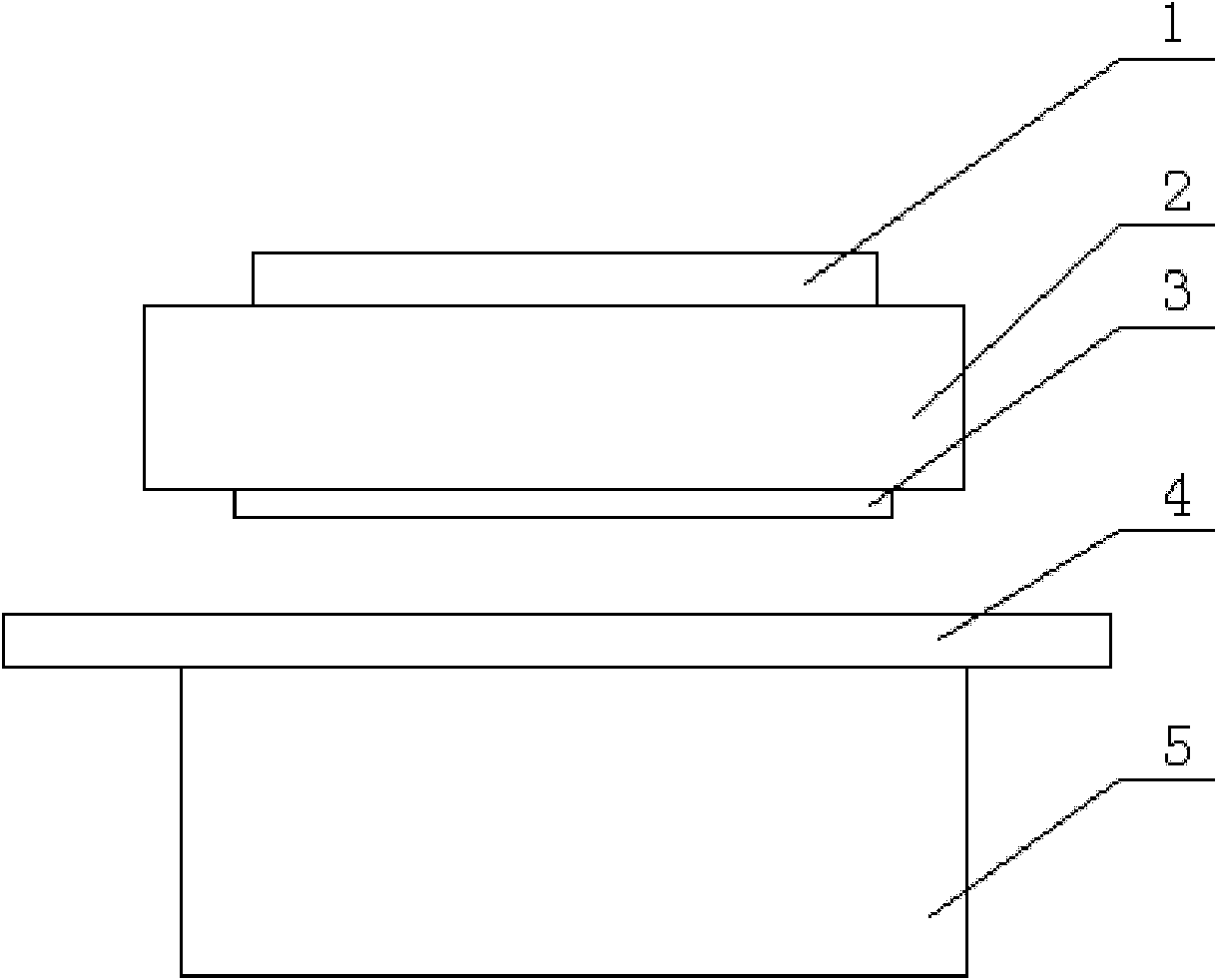

Hot mark stamping mechanism, hot mark stamping system and hot mark stamping method of hot mark stamping system

ActiveCN104608480AAchieve automatic attachmentNo damageRotary pressesMechanical engineeringHeating temperature

The invention discloses a hot mark stamping mechanism, a hot mark stamping system and a hot mark stamping method of the hot mark stamping system. The hot mark stamping mechanism comprises a frame and a hot mark stamping device arranged on the frame. The hot mark stamping device comprises a first driving mechanism, a knife mold device and at least one hot mark stamping site, the hot mark stamping sites are arranged at the bottom of the knife mold device, and a thermocouple sensor is further arranged on the knife mold device and used for controlling the heating temperature of the knife mold device. After the thermocouple sensor senses that the knife mold device is heated to a proper temperature, the knife mold device moves vertically under the effect of the first driving mechanism, so that mark stamping is performed on a line through the hot mark stamping sites. The hot mark stamping system comprises the hot mark stamping mechanism and further comprises a line feeding mechanism and a rack. The hot mark stamping method is applied to the hot mark stamping system.

Owner:苏州启成精密工业有限公司

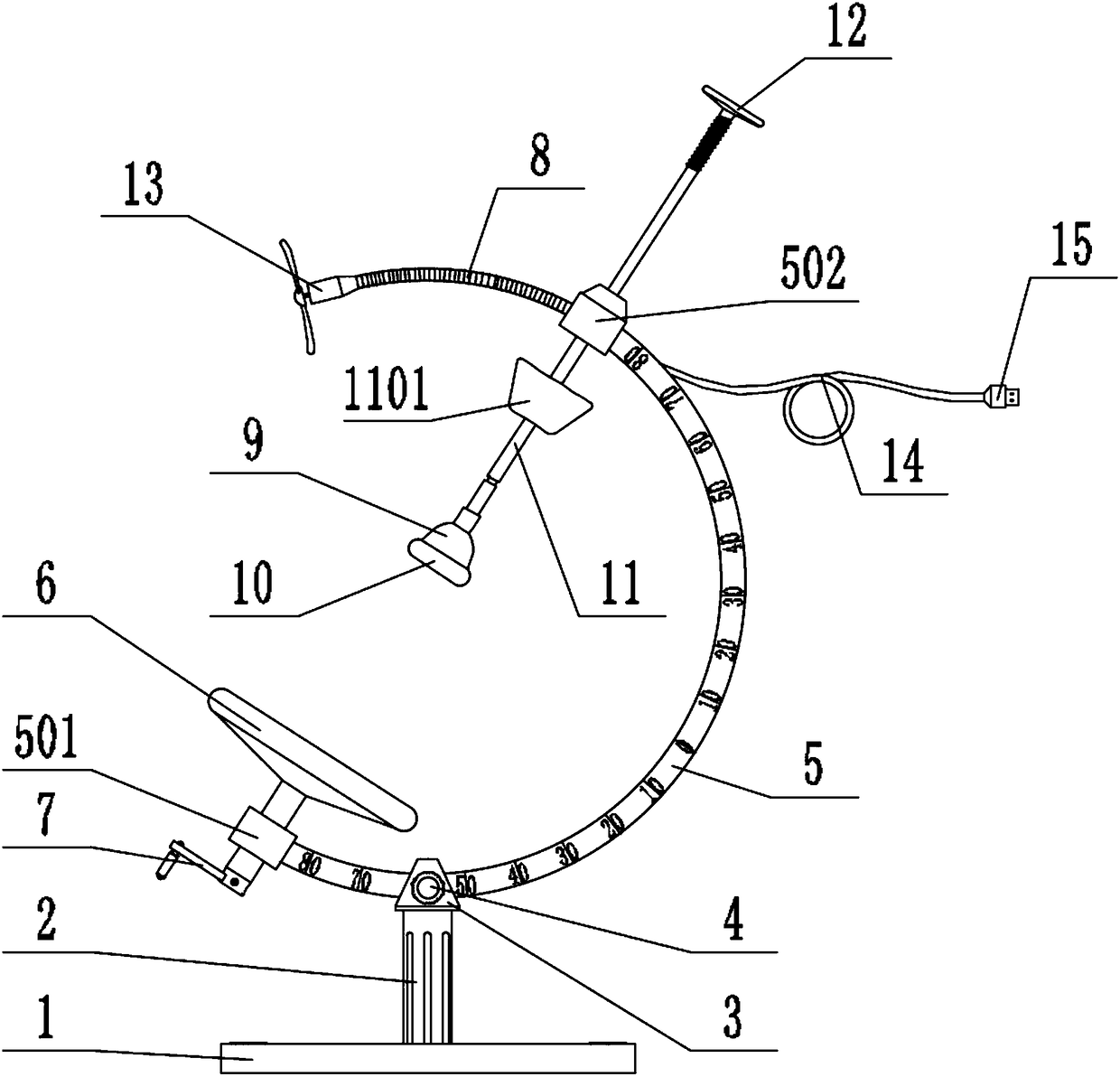

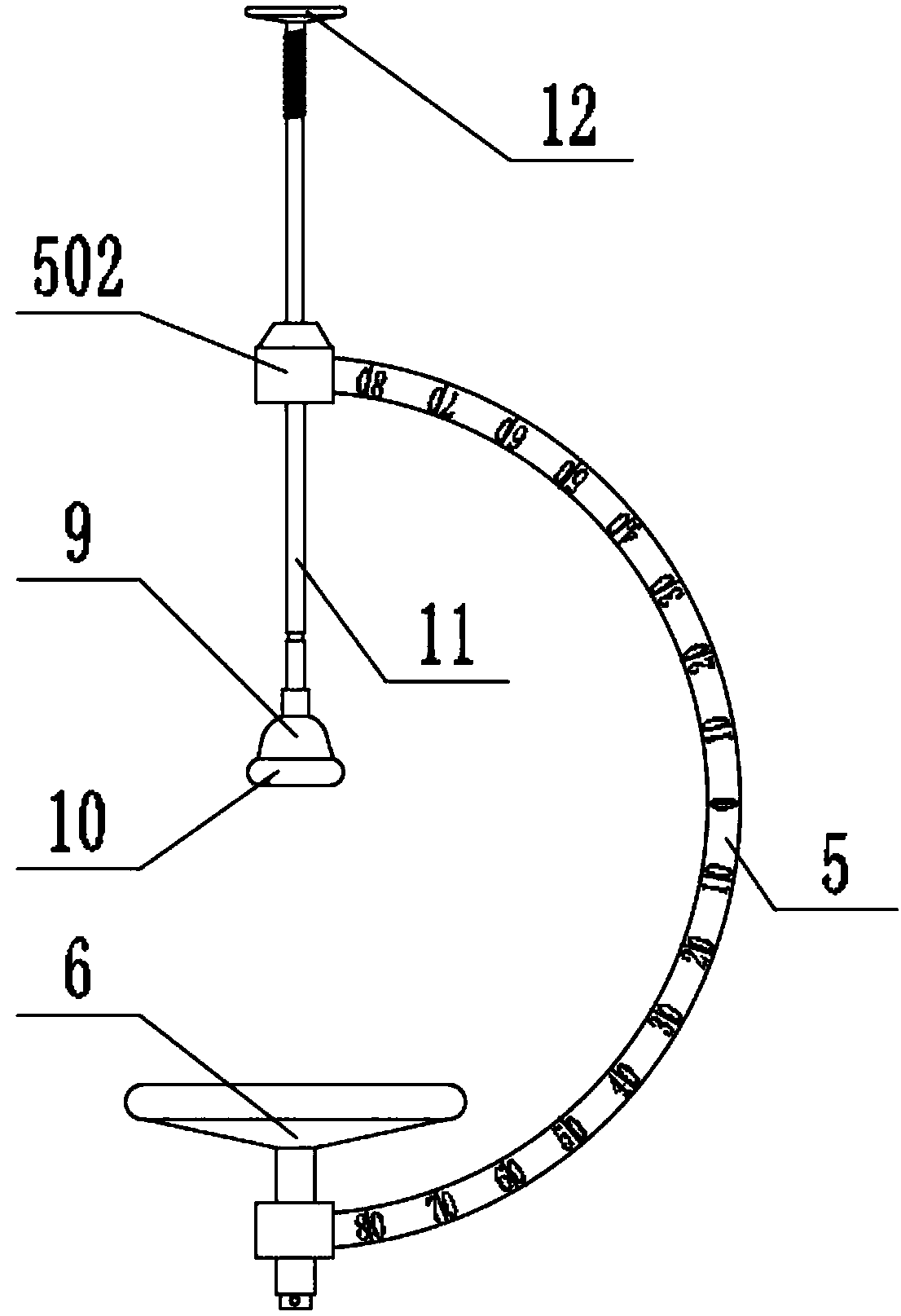

Carving device for ceramic art

ActiveCN108515801AEasy flipEasy to engraveHand artistic toolsOther artistic work equipmentsEngineeringCarving

The invention provides a carving device for ceramic art. The carving device comprises a wire and a power connector, a cylindrical support column is mounted on the top end surface of a base, and the bottom of an angle locking block is mounted on the top end surface of the cylindrical support column. A fixing bolt is mounted on the angle locking block. A sliding strip is of an arc-shaped strip structure, and the sliding strip is externally provided with scales. An upper connecting block is mounted at the top end of the sliding strip, and a lower connecting block is mounted at the lower end of the sliding strip. A rotating handle is mounted at the bottom of a working table through a countersunk hexagonal bolt, and the working table is connected with the lower connecting block. The carving device for the ceramic art is beneficial for turning over a ceramic product placed in the carving device, the end surfaces of the ceramic product can be presented at a better angle in the eyes of a carver, the carving operation on the ceramic product of the carver in the later stage is facilitated, the difficulty of carving is reduced, and the effect of ceramic carving is indirectly improved.

Owner:福建德化博昌陶瓷文化有限公司

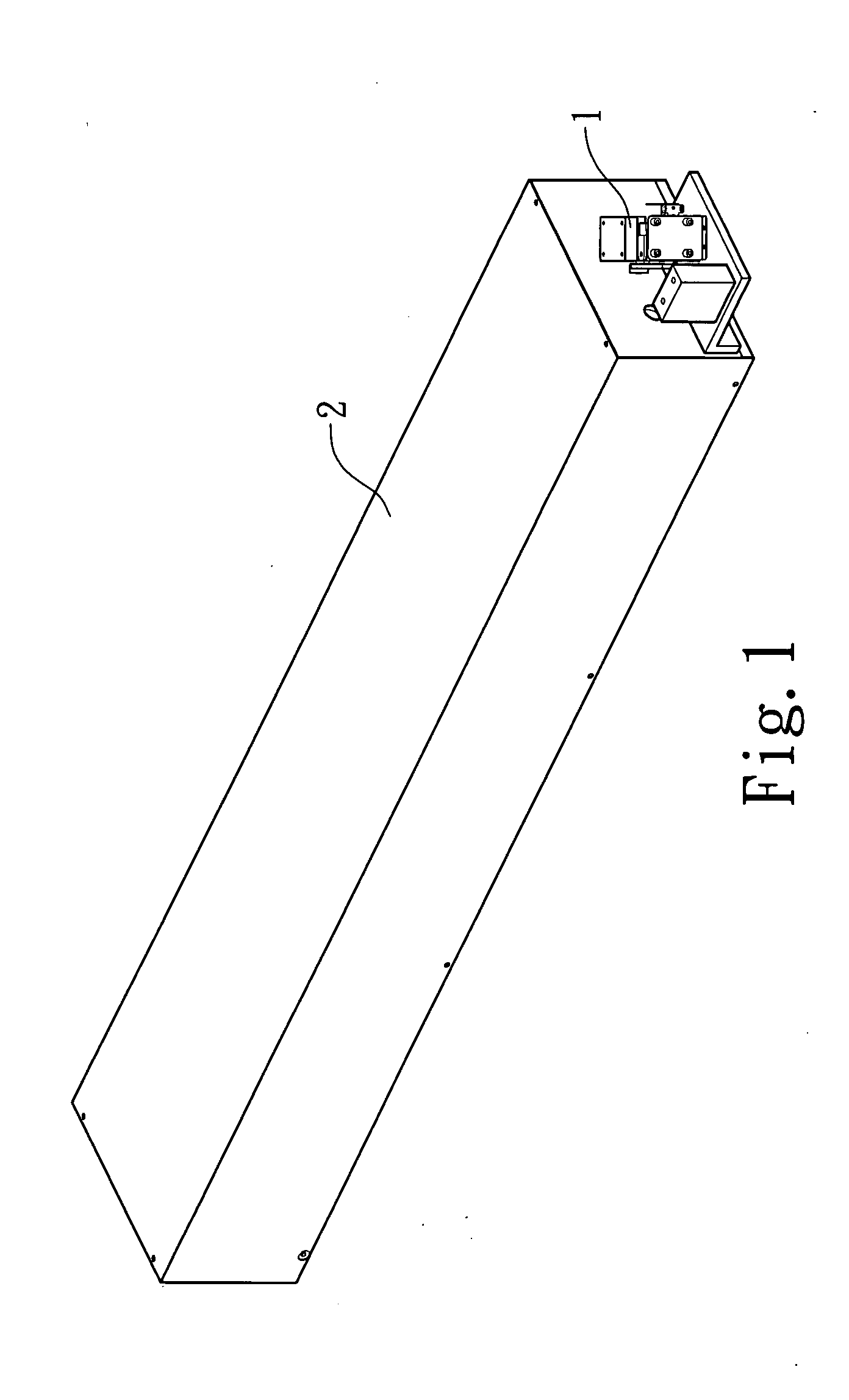

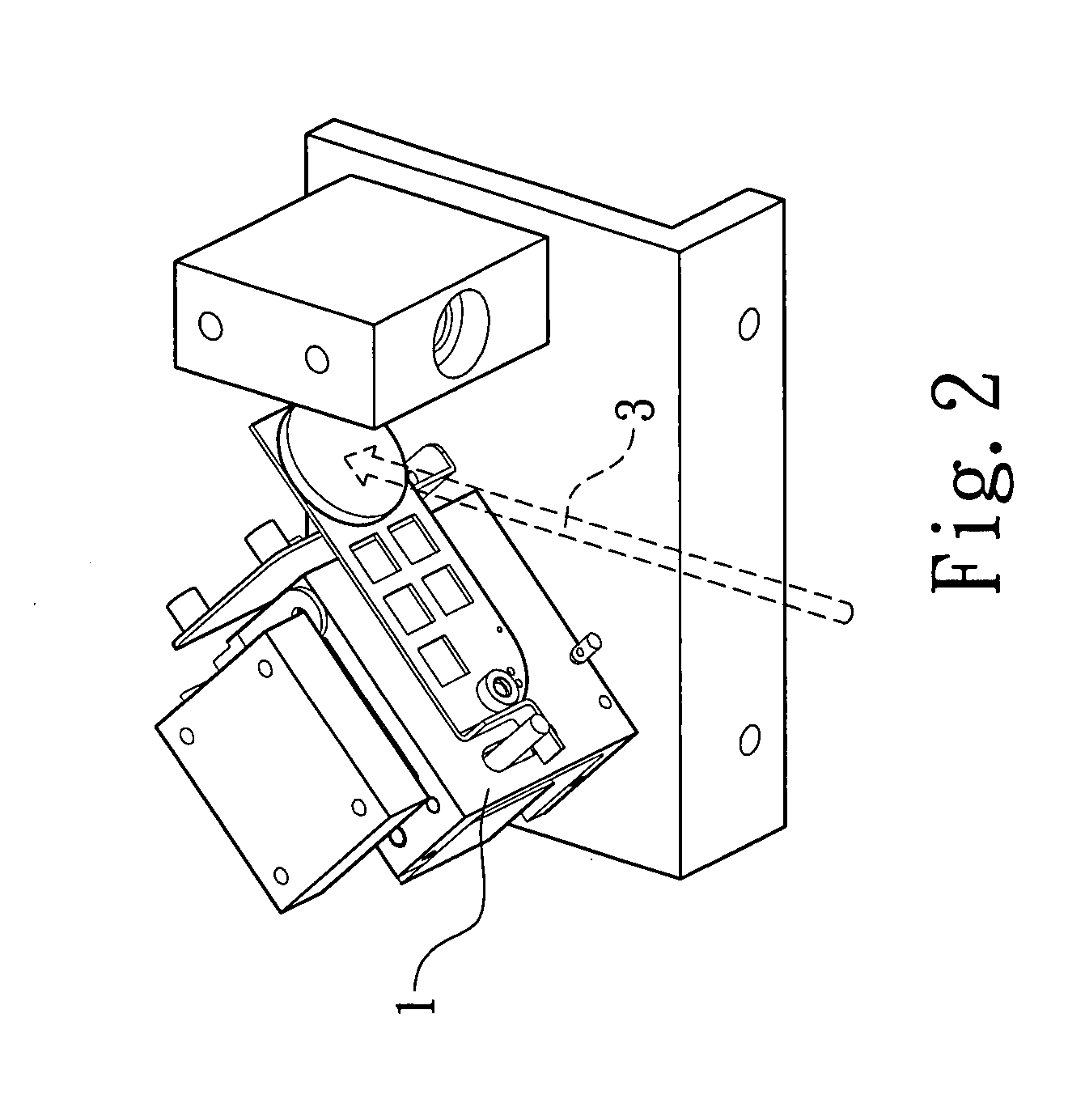

Laser engraving machine

InactiveCN112548348AHealth effectsReduce labor intensityLaser beam welding apparatusLaser engravingElectric machinery

The invention relates to the technical field of laser engraving, and discloses a laser engraving machine. The laser engraving machine comprises a box body, wherein a collecting box is arranged at thebottom of the inner wall of the box body, a dust suction mechanism is arranged on the inner wall of the collecting box, a spraying mechanism is arranged at the bottom of the dust suction mechanism, fixing mechanisms are arranged at the two ends of the top of the collecting box, and a translation mechanism is arranged at the top of the inner wall of the box body. According to laser engraving machine, by arranging the dust suction mechanism and starting a first motor, the first motor can drive a rotary disc and fan blades to rotate, so that dust generated by engraving is sucked into the box bodyto be collected, the situation that the dust drifts away and is inhaled by people to influence the human health is avoided, and the labor intensity of cleaning personnel is also reduced.

Owner:SUZHOU MIKE LASER TECH SERVICE CO LTD

Stone processing device for road and bridge construction

InactiveCN109703254AImprove stabilityAvoid displacementCleaning using gasesSound producing devicesWorking environmentEngineering

The invention relates to the technical field of road and bridge construction, in particular to a stone processing device for road and bridge construction. According to the stone processing device, thestability of stone on a containing plate can be enhanced, the stone is prevented from shifting in the carving process, and the carving effect is improved; meanwhile, noise generated during carving isrelieved, and the work environment is improved; the stone can be conveniently carried and placed on a workbench, physical power during carrying and placing is saved, and the labor degree is reduced;and meanwhile, dust generated in the carving process can be treated, the protection effect to the health of workers can be enhanced, the environment protection effect can be improved, and use reliability can be enhanced. The stone processing device comprises a workbench, a main engine, a controller, a carving machine, the containing plate and a base, and further comprises a first adjusting part, asecond adjusting part, a first fixed plate and a second fixed plate. The stone processing device further comprises a moving seat and an electric cylinder, further comprises a vacuum shell, a first sound absorption part and a second sound absorption part, and further comprises an exhaust fan, a filter box, a support, an input pipe, a communicating pipe, an output pipe and a suction head, and the suction head is arranged at the input end of the input pipe.

Owner:山西云度知识产权服务有限公司

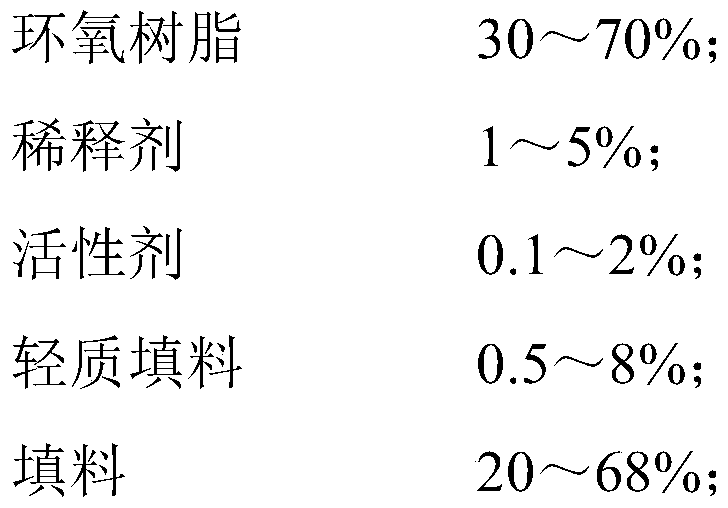

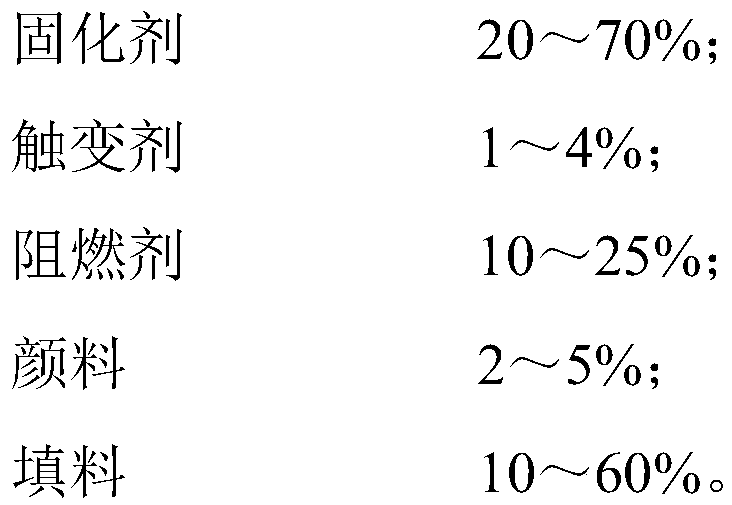

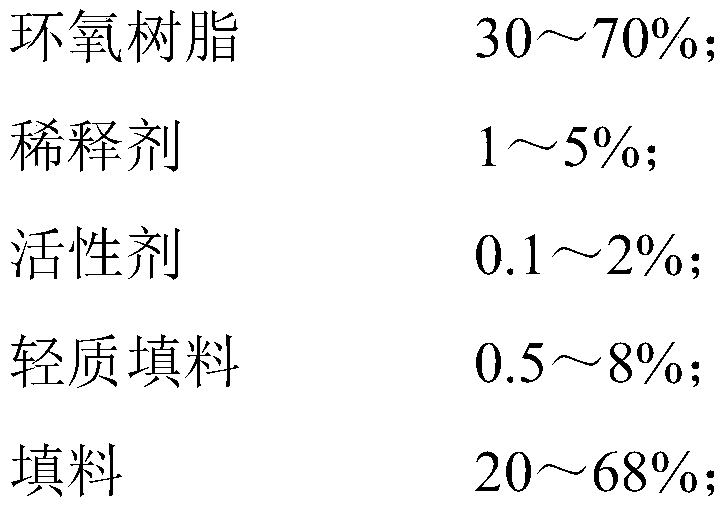

Manually carved model epoxy resin mud and preparation method thereof

PendingCN111138807ARealize construction with waterExcellent hand engraving performance with waterPolymer scienceFirming agent

The invention discloses a manually carved model epoxy resin mud. The manually carved model epoxy resin mud comprises a component A and a component B. The component A comprises epoxy resin, a diluent,an activator, a light filler and a filler. The component B comprises a curing agent, a thixotropic agent, a flame retardant, a pigment and a filler. The invention further discloses a preparation method. Water-carrying construction of an oily material can be realized, and the contradiction between system viscosity and constructability is solved, so the thixotropy is good, the thickness is 10mm, noflow drop exists, and the engraving detail expressive force is strong; the bonding shearing strength and the surface construction water resistance of a base material can be effectively improved, and the physical and chemical properties and the artistic expressive force of a modeling material are guaranteed; and the manually carved model epoxy resin mud has the characteristics of light weight, highstrength, aging resistance, flame retardance, good sculpture property, high smoothness, good self-adhesion property and good repairability, and is particularly suitable for landscape modeling in thetravel industry.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

Graver

InactiveCN101683804AImprove wear resistanceImprove engraving effectEngravingEngineeringSquare pyramid

The invention discloses a graver comprising a graver body and is characterized in that the graver body is a cylinder structure, one end of the graver body is connected with a graver handle, and the other end of the graver body is provided with a graver head; the graver head is designed into a pyramid structure, is made of diamonds and is a square pyramid structure. The invention has the beneficialeffect that the graver can easily grave V-shaped slot lines on an acryl board by changing the conoid graver on the traditional engraving machine into a square pyramid graver; meanwhile, because the graver head of the graver of the invention is made of diamonds, the graver of the invention has better abrasion performance, longer service life, greatly improved graving speed, better graving effect and improved working efficiency than the traditional graver.

Owner:SHANGHAI EDGE LIGHT IND

Ironing and engraving dyeing method

InactiveCN101844468AEliminate the steps of high temperature coloringLower working temperatureDecorative surface effectsAblative recordingEngineeringHeating temperature

The invention relates to an ironing and engraving dyeing method, which comprises a plate making and plate loading process, an ironing and engraving plate calcining process, a heating process and an ironing and engraving process. A ironing and engraving plate is colored after the plate making, and the plate loading process is carried out after the coloring, wherein the heating temperature of the ironing and engraving plate is between 70 and 120 DEG C, the pressurized pressure in the ironing and engraving process is between 10 and 30 kg, and the time for ironing and engraving ironing and engraving materials through pressurization is between 1 and 10 seconds. The invention sets the color on the ironing and engraving plate in advance, the expressive force on the product contents after the coloring is richer, and the colors required by the ironed and engraved materials can be freely selected, so the application range of the ironing and engraving method is wider. Because a heating method is adopted for coloring during the coloring, the color attachment is firmer, and the color is not easy to fade.

Owner:王运国

Method for manufacturing salt sculpture

InactiveCN110341364AThe production process is simpleImprove yieldOrnamental structuresWhitening AgentsColor changes

For overcoming the defects existing in an existing method for producing salt sculpture, the invention provides a novel process which takes salt solution as a raw material, and carries out filtrating,chelating impurity removal, concentrating, shaping, demoulding and the like to prepare the salt sculpture. The method can effectively avoid the problem of color change of subsequent products without adding reagents such as a fluorescent whitening agent to the salt, the prepared salt sculpture works are long in storage time and high in ornamental value, the product rejection rate in the productionprocess is greatly reduced, the production efficiency is high, and the economic value is high.

Owner:陆杨

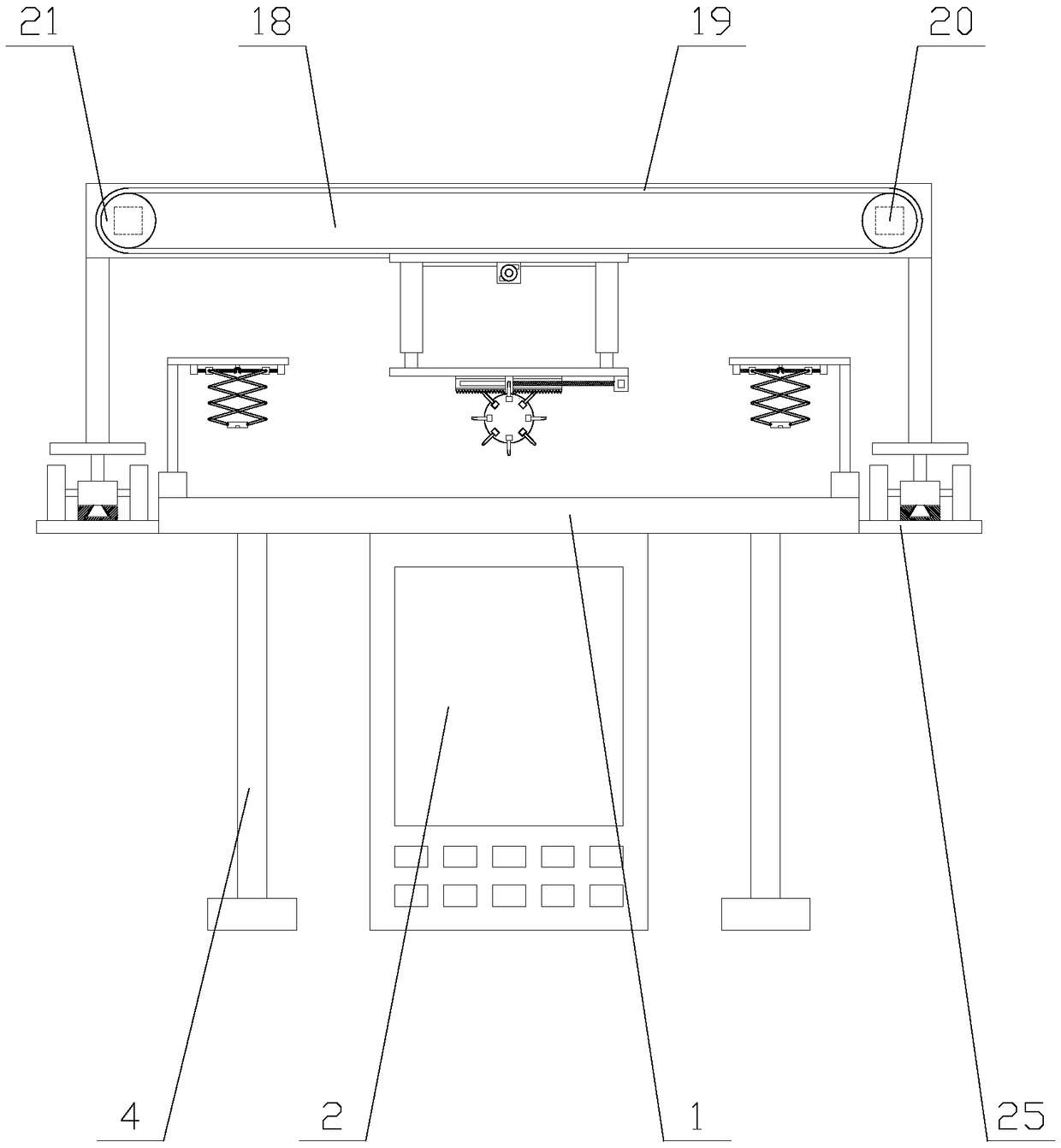

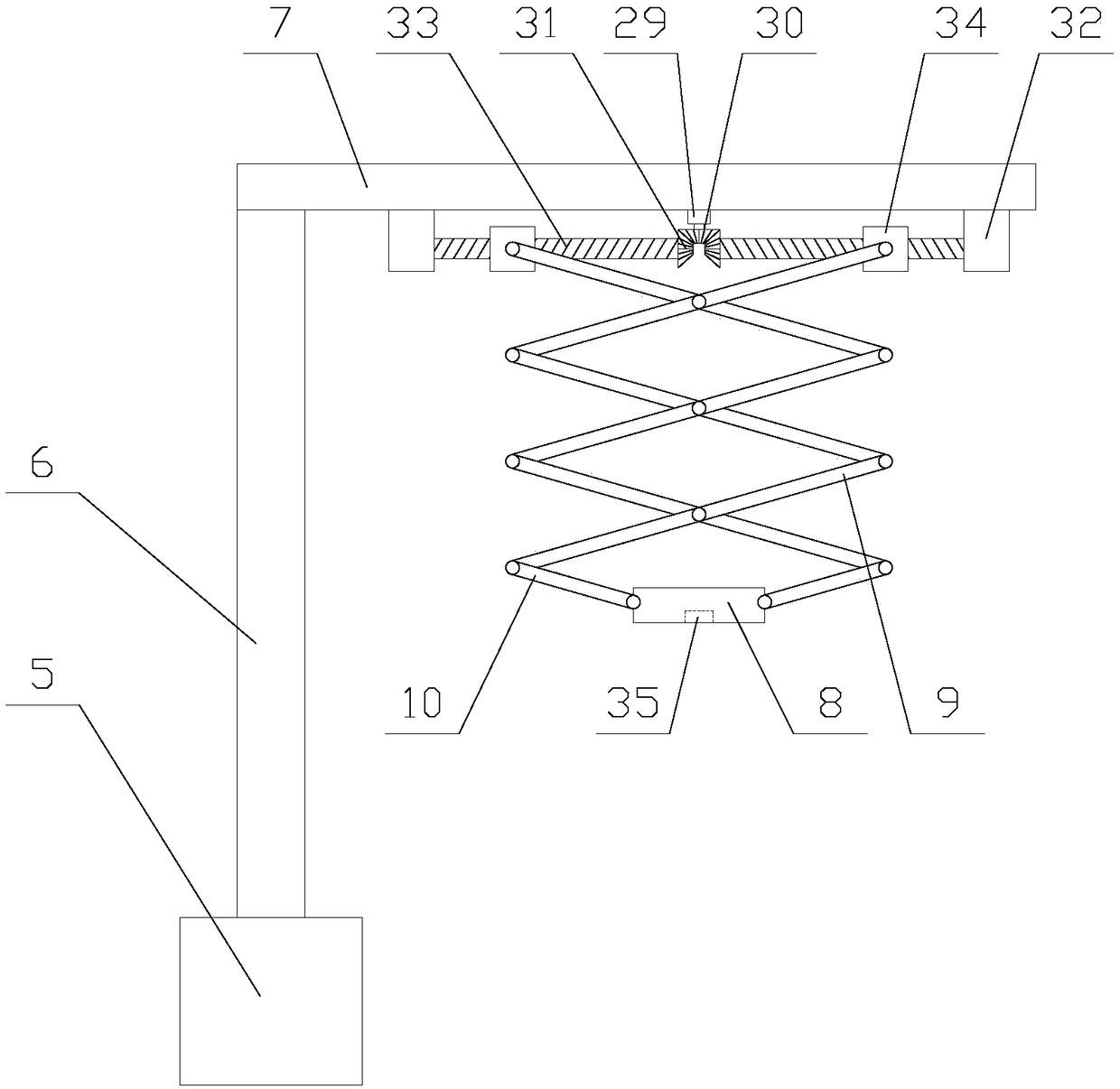

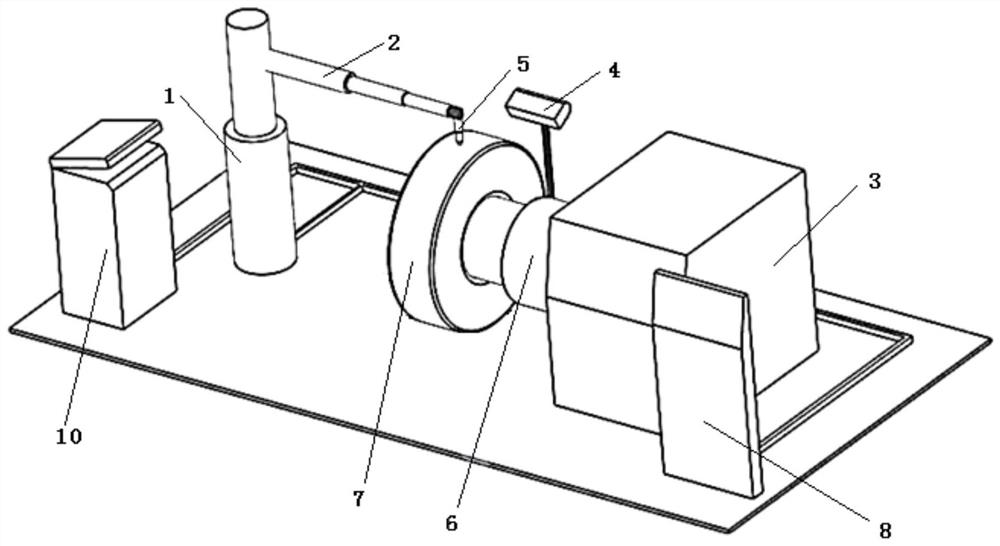

Tire engraving system

PendingCN111907245AHigh precisionHigh degree of automationTyresMetal working apparatusElectric machineryDrive motor

The invention discloses a tire engraving system, and belongs to the technical field of tires. According to the technical scheme, the system comprises a first electric hydraulic push rod, a second electric hydraulic push rod, a mounting base and a scanner. The first electric hydraulic push rod is vertically arranged, the second electric hydraulic push rod is horizontally installed on a push rod body of the first electric hydraulic push rod, and a tool bit is installed on a push rod body of the second electric hydraulic push rod. A rotating shaft is horizontally mounted on the mounting base andis driven by a driving motor, and a tire is mounted on the rotating shaft; and the scanner is located at one side of the tire, and the first electric hydraulic push rod, the second electric hydraulicpush rod, the driving motor and the scanner are electrically connected with a controller. The system is safe, efficient, high in precision and high in automation degree.

Owner:泰凯英(青岛)专用轮胎技术研究开发有限公司

Pattern transposition carving technical method of landscape sculpture

InactiveCN104260588AGood engraving effectRealize continuous replacementDecorative surface effectsStone carvingParaffin oils

The invention relates to a pattern transposition carving technological method of a landscape sculpture. The method comprises the following steps: (1) selecting paraffin, gypsum powder, magnesia, cement and silicone rubber as materials for later use; (2) smelting the paraffin in a vessel to produce a stencil plate, rubbing a designed to-be-carved pattern onto the stencil plate, and carving the concave-convex patterns by utilizing an engraving cutter according to the carving patterns; (3) duplicating the well-carved stencil plate to form a female mold by utilizing the magnesia or cement; (4) injecting the silicone rubber into the female mold, and taking out the silicone rubber after being solidified; and (5) adhering the produced silicone rubber patterns to a sample model of the sculpture. By adopting the method, the sample model which is more attractive and beautiful and has more complicated structure than the traditional stone sculpture can be processed. The complicated landscape sculpture can be completed immediately in pouring by adopting the sample model in a mold production way, the production speed is high, the cost is low, and the mass production needed by the beautification of the city can be completely satisfied.

Owner:纪汉伟

Electronic sculpturing machine

The present invention relates to an electronic sculpturing machine, comprising a machine body which comprises a working bench and a machine cover, wherein the working bench comprises front and back tips for supporting a processing cylinder, and a sculpturing car; a makeup work station which uses a brand new rip analyzer, can accept PS, EPS, PDF, TIFF makeup, and can realize integrated tension enlarging and reducing; a DTG control circuit board which comprising a 2050CPU board, a 7070 board, a 3010 board, a 8090 board, a FIFO card and a 7020 sculpturing head amplifier board; a DTG control software which comprises a preset menu, trail sculpturing menu, a sculpturing menu, a tool sculpturing menu and a website button; a PLC controller for overall control to realize fast forward raising, head resting, head backing and car driving and the like; a website tester for measuring sculpturing websites and correcting positions. The weight of the present invention is reduced, the whole machine is beautiful, and material expenses are reduced greatly; the national energy-conservation requirements are satisfied. The operations are simple and easy to be learned; the electronic sculpturing machine is humanized. A Chinese control interface and an English control interface can be transformed, which is in favour of popularizing the electronic sculpturing machine in international markets.

Owner:东莞东运机械制造有限公司

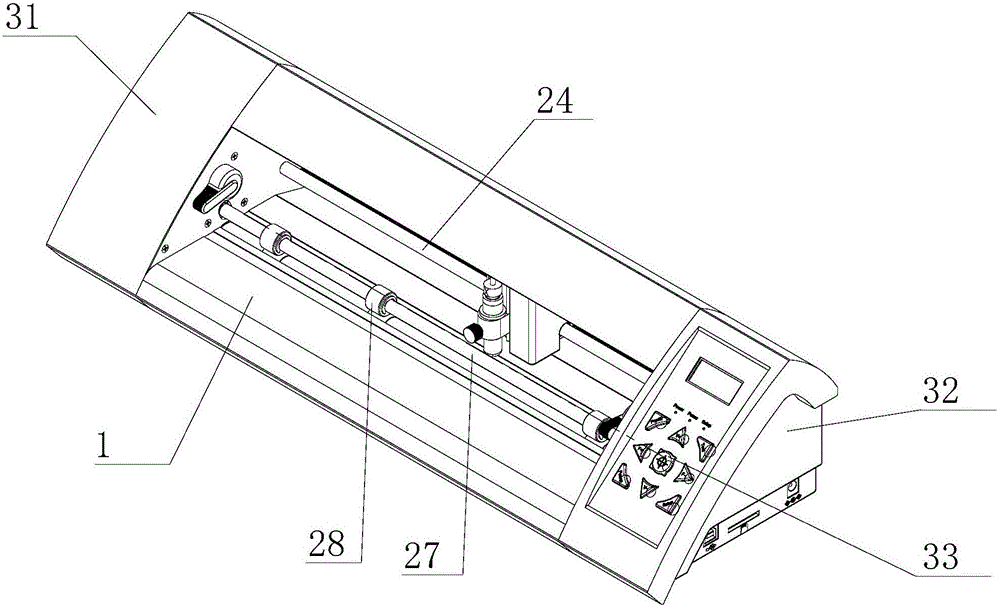

High-precision artistic type computer carving machine

InactiveCN106079997AIncrease stiffnessImprove performanceOther artistic work equipmentsEngravingEngineeringMechanical engineering

The invention provides a high-precision artistic type computer carving machine which comprises a machine case, an X-direction transmission mechanism and a Y-direction transmission mechanism. The machine case comprises a base. A first side plate and a second side plate are vertically arranged at the two ends of the base correspondingly. The X-direction transmission mechanism comprises an X-direction motor, a first X-direction bearing, an X-direction synchronous belt, a second X-direction bearing and a trolley. The X-direction motor is installed on the side, away from the second side plate, of the first side plate. One end of the X-direction synchronous belt is connected with the X-direction motor through the first X-direction bearing, and the other end of the X-direction synchronous belt is connected with the second X-direction bearing. The second X-direction bearing is installed on the second side plate. The movable trolley is erected on the X-direction synchronous belt. The Y-direction transmission mechanism comprises a Y-direction motor and a main roller. The Y-direction motor is installed on the side, away from the first side plate, of the second side plate. One end of the main roller is connected with the Y-direction motor and driven by the Y-direction motor to rotate, and the other end of the main roller is rotationally connected with the first side plate. According to the high-precision artistic type computer carving machine, a brand-new full-automatic red light edge finding positioning mode is adopted, and thus the contour can be cut more freely.

Owner:HEFEI KAXING DIGITAL CONTROL EQUIP

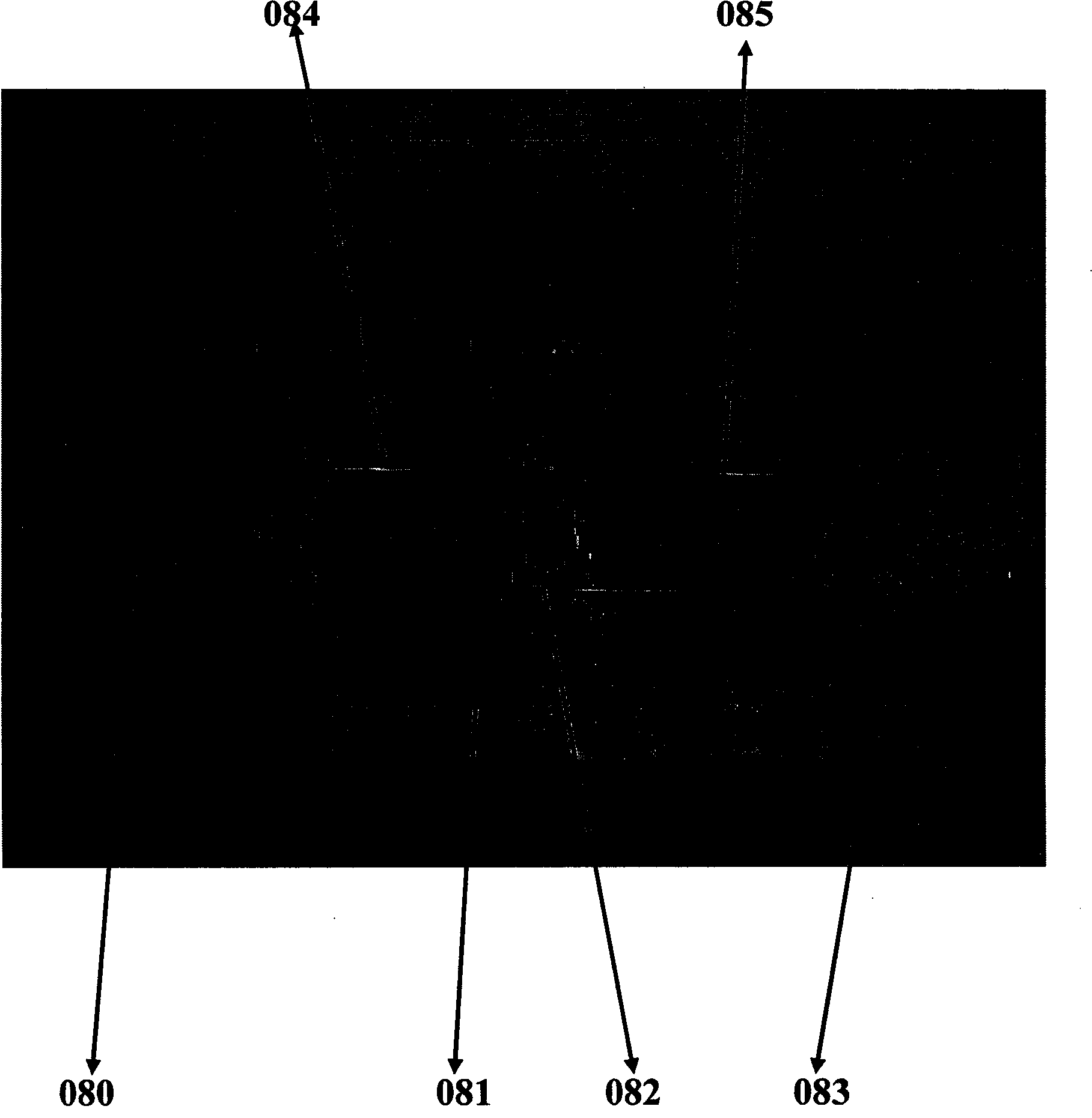

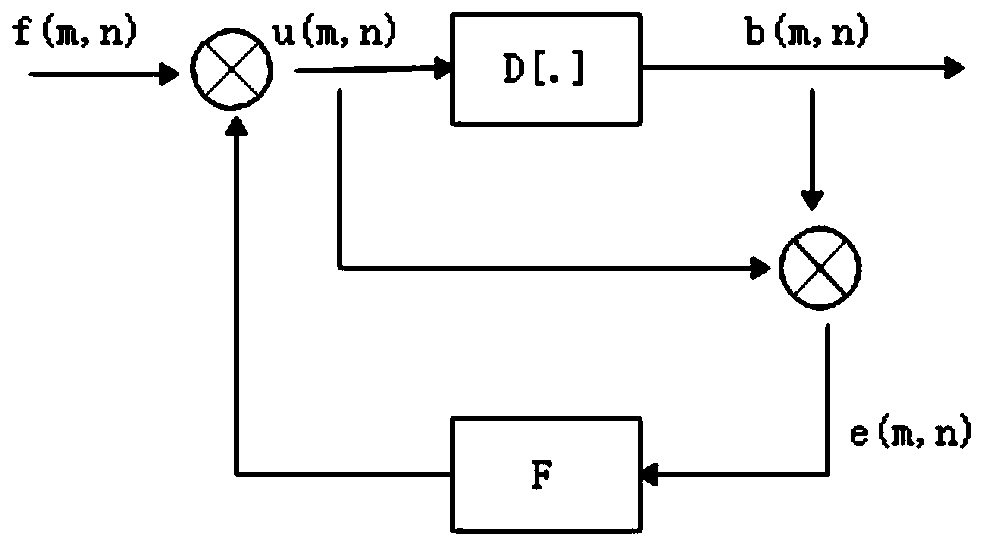

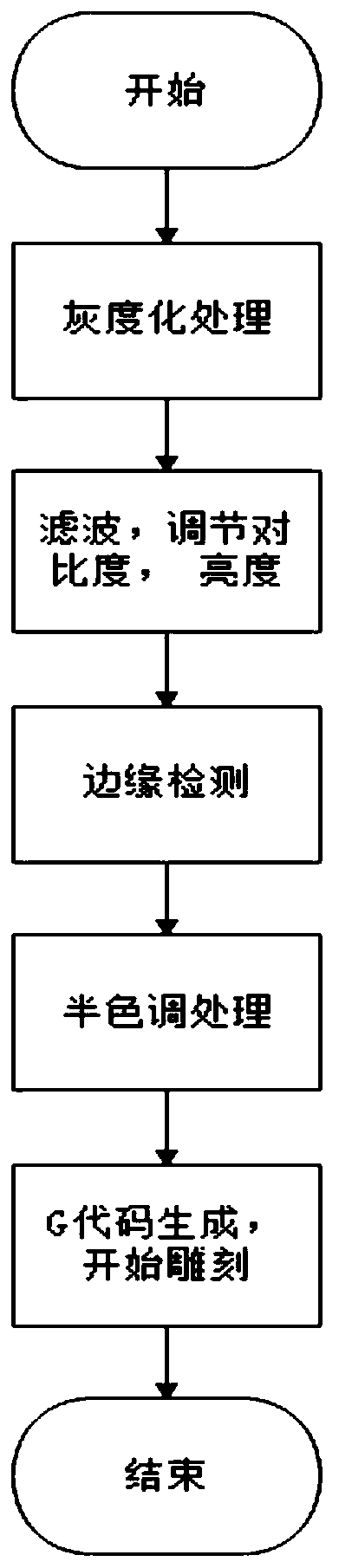

A method of image laser engraving based on halftone technology

ActiveCN109175718BEasy to operateImprove engraving effectLaser beam welding apparatusGradient operatorsAlgorithm

The invention discloses an image laser engraving method based on the halftone technology. The image laser engraving method mainly comprises the steps of (1) selecting an original image to be engravedand conducting graying on the original image to generate an image I; (2) conducting anisotropic filtering on the image I and adjusting the contrast ratio and the brightness of the image I to generatean image II; (3) conducting edge detection on the image II through a gradient operator to generate an image III; (4) conducting halftone treatment on the image II to generate an image IV; and (5), generating G-codes of the image IV according to the resolution ratio of a laser engraving machine. The laser engraving machine conducts image engraving according to the G-codes. Through the image laser engraving method based on the halftone technology, the complex operation in an existing DIY engraving technology is simplified, and the user operation process is simplified; the engraving effect duringimage engraving is improved, user experience is improved, the automation degree is high, and the image engraving effect is good.

Owner:CHONGQING UNIV IND TECH RES INST

Porcelain green body sculpting device

InactiveCN109334321AGuaranteed working environmentImprove viewing valueModel makingEngravingClosed loopWorking environment

The invention belongs to the field of porcelain production, and relates to a porcelain green body sculpting device. The sculpting device comprises a table frame, a motor, a belt mechanism, a rotatingworkbench and a graver component; the table frame comprises a table top frame supported by four supporting legs; the bottom ends of the four supporting legs are welded on one metal plane; the motor isvertically upwards fixed to one side surface of the table frame and dives the belt mechanism to enable the rotating workbench to rotate; the graver component is arranged at the upper end of a supporting column; the supporting column is arranged on one side edge of the table top frame; and supporting baffles in the splayed state are arranged on two sides of the supporting column. The rotating workbench of the sculpting device rotates stably and cooperates with a graver fixed to a moving rod for closed-loop graving, and lines on porcelain green bodies are smooth, consistent and attractive and elegant in appearance and have the ornamental value. The supporting baffles of the sculpting device can block powder splashing during graving, so that the working environment of a worker is guaranteed,and the sculpting device has the very good use effect during actual production.

Owner:禹州市锦丰源瓷业有限公司

PVC processing part carving equipment for production of semiconductors

PendingCN110789257AGuaranteed shock absorptionStable structureModel makingEngravingWorking environmentSemiconductor

The invention belongs to the field of processing of semiconductors, and particularly relates to PVC processing part carving equipment for production of semiconductors. To solve the problems that existing equipment generates vibration, has short service life and a poor carving effect and is not provided with a collection and protection device, and the working environment is influenced, the invention provides the PVC processing part carving equipment. The PVC processing part carving equipment comprises an equipment body, bases are fixedly connected to the bottom of the side wall of the equipmentbody, slant telescopic rods are rotatably connected to the side walls of the bases, connecting pieces are rotatably connected to the upper ends of the slant telescopic rods, and connecting blocks arefixedly connected to the side walls of one sides of the connecting pieces; lengthening plates are fixedly connected to the sides, away from the connecting blocks, of the side walls of the connectingblocks, insertion grooves are formed in the inner side walls of the equipment body, one ends of the lengthening plates are inserted in the insertion grooves, and a workbench is fixedly connected to the side walls of one sides of the connecting blocks. According to the PVC processing part carving equipment, a damping device is added, so that the service life is prolonged, and the carving effect isgood; through the addition of a collection and protection device, the working environment is guaranteed.

Owner:苏州羽美尚精密机械有限公司

Technology of aging wooden products

InactiveCN100532037CGood color gradationGreat contrast between black and whiteNatural patternsDecorative surface effectsWater temperaturePotassium permanganate

The invention discloses a process method for making old wood products, which is realized through the following steps: first, 800g-1200g of potassium permanganate oxidant is put into a container, diluted with 10-20 liters of water, and the water temperature is controlled at 30°C Melt it at ~50°C, then put the processed wood product in the container, soak it for 2-5 minutes and then take the wood product out of the container. At this time, the surface of the oxidized wood product shows the effect of wood charring; after After 5-10 hours of natural drying of wood products, sanding, polishing and painting can be done. Features: Adopting the process method provided by the invention, the process steps are simple, easy to operate, low cost, good effect, and the success rate of carbonization reaches 100%. The oxidized wood products have good color levels and a large contrast between black and white, which can fully reflect the texture of natural wood. Especially the woodcarving handicrafts oxidized by this method can highlight the engraving effect, improve the grade of handicrafts, and at the same time give people a beautiful enjoyment.

Owner:陈东明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com