Water balance structure for machine tailstock

A technology of machine tool tailstock and water balance, applied in the direction of tailstock/top, tool holder accessories, metal processing machinery parts, etc. Avoid overweight phenomenon and reduce the effect of matching error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

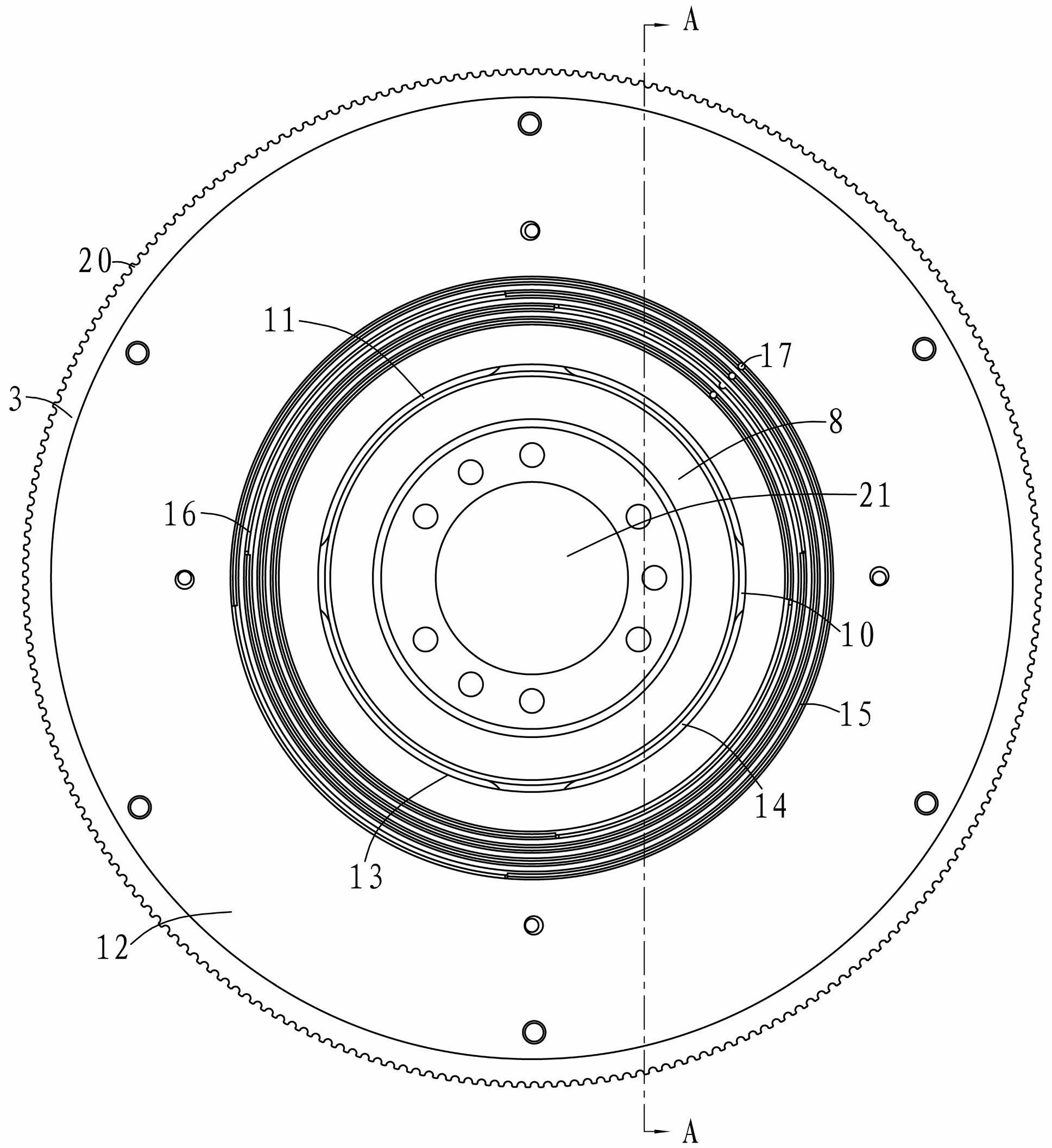

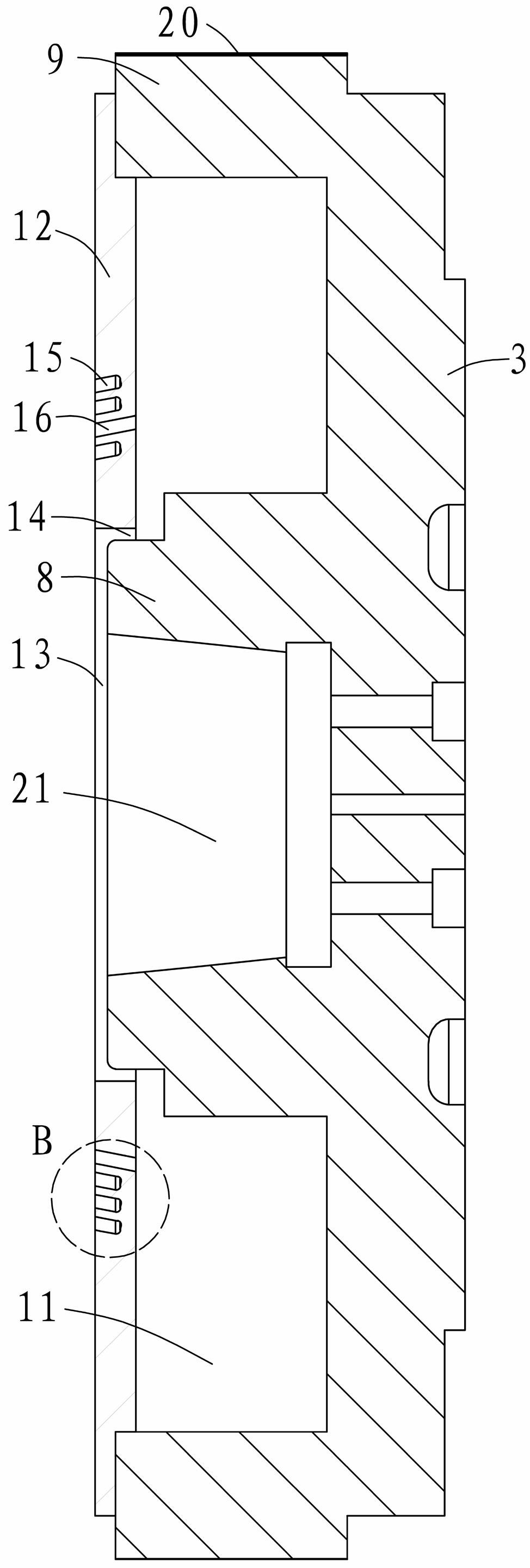

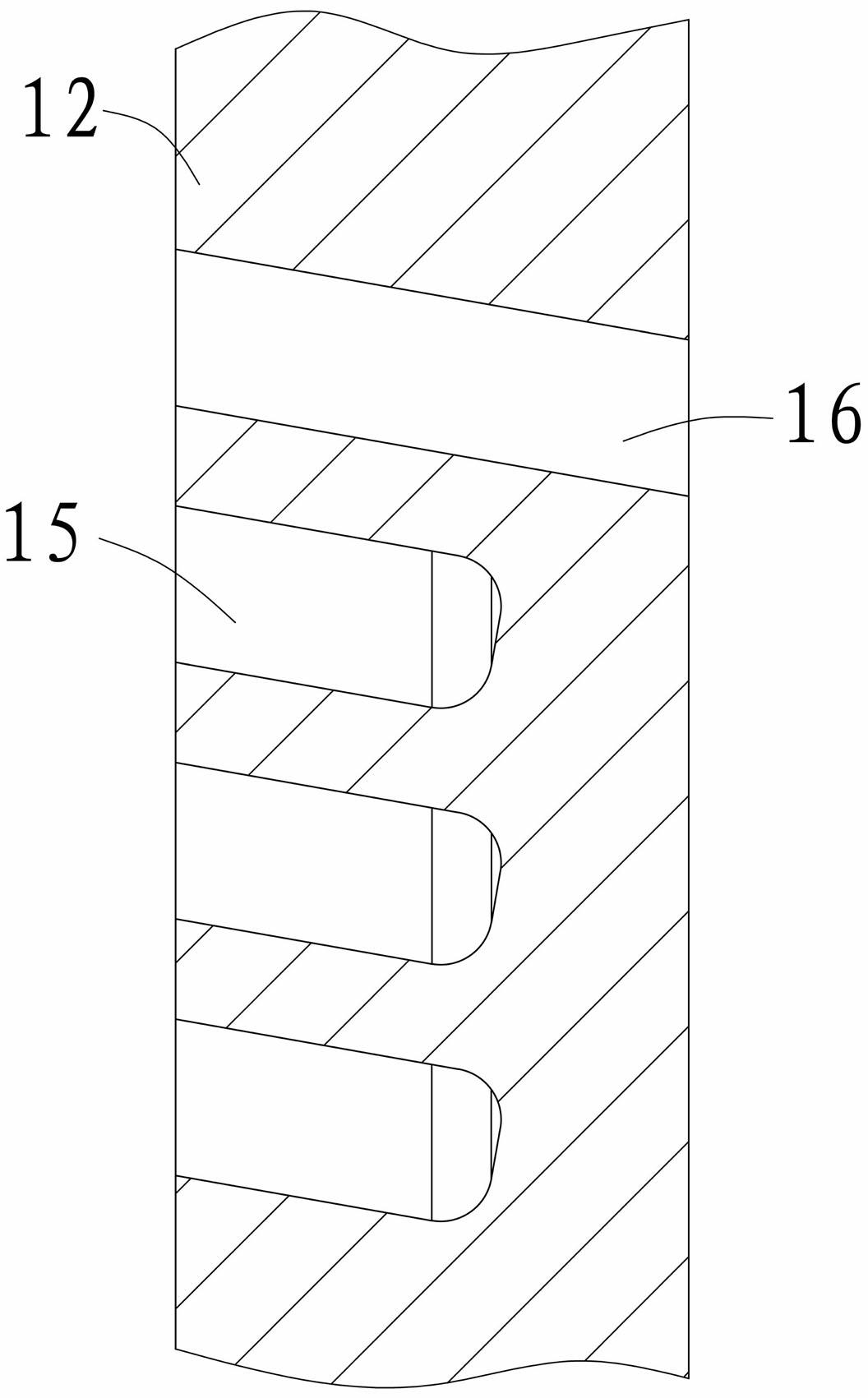

[0029] see Figure 1-8 As shown, the present invention relates to a water balance structure of a machine tool tailstock. A synchronous pulley connection plate (3) is fixedly connected to the clamp (2) of the machine tool tailstock (1). The synchronous pulley connection plate (3) It is connected with the synchronous small pulley (4) connected to the side of the tailstock (1) of the machine tool through the belt (5), and the front cover (6) is connected to the side of the tailstock (1) of the machine tool corresponding to the fixture (2). The belt shell (7) of the tailstock (1) of the machine tool passes through the fixture (2), and is covered on the synchronous pulley connection plate (3) and the small synchronous pulley (4). The synchronous pulley connection plate (3 ) has a mounting groove (8) in the middle, and the cavity formed by the mounting groove (8) and the disc wall (9) is divided into two or more cavities (11) by the rib plate (10). The synchronous pulley connects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com