Ironing and engraving dyeing method

A dyeing method and burn-in technology, applied in the field of burn-in dyeing, can solve the problems of narrow material adaptability, waste of resources, unsatisfactory expressiveness, etc., and achieve significant economic and social benefits, save possible resources, and rich expressiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

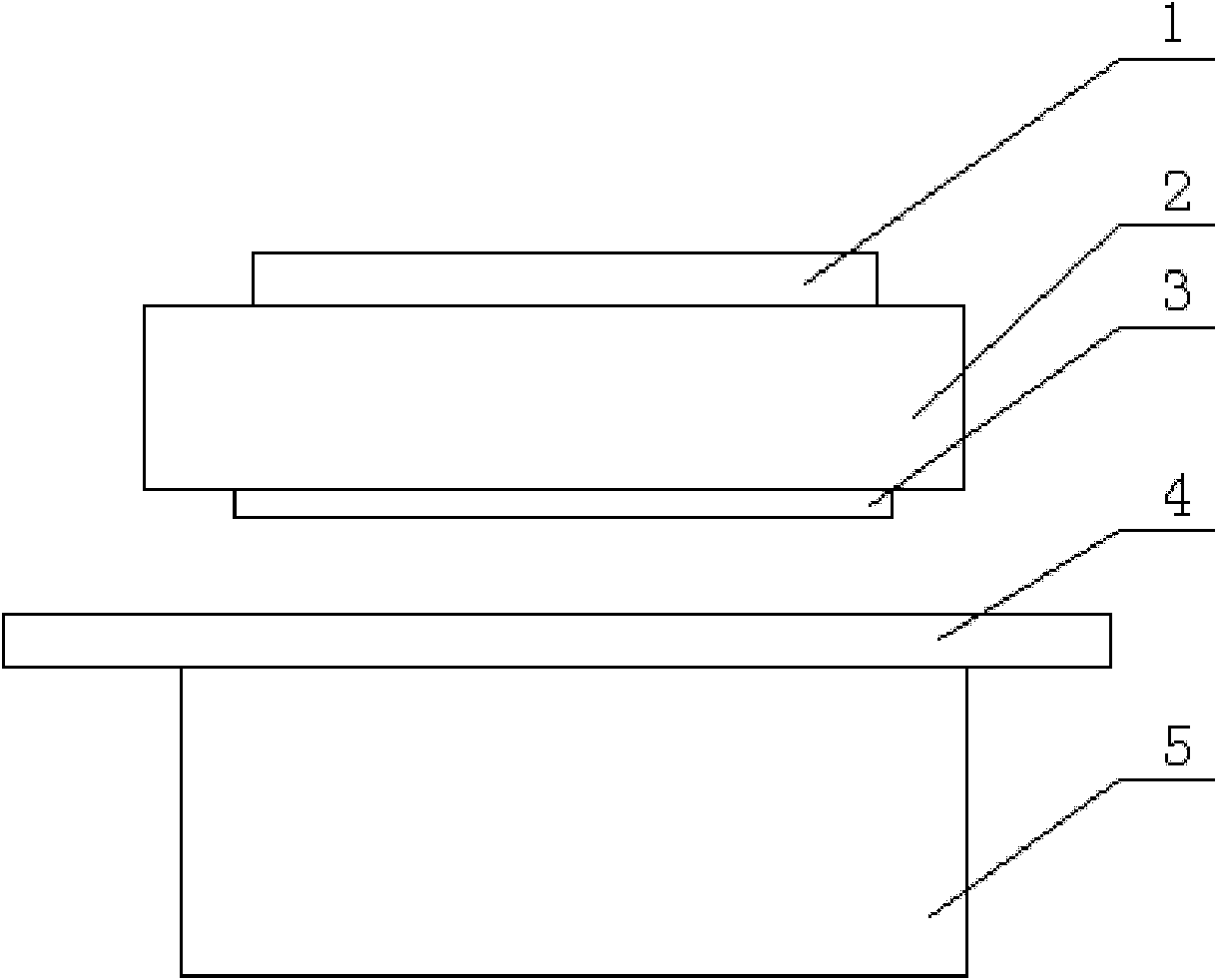

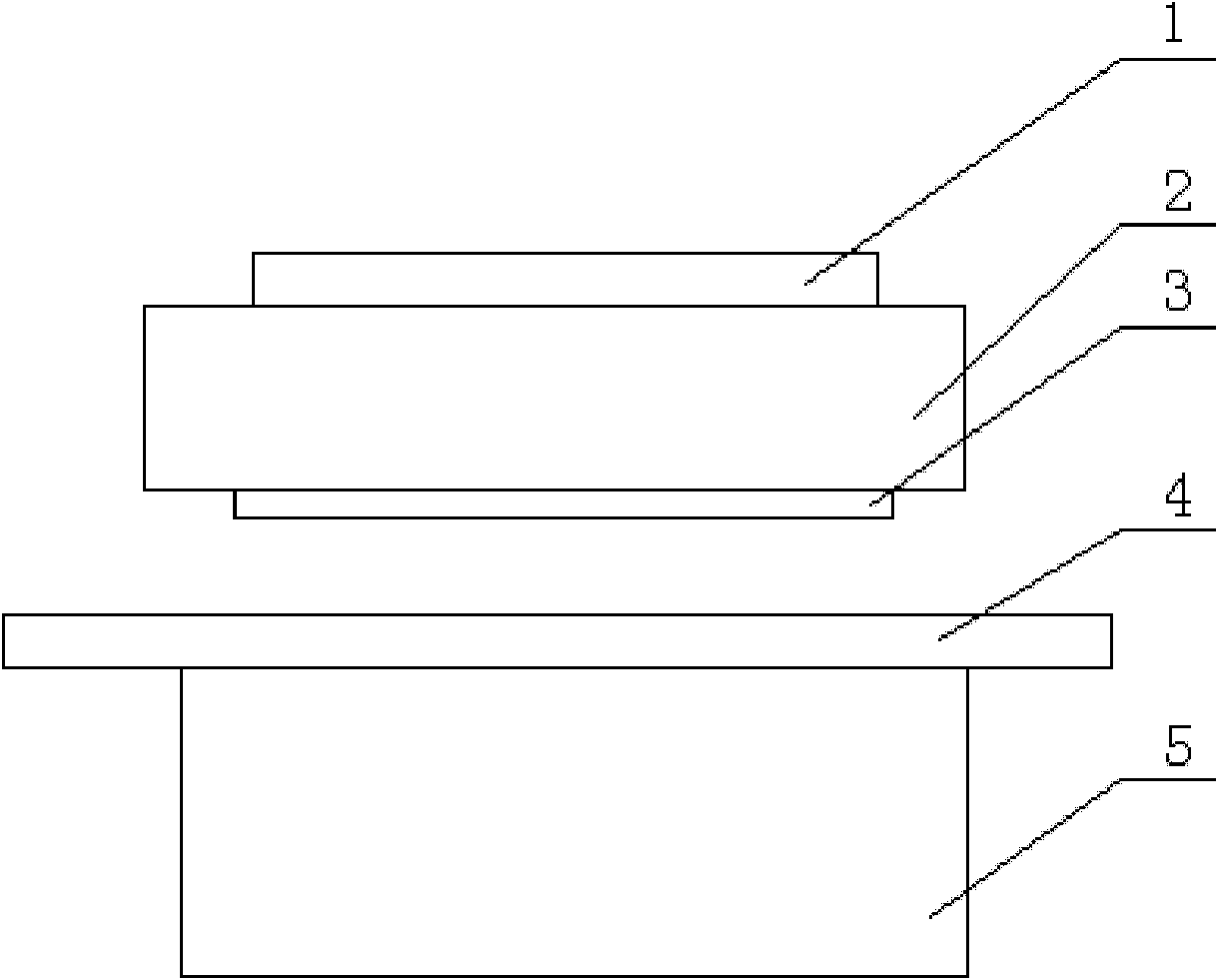

[0017] First of all, various required specifications and shapes are made by etching or engraving, with patterns, characters, and pictures. The materials used include copper, iron, aluminum and other metal materials or pipes.

[0018] The burnt plate of the present invention includes five forms, wherein one is a flat burnt plate, the second is a concave-convex burnt plate, the third is a dot burnt plate, the fourth is a combined burnt plate, and the fifth is a drum type burnt plate.

[0019] A kind of dyeing method of burnt engraving, the steps are:

[0020] (1) plate making process, coloring according to the color pattern of the burnt pattern after plate making;

[0021] (2) Plate loading process;

[0022] (3) Burning process and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com