Patents

Literature

33results about How to "Easy to engrave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

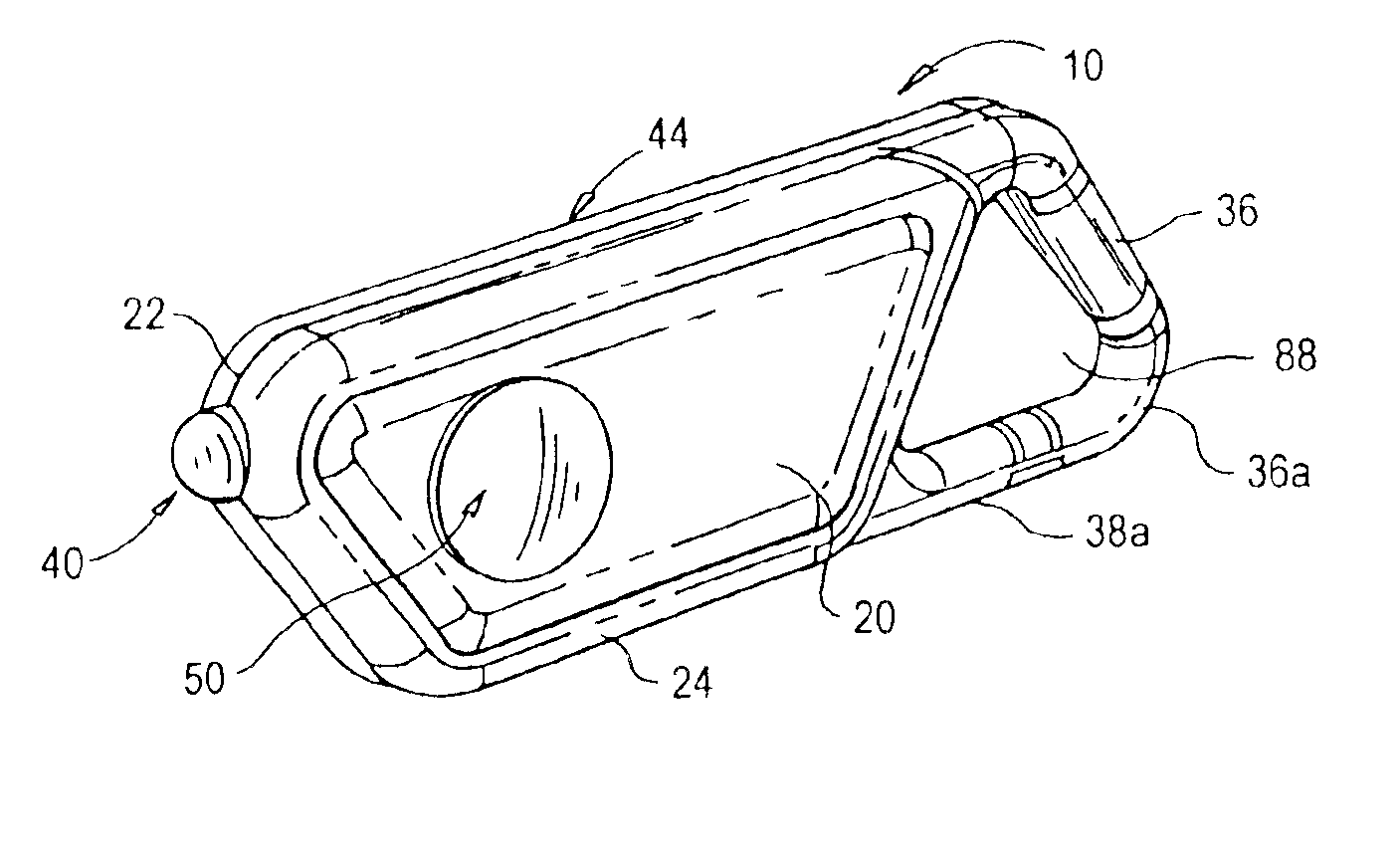

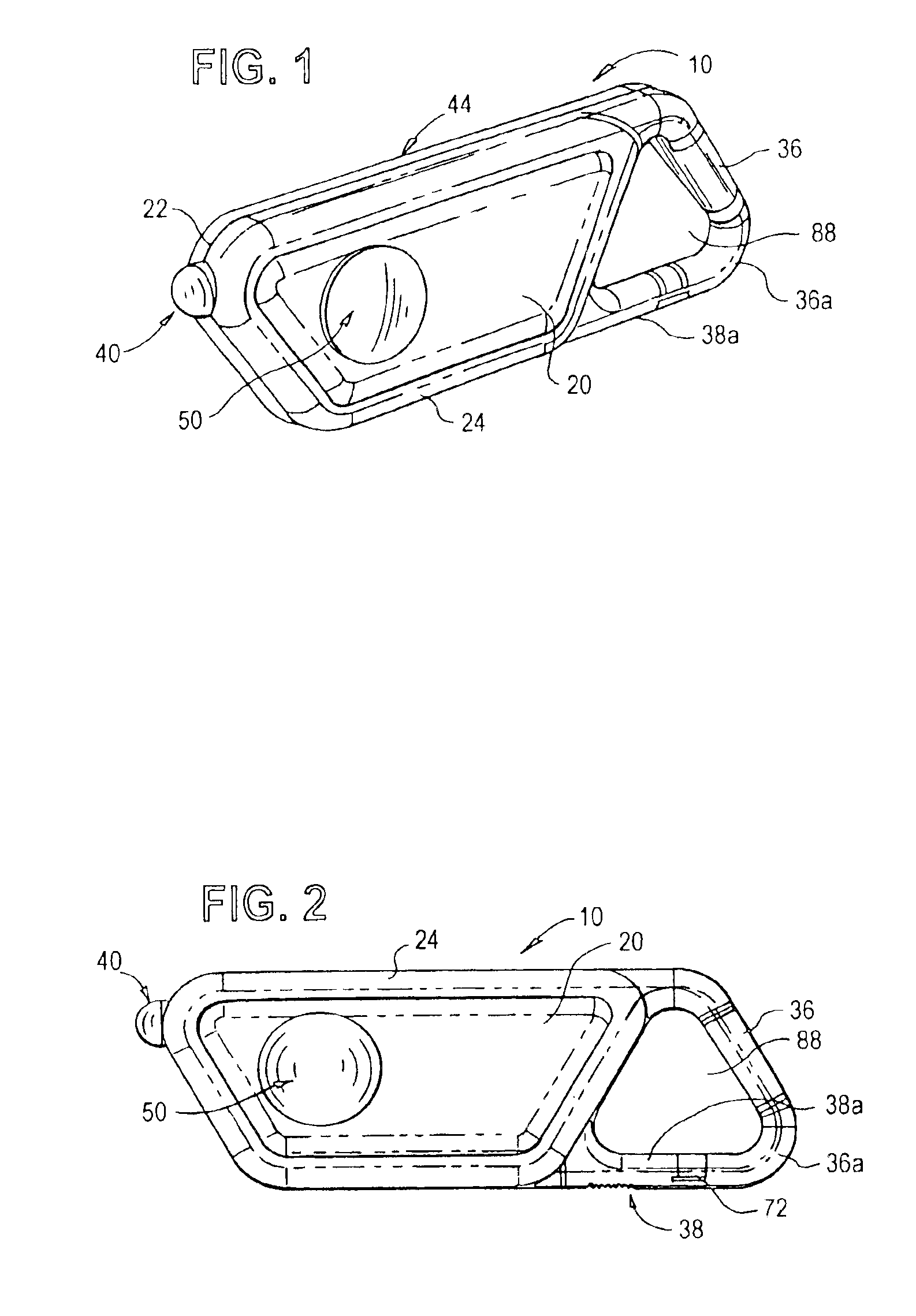

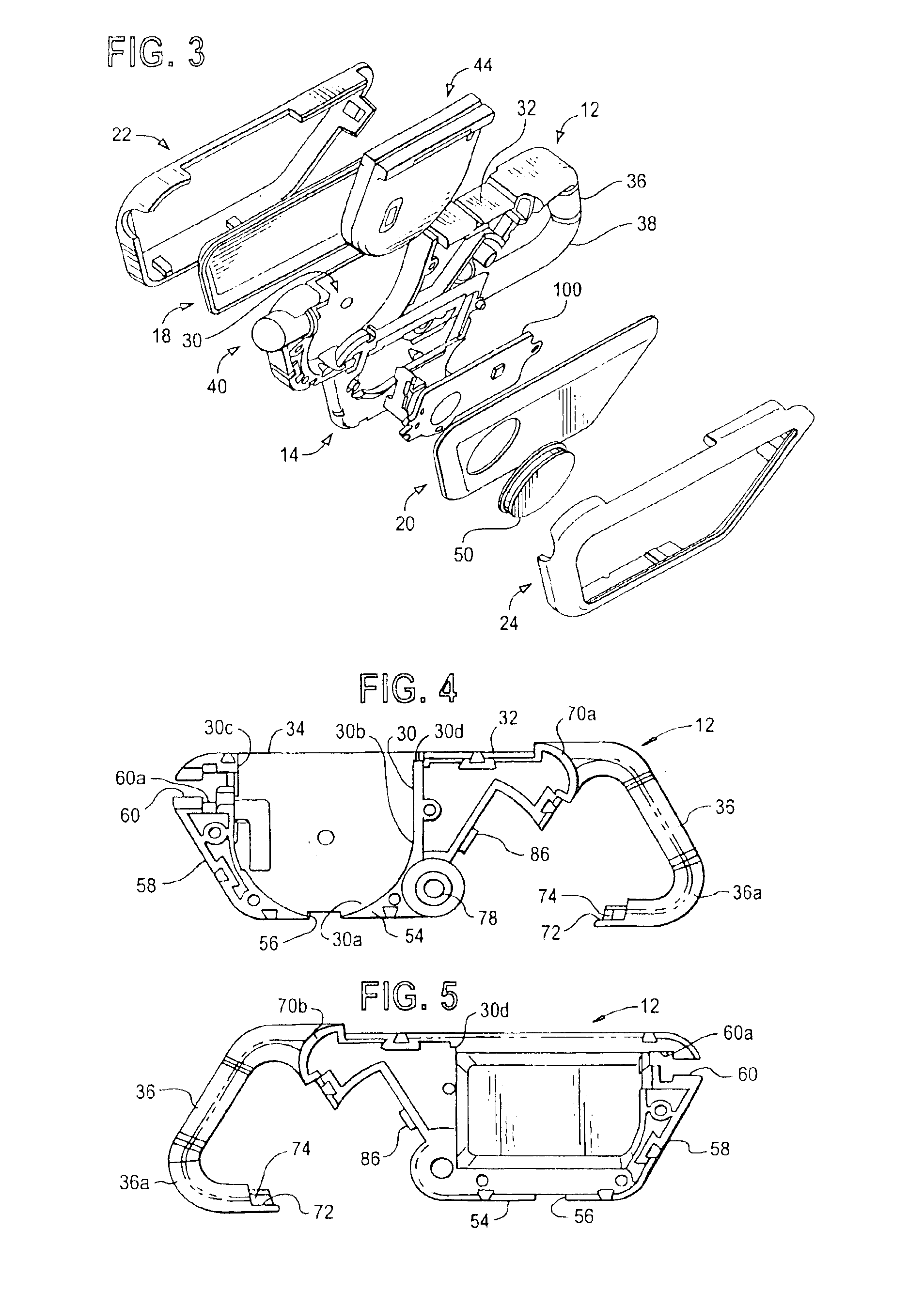

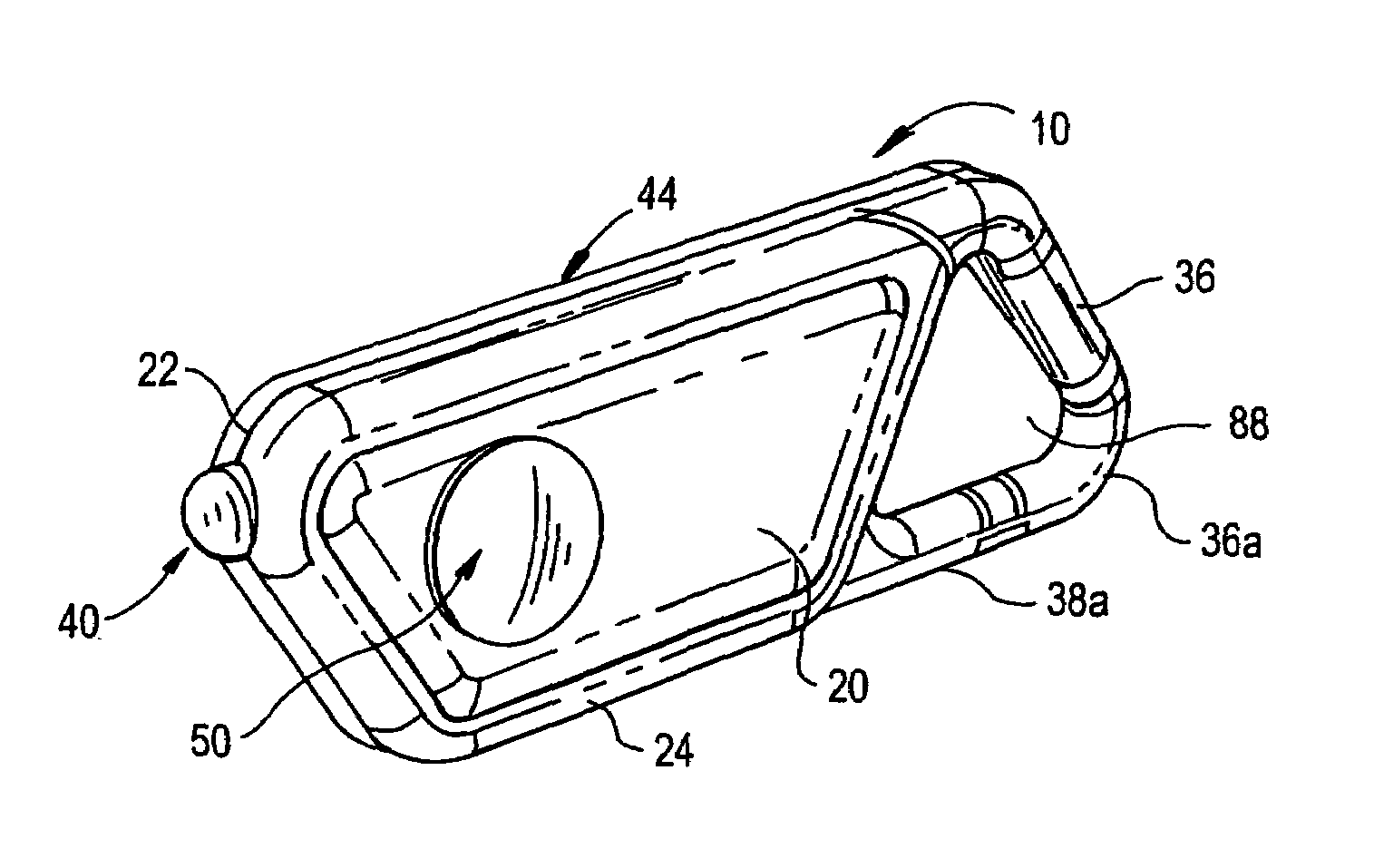

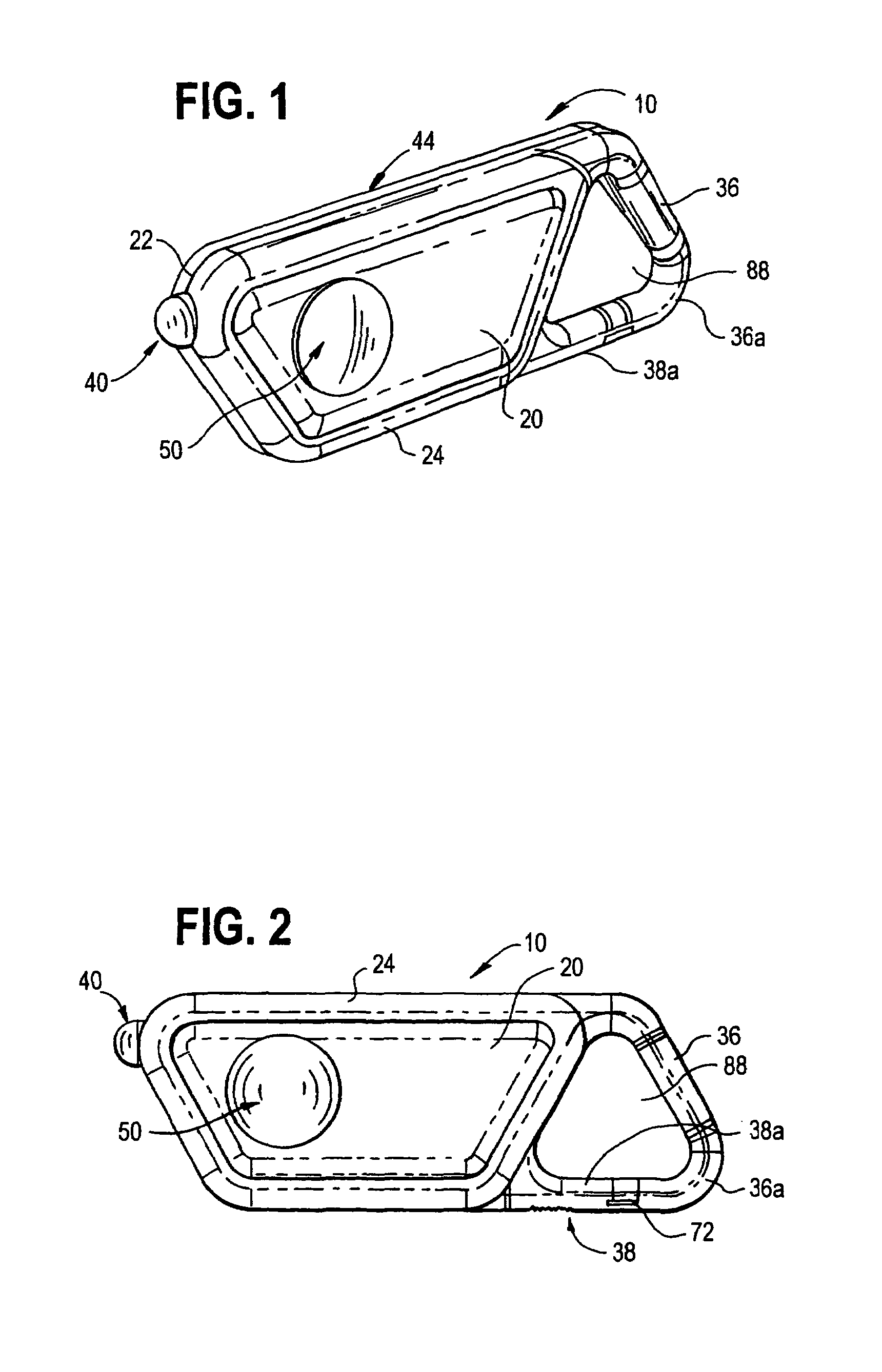

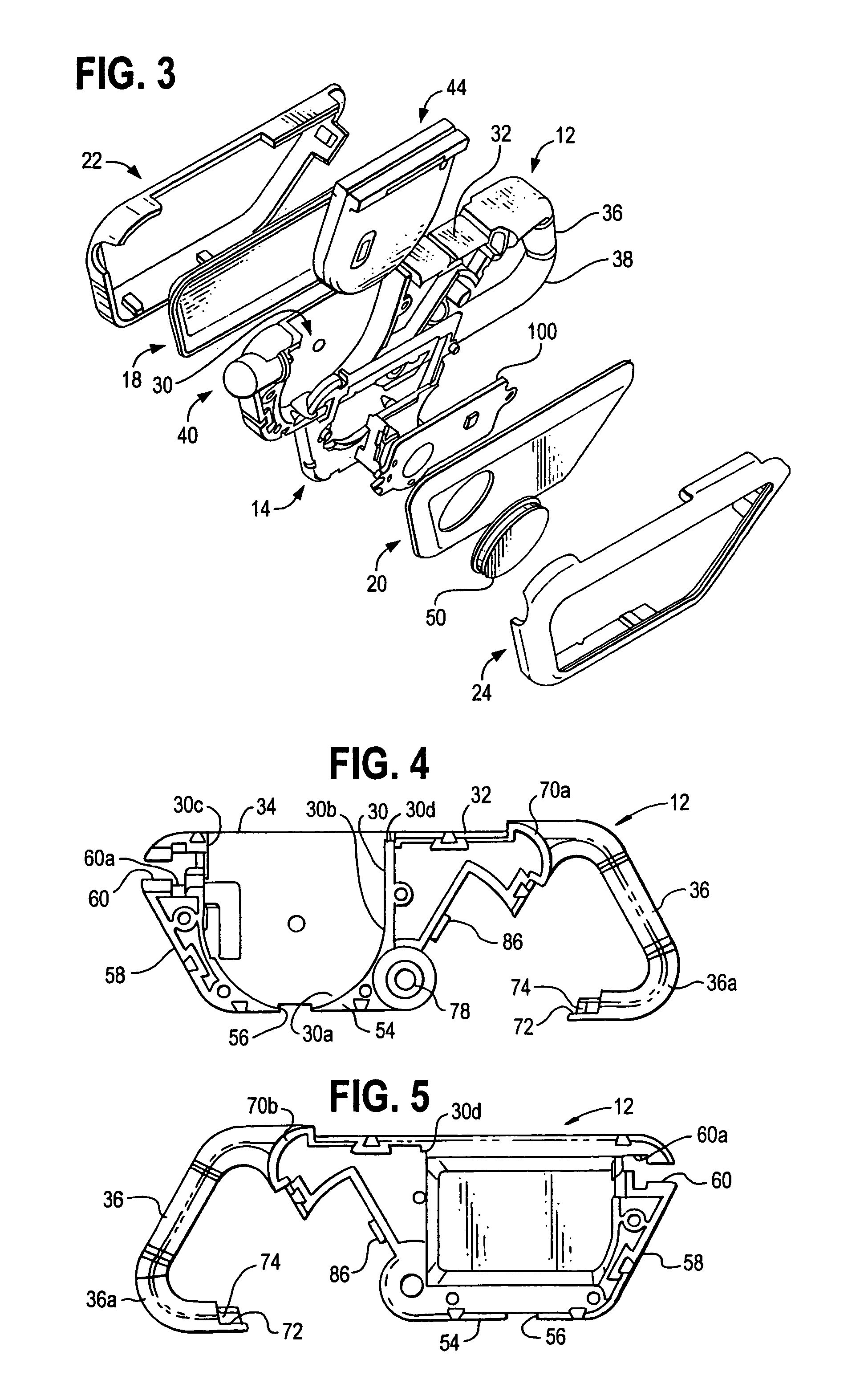

Miniature flashlight having replaceable battery pack and multiple operating modes

InactiveUS6942357B2Easy to engraveImprove protectionPoint-like light sourceTime-programme switchesEngineeringFlashlight

A method and apparatus are provided for operating a flashlight using a light emitting diode as a primary light source. The method includes the steps of activating the light emitting diode as the primary light source of the flashlight under one of a plurality of different operating modes and selecting the operating mode using a momentary contact disposed on an outer surface of the flashlight. In the disclosed embodiments, the flashlight takes the form of a relatively small size, generally flat housing having metallic side panels that may be of various colors and have indicia printed on them. The housing has an integral keyring extension enabling an article to be attached to the flashlight or for the flashlight to be attached to other articles, such as the clothing of a user.

Owner:ARMAMENT SYST & PROCEDURES

Processing technology of surface of copper busbar

The invention belongs to the technical field of copper busbar processing and particularly discloses a processing technology of the surface of a copper busbar. The processing technology comprises the following steps of (1) preparation, (2) powering on, (3) preheating and cleaning of the surface of the copper busbar, (4) lettering processing of the surface of the copper busbar, (5) cooling, (6) completion of lettering processing, and (7) tinplating. According to the processing technology, compared with the prior art, the surface of the copper busbar is subjected to lettering processing, so thatthe copper busbar is easy to distinguish in the using process, and the performance of the copper busbar cannot be affected after processing.

Owner:重庆鸽牌电线电缆有限公司

Miniature flashlight having replaceable battery pack and multiple operating modes

InactiveUS7261433B2Easy to engraveImprove protectionElectrical apparatusPoint-like light sourceLight sourceBattery pack

A method and apparatus are provided for operating a flashlight using a light emitting diode as a primary light source. The method includes the steps of activating the light emitting diode as the primary light source of the flashlight under one of a plurality of different operating modes and selecting the operating mode using a momentary contact disposed on an outer surface of the flashlight. In the disclosed embodiments, the flashlight takes the form of a relatively small size, generally flat housing having metallic side panels that may be of various colors and have indicia printed on them. The housing has an integral keyring extension enabling an article to be attached to the flashlight or for the flashlight to be attached to other articles, such as the clothing of a user.

Owner:ARMAMENT SYST & PROCEDURES

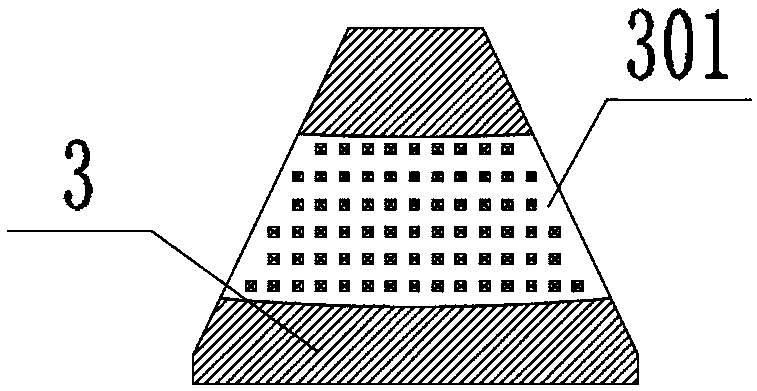

Blank material use for preparing porous decorated porcelain by intermediate-temperature firing and porous decorated porcelain preparing method by intermediate-temperature firing

The invention discloses a blank material use for preparing a porous decorated porcelain by intermediate-temperature firing and a porous decorated porcelain preparing method by intermediate-temperature firing. A synthetic flux is added into the blank material, a composite fluxing function is exerted by combination of a plurality of flux components, and the firing temperature is largely reduced under a circumstance of not increasing the using amount of the flux. The method includes steps of preparing the blank material, moulding by slip casting, sculpturing, making porous patterns, kneading and pasting porcelain patterns, glazing, firing in an oxidation atmosphere having a temperature of 1250-1280 DEG C, performing colored drawing, decorating and roasting at 750-800 DEG C. By tests and research on the synthetic flux, the blank material, glaze, and other formulas, the firing temperature of the porous decorated porcelain is largely reduced, the porous decorated porcelain can be prepared by oxidation and firing at an intermediate temperature of 1250 DEG C, and therefore coloring of all intermediate colorants can be stable, the color of the porous decorated porcelain is largely enriched, and the appearance is more beautiful. The firing temperature is low and the firing period is short. The method saves energy, reduces consumption, and increases the grade of quality of products.

Owner:潮州市广嘉陶瓷制作有限公司

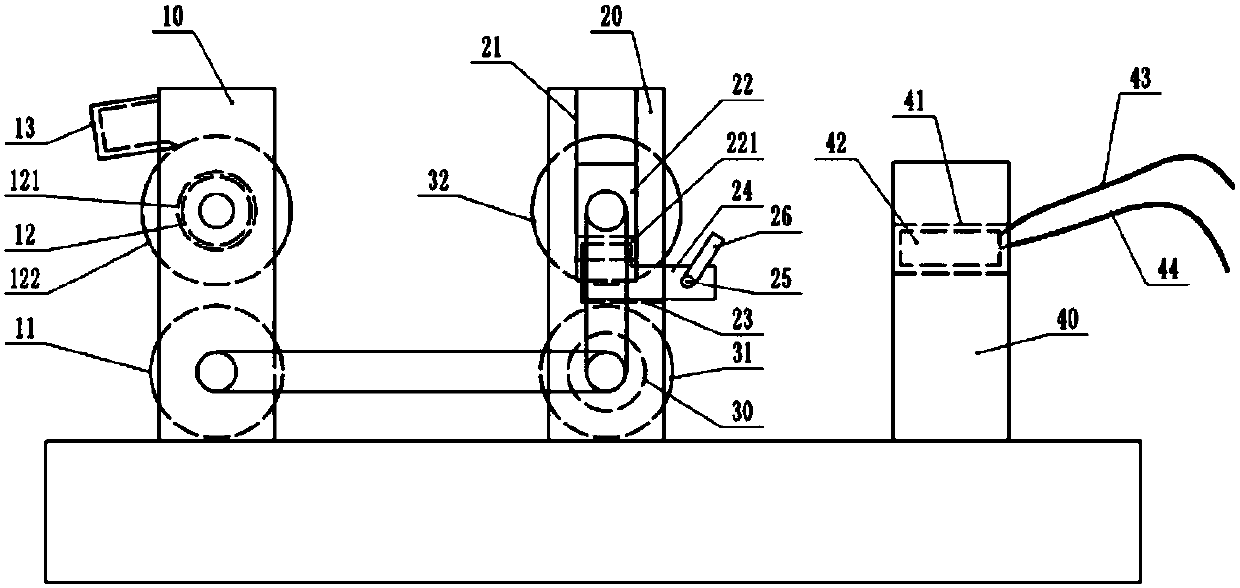

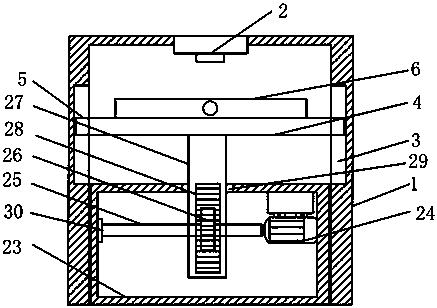

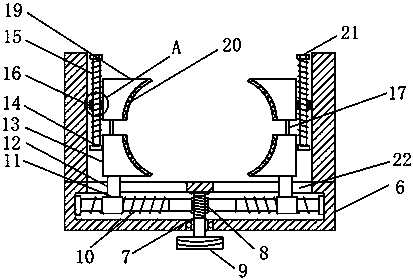

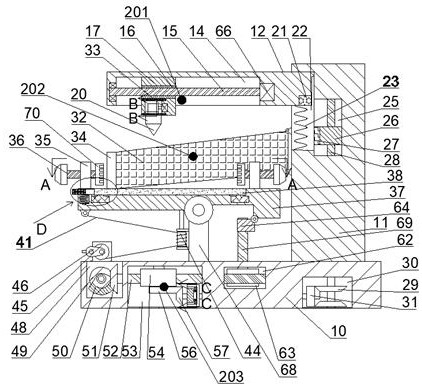

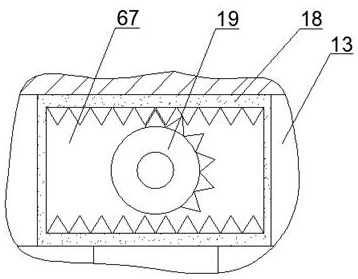

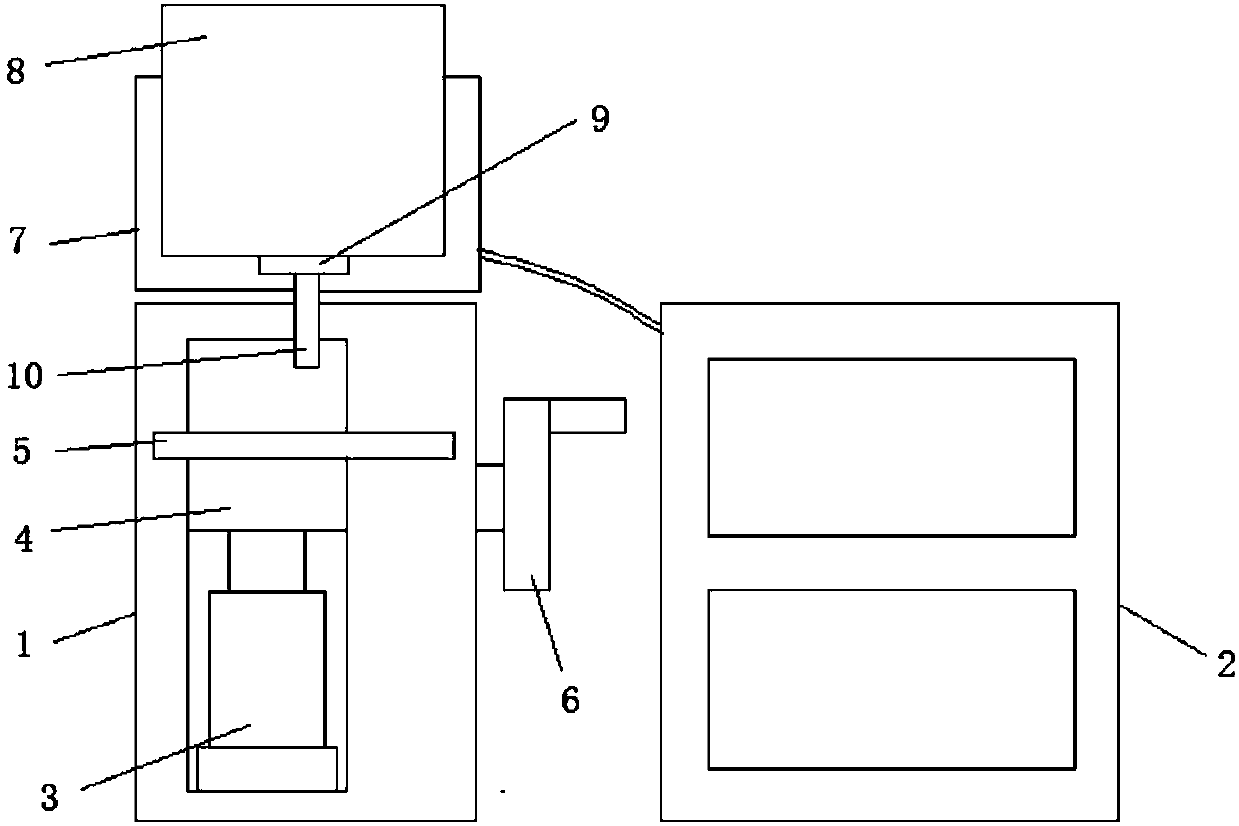

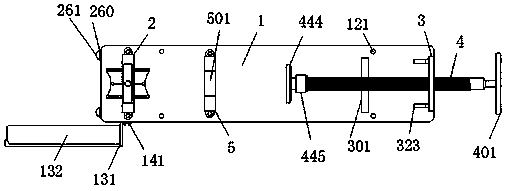

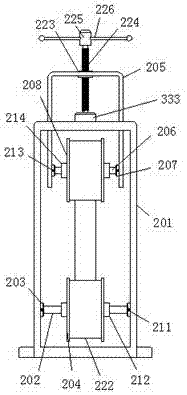

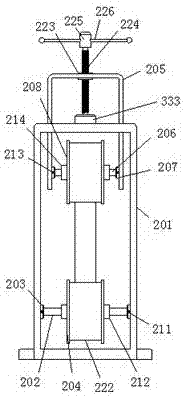

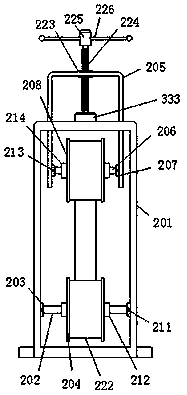

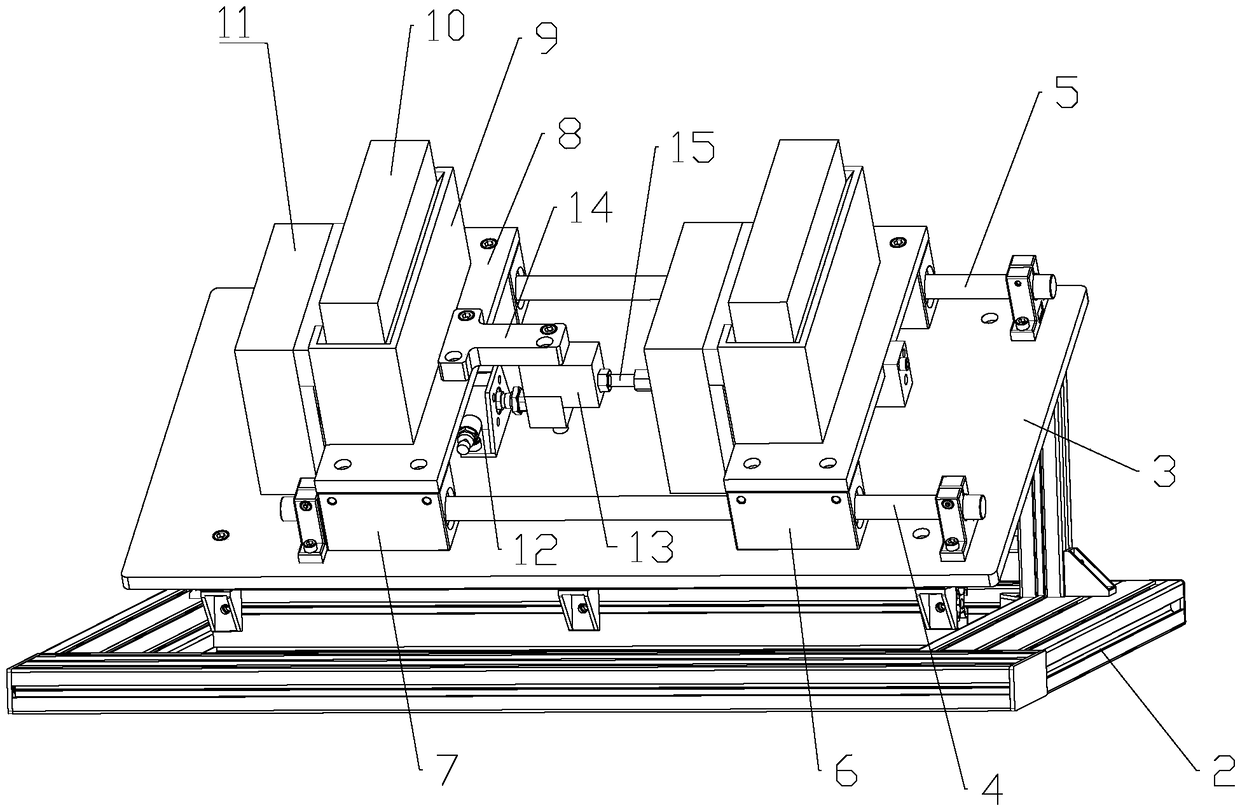

Fixing clamping device for laser engraving machine

InactiveCN110977211AEasy to operateEasy for engravingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryRotational axis

The invention discloses a fixing clamping device for a laser engraving machine. The fixing clamping device includes a machine frame, a clamping box and an adjustment box, a laser engraving head is fixedly connected to the upper part of the machine frame, a worktable is horizontally arranged and slidably installed in the machine frame, the clamping box is fixedly connected to the upper part of theworktable, a worm is rotatably installed inside the clamping box, a first threaded sleeve is fixedly connected to one end of a sliding rod, and one side of a second threaded sleeve is fixedly connected to a second clamping block; and one end of a rotating shaft of a motor is fixedly connected to a rotating rod, one side of a gear is in meshing connection with a rack, and the rack is fixedly connected to one side of a supporting column, and the upper part of the supporting column is fixedly connected to the bottom of the worktable. By arranging the worktable inside the machine frame, arrangingthe clamping box on the upper part of the worktable and arranging the adjustment box at the bottom of the worktable, a workpiece to be engraved can be clamped and fixed, and the height adjustment canbe conveniently carried out.

Owner:芜湖镭科智能科技股份有限公司

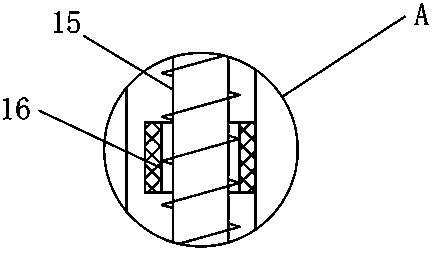

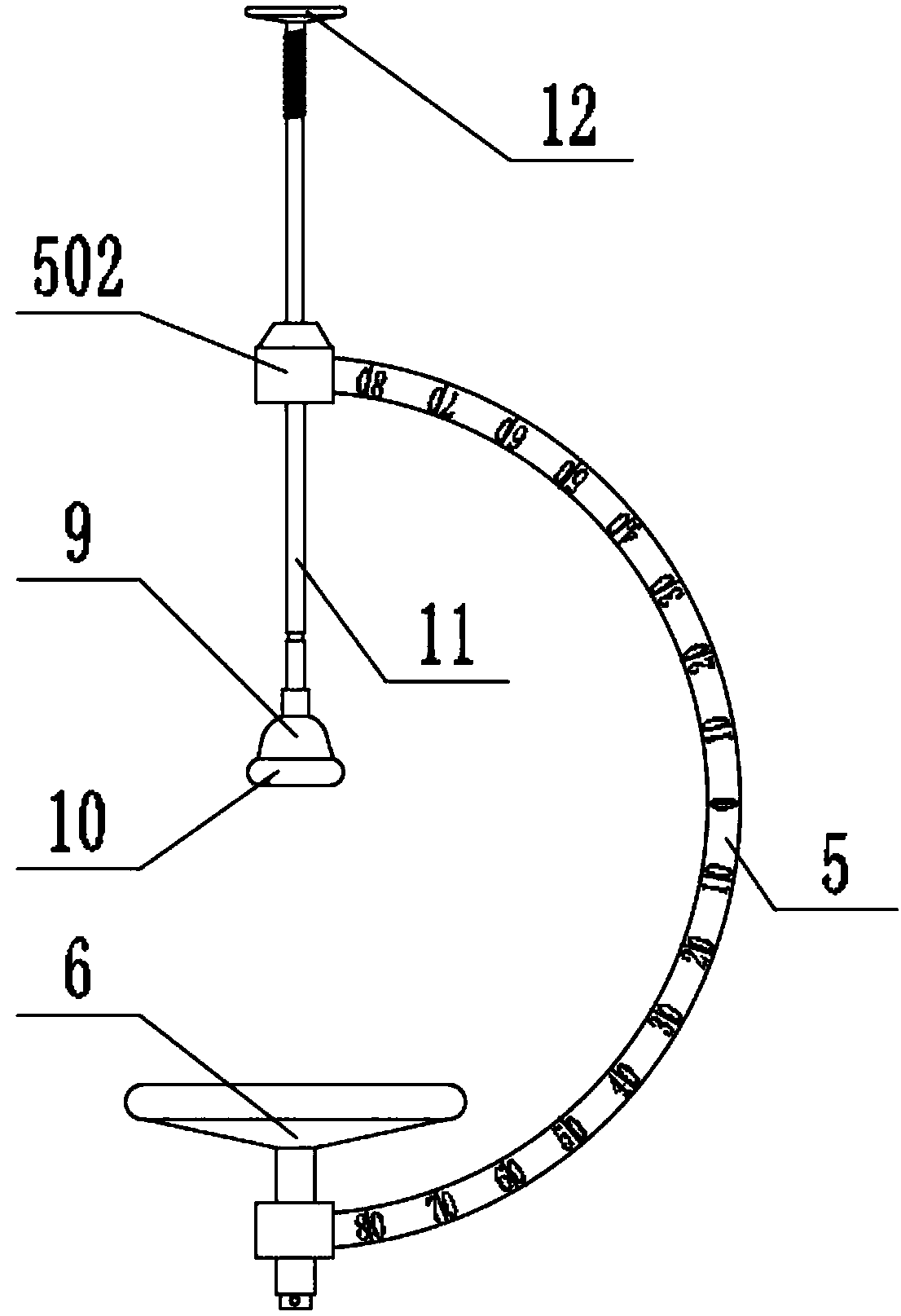

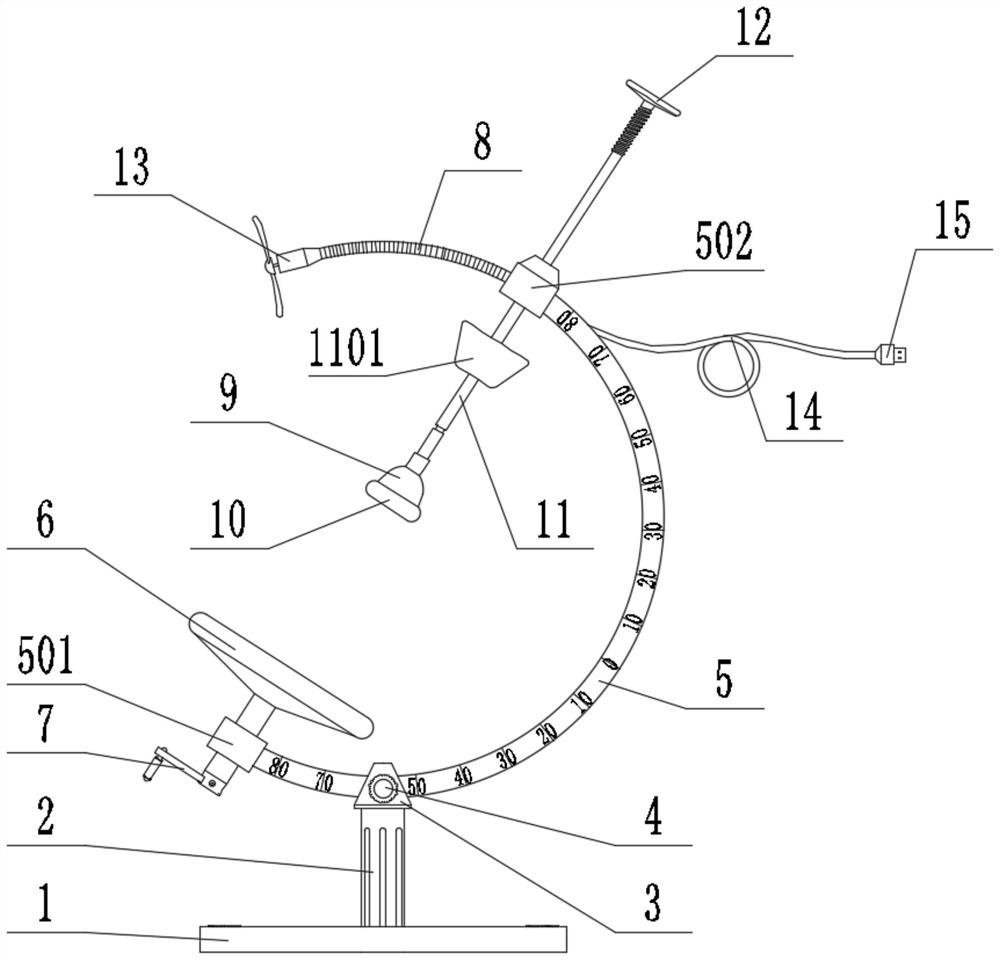

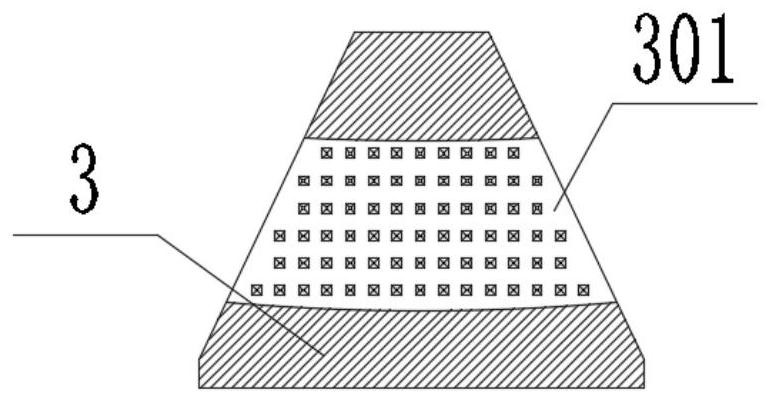

Carving device for ceramic art

ActiveCN108515801AEasy flipEasy to engraveHand artistic toolsOther artistic work equipmentsEngineeringCarving

The invention provides a carving device for ceramic art. The carving device comprises a wire and a power connector, a cylindrical support column is mounted on the top end surface of a base, and the bottom of an angle locking block is mounted on the top end surface of the cylindrical support column. A fixing bolt is mounted on the angle locking block. A sliding strip is of an arc-shaped strip structure, and the sliding strip is externally provided with scales. An upper connecting block is mounted at the top end of the sliding strip, and a lower connecting block is mounted at the lower end of the sliding strip. A rotating handle is mounted at the bottom of a working table through a countersunk hexagonal bolt, and the working table is connected with the lower connecting block. The carving device for the ceramic art is beneficial for turning over a ceramic product placed in the carving device, the end surfaces of the ceramic product can be presented at a better angle in the eyes of a carver, the carving operation on the ceramic product of the carver in the later stage is facilitated, the difficulty of carving is reduced, and the effect of ceramic carving is indirectly improved.

Owner:福建德化博昌陶瓷文化有限公司

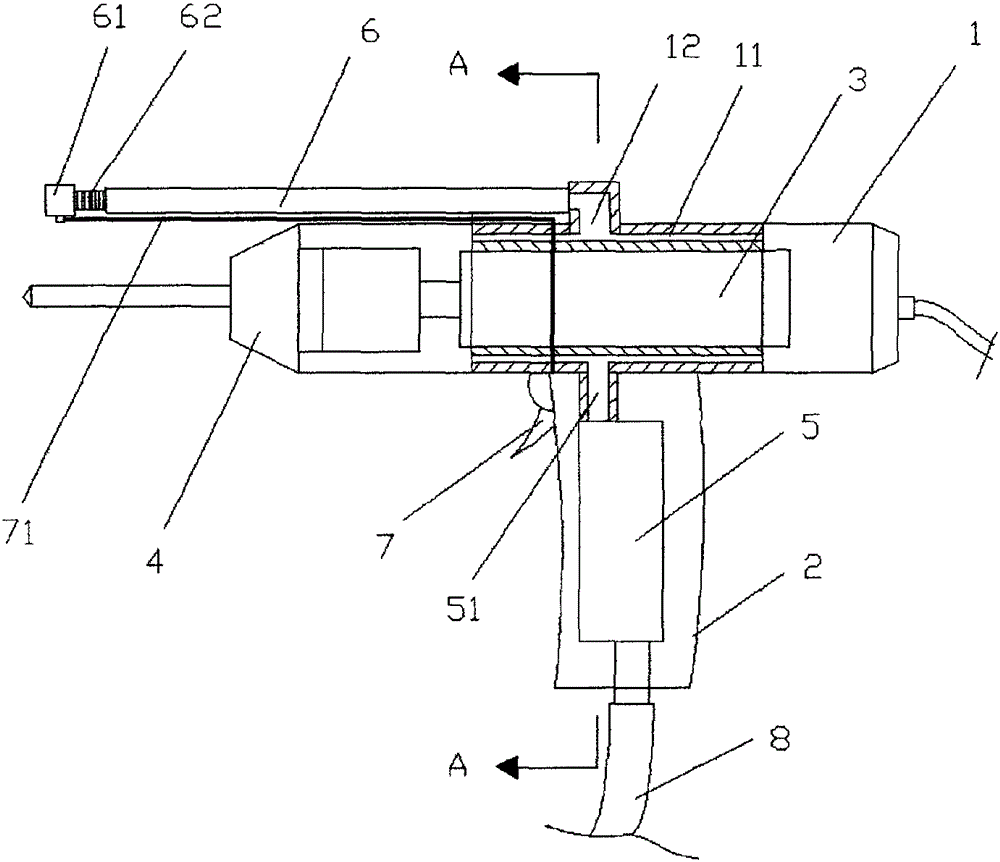

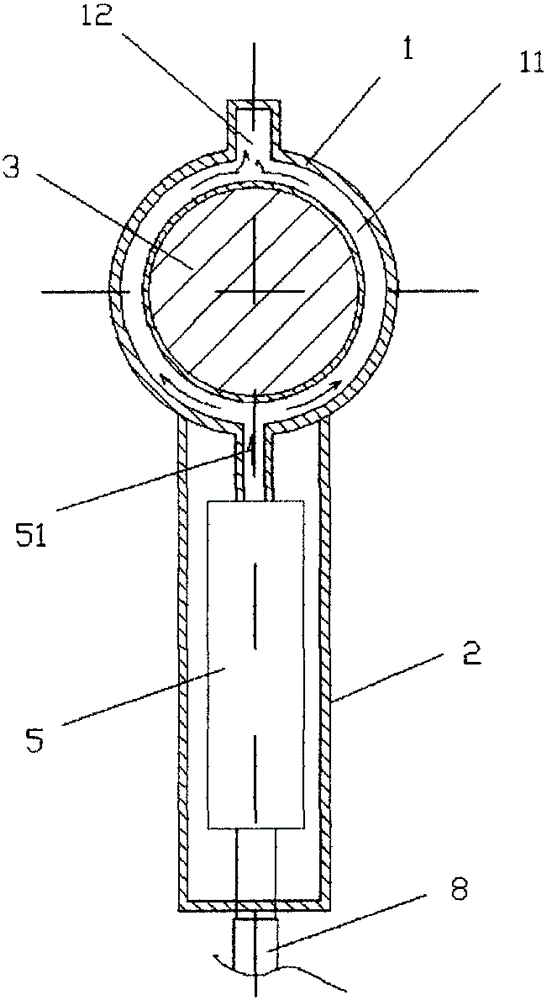

Dustproof multifunctional stone carving device

InactiveCN103253053AFlexibleTo achieve the purpose of dust removalEngravingInlet channelStone carving

A dustproof multifunctional stone carving device comprises a driving portion, a holding portion, a motor and a clamp. The driving portion and the holding portion are connected in a T shape, the motor can drive the clamp, the clamp can fixedly clamp a drill bit, a water pump externally connected with a water pipe is arranged in the holding portion, an annular water cavity is arranged at the periphery of the motor, a cavity body of the water cavity is communicated with a water inlet channel of the water pump and a water outlet channel of a water spraying pipe, a traction cable is connected at the sprayer head position of the water spraying pipe in the lateral direction of the drill bit, the other end of the traction cable is connected with a control key, and the control key can control a water outlet angle of the sprayer head. A bendable water outlet pipe can be connected in a water outlet channel communicated with the water cavity, the water outlet pipe can adjust an angle of the sprayer head at 360 degrees, a water spraying angle of the sprayer head of the water outlet pipe can be mutually bent according to required water spraying directions to spray water on processed portions, and accordingly the purpose of removing dust by spraying water is achieved.

Owner:李玲

Manual clamping dyeing printing plate and preparation method thereof

The invention relates to a manual clamping dyeing printing plate and a preparation method thereof. The manual clamping dyeing printing plate adopts a two-layer overlapping type design and is composedof main printing plate bodies with patterns and auxiliary printing plate bodies with round holes. The application method comprises the following steps of placing fabrics in the manual clamping dyeingprinting plate, fixing and clamping the periphery by using G-shaped clamps and selecting a dye for dyeing. The preparation method comprises the following steps of designing the patterns of the clamping dyeing printing plate, overlaying, aligning and fixing two transparent or semitransparent high-temperature-resistant perspex sheets, and engraving the patterns at a time by using a laser computer engraving machine so so as obtain the two main printing plate bodies with the symmetric patterns; punching two pieces of stainless iron or stainless steel for round holes so as to obtain the two auxiliary printing plate bodies; and pasting the main printing plate bodies on the auxiliary printing plate bodies separately by using glue. The manual clamping dyeing printing plate adopts the two-layer overlapping type design and has the advantages of being flexible, convenient, scientific and reasonable, various dyeing techniques can be applied, and the artistic expressive force of clamping dying canbe enriched. According to the manual clamping dyeing printing plate and the preparation method thereof, clamping dyeing printing plate materials can be obtained conveniently, can be stored easily andcan be engraved conveniently, and therefore various costs can be greatly saved, and the production efficiency can be improved.

Owner:DONGHUA UNIV

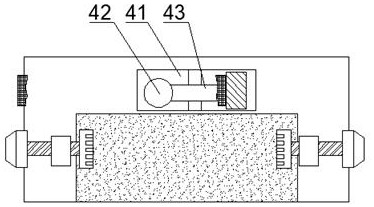

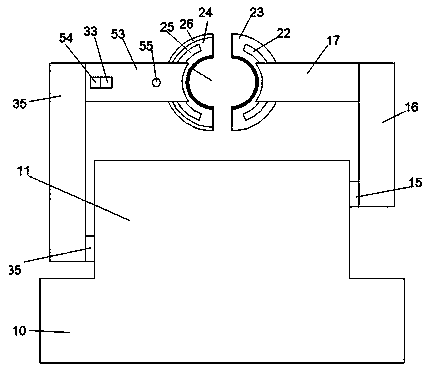

Multi-angle adjustment type metal carving machine

InactiveCN112605475AEasy to replaceEasy to engraveMaintainance and safety accessoriesEngineeringCarving

The invention relates to the technical field of metal carving, in particular to a multi-angle adjustment type metal carving machine which comprises a machine body and a supporting rod fixedly arranged at the upper end of the machine body. An adjusting block used for adjusting the carving angle is hinged to the top end of the supporting rod, fixing blocks which are symmetrical left and right are fixedly arranged at the upper end of the adjusting block, screws which are symmetrical left and right are in threaded fit connection with the interiors of the fixing blocks, and clamping blocks are fixedly arranged at the tail ends of the screws. According to the multi-angle adjustment type metal carving machine, a to-be-carved part is separated from a human body through a transparent net, angle adjustment is conducted through an adjusting device after the to-be-carved part is placed, meanwhile, distance contraction adjustment of the transparent net is conducted along with the angle of the to-be-carved part, the moving distance range of a carving knife on the upper side is changed along with the rotation of the to-be-carved part to facilitate carving, and in the carving process, a damping plate convenient to replace at any time is arranged on the adjusting block where the to-be-carved part is placed.

Owner:曲周县京利信贸易有限公司

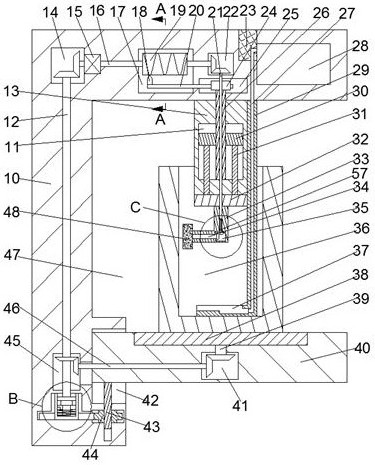

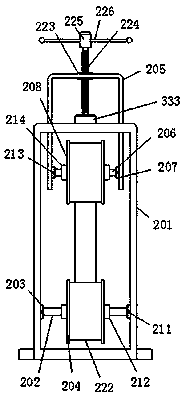

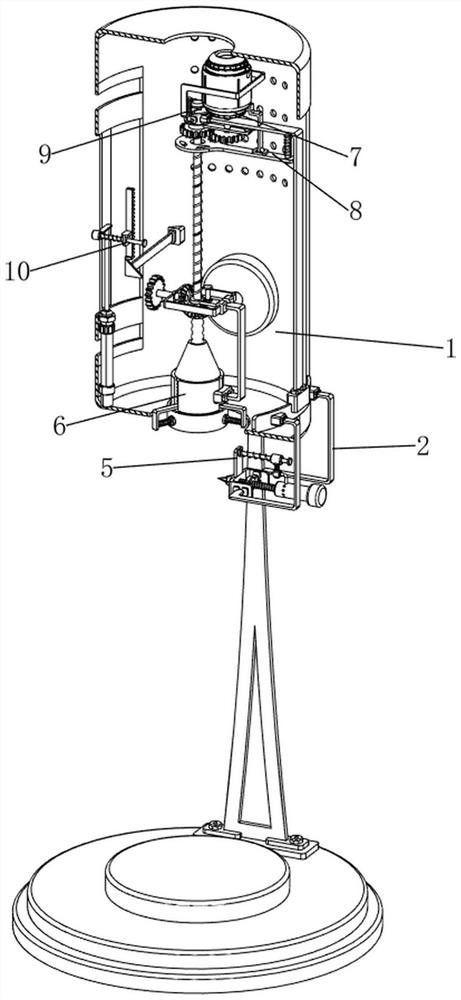

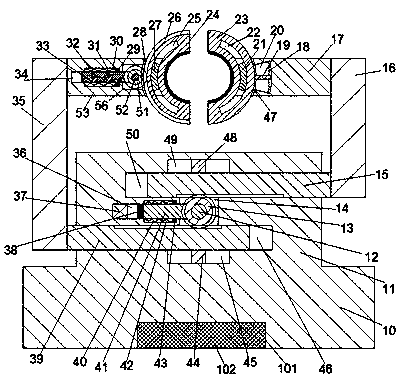

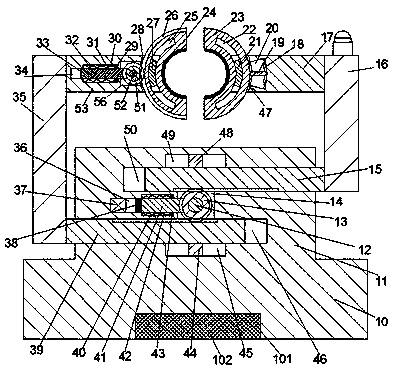

Precious wood cup body inner wall engraving and grinding device

InactiveCN111604725AReduce wasteIncrease profitGrinding carriagesRevolution surface grinding machinesMaterials scienceCarving

The invention discloses a precious wood cup body inner wall engraving and grinding device. The precious wood cup body inner wall engraving and grinding device comprises a machine body, a working cavity with a rightward opening and a forward opening is formed in the machine body, a lifting cavity with a rightward opening is formed in the lower side of the left end wall of the working cavity, a lifting device is arranged in the lifting cavity, a rotary driving cavity with a part of an opening facing rightwards is formed in the left side of the lifting cavity, a connecting cavity located below the lifting cavity is formed in the lower side of the rotary driving cavity. According to the precious wood cup body inner wall engraving and grinding device, ground wood chippings can be collected at the first time, and therefore waste of precious wood is reduced to the minimum, and the collected wood chippings can be further reused, so that the utilization rate of the precious wood is increased, meanwhile, the inner wall of the wood can be completely polished to be flat in a short time, subsequent engraving operation on the inner wall is facilitated, and meanwhile the overall engraving efficiency is improved.

Owner:宁波辣生科技有限公司

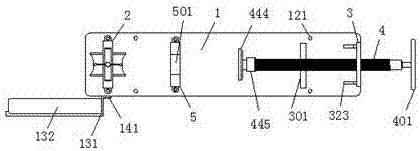

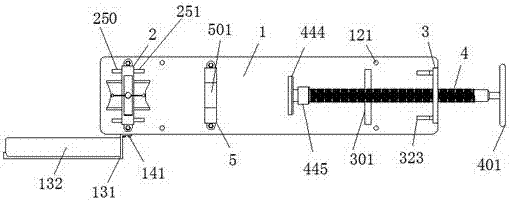

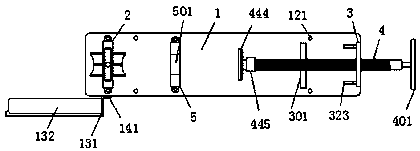

Numerical control carving machine

InactiveCN107599709AImprove engraving accuracyEasy to operateModel makingEngravingDrill bitEngineering

The invention discloses a numerical control carving machine which comprises a base and a PLC controller, wherein a telescopic device is arranged at the lower end of the base and is fixed with the base; a sliding block is arranged above the telescopic device; a working table is arranged above the sliding block; a hand wheel is arranged on the right side of the base; a carving module is arranged above the base; a carving machine body is arranged on the carving module; a drill bit is arranged at the lower end of the carving machine body; a blade is arranged at the lower end of the drill bit; andthe PLC controller is positioned on the right side of the base. The numerical control carving machine has the advantages of being stable in structure, high in working efficiency, carving in an intelligent numerical control manner and precise in carving.

Owner:合肥瑞虎机电设备有限公司

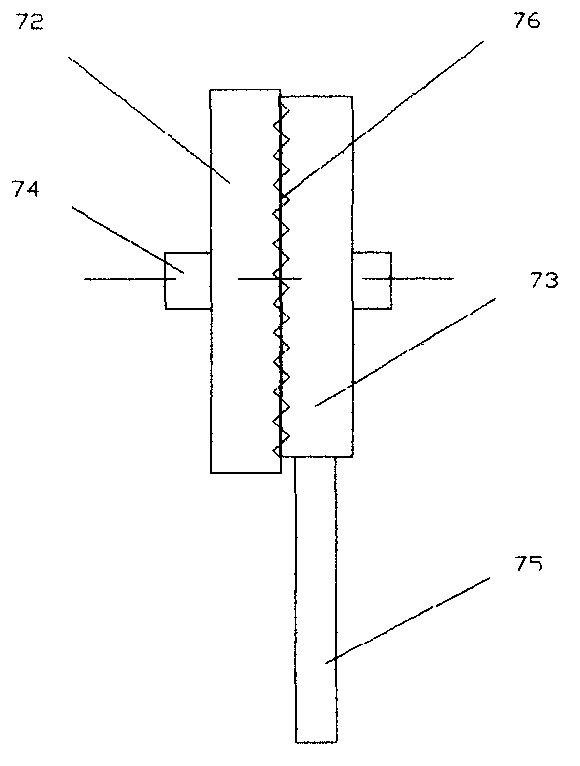

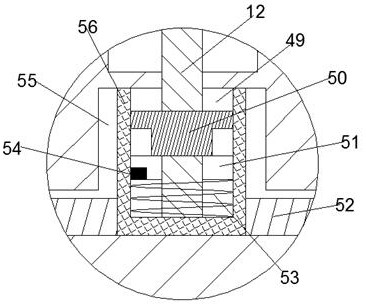

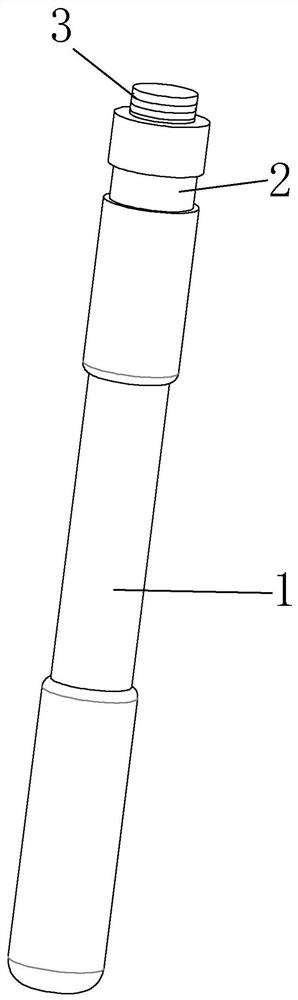

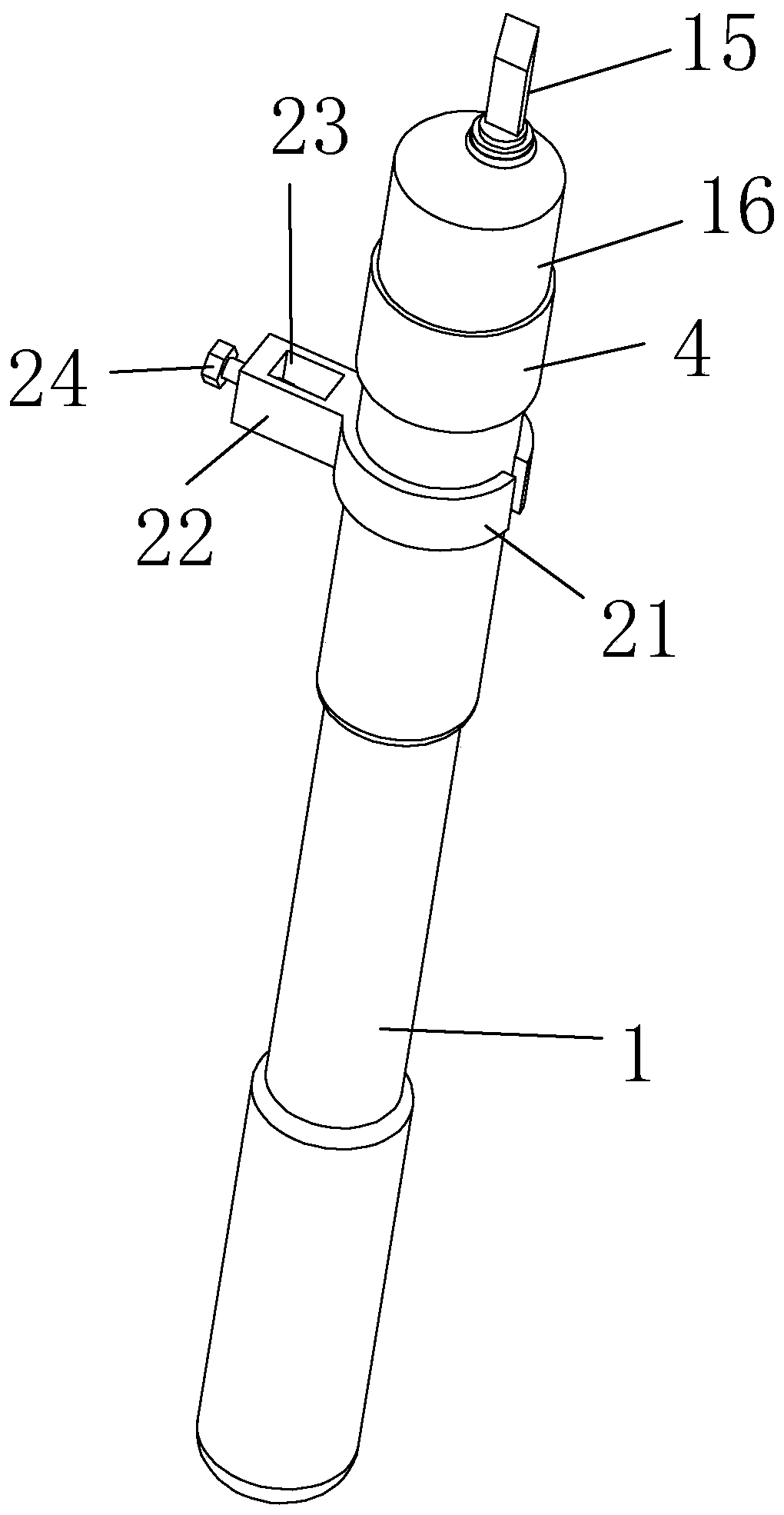

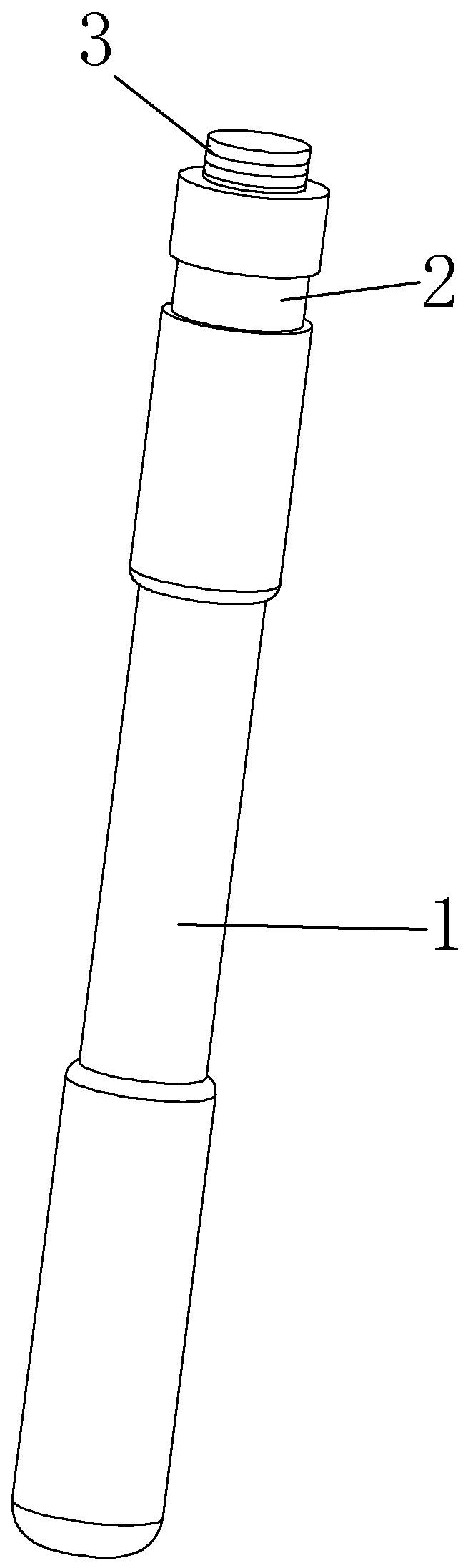

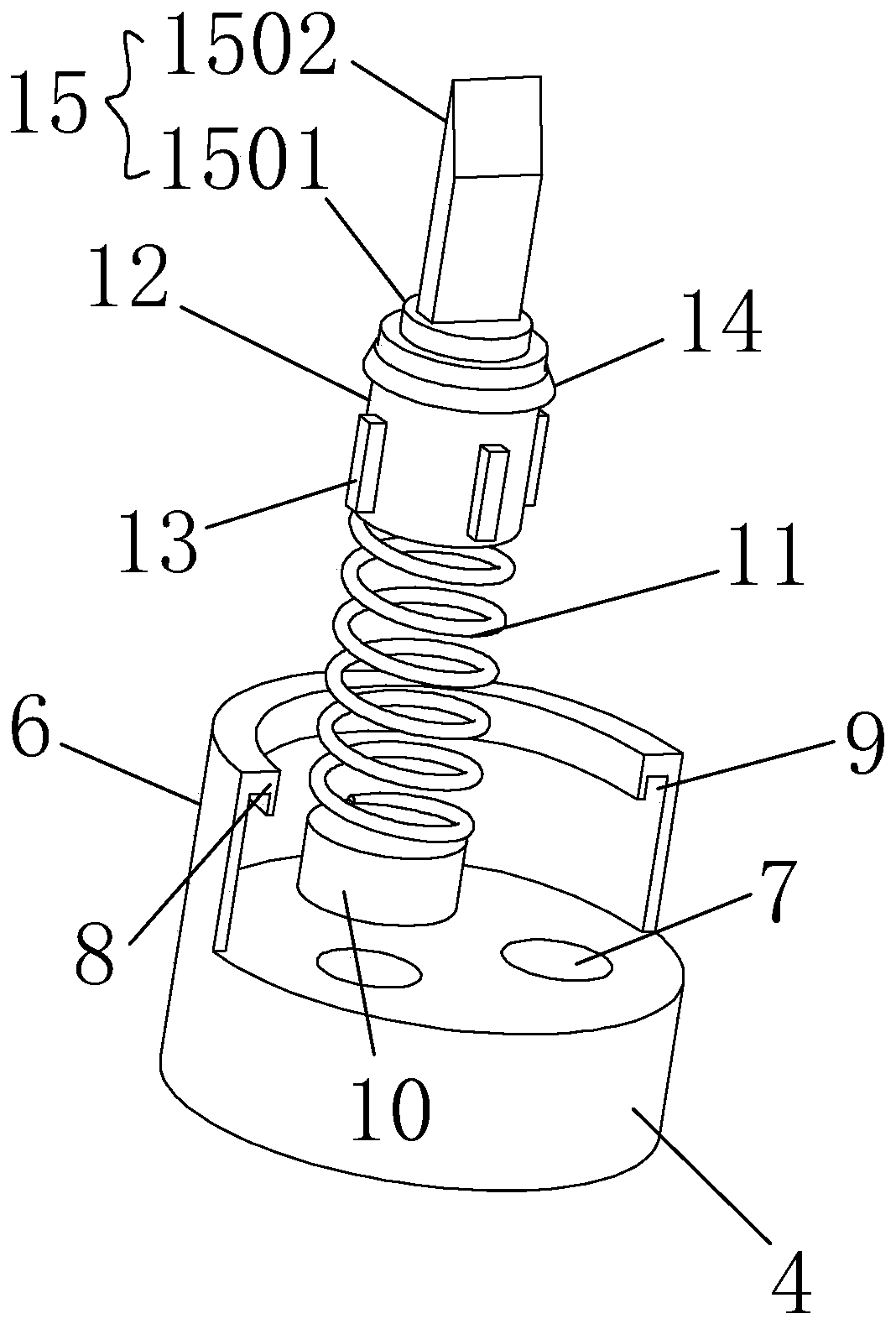

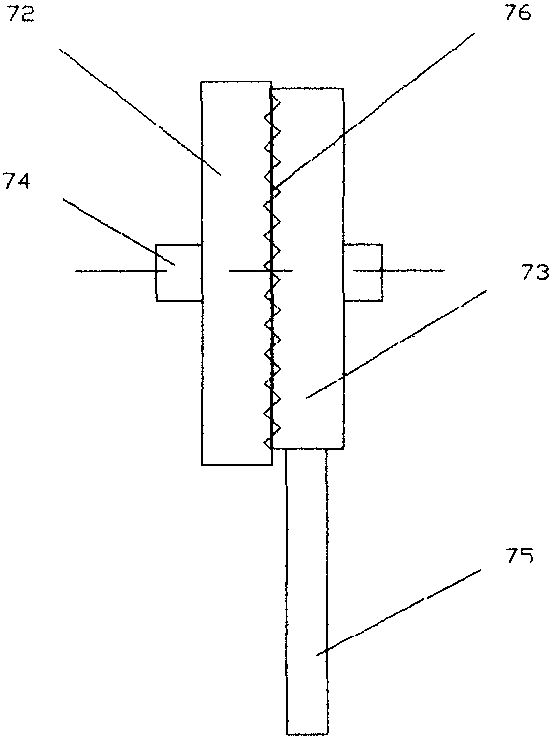

A kind of artistic sculpture carving knife with multiple knives in one

ActiveCN110039934BShorten the timeGuaranteed cutHand artistic toolsScrew threadIndustrial engineering

The invention relates to the technical field of carving tools, in particular to an artwork graver integrated with multiple tools. The artwork graver comprises a graver handle, and the center of the tail end of one side of the graver handle is provided with a cylindrical base through a thread; the surface of the tail end of the side, away from the graver handle, of the cylindrical base is fixedly provided with a lower sleeve; an upper sleeve is clamped into the lower sleeve, and the position, at the bottom of the interior of the lower sleeve, of the surface of the cylindrical base is provided with three uniformly-distributed threaded installation grooves in the circumferential direction; first connection columns are installed in the threaded installation grooves through threads, and springsare fixedly welded to the tail ends of the sides, away from the cylindrical base, of the first connection columns; second connection columns are welded to the tail ends of the sides, away from the first connection columns, of the springs; the tools are fixedly installed at the tail ends of the sides, away from the springs, of the second connection columns through threads, and conical limiting rings are fixedly arranged on the surfaces of the sides, close to the tools, of the second connection columns in the circumferential direction; and the surface of the tail end of the side, away from thelower sleeve, of the upper sleeve is provided with a cylindrical hole. The artwork graver has the advantages of being simple in structure and convenient to use.

Owner:温州亨嘉文化传媒有限公司

Improved metal carving device

InactiveCN108189602ASafe and stable clampingEasy to processOther artistic work equipmentsModel makingEngineeringSlide plate

The invention discloses an improved metal carving device. The improved metal carving device comprises a table plate, wherein a positioning and clamping device is arranged at a position close to the left side of the top of the table plate; a vertical plate is arranged on the right side of the top of the table plate; a screw hole is formed in the vertical plate; a first screw rod is matched with theinside of the screw hole; a first rotating handle is arranged at the right end of the first screw rod; a pushing and sliding plate is arranged at the left end of the first screw rod; a balancing plate is fixedly mounted between the pushing and sliding plate and the vertical plate at the top of the table plate; the first screw rod passes through the balancing plate is in fit connection with the balancing plate; a propping plate is arranged between the positioning and clamping device and the vertical plate at the top of the table plate; a first placing cavity used for supporting metal parts isformed in the top of the propping plate. The whole structure of the device is relatively simple; through cooperation of a first clamping wheel and a second clamping wheel, the metal parts can be clamped and fixed.

Owner:FOSHAN SAIWEI LAITE INTELLIGENT EQUIP CO LTD

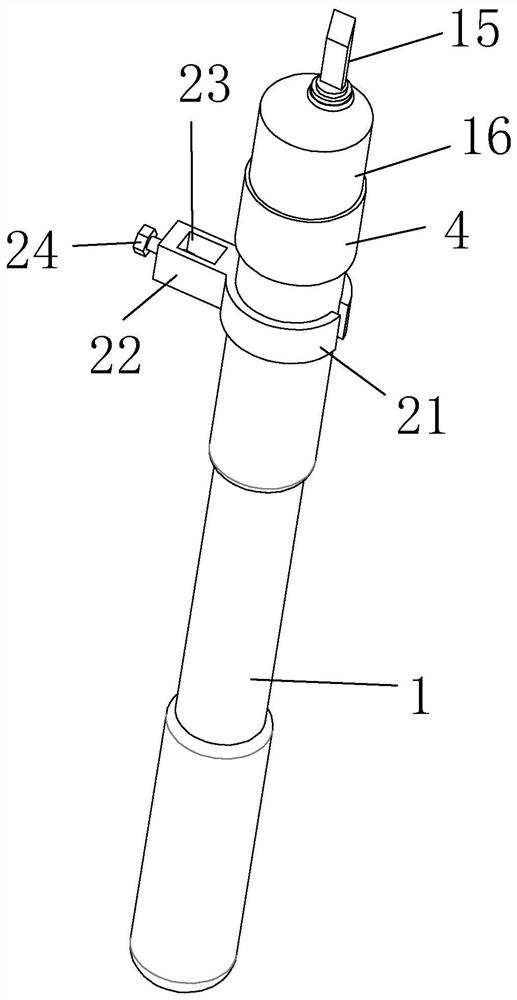

Artwork graver integrated with multiple tools

ActiveCN110039934AEngraving work is stableShorten the timeHand artistic toolsEngineeringKnife handles

The invention relates to the technical field of carving tools, in particular to an artwork graver integrated with multiple tools. The artwork graver comprises a graver handle, and the center of the tail end of one side of the graver handle is provided with a cylindrical base through a thread; the surface of the tail end of the side, away from the graver handle, of the cylindrical base is fixedly provided with a lower sleeve; an upper sleeve is clamped into the lower sleeve, and the position, at the bottom of the interior of the lower sleeve, of the surface of the cylindrical base is provided with three uniformly-distributed threaded installation grooves in the circumferential direction; first connection columns are installed in the threaded installation grooves through threads, and springsare fixedly welded to the tail ends of the sides, away from the cylindrical base, of the first connection columns; second connection columns are welded to the tail ends of the sides, away from the first connection columns, of the springs; the tools are fixedly installed at the tail ends of the sides, away from the springs, of the second connection columns through threads, and conical limiting rings are fixedly arranged on the surfaces of the sides, close to the tools, of the second connection columns in the circumferential direction; and the surface of the tail end of the side, away from thelower sleeve, of the upper sleeve is provided with a cylindrical hole. The artwork graver has the advantages of being simple in structure and convenient to use.

Owner:温州亨嘉文化传媒有限公司

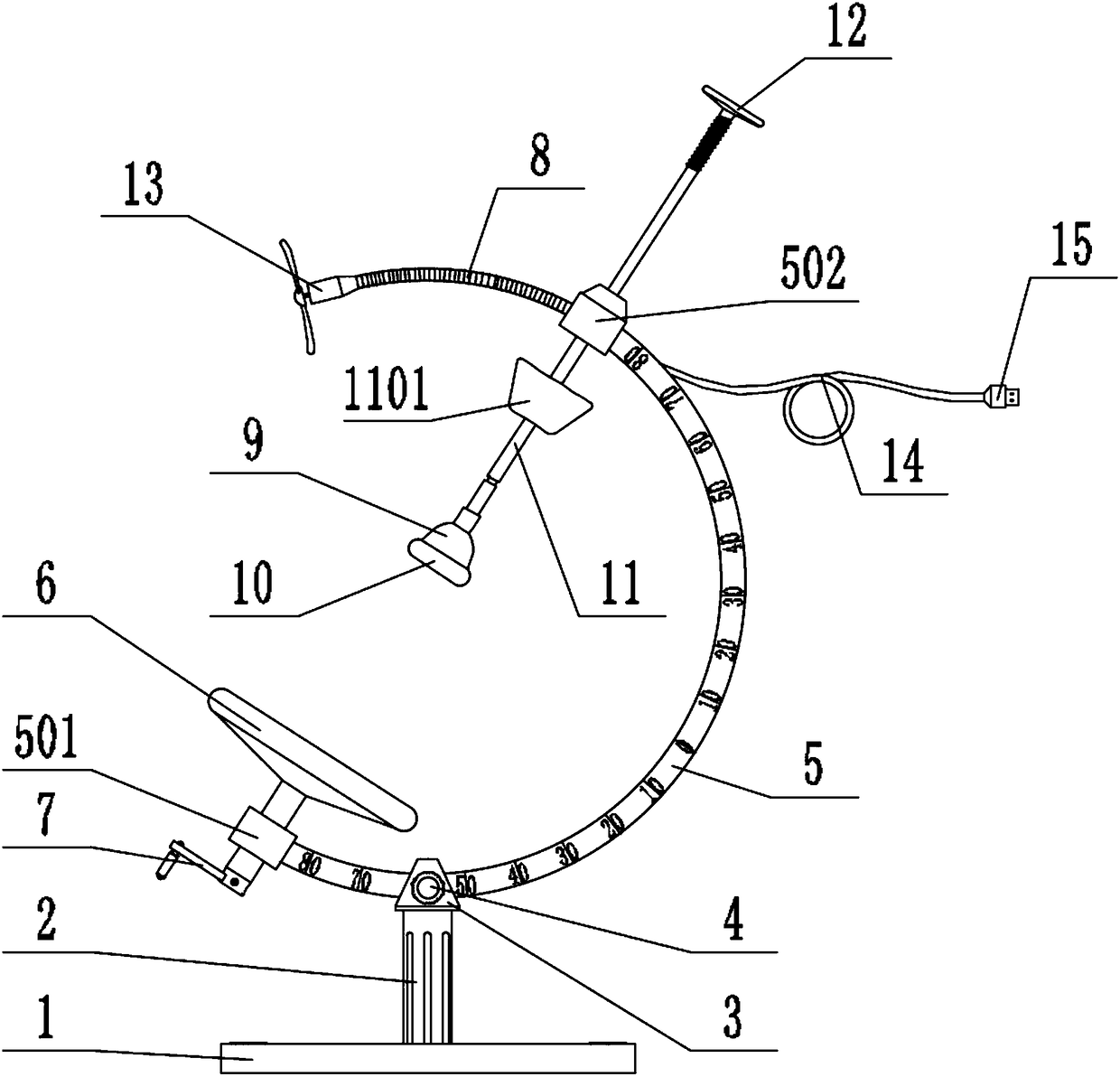

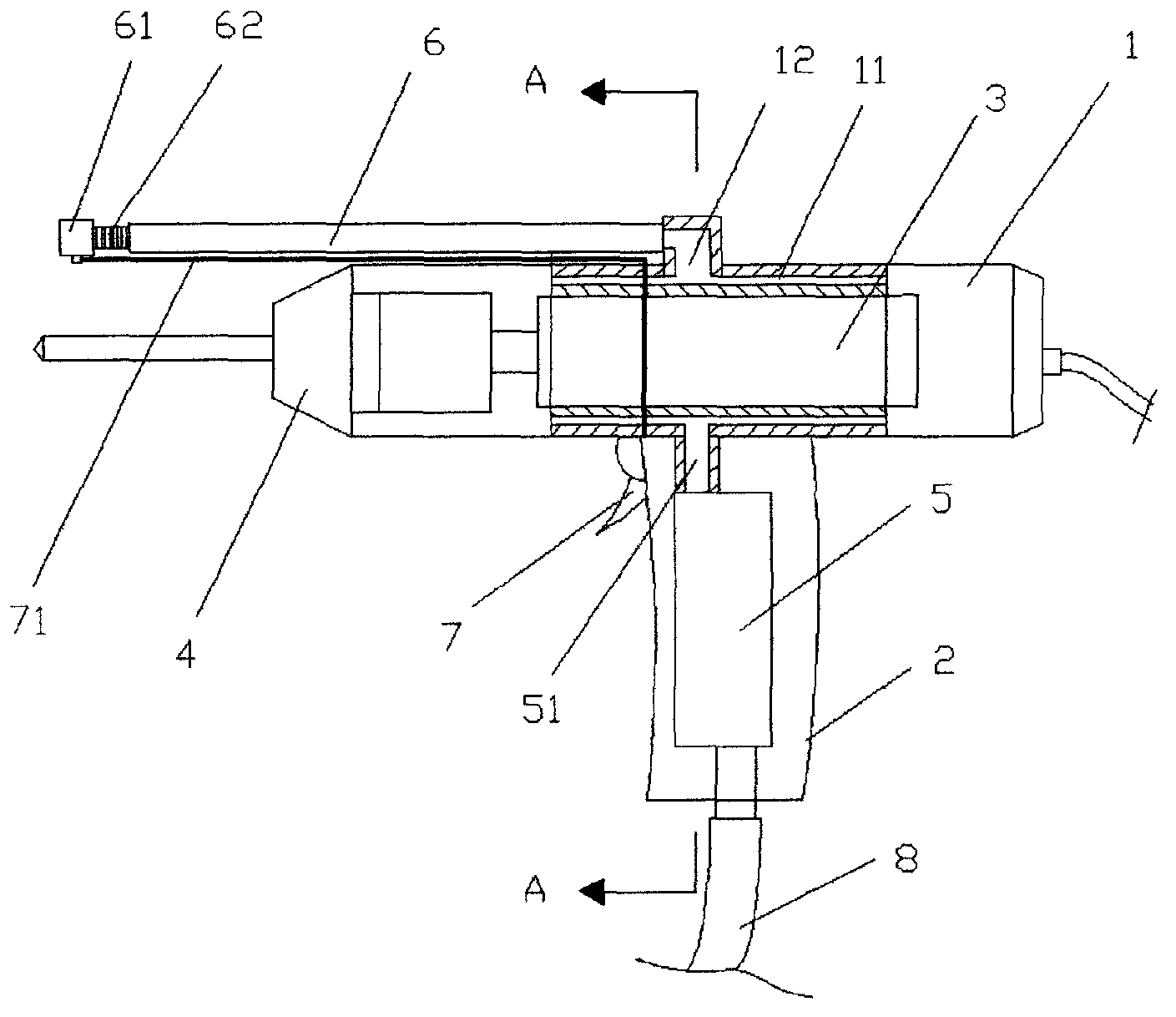

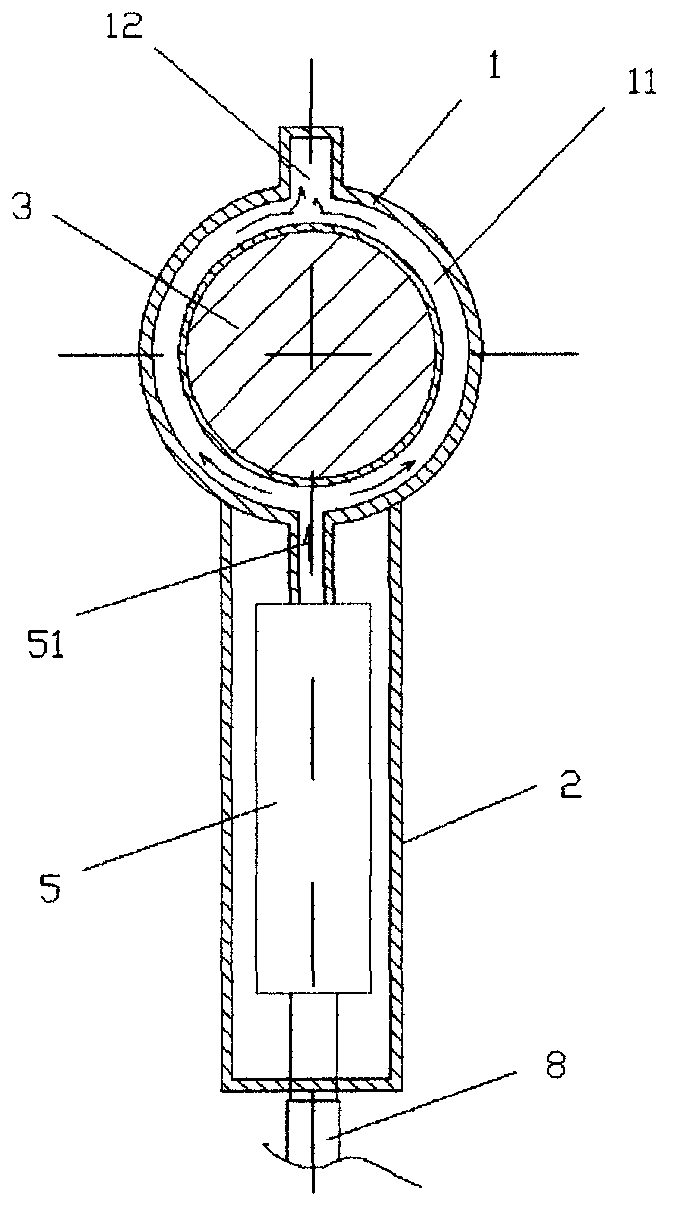

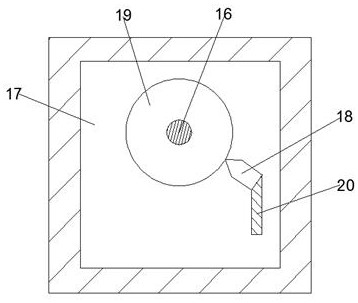

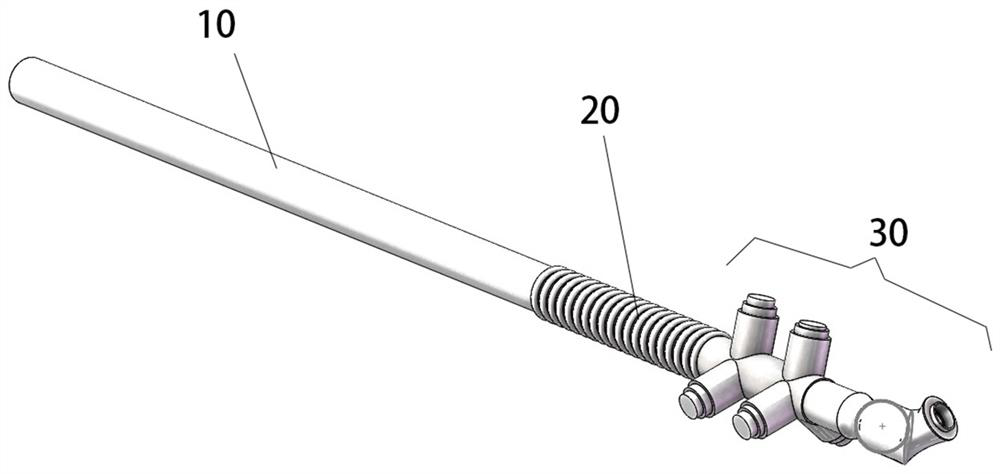

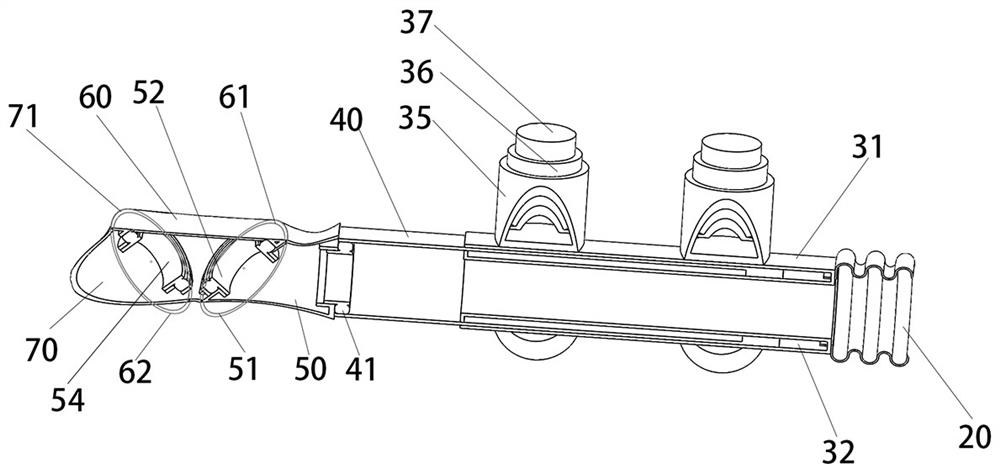

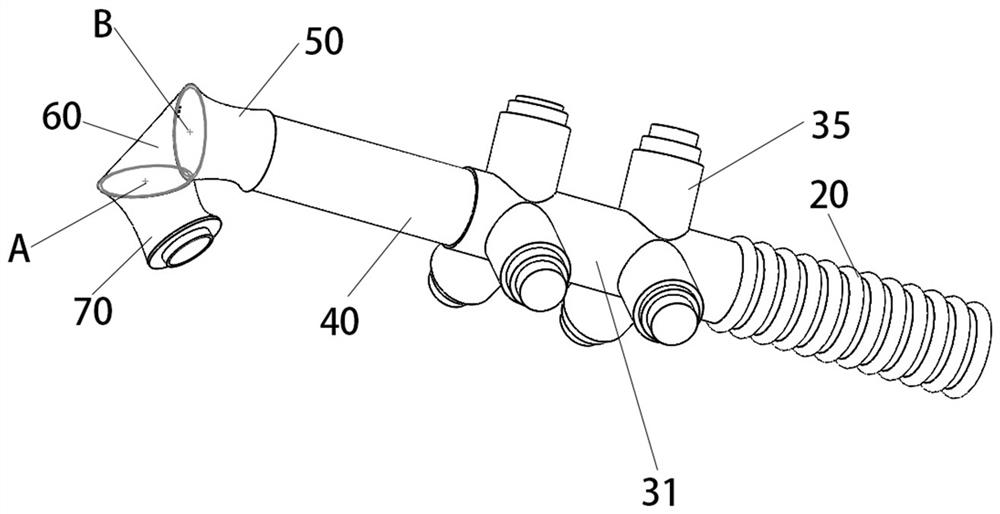

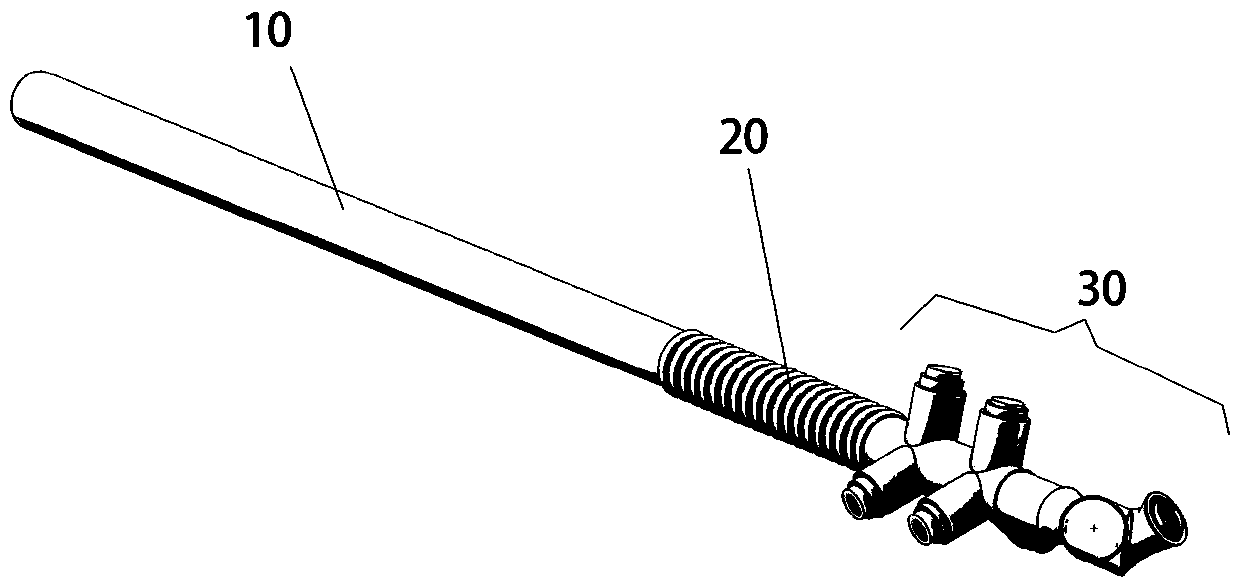

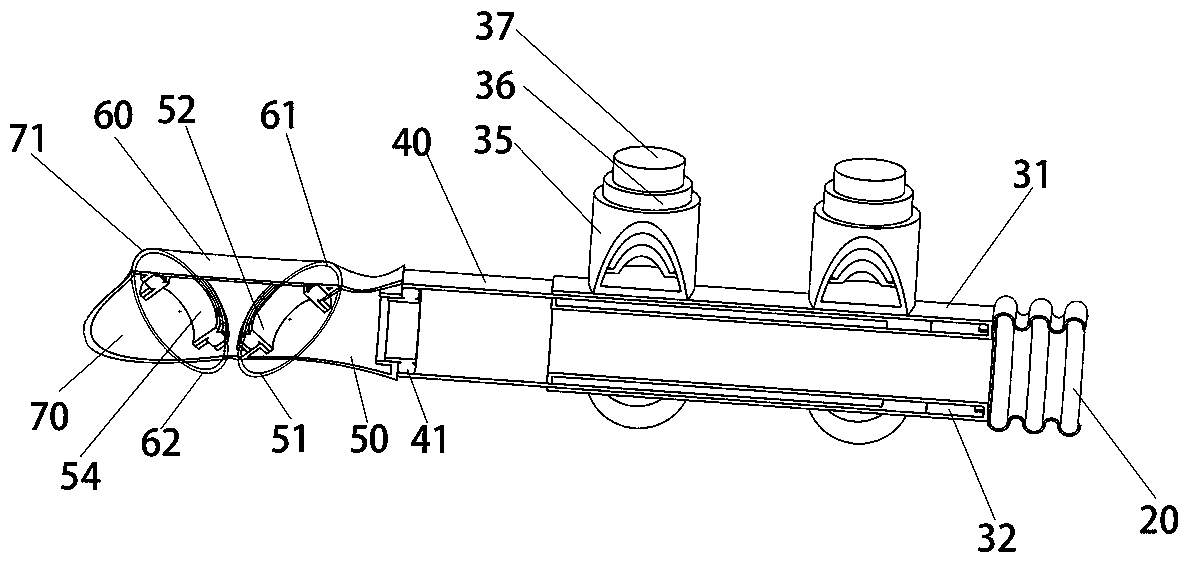

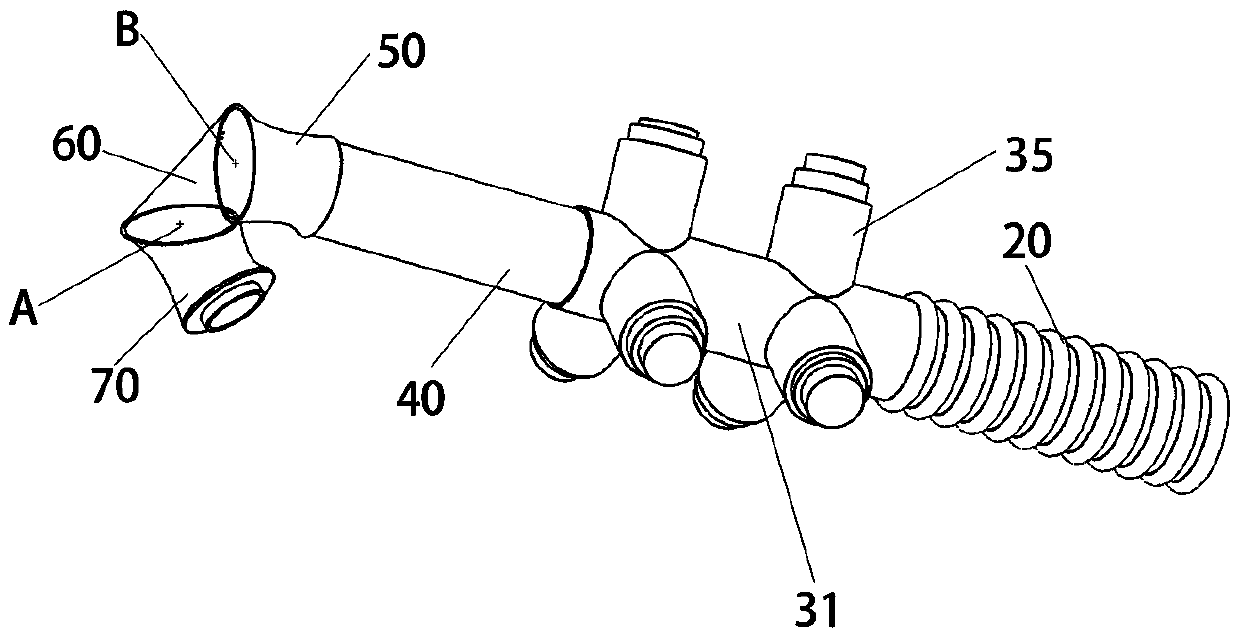

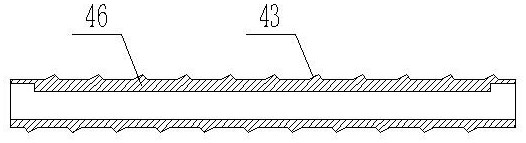

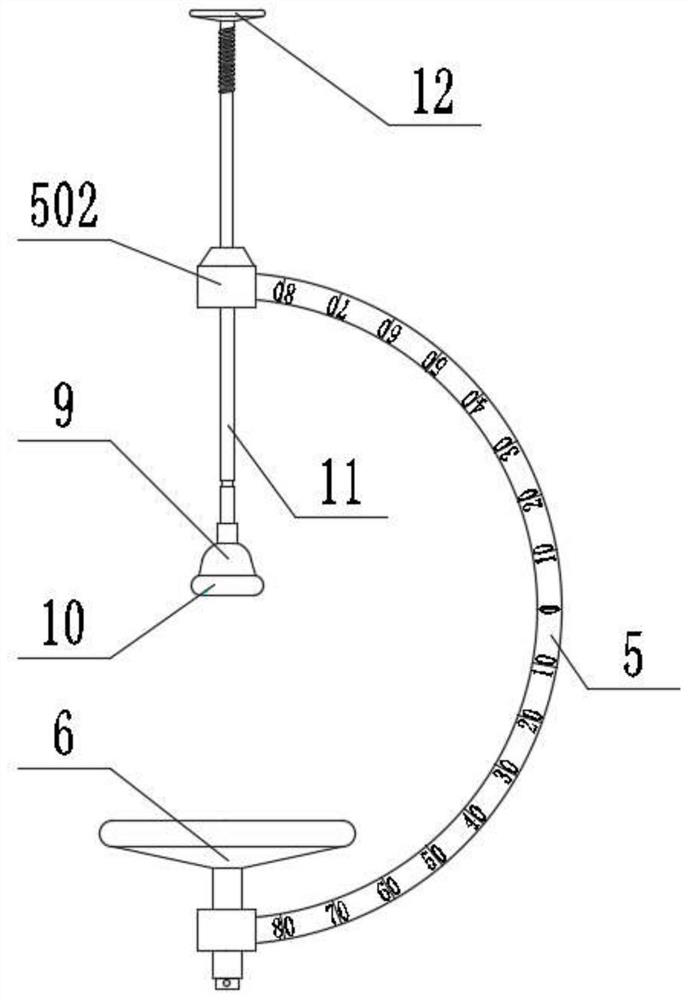

A kind of engraving equipment and engraving method of hollow jadeware

ActiveCN111002743BRich carving angleEasy to engraveHand artistic toolsOther artistic work equipmentsIndustrial engineeringCarving

A hollow jade engraving device, comprising a handle pipe, a corrugated pipe, and an adjusting operation part fixed in series in sequence; There is a telescopic tube and the telescopic tube can slide in the annular groove. The power of the telescopic tube is a telescopic oil cylinder, specifically: the cylinder end of the telescopic oil cylinder is fixed in the fixed pipe, and the piston end of the telescopic oil cylinder is fixed to the rear end of the telescopic tube. The outer surface of the fixing pipe fixes two sets of support frames arranged before and after, each set of support frames includes three radially distributed legs, and the three legs are evenly distributed on the same plane. The invention also discloses an engraving method using the engraving equipment. Compared with the prior art, the present invention is designed with a bellows and an adjusting elbow, so that the engraving head can be bent on the axis of the handle, and even complex bending can be done, which enriches the engraving angle and facilitates engraving operations.

Owner:王冠军

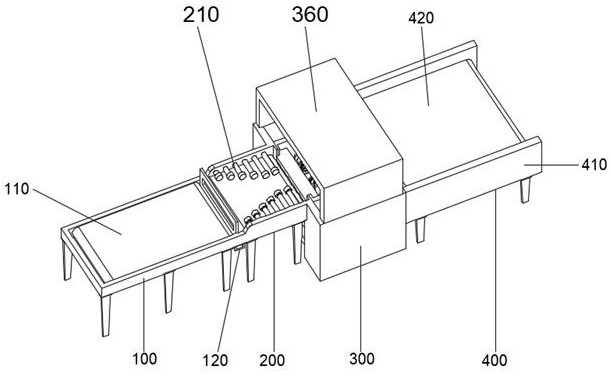

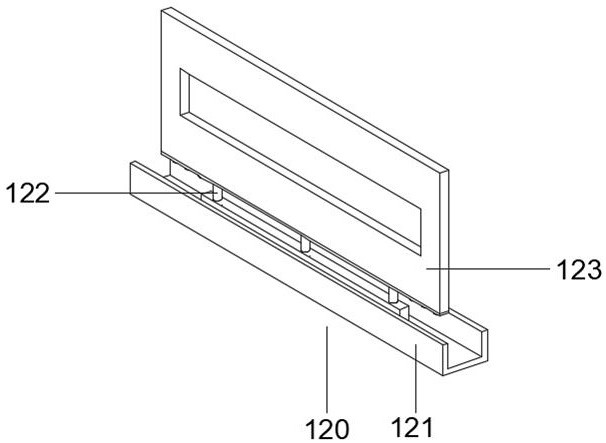

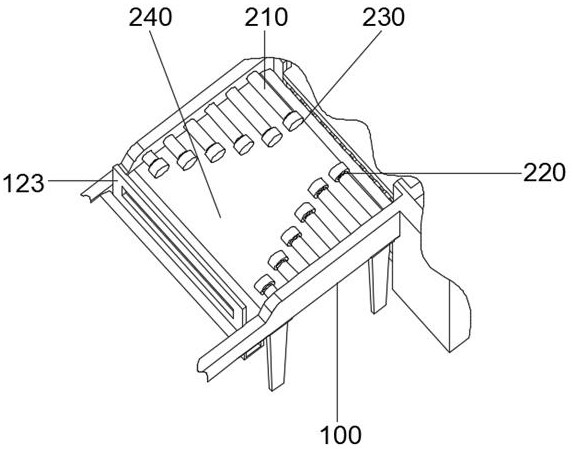

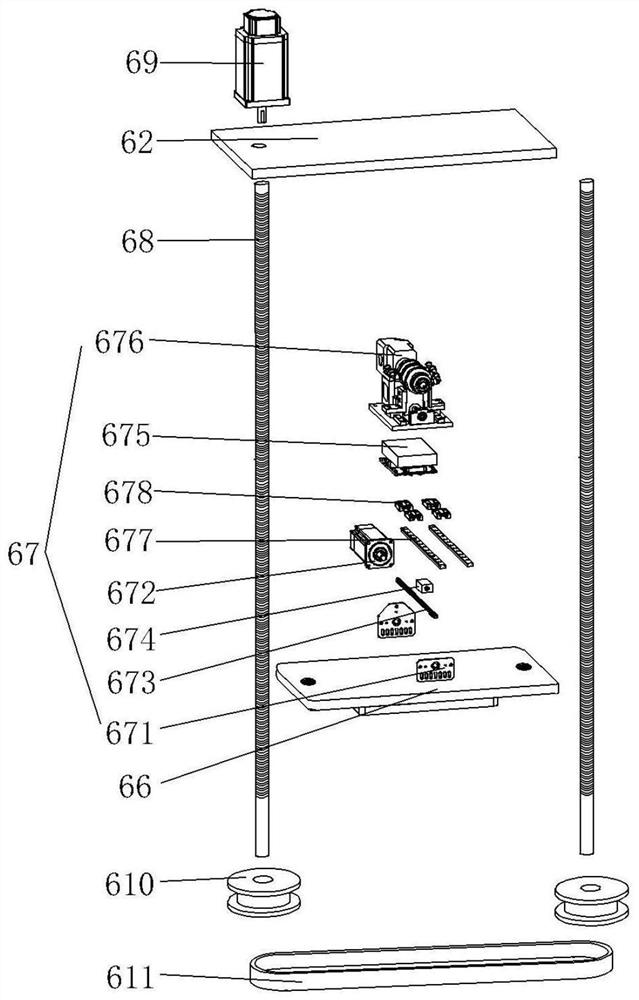

Stereoscopic three-dimensional laser etching equipment for intelligent surface treatment and process thereof

InactiveCN114393319AEasy to engraveImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLaser etchingEngineering

The invention discloses intelligent three-dimensional laser carving equipment for surface treatment, and relates to the technical field of laser carving equipment, and the technical scheme is that the intelligent three-dimensional laser carving equipment comprises a supporting frame, a carving plate positioning assembly is fixedly mounted on the inner wall of the supporting frame, a material clamping assembly is arranged on the right side of the carving plate positioning assembly, and the material clamping assembly is fixedly mounted on the inner wall of the supporting frame; the discharging assembly is fixedly installed on the right side of the material clamping assembly, the material clamping assembly comprises two sets of side plates, the two sets of side plates are symmetrically arranged in the front-back direction, the inner walls of the two sets of side plates are rotationally connected with rotating shafts through bearings, and second gears are fixedly installed on the outer walls of the rotating shafts. And an electric push rod is arranged to lift or retract to take and release the carving plate, so that the position of the carving plate is conveniently adjusted, pattern carving is conveniently performed on the surface of the carving plate, and the practicability of the equipment is improved.

Owner:深圳市正亚实业有限公司

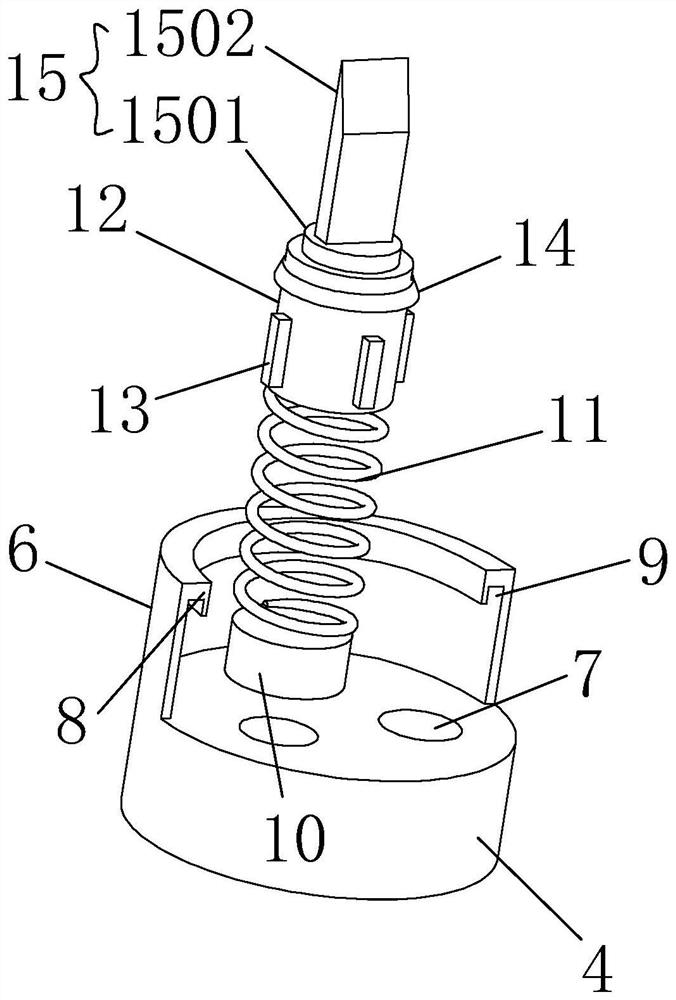

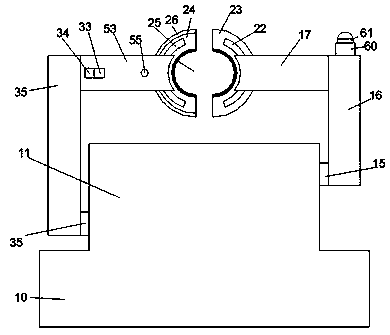

Carving equipment and caving method for hollow jade ware

ActiveCN111002743ARich carving angleEasy to engraveHand artistic toolsOther artistic work equipmentsEngineeringCarving

The invention discloses carving equipment for hollow jade ware. The carving equipment comprises a handle pipe, a corrugated pipe and an adjusting operation part which are sequentially connected in series and fixed, wherein the adjusting operation part comprises a fixed pipe, an annular groove with a front opening is formed in the pipe wall of the fixed pipe, a telescopic pipe is arranged in the annular groove and can slide in the annular groove, and the power of the telescopic pipe is a telescopic oil cylinder. Specifically, the cylinder body end of the telescopic oil cylinder is fixed in thefixed pipe, the piston end of the telescopic oil cylinder fixes the rear end of the telescopic pipe, two sets of supporting frames arranged front and back are fixed to the outer surface of the fixed pipe, each set of supporting frame comprises three supporting legs distributed in the radial direction, and the three supporting legs are evenly distributed on the same plane. The invention further discloses a carving method using the carving equipment. Compared with the prior art, the corrugated pipe and an adjusting elbow are designed, so that the carving operation head is bent on the axis of thehandle and even can be bent complexly, the carving angle is enriched, and carving operation of people is facilitated.

Owner:王冠军

A processing method for the helical gear sleeve of the lower gear roller mechanical scoring machine

Owner:BAOTOU WEIFENG ELECTROMAGNETIC MATERIAL

Sculpting devices for ceramic art

ActiveCN108515801BEasy flipEasy to engraveHand artistic toolsOther artistic work equipmentsEngravingEngineering

The invention provides an engraving device for ceramic art, including electric wires and power connectors, a cylindrical support column is installed on the top end surface of the base, and the angle locking fast bottom is installed on the top end surface of the cylindrical support column, and the fixing bolt is installed on the top surface of the cylindrical support column. Angle locking is fast, the slider is an arc-shaped strip structure, and the outside of the slider is provided with a scale, an upper connecting block is installed on the top of the slider, and a lower connecting block is installed on the lower end of the slider, so The above-mentioned rotating handle is installed on the bottom of the workbench through countersunk head hexagonal bolts, and the workbench is connected with the lower connecting block, which is conducive to turning over the ceramic products placed inside the device, so that the end faces of the ceramic products can be engraved at a better angle. In the eyes of the master, it is convenient for the engraver to carry out engraving work on ceramic products in the later stage, which reduces the difficulty of engraving and indirectly improves the effect of ceramic engraving.

Owner:福建德化博昌陶瓷文化有限公司

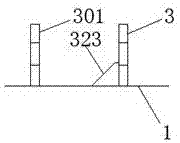

Metal engraving device

InactiveCN107499042ASafe and stable clampingEasy to processModel makingEngravingSlide plateEngineering

The invention discloses a metal engraving device. The metal engraving device comprises a bedplate, wherein a positioning and clamping device is arranged on the left side of the top of the bedplate, a vertical plate is arranged on the right side of the top of the bedplate, a spiral hole is formed in the vertical plate, a first spiral rod is matched in the spiral hole, a first rotating handle is arranged on the right end of the first spiral rod, a push sliding plate is arranged on the left end of the first spiral rod, a balance plate is fixedly installed on the top of the bedplate and is located between the push sliding plate and the vertical plate, the first spiral rod passes through the balance plate and is in matching connection with the balance plate, an abutting plate is arranged on the top of the bedplate and is located between the positioning and clamping device and the vertical plate, and a first putting cavity which is used for supporting a metal piece is formed in the top of the abutting plate. The metal engraving device has the advantage of simple overall structure, and a first clamping wheel is matched with a second clamping wheel, so that the metal piece can be fixedly clamped.

Owner:惠州市佑成五金制品有限公司

Blank for medium-temperature firing through-flower porcelain and preparation method for medium-temperature firing through-flower porcelain

Owner:潮州市广嘉陶瓷制作有限公司

Brass rod surface anti-skid pattern engraving equipment

The invention relates to anti-skid pattern engraving equipment, in particular to brass rod surface anti-skid pattern engraving equipment. The invention aims to provide the brass rod surface anti-skid pattern engraving equipment capable of preventing the brass rod from shaking. The brass rod surface anti-skid pattern engraving equipment comprises a connecting frame, a first connecting rod, a nut block, a pattern scraping device, a clamping mechanism and the like, the first connecting rod is arranged on the upper portion of the right side of the connecting frame, the nut block is arranged on the left side of the lower portion of the first connecting rod, and the pattern scraping device used for engraving the brass rod is arranged on the inner side of the nut block in a threaded mode. The pattern scraping device penetrates through the left side of the lower portion of the first connecting rod, and a clamping mechanism used for preventing the pattern scraping device from moving is arranged on the first connecting rod. A brass rod is placed in a threaded connecting pipe, and the brass rod can be clamped by a clamping rod under the action of the clamping rod, so that the brass rod is prevented from shaking, and anti-slip patterns are prevented from being carved obliquely.

Owner:YINGTAN SHENGFA COPPER

Novel metal engraving device

The invention discloses a novel metal engraving device which comprises a platen, wherein a positioning and clamping device is arranged in a location, abutted against the left side, of the top of the platen; a vertical plate is arranged on the right side of the top of the platen; a screw hole is formed in the vertical plate; a first screw rod is matched in the screw hole; a first rotation handle is arranged at the right end of the first screw rod; a push sliding plate is arranged at the left end of the first screw rod; a balance plate is fixedly mounted on the top of the platen and located between the push sliding plate and the vertical plate; the first screw rod penetrates through the balance plate and is connected with the balance plate in a matching manner; a push-against plate is arranged on the top of the platen and located between the positioning and clamping device and the vertical plate; and a first placement cavity for putting up a metal part is arranged on the top of the push-against plate. The device is relatively simple in overall structure, and the clamping and fixing of the metal part can be achieved by the matching of a first clamping wheel and a second clamping wheel.

Owner:宁波鄞州义旺电子科技有限公司

metal engraving device

InactiveCN107499042BSafe and stable clampingEasy to processModel makingEngravingSlide plateEngineering

The invention discloses a metal engraving device. The metal engraving device comprises a bedplate, wherein a positioning and clamping device is arranged on the left side of the top of the bedplate, a vertical plate is arranged on the right side of the top of the bedplate, a spiral hole is formed in the vertical plate, a first spiral rod is matched in the spiral hole, a first rotating handle is arranged on the right end of the first spiral rod, a push sliding plate is arranged on the left end of the first spiral rod, a balance plate is fixedly installed on the top of the bedplate and is located between the push sliding plate and the vertical plate, the first spiral rod passes through the balance plate and is in matching connection with the balance plate, an abutting plate is arranged on the top of the bedplate and is located between the positioning and clamping device and the vertical plate, and a first putting cavity which is used for supporting a metal piece is formed in the top of the abutting plate. The metal engraving device has the advantage of simple overall structure, and a first clamping wheel is matched with a second clamping wheel, so that the metal piece can be fixedly clamped.

Owner:惠州市佑成五金制品有限公司

Dynamic stable machine tool

InactiveCN108747458ASimple structureEasy to useLarge fixed membersPositioning apparatusMachine toolEngineering

The invention discloses a dynamic stable machine tool. The dynamic stable machine tool comprises a base; a base table is fixedly arranged at the upper end of the base; a first chute with a mouth partto the left side and a second chute with a mouth part to the right side and positioned above the first chute are arranged in the base table; a first communicating groove communicates between the firstchute and the second chute; a first slide block and a second slide block are slidingly mounted in the first chute and the second chute; a first tooth-shaped bar and a second tooth-shaped bar are arranged on opposite end surfaces of the first slide block and the second slide block; a first tooth-shaped wheel, matched and connected with the first tooth-shaped bar and the second tooth-shaped bar, isrotationally mounted in the first communicating groove through a first rotating rod; the front end of the first rotating rod is rotationally mounted in the front end wall of the first communicating groove; and the back end is in power connection with an electric rotating machine fixedly mounted in the back end wall of the first communicating groove.

Owner:郭超杰

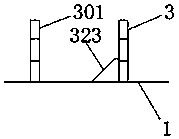

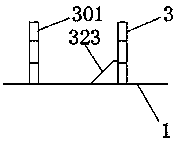

Bracket applied to surface engraving of stainless steel plate

The invention discloses a bracket applied to surface engraving of a stainless steel plate. According to the bracket applied to surface engraving of the stainless steel plate, a body of the bracket isprovided with a supporting plate; the supporting plate is an inclined plate of which one side is high and the other side is low; thus, the stainless steel plate body is inclined after the stainless steel plate is placed on the supporting plate, so the surface of the stainless steel plate can be engraved conveniently. The surface of the supporting plate is further provided with two supporting bodies which can move and slide horizontally; each supporting body is driven by a cylinder, and thus the stainless steel plate can be horizontally moved as needed in an engraving process and a more convenient engraving process is realized.

Owner:杭沣

A kind of hand-stitched pattern and its preparation method

InactiveCN107933078BSolve the problem that it is impossible to completely accurately align the plateThe depth of the hand-engraved groove is not easy to controlRotary pressesLaserComputer engineering

The invention relates to a manual clamping dyeing printing plate and a preparation method thereof. The manual clamping dyeing printing plate adopts a two-layer overlapping type design and is composedof main printing plate bodies with patterns and auxiliary printing plate bodies with round holes. The application method comprises the following steps of placing fabrics in the manual clamping dyeingprinting plate, fixing and clamping the periphery by using G-shaped clamps and selecting a dye for dyeing. The preparation method comprises the following steps of designing the patterns of the clamping dyeing printing plate, overlaying, aligning and fixing two transparent or semitransparent high-temperature-resistant perspex sheets, and engraving the patterns at a time by using a laser computer engraving machine so so as obtain the two main printing plate bodies with the symmetric patterns; punching two pieces of stainless iron or stainless steel for round holes so as to obtain the two auxiliary printing plate bodies; and pasting the main printing plate bodies on the auxiliary printing plate bodies separately by using glue. The manual clamping dyeing printing plate adopts the two-layer overlapping type design and has the advantages of being flexible, convenient, scientific and reasonable, various dyeing techniques can be applied, and the artistic expressive force of clamping dying canbe enriched. According to the manual clamping dyeing printing plate and the preparation method thereof, clamping dyeing printing plate materials can be obtained conveniently, can be stored easily andcan be engraved conveniently, and therefore various costs can be greatly saved, and the production efficiency can be improved.

Owner:DONGHUA UNIV

Novel dynamic stabilization machine tool

The invention discloses a novel dynamic stabilization machine tool. The machine tool comprises a base, a base table is fixedly arranged at the upper end of the base, a first sliding groove with a opening part facing leftward is arranged in the base table, and a second sliding groove with the opening part facing rightwards and located above the first sliding groove is arranged in the base table, acommunicating first through-connection groove is formed between the first sliding groove and the second sliding groove, and a first sliding block and a second sliding block are installed in the firstsliding groove and the second sliding groove in a sliding mode respectively; and the opposite end faces of the first sliding block and the second sliding block are respectively provided with a first tooth-shaped strip and a second tooth-shaped strip, a first tooth-shaped wheel which is connected with the first tooth-shaped strip and the second tooth-shaped strip in a matched mode is rotatably installed in the first through-connection groove through a first rotating rod; and the front end of the first rotary rod is rotationally installed in the front end wall of the first through-connection groove, the rear end of the first rotary rod is in power connection with an electric machine which is fixedly installed in the rear end wall of the first through-connection groove.

Owner:郭超杰

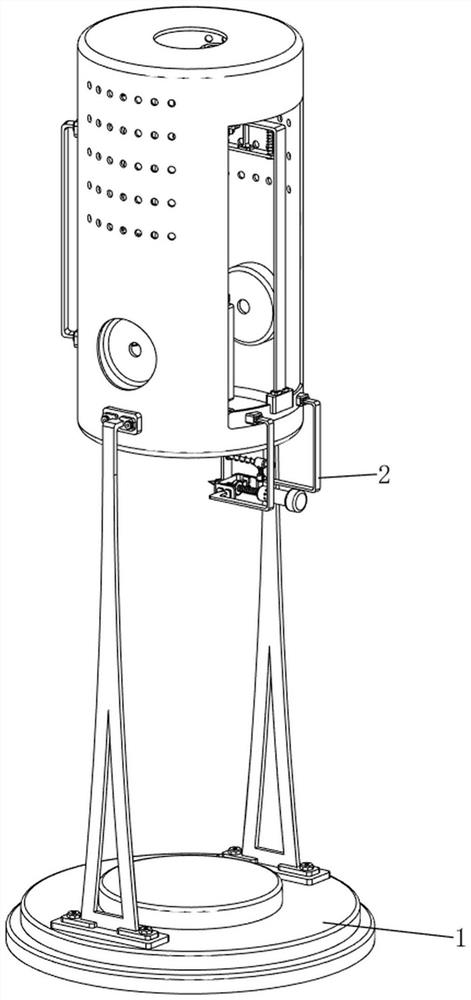

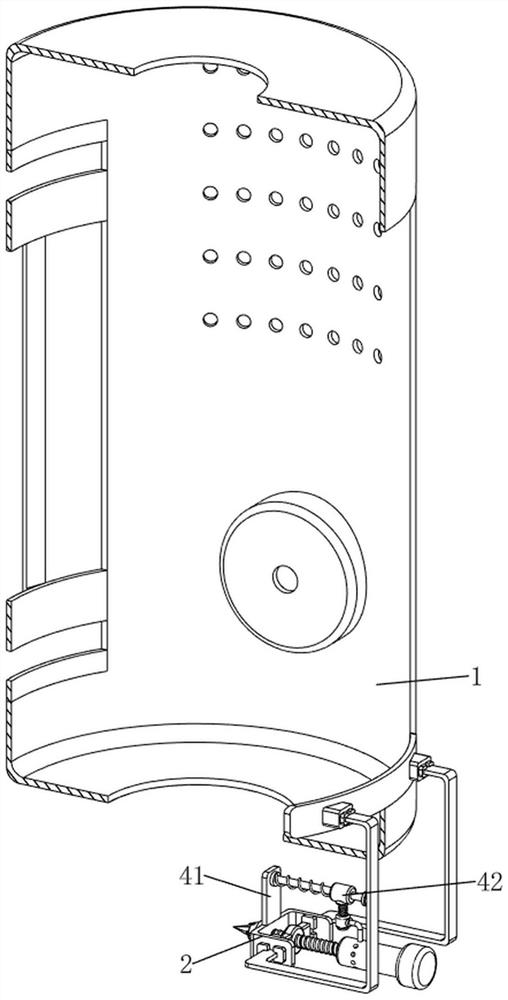

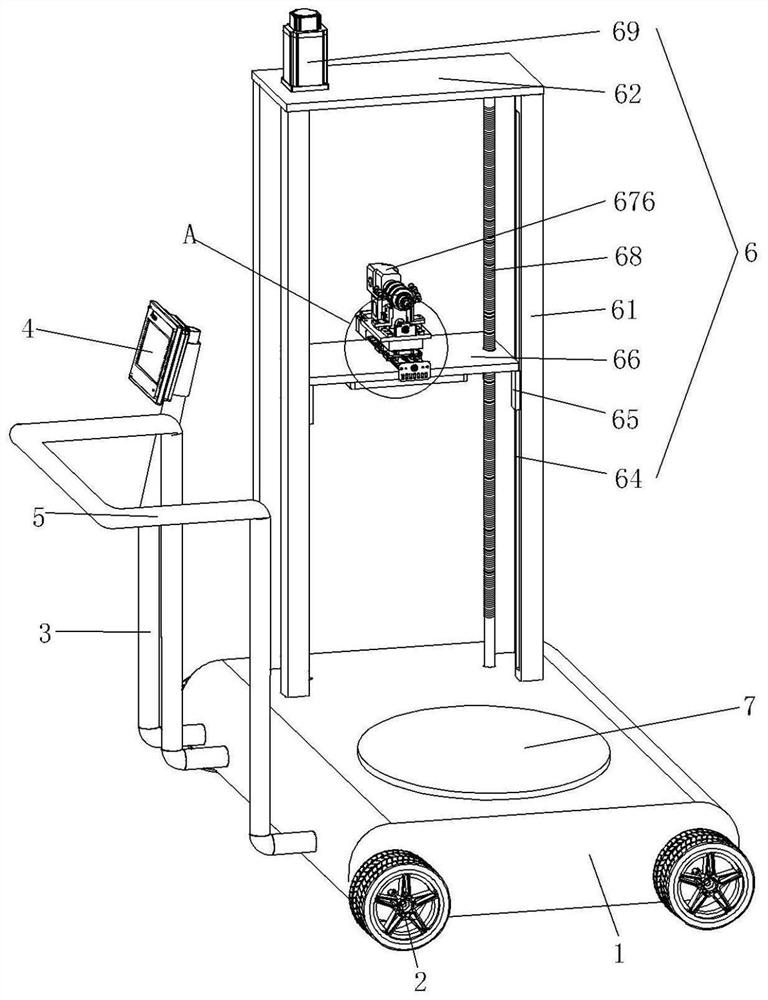

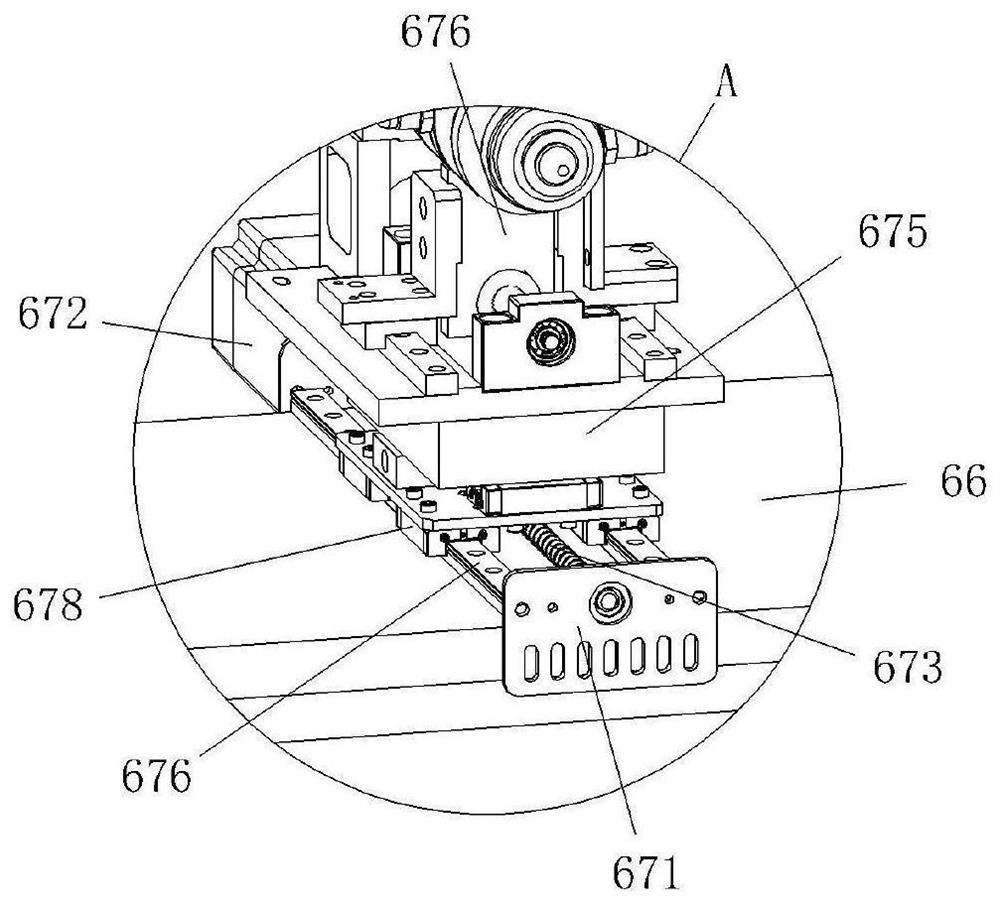

Movable three-dimensional laser engraving device

InactiveCN112548357AEasy to engraveEasy to operateLaser beam welding apparatusLaser engravingMechanical engineering

The invention discloses a movable three-dimensional laser engraving device. The movable three-dimensional laser engraving device comprises a base, wheels, supporting columns, a control panel, a push handle, a vertical laser engraving mechanism, a circular table and a rotating mechanism, wherein the wheels are rotationally arranged at the left ends and the right ends of the front side and the rearside of the base, the supporting columns are fixedly arranged on one sides of the wheels, the control panel is fixedly arranged on one sides of the top ends of the outer walls of the supporting columns, the push handle is fixedly arranged on one side of the base, the vertical laser engraving mechanism is arranged on the rear side of the top end of the base, the circular table is rotationally arranged at the top end of the base, and the rotating mechanism is arranged in an inner cavity of the base. According to the movable three-dimensional laser engraving device, a position of a mounting tablecan be adjusted by arranging a laser translation assembly, so that a front-back position of the laser engraving machine is adjusted, a proper distance is kept between the laser engraving machine anda to-be-machined product, engraving machining is facilitated, workers do not need to manually move the laser engraving machine, operation is easy, and practicability is high.

Owner:张正阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com