Processing technology of surface of copper busbar

A processing technology, copper bar technology, applied in the field of copper bar surface processing technology, can solve the problem of no information on the copper bar surface, copper bar is difficult to distinguish, etc., to achieve the effect of preventing oxidation, protection performance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

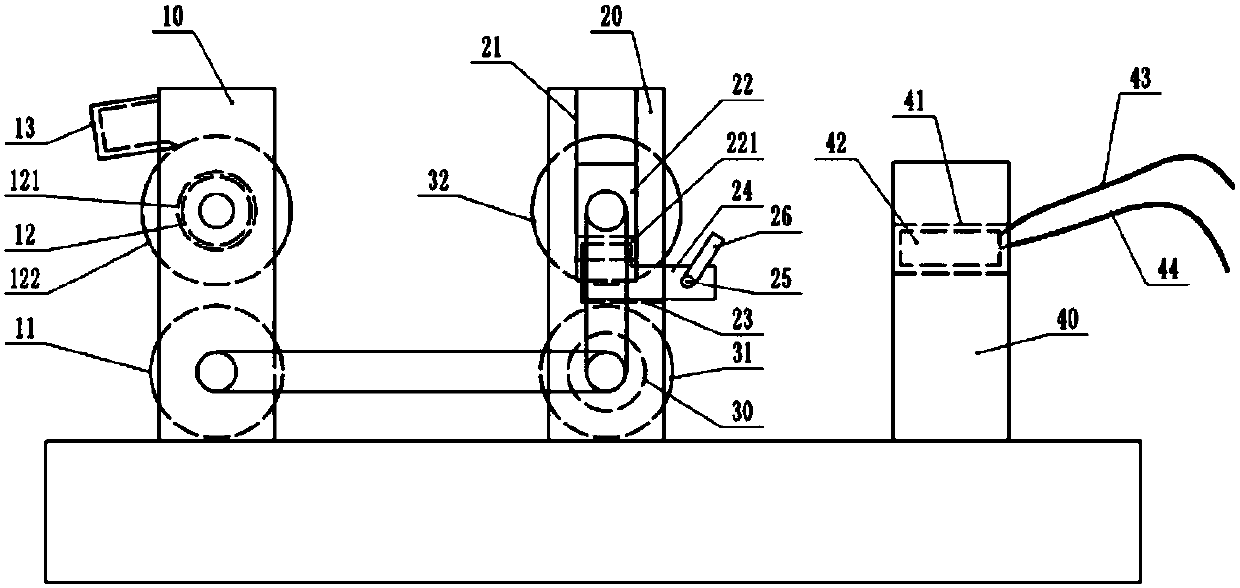

[0031] The reference signs in the accompanying drawings include: support frame 10, first conveying roller 11, cleaning roller 12, heating resistor 121, porous cleaning cotton 122, housing 13, supporting frame 20, chute 21, slider 22, inclined plane 221, transverse groove 23, support block 24, screw rod 25, handle 26, motor 30, second conveying roller 31, lettering roller 32, support block 40, transverse plate 41, cooling cavity 42, water outlet pipe 43, water inlet pipe 44.

[0032] Such as figure 1 As shown, a processing technology for the surface of copper bars uses a lettering mechanism to process copper bars. The lettering mechanism includes a workbench and a cleaning unit, lettering unit and shaping unit fixed on the workbench in sequence; the cleaning unit includes a support frame 10, The first transmission roller 11, the cleaning roller 12 and the housing 13, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com