Plastic cylinder ring-shaped engraving device with up-down adjustable cutter

A plastic cylinder, adjustable technology, applied in the direction of engraving, decorative arts, painting tools, etc., can solve the problems of low efficiency, troublesome manual engraving, poor effect, etc., and achieve the effect of high efficiency and good engraving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

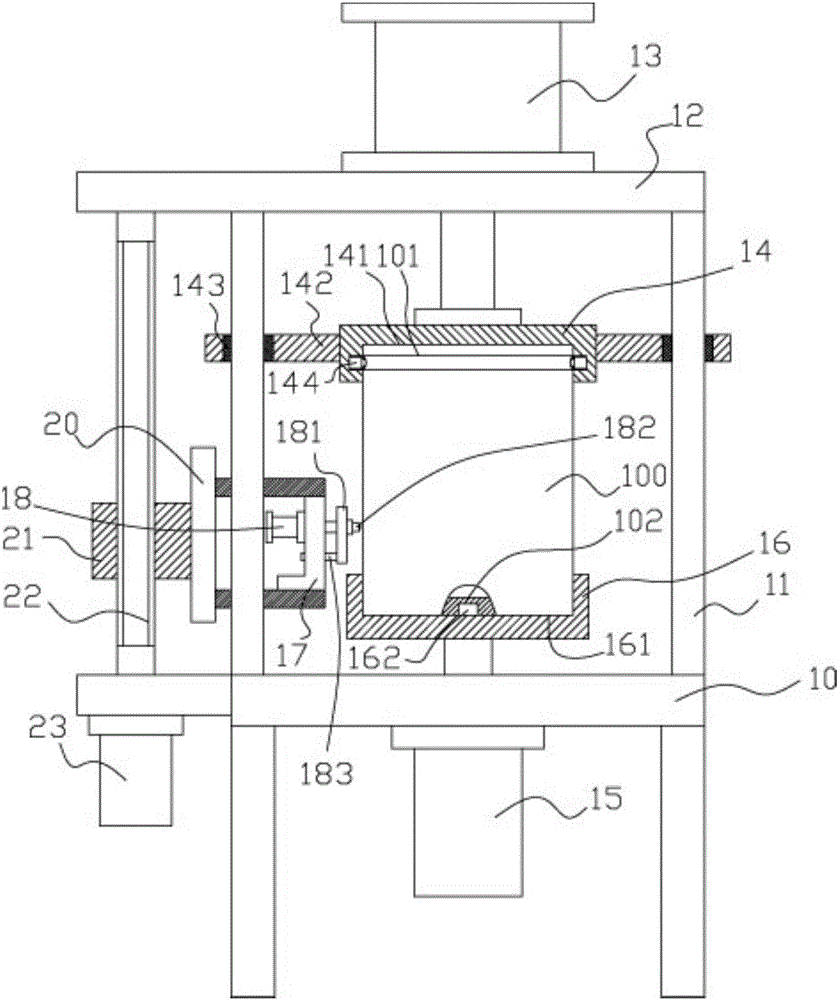

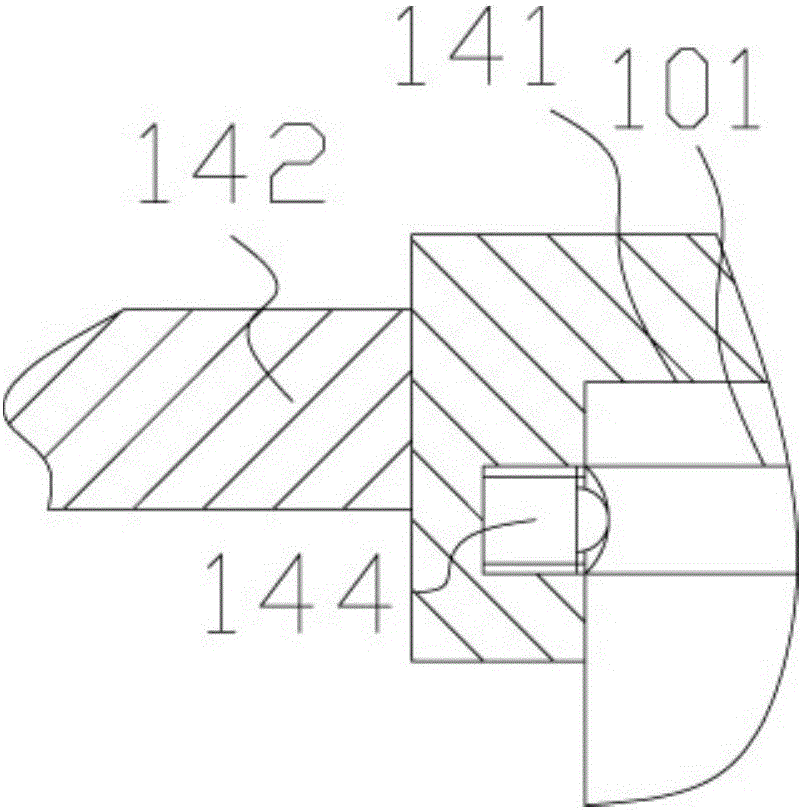

[0016] Example: see Figure 1 to Figure 2 As shown, a plastic cylinder annular engraving device with up and down adjustable cutters includes a frame 10, the top surface of the top plate of the frame 10 is fixed with two support columns 11, and the top ends of the two support columns 11 are fixed on On the bottom surface of both ends of the upper top board 12, the middle part top surface of the upper top board 12 is fixed with a compression cylinder 13, and the push rod of the compression cylinder 13 passes through the upper top board 12 and is fixed with an upper clamping plate 14, and the upper clamping plate 14 The middle part of the bottom surface has an upper groove 141, and the bottom surface of the middle part of the top plate of the frame 10 is fixed with a rotating motor 15. The middle part of the top surface of the plate 16 has a lower placement groove 161, and the upper end and lower end of the plastic cylinder 100 are respectively inserted into the corresponding upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com