Tire engraving system

A tire and engraving technology, which is applied in tire, engraving, decorative art, etc., can solve the problems of difficult fixing of tires, low engraving precision, and difficulty in engraving, and achieve the effect of easier engraving, high degree of automation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

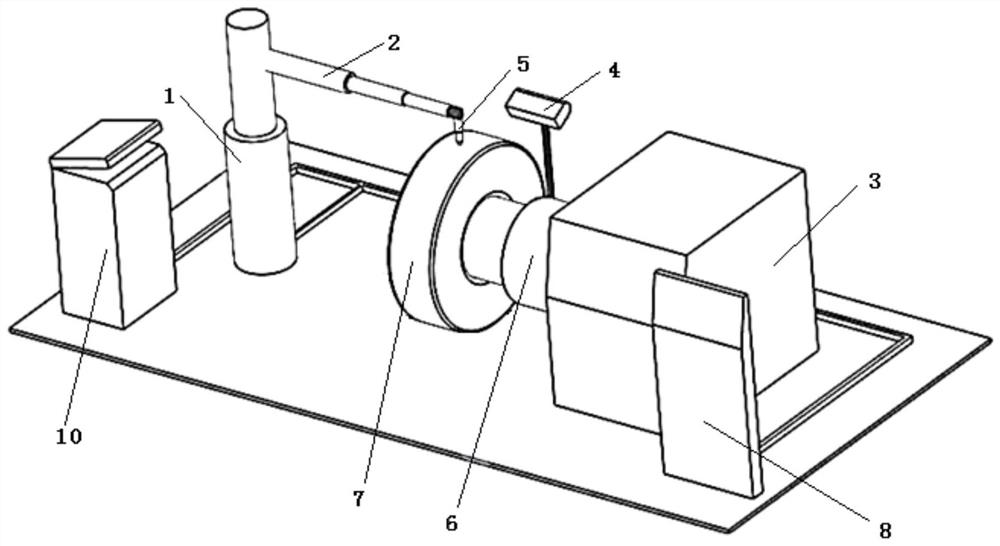

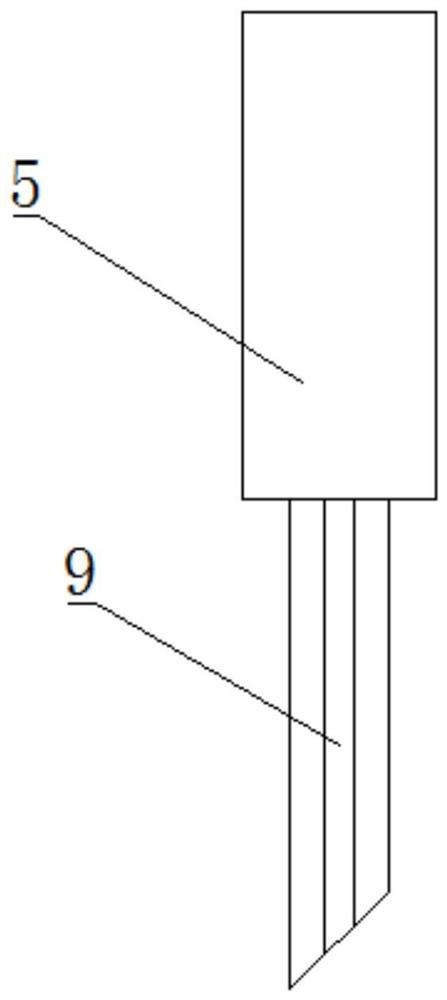

[0021] Such as figure 1 As shown, the present embodiment provides a tire engraving system, including a first electro-hydraulic push rod 1, a second electro-hydraulic push rod 2, a mount 3 and a scanner 4; the first electro-hydraulic push rod 1 is vertically The second electro-hydraulic push rod 2 is installed horizontally on the push rod of the first electro-hydraulic push rod 1, and the cutter head 5 is installed on the push rod of the second electro-hydraulic push rod 2; There is a rotating shaft 6, the rotating shaft 6 is driven by the drive motor through the bearing, the tire 7 is installed on the rim, and then installed on the rotating shaft 6 through the mounting hole bolts of the rim; For the camera, the first camera adopts a depth-of-field camera, and the first electro-hydraulic push rod 1, the second electro-hydraulic push rod 2, the drive motor and the depth-of-field camera are electrically connected to the controller 8 respectively.

[0022] working principle:

[...

Embodiment 2

[0026] On the basis of Embodiment 1, the scanner 4 also includes a second camera electrically connected to the controller 8, and the second camera monitors the pattern state of the surface of the tire 7 together with the depth of field camera, and feeds back to the controller 8, so that Play the role of calibrating the depth of field camera.

Embodiment 3

[0028] On the basis of Embodiment 2, the scanner 4 also includes a lamp electrically connected to the controller 8, the lamp is a commonly used marking lamp in the field, and the marking line drawn by the lamp is along the tire 7 axial direction. The direction is marked on the tire 7 surface, thereby the controller 8 can be quickly calibrated to the width of the tire 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com