Hot mark stamping mechanism, hot mark stamping system and hot mark stamping method of hot mark stamping system

A technology of driving mechanism and rotating mechanism, which is applied in printing machines, rotary printing machines, printing, etc., can solve the problem of not being able to meet the requirements of thermal printing color temperature and precision, and unable to control the position of thermal marking and line body, thermal printing, etc. The heating temperature of the marking machine cannot be well controlled, etc., so as to achieve the effect of good marking effect, ensuring accuracy and meeting the requirements of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

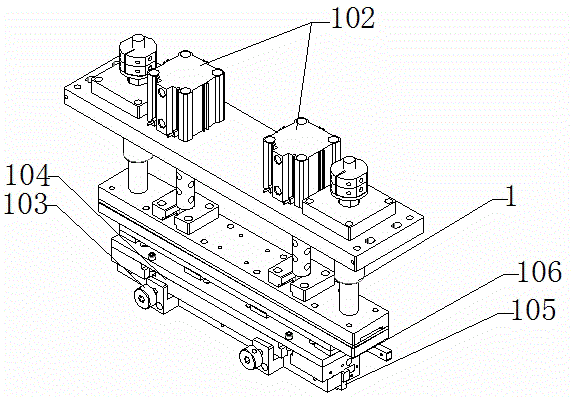

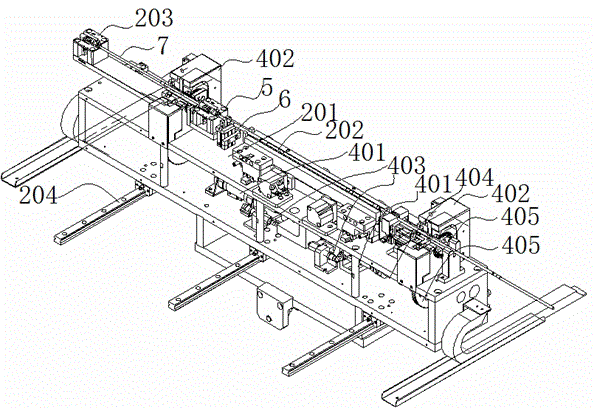

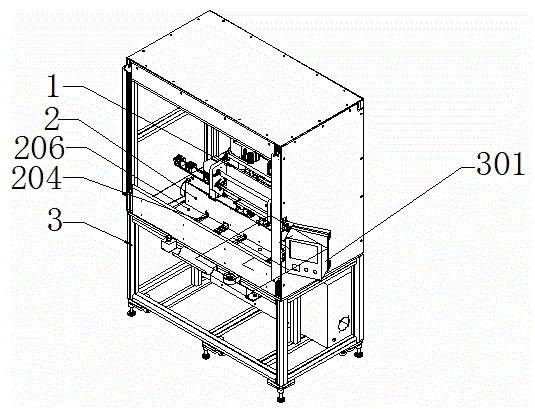

[0049] In order to achieve the purpose of the present invention, in some embodiments, such as figure 1As shown, the thermal marking mechanism includes a frame body 101 and a thermal marking device arranged on the frame body. The thermal marking device includes a first driving mechanism 102, a knife mold device and at least one thermal marking position 103. The thermal marking device The position 103 is located at the bottom of the die cutting device, and the die die device is also provided with a thermocouple sensor (not shown), and the thermocouple sensor is used to control the heating temperature of the die die device, and the thermocouple sensor senses After the die-cutting device is heated to a suitable temperature, the first driving mechanism 102 drives the die-cutting device to move up and down, so as to mark on the wire body 7 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com