Fuel cell gas diffusion layer batch hydrophobic treatment method and production line thereof

A gas diffusion layer and water treatment technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting the performance of the diffusion layer, uneven PTFE content, dripping, etc., and achieve good water-gas balance performance, The doped hydrophobic agent is uniform and the effect of particle distribution is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

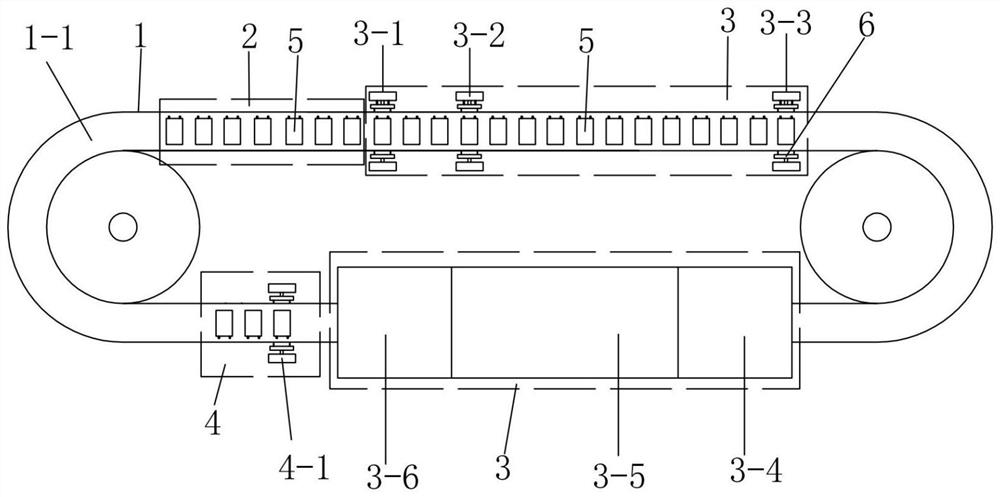

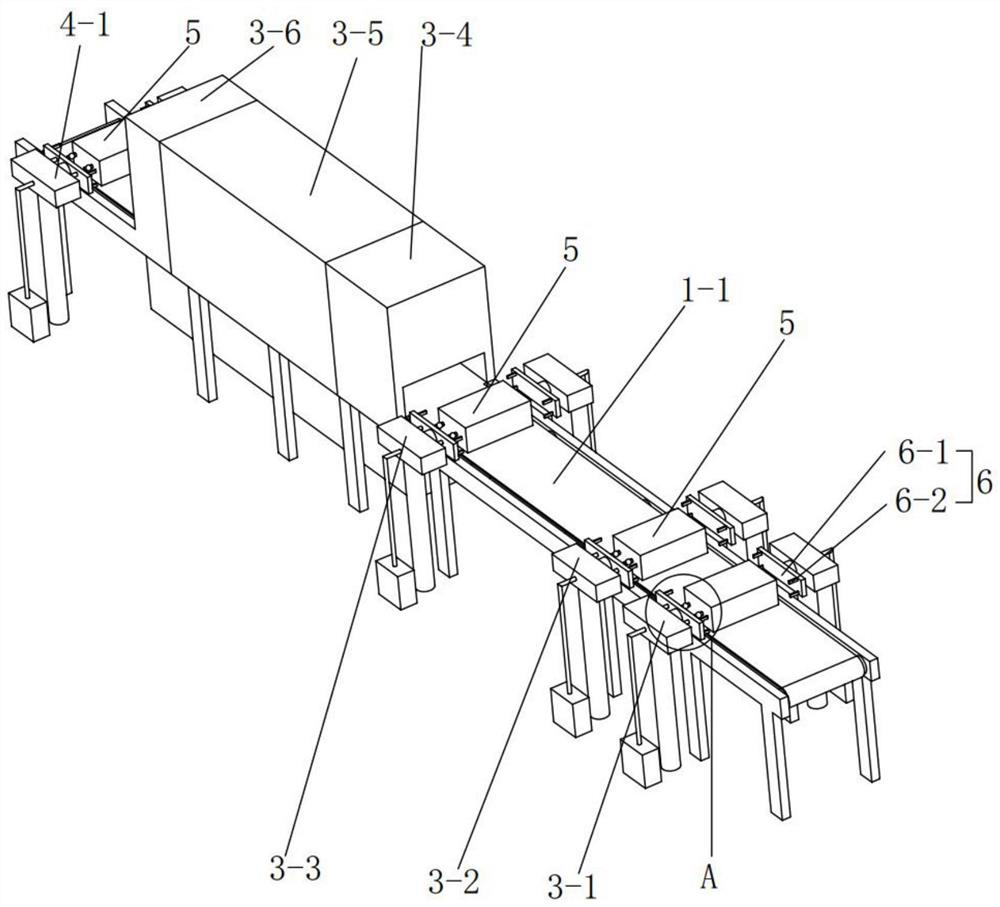

[0047] Embodiment: The present invention discloses a production line that can realize the hydrophobic treatment of the gas diffusion layer. figure 1 shown, and the circular conveying track 1-1 is controlled by a servo motor to realize step-by-step conveying; according to the technological method provided by the present invention, the conveying platform 1 can be divided into three areas, namely the feeding area 2, the working area 3 and the Discharge area 4.

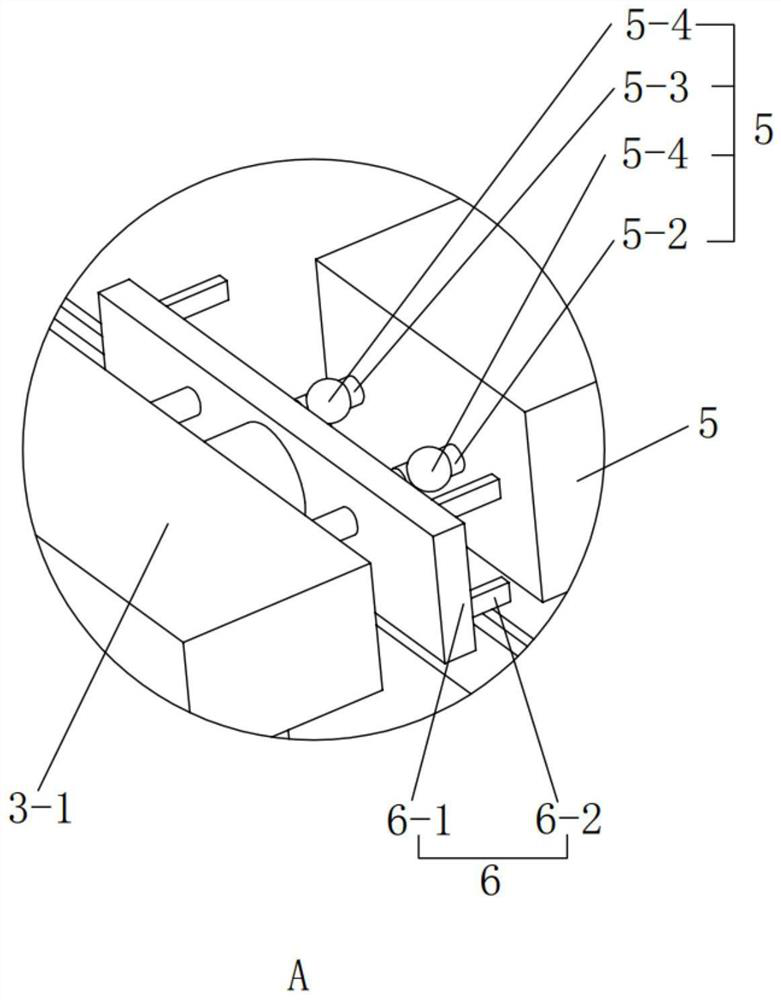

[0048] like figure 1 and 2 As shown, a plurality of metal sealing boxes 5 are arranged on the annular conveying track 1-1 in the feeding area 2, and the metal sealing boxes 5 are placed on the annular conveying track 1-1 according to the specified standard intervals. In order to facilitate the metal sealing box 5 The position of the metal sealing box 5 is limited, and the frame line diagram of the placement of the metal sealing box 5 can be posted or painted on the annular conveying track 1-1, so that the staff can accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com