Hydrophobic thermal-insulation sound-insulation foam concrete and preparation method thereof

A technology of foam concrete, thermal insulation and sound insulation, which is applied in the field of building sound insulation and thermal insulation materials, can solve the problems of poor thermal insulation and sound insulation performance, improve thermal insulation performance and sound insulation performance, improve crack resistance and stability, and improve foam The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

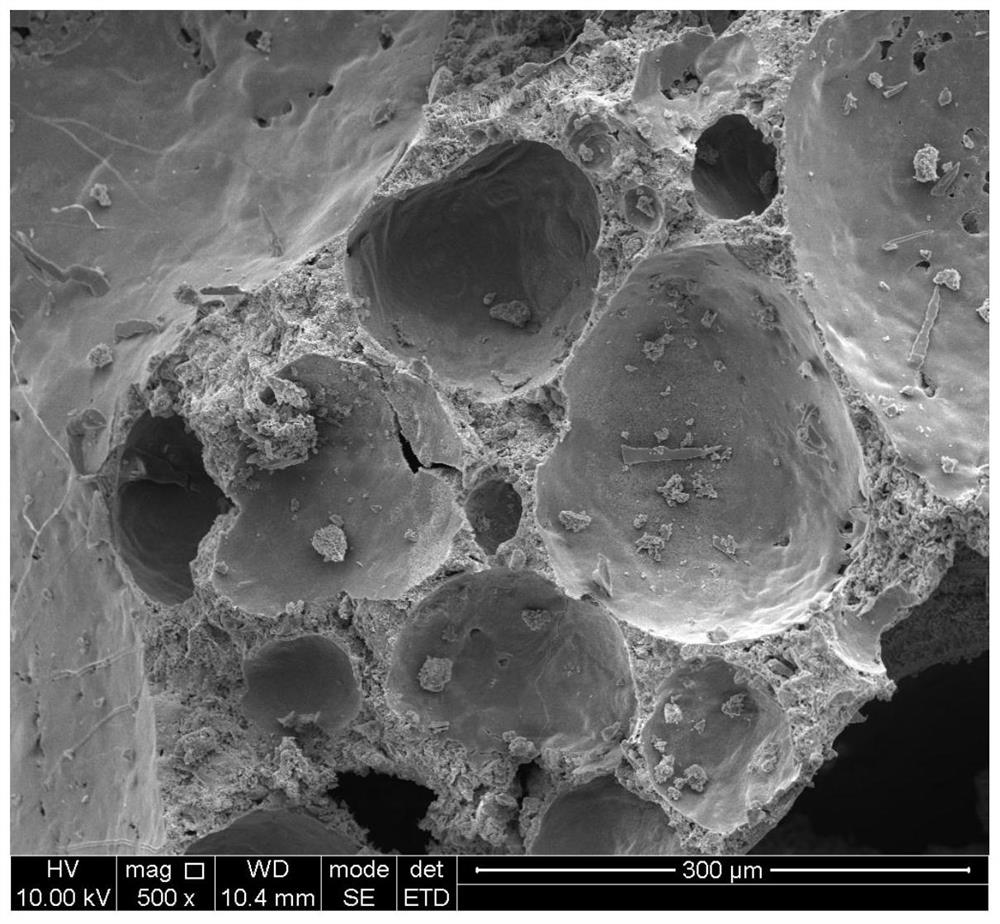

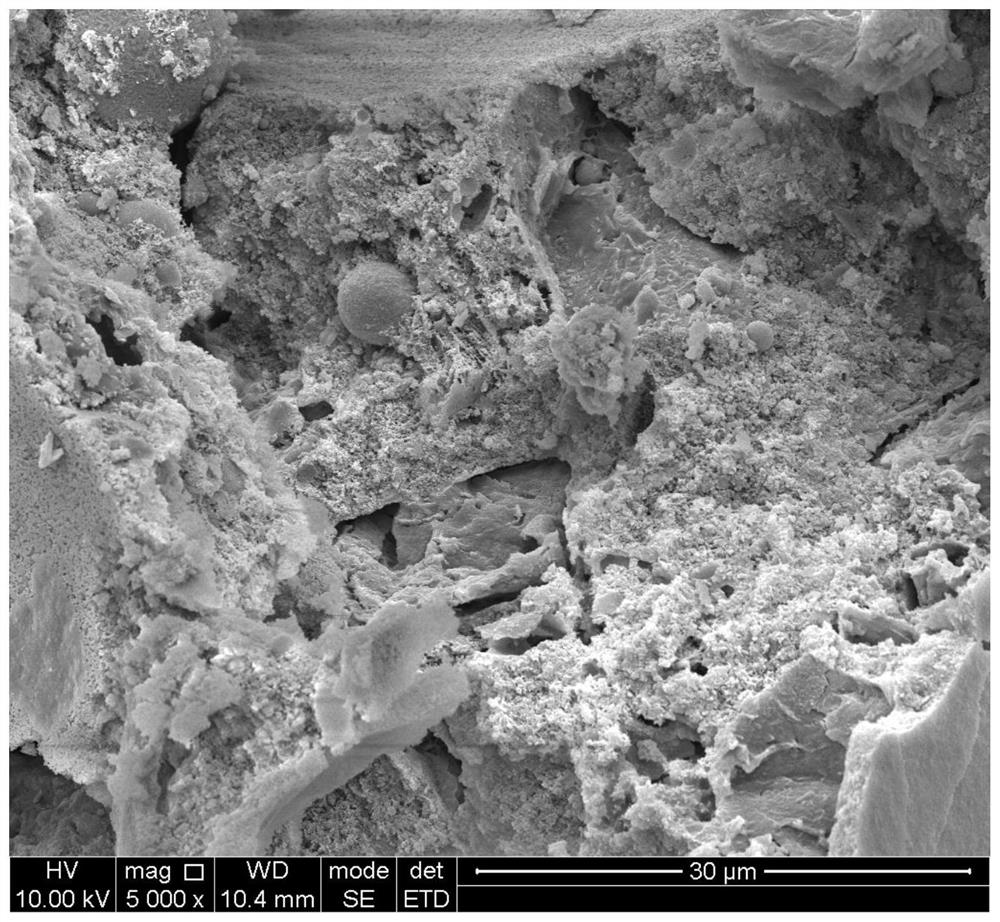

Image

Examples

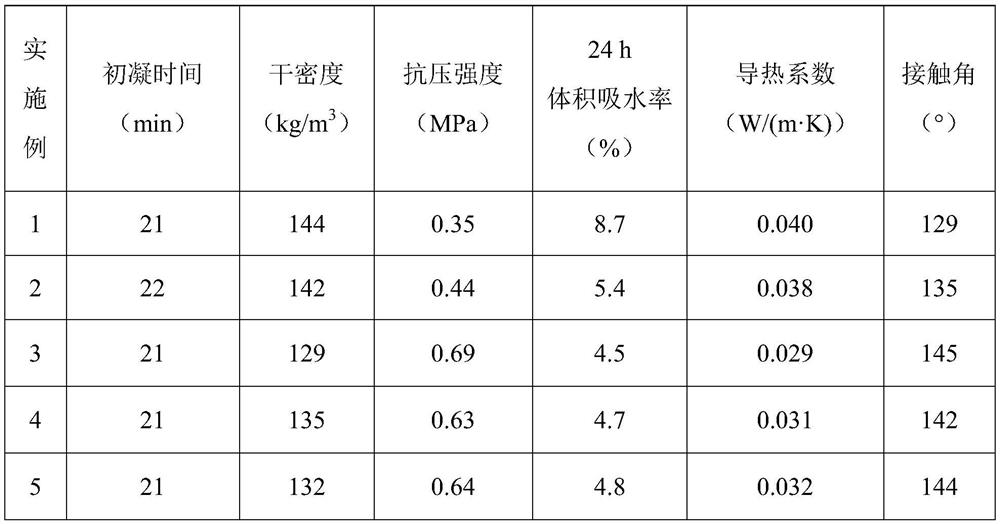

Embodiment 1

[0041]This example provides a kind of hydrophobic thermal insulation and sound insulation foam concrete material, including the following components by mass: 50 parts of Portland cement, 18 parts of mineral admixture, 19 parts of water, 1.5 parts of water reducer, 4.5 parts of coagulant and 6 parts of complex foaming agent;

[0042] Wherein, the composition and mass ratio of composite foaming agent are 3 parts of blowing agent and 3 parts of composite water-repellent; Foaming agent is animal protein active foaming agent; Composite water-repellent comprises the component of following mass parts: 1 part of sodium silanolate, 0.5 part of calcium stearate, 3 parts of polypropylene emulsion and 7 parts of water; Portland cement is 52.5 grade Portland cement; its length is 1 mm to 4 mm, and the aspect ratio is 40 to 60:1 , tensile strength ≥ 3500MPa, elastic modulus ≥ 50GPa, elongation at break ≥ 2.5%, maximum working temperature ≥ 600°C; coagulant consists of the following raw mate...

Embodiment 2

[0053] The components and mass ratio of an ultra-light foam concrete material are 50 parts of Portland cement, 18 parts of mineral admixture, 3 parts of short inorganic fiber, 19 parts of water, 1.5 parts of water reducing agent, 4.5 parts of coagulation accelerator, 6 parts of complex foaming agent;

[0054] Wherein, the composition and mass ratio of composite foaming agent are 3 parts of blowing agent and 3 parts of composite water-repellent; Foaming agent is animal protein active foaming agent; Composite water-repellent comprises the component of following mass parts: 1 part of sodium silanolate, 0.5 part of calcium stearate, 3 parts of polypropylene emulsion and 7 parts of water; Portland cement is 52.5 grade Portland cement; short inorganic fiber is basalt fiber; its length is 1mm ~ 4mm, long diameter The ratio is 40~60:1, the tensile strength is ≥3500MPa, the elastic modulus is ≥50GPa, the elongation at break is ≥2.5%, and the maximum working temperature is ≥600℃; the co...

Embodiment 3

[0065] The components and mass ratio of an ultra-light foam concrete material are 50 parts of Portland cement, 18 parts of mineral admixture, 3 parts of short inorganic fiber, 19 parts of water, 1.5 parts of water reducing agent, 4.5 parts of coagulation accelerator, 6 parts of complex foaming agent;

[0066] Among them, the composition and mass ratio of the complex foaming agent are 3 parts of foaming agent, 3 parts of composite water repellent, and 0.06 parts of stabilizer; the foaming agent is an animal protein active foaming agent; the stabilizer is a nonionic surfactant , the nonionic surfactant comprises the following components by mass: 1 part of methyl cellulose, 1 part of ethyl cellulose, 1 part of hydroxypropyl methyl cellulose, 3 parts of starch ether and 1 part of lithium carbonate; The water-repellent agent includes the following components by mass: 1 part of sodium methyl siliconate, 0.5 part of calcium stearate, 3 parts of polypropylene emulsion and 7 parts of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com