Fuel cell gas diffusion layer continuous preparation method and production line

A technology of gas diffusion layer and conductive carbon layer, which is applied in the direction of fuel cells, electrical components, battery electrodes, etc., can solve the problems of prolonging the preparation time of gas diffusion layer, poor uniformity, and failure to achieve uniformity of diffusion layer coating, and achieve The effect of avoiding the problem of slurry penetration and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

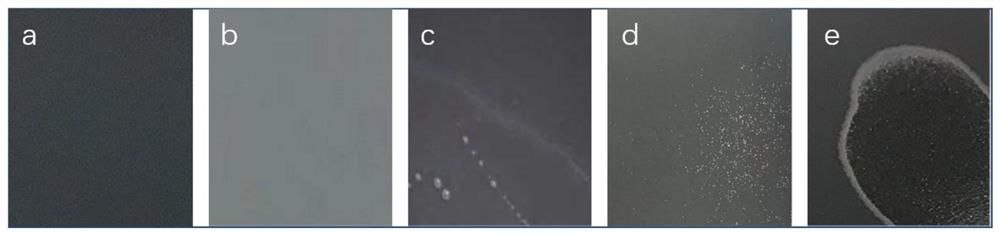

[0061] Step (1): prepare a pore-forming agent solution: weigh 100 g of ammonium bicarbonate and 2000 ml of deionized water, mix them evenly, and set aside for later use;

[0062] Configure conductive carbon slurry: weigh 200g of graphene, 800ml of deionized water, and 3600ml of anhydrous ethanol respectively, mix them evenly, and use a high-speed mixer to stir for 30min at a speed of 1100r / min.

[0063] To configure the hydrophobic agent solution: Weigh 100 g of PTFE emulsion and 2000 ml of deionized water, mix them evenly, and place them in an ultrasonic cleaning machine for ultrasonic treatment for 10 min, for later use.

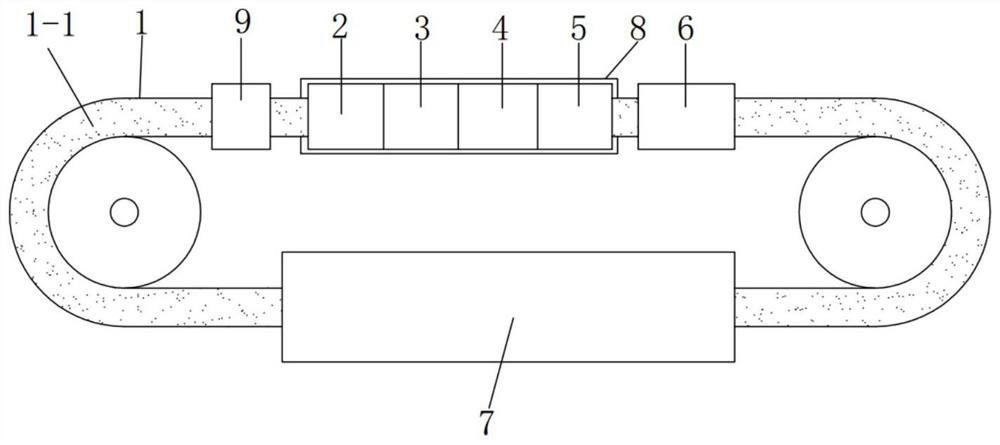

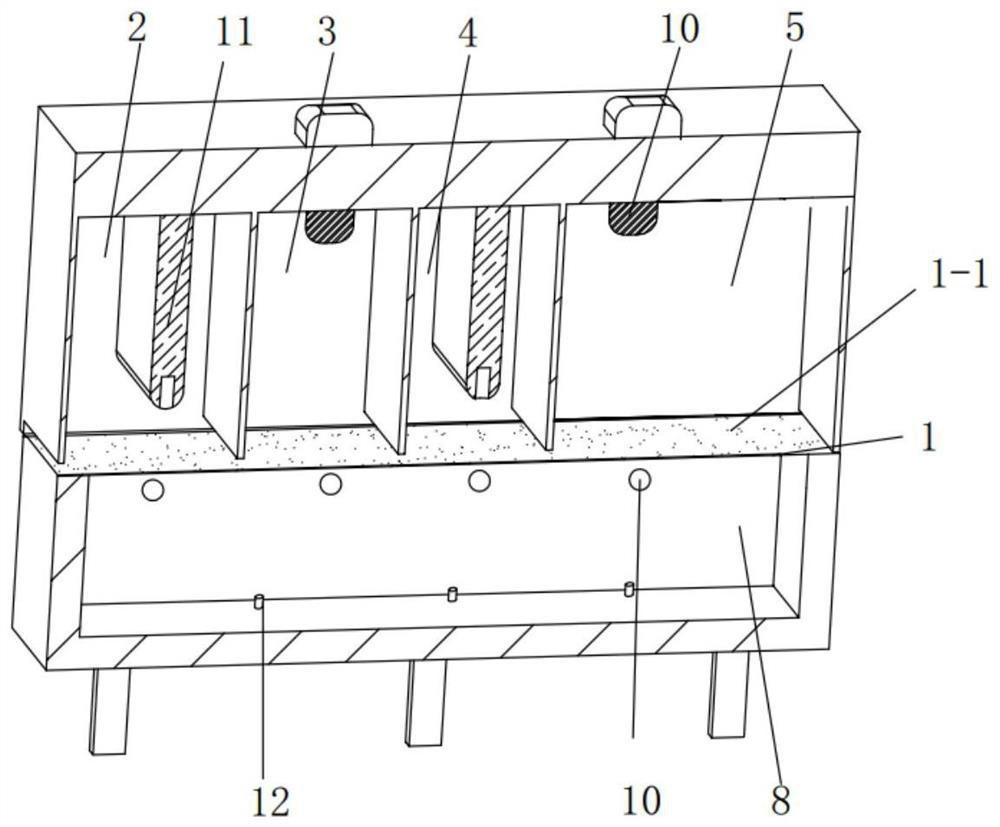

[0064] The prepared pore-forming agent solution and conductive carbon slurry are respectively fed into the first slurry spraying area 2 and the second slurry spraying area 4, and communicated with the nozzles in each area respectively for use; the configured hydrophobic agent The solution is fed into the first atomization zone 3, the second atomization zon...

Embodiment 2

[0075] Preparation of pore-forming agent solution: Weigh 100g of sodium carbonate and 2500ml of deionized water and mix them evenly for later use;

[0076] Configure the conductive carbon slurry: respectively weigh 200g of acetylene black, 1600ml of deionized water, and 4200ml of ethanol, mix them evenly, and stir with a high-speed mixer for 30min at a speed of 1100r / min, and take them out for use after the time is up;

[0077] To configure the hydrophobic agent solution: Weigh 100 g of polyvinylidene fluoride emulsion and 2500 ml of deionized water, mix them evenly, and place them in an ultrasonic cleaning machine for ultrasonic treatment for 10 min, for use.

[0078]The prepared pore-forming agent solution and conductive carbon slurry are respectively fed into the first slurry spraying area 2 and the second slurry spraying area 4, and communicated with the nozzles in each area respectively for use; the configured hydrophobic agent The solution is fed into the first atomizati...

Embodiment 3

[0089] Preparation of pore-forming agent solution: Weigh 100g of sodium bicarbonate and 3000ml of deionized water and mix them evenly for later use;

[0090] Configure the conductive carbon paste: weigh 200g of carbon nanotubes, 2400ml of deionized water, and 4800ml of ethanol, respectively, and mix them, and use a high-speed mixer to stir for 30 minutes at a speed of 1100 r / min.

[0091] To configure the hydrophobic agent solution: Weigh 100 g of ethylene-tetrafluoroethylene emulsion and 3000 ml of deionized water, mix them evenly, and place them in an ultrasonic cleaning machine for sonication for 10 min for later use.

[0092] The prepared pore-forming agent solution and conductive carbon slurry are respectively fed into the first slurry spraying area 2 and the second slurry spraying area 4, and communicated with the nozzles in each area respectively for use; the configured hydrophobic agent The solution is fed into the first atomization zone 3, the second atomization zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com