Method and device for engraving three-dimensional patterns in glass

A three-dimensional pattern and glass technology, which is applied in decorative art, technology for producing decorative surface effects, laser welding equipment, etc., can solve problems such as insufficient power stability, dislocation of pattern splicing, and unstable laser light path, etc., to reduce vibration, The laser focus point is stable and the effect of improving the engraving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

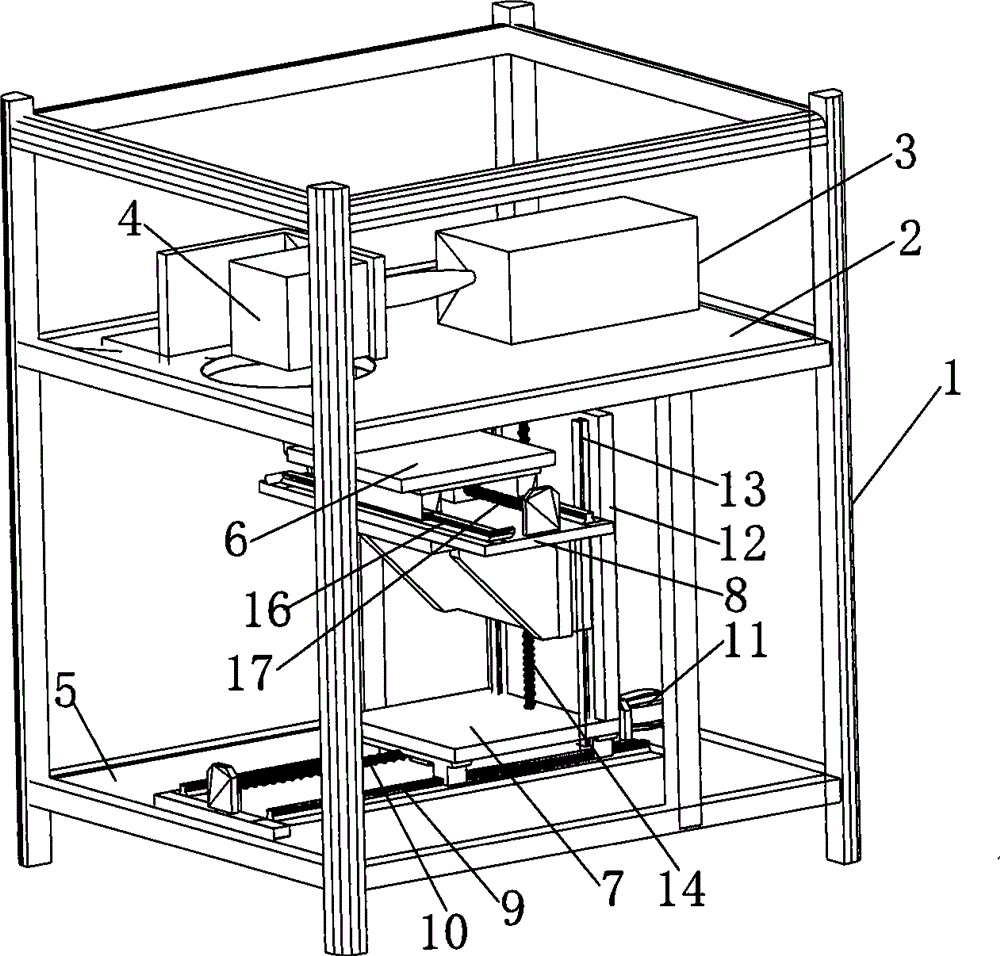

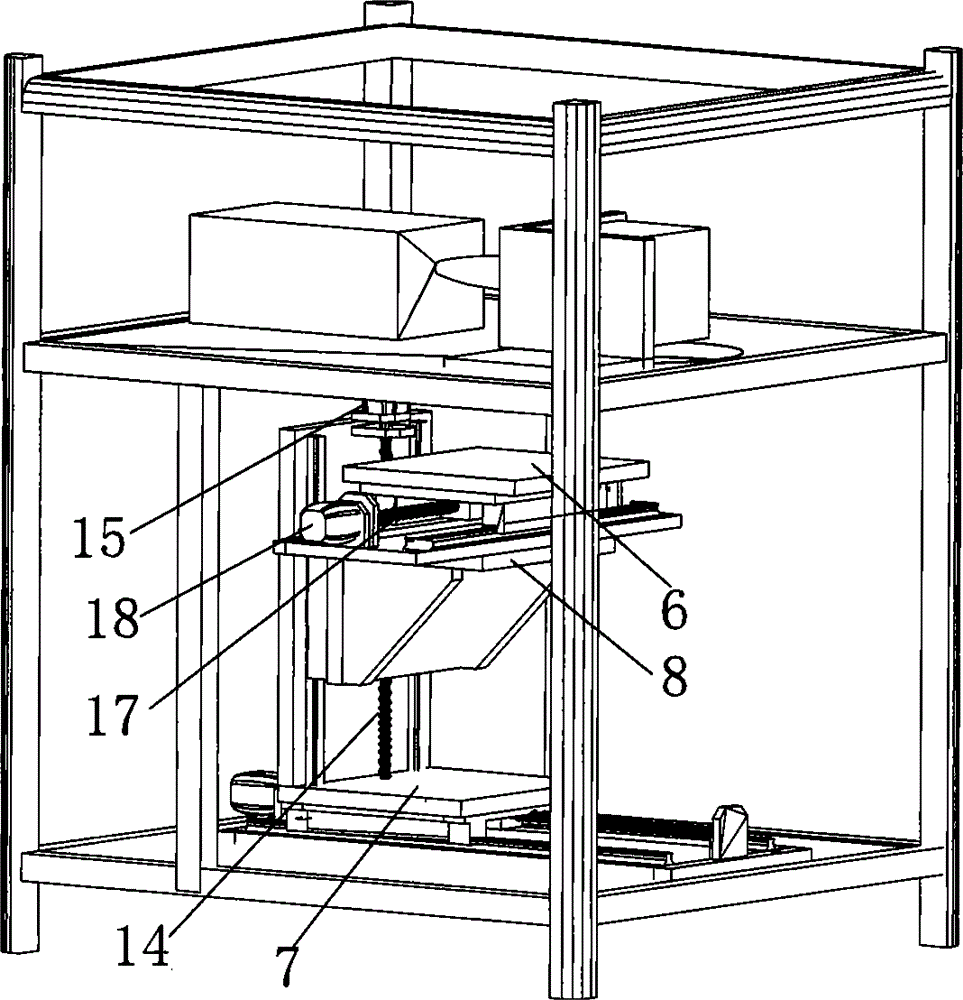

[0024] Embodiment: A method for engraving a three-dimensional pattern in glass, including a process of forming a damage point in the glass by using a laser focusing method, and also including a process of moving the glass to make the laser focus point engrave it.

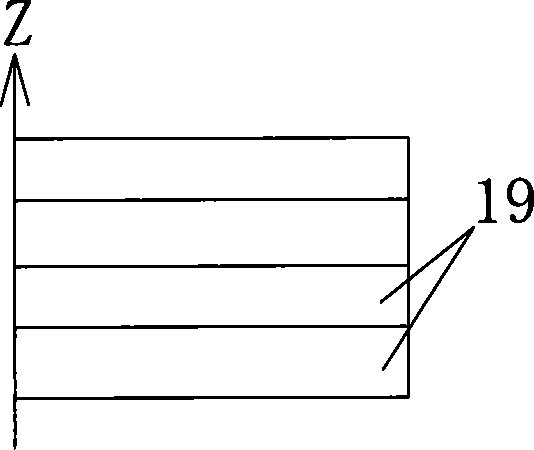

[0025] Specifically, before the laser forms the first damage point in the glass, a glass displacement path range is first set, and in the process of setting the glass displacement path range, the engraved area is divided into one or More than two parallel engraving partitions, any one of the engraving partitions is composed of at least one plane and the outer surface of the glass, any one of the above-mentioned planes forms an angle less than or equal to 90 degrees with the X-Y axis plane, and any phase The adjacent planes are all parallel to each other. In the process of forming the damage point by laser focusing method, the glass is first moved so that the first engraved partition reaches below the laser focus poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com