Patents

Literature

53 results about "Glass engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass engraving is a form of decorative glasswork that involves engraving a glass surface or object. It is distinct from glass art in the narrow sense, which refers to moulding and blowing glass, and from glass etching which uses acidic, caustic, or abrasive substances to achieve artistic effects. Some artists may combine two or more techniques. There are several different types of glass engraving.

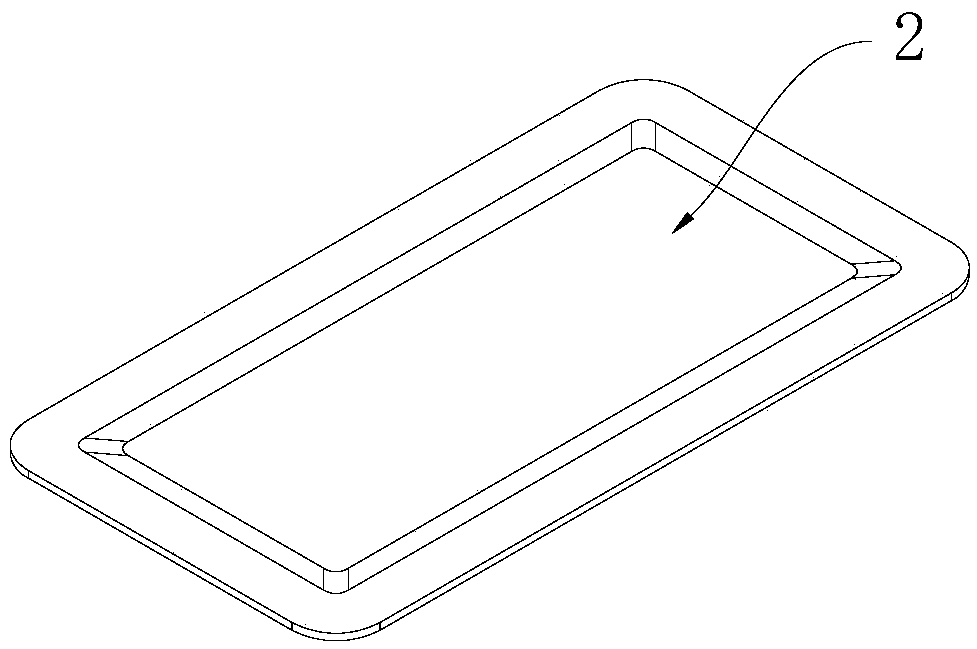

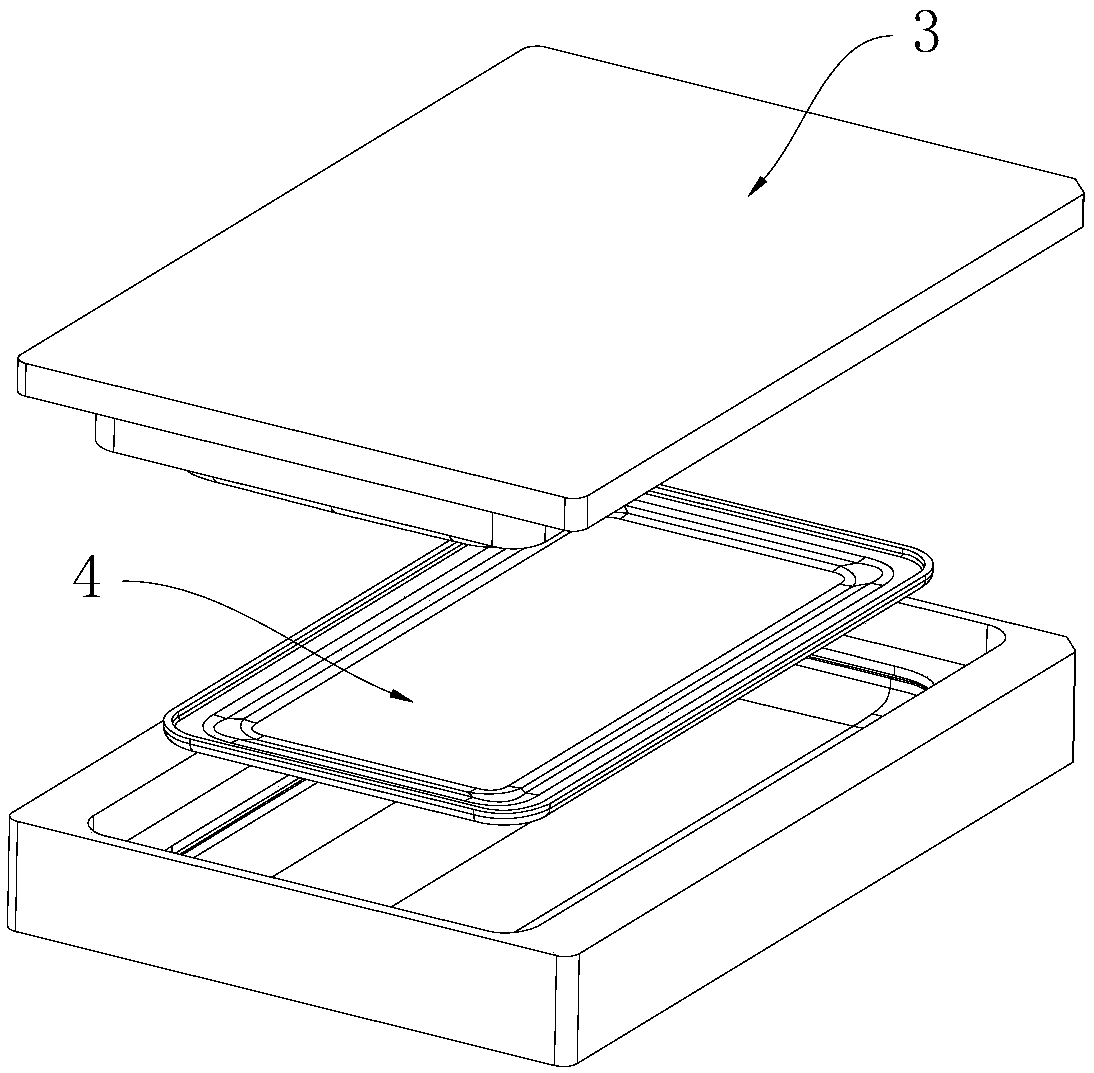

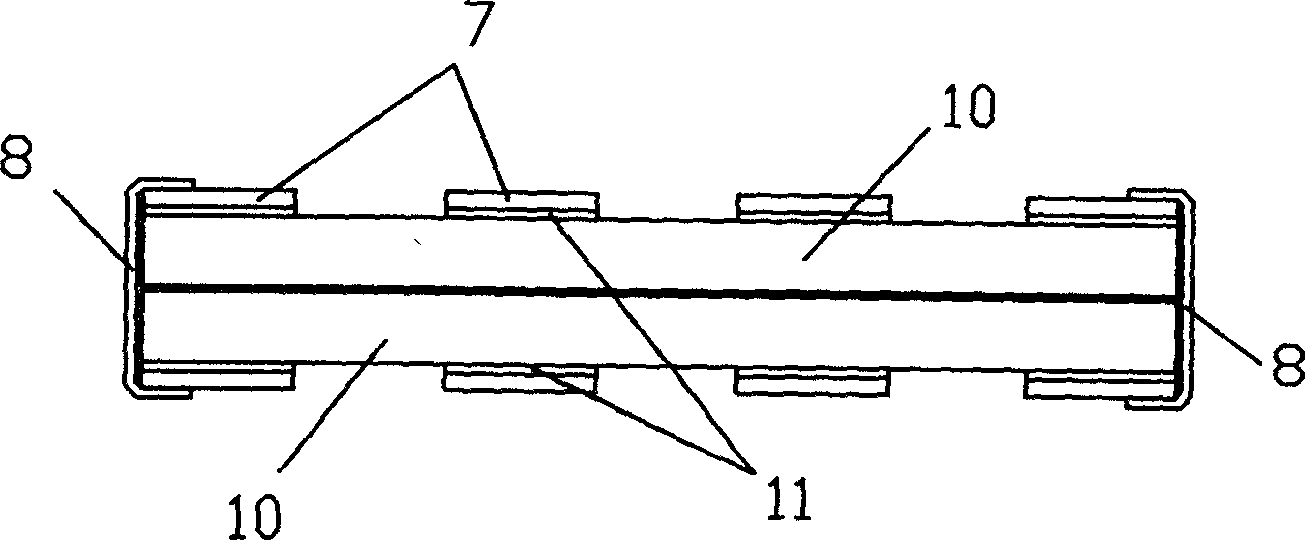

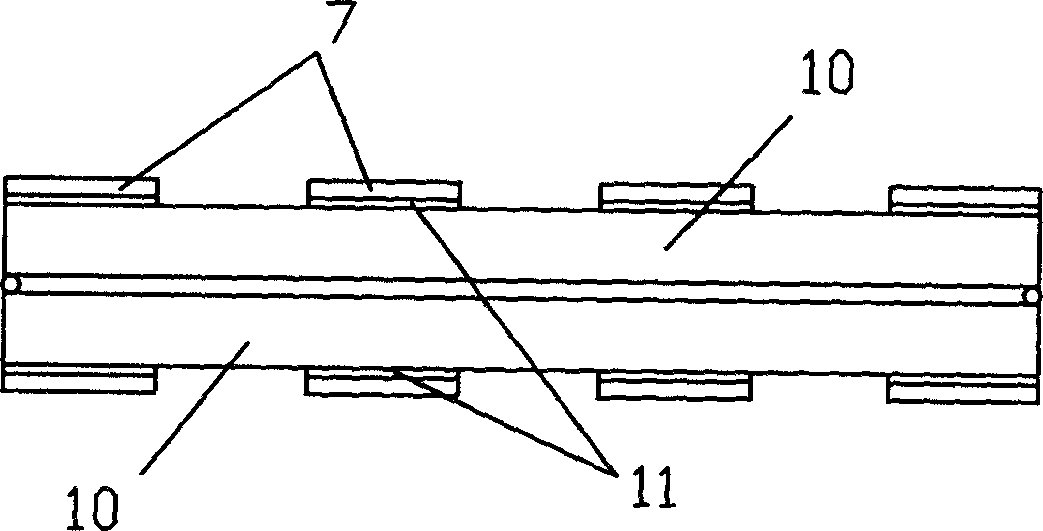

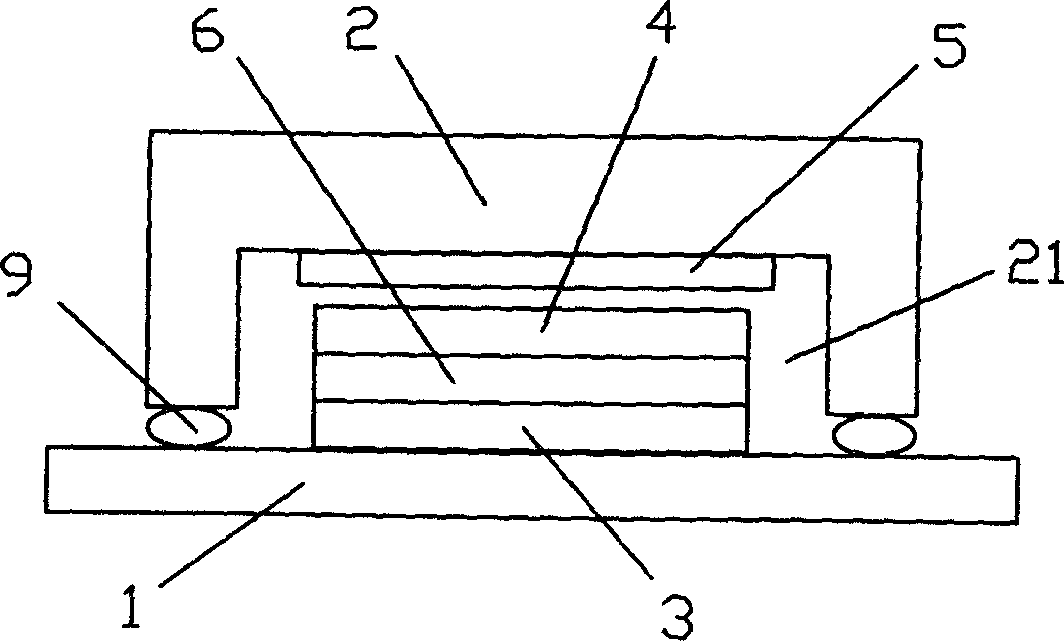

Method for making glass rear cover of organic electroluminescence display

ActiveCN1631828AAvoid deformationSolve the problem that it is impossible to make high-precision alignment marks at the same timeDisplay deviceElectric drive

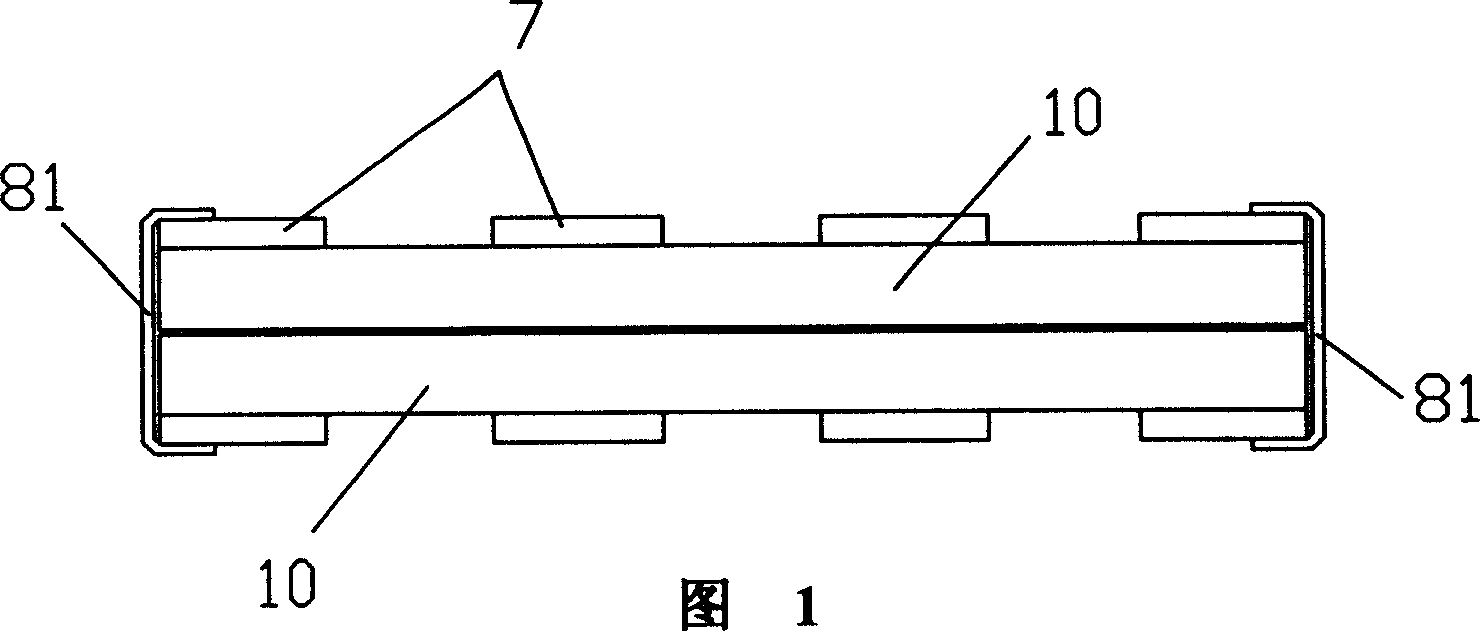

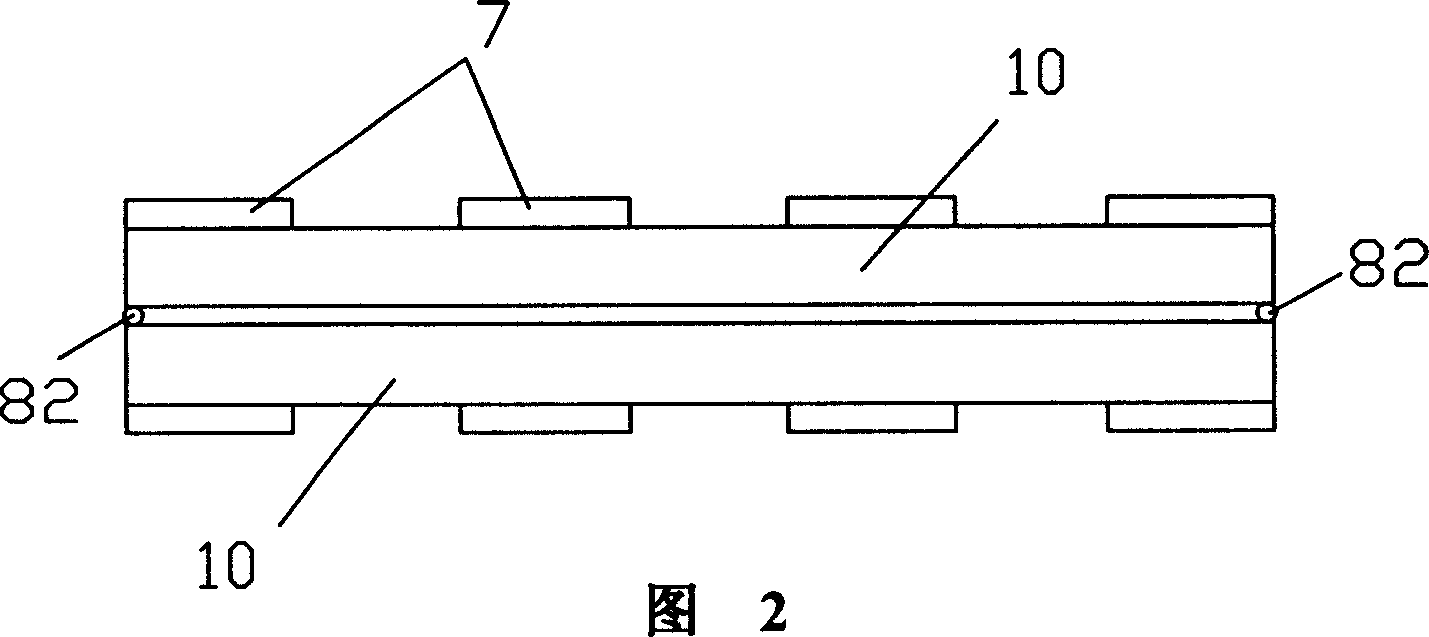

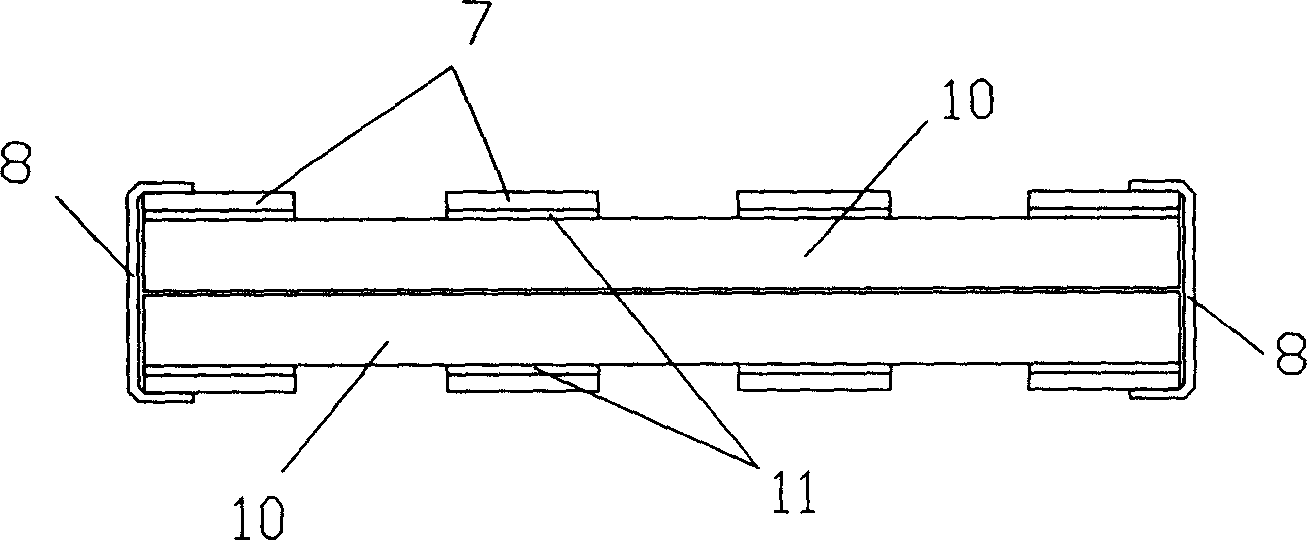

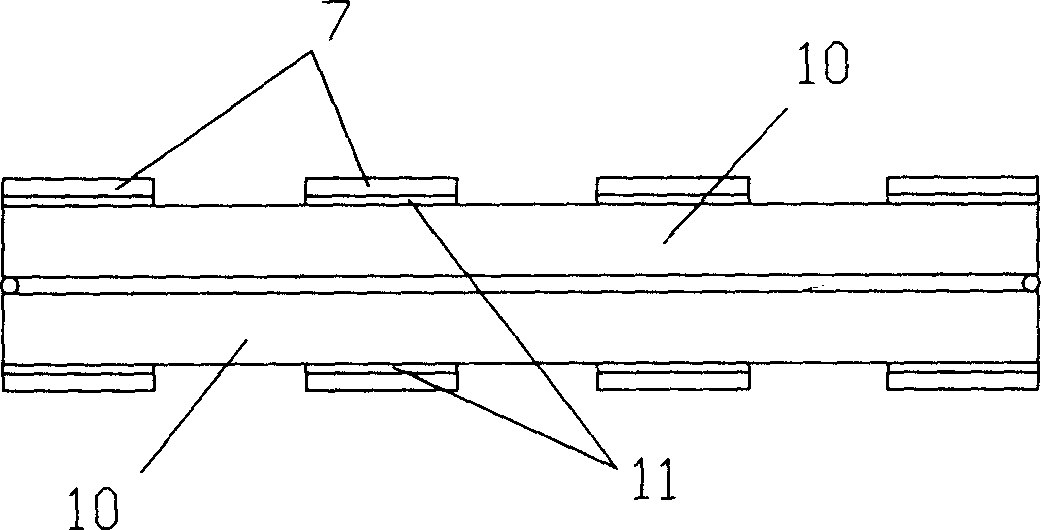

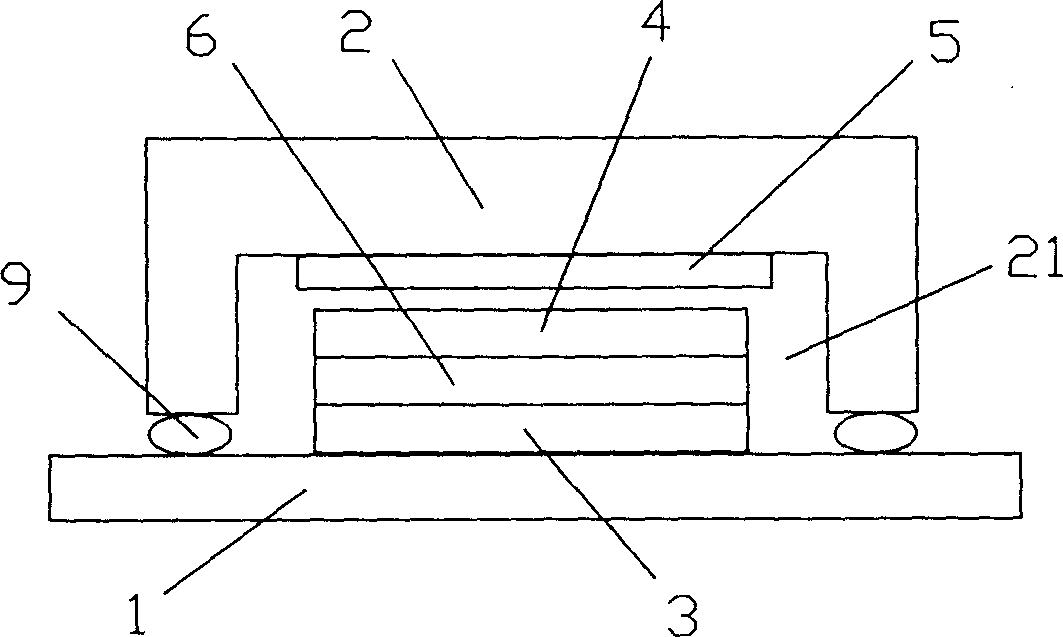

Disclosed is a method for making glass back cover of organic electric-driver flaring display, which includes the following steps: firstly, wash the glass plate (10), then paste a layer of erosion-resisting film (7) on its face ; then cut the figure by laser and clear the film (7) in the figure; stick the two glass plates with figure on their backs and seal their edges, use etching solution to etch, reaching the depth needed; clear away proteting film (7) the glass plate (10), separate and cut the two plates (10), obtaining the glass back cover (2) of organic electric-driven flaring display. The invention has high accuracy and efficiency, low cost, can be applied in glass engraving, etch on viehcle glass and other industries.

Owner:TRULY SEMICON

Machining control method for glass engraving and milling machine

InactiveCN105522484AImplement automatic detectionReduce machining errorsAutomatic grinding controlMachine controlEngineering

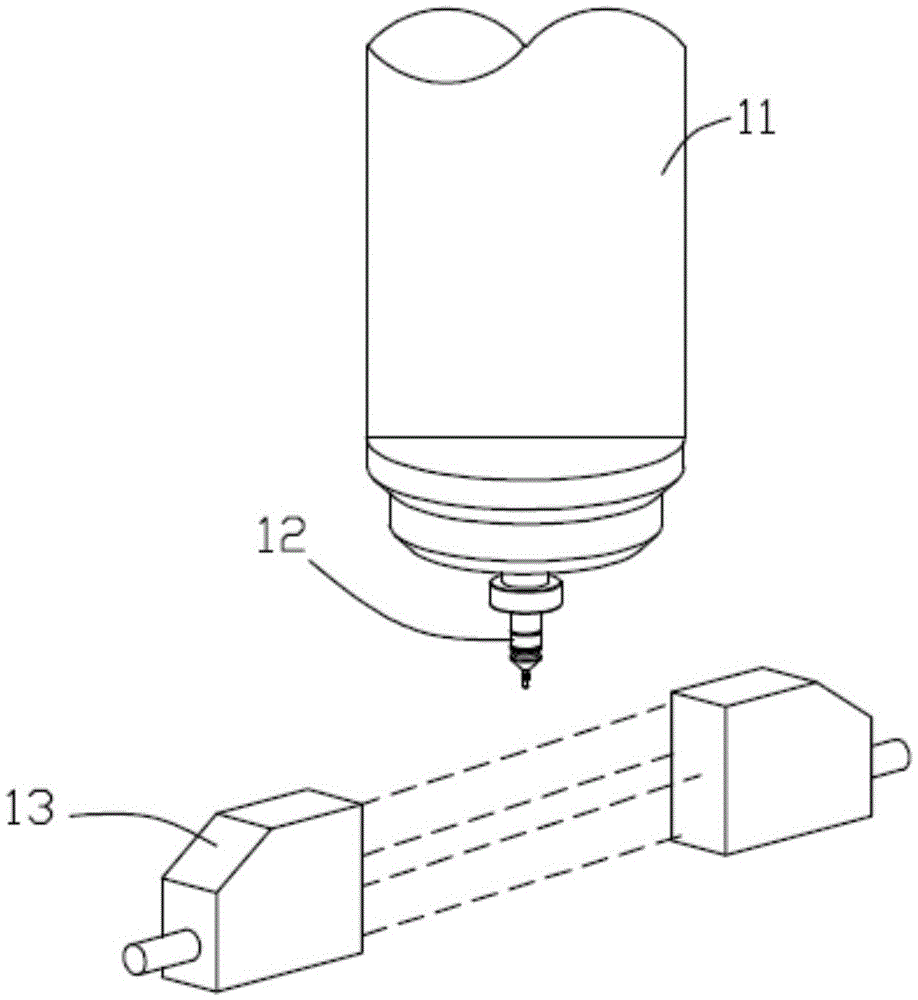

The invention provides a machining control method for a glass engraving and milling machine. The machining control method comprises the steps of detecting boundary dimension data of cutters located in the detection area through an optical detection system, then obtaining the abrasion loss X of the cutters and controlling a main shaft to move for feed compensation according to the abrasion loss X of the cutters; controlling and enabling the main shaft to rotate, detecting the deflection values of the cutters at different rotation speeds and judging whether to carry out machining or grab the cutters again. According to the invention, the cutters for glass engraving and milling can be automatically detected, the main shaft can be controlled to move for feed compensation according to the actual abrasion loss, the machining errors can be reduced, and the machining quality can be improved; deflection of the cutters at different rotation speeds can be automatically detected for judging whether to carry out machining, and therefore the yield of product machining can be improved, and the loss can be lowered.

Owner:苏州瑞格思创光电科技有限公司

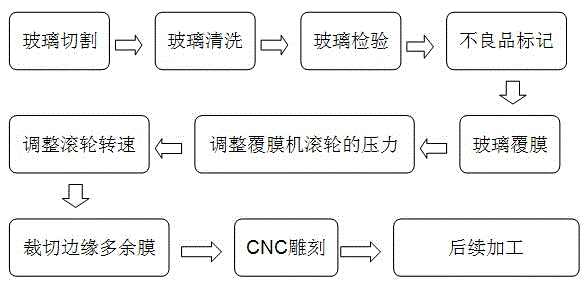

Technology for reducing scratches of glass optical lenses during engraving

InactiveCN104478204AReduce exposureReduce polishing processFlexible article cleaningGlass severing apparatusLarge screenEngineering

The invention relates to a technology for reducing scratches of a glass optical lens during engraving, and concretely relates to a production technology of the glass screen of a large-screen intelligent mobile phone and a panel computer before an engraving process. The technology comprises the following steps: cutting large piece glass, cleaning, examining, carrying out double side film coverage by adopting a film covering machine, cutting off the superfluous film at the edge of glass after the glass film coverage, engraving the glass, uncovering the film after glass engraving, and subsequently processing. The film coverage treatment process of the right side and the wrong side of the glass lens is carried out before the engraving process, so the technology reduces the contact of the surface of the glass with the outside in the engraving process, thereby the scratching probability is reduced, and the yield is improved; and no polishing treatment is carried out after the glass product is engraved, so the polishing process is omitted, and the production cost is reduced.

Owner:中环高科(天津)股份有限公司

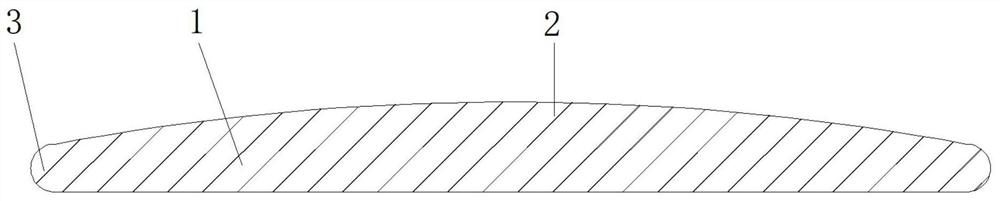

Molding processing method of 3D curved glass with non-equal thickness

InactiveCN108911491ASmall sizeImprove rigidityGlass reforming apparatusGlass engraverGlass engraving

The invention discloses a molding processing method of 3D curved glass with non-equal thickness. The method is realized based on a glass engraving machine, a mould processing device and a 3D glass hotbending machine. The method comprises the following steps: S1, processing a planar uniform-thick glass substrate with predetermined thickness by utilizing the glass engraving machine, and requiring acurved surface required by processing one or more surfaces of the glass substrate so as to obtain a 3D curved glass workpiece; S2, manufacturing a mould by utilizing a mould processing device, and requiring that a pressing profiling surface of the mould is matched with the surface shape of the 3D curved glass workpiece; S3, loading the mould on a 3D glass hot bending machine, drying the mould toperform hot pressing on the heated 3D curved glass workpiece by utilizing the 3D glass hot bending machine; cooling the 3D curved glass workpiece after hot pressing molding is carried out so as to obtain the 3D curved glass product.

Owner:深圳市环球同创机械有限公司

Method for fabricating organic electroluminescent display and back cover made from glass

The processing method includes following steps: at first to clean glass plate and plate thin transitional layer and paint photonasty anti-corrosion pretecting layer at the obverse side, to remove the transitional and pretecting layers in pattern to make corrosion pattern by photoetching, to fit two glass plates with etched flute pattern together back to back and seal the around edge, then to etch it till required deep by etching solution, to remove the protecting layer and transitional layer at surface of the glass plates and separate the two glass plates, the glass rear lid of organic electroluminescence display is produced.

Owner:TRULY SEMICON

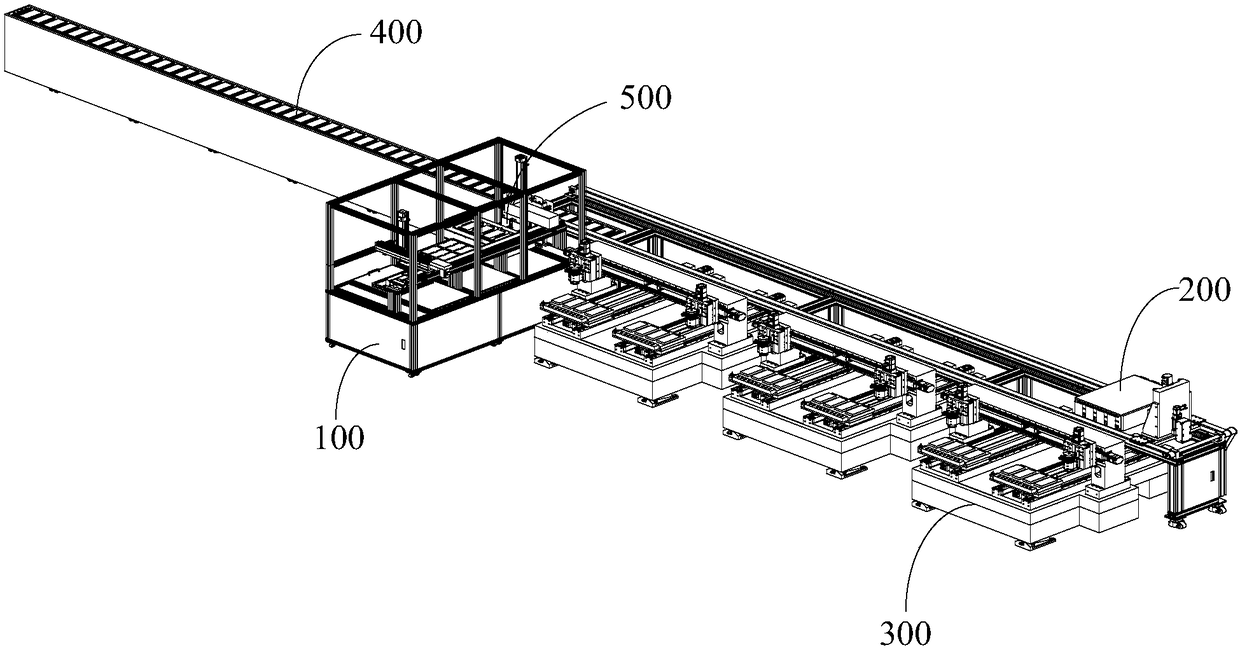

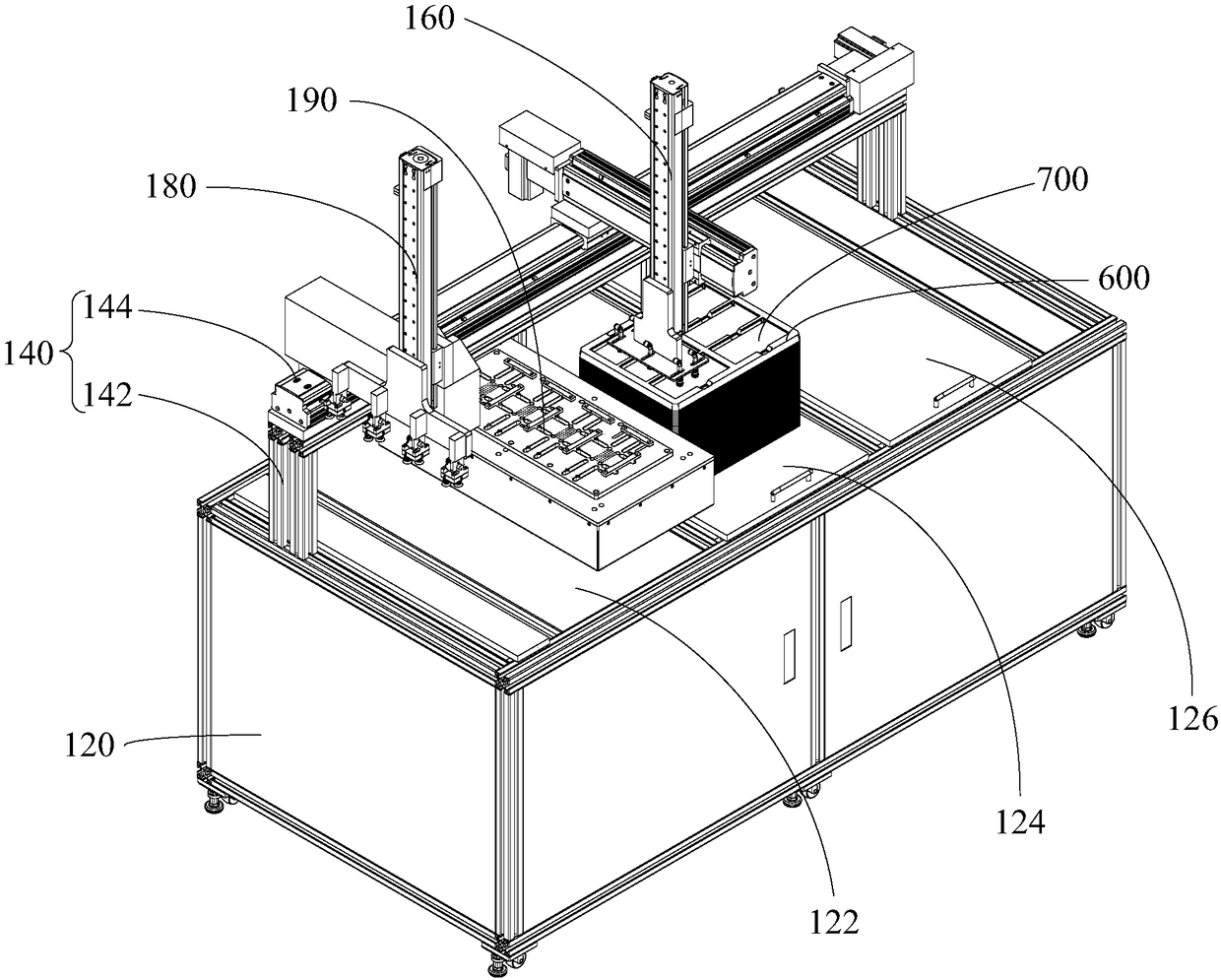

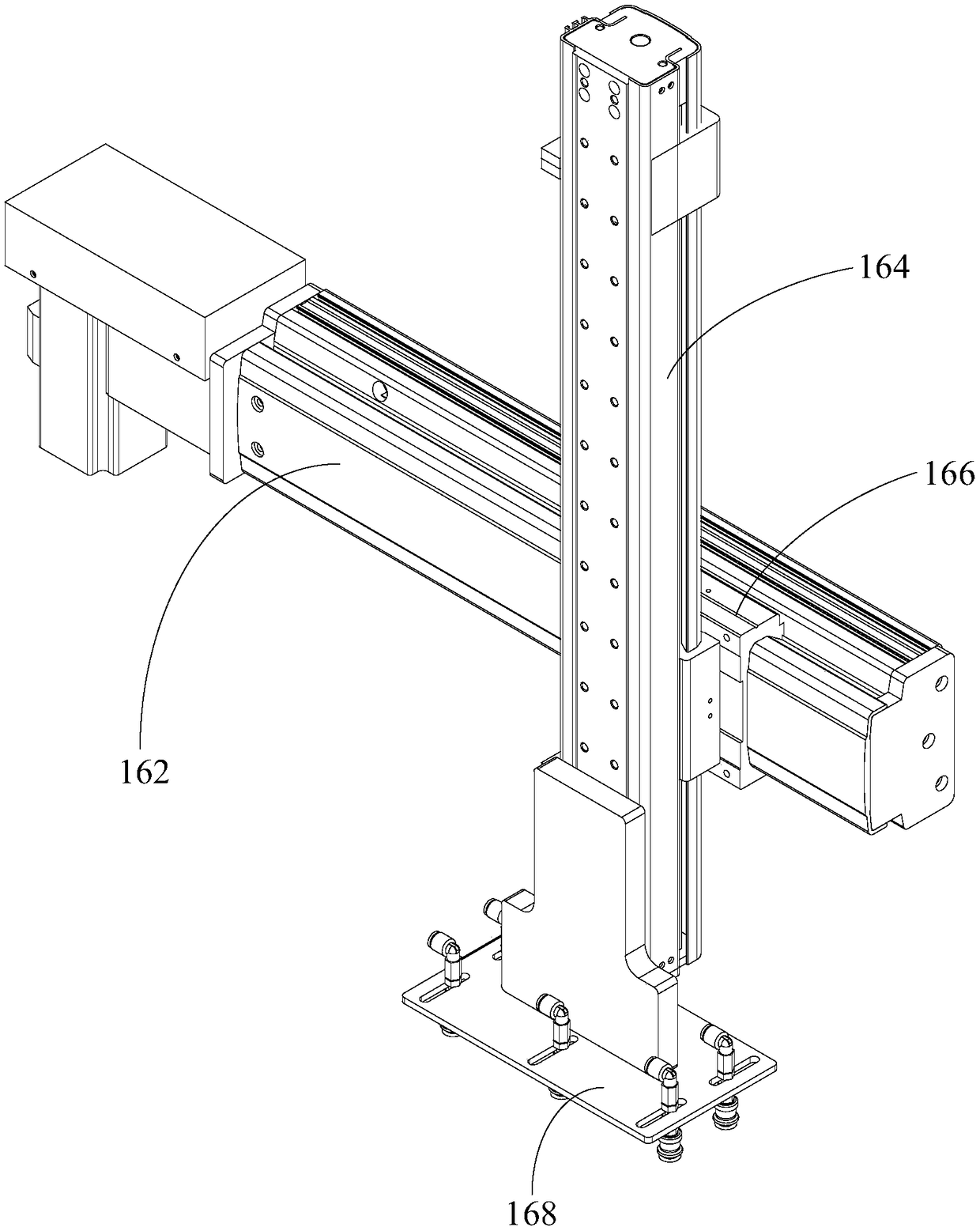

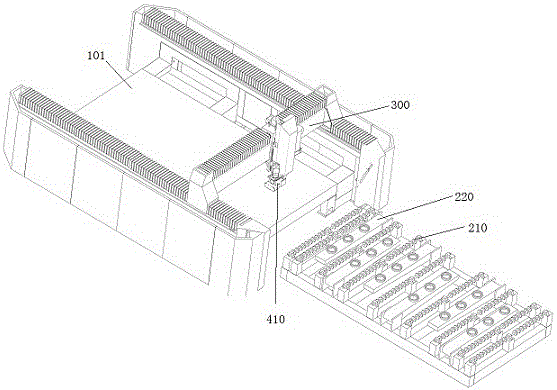

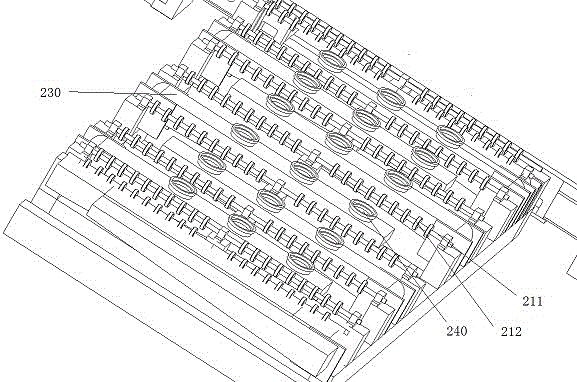

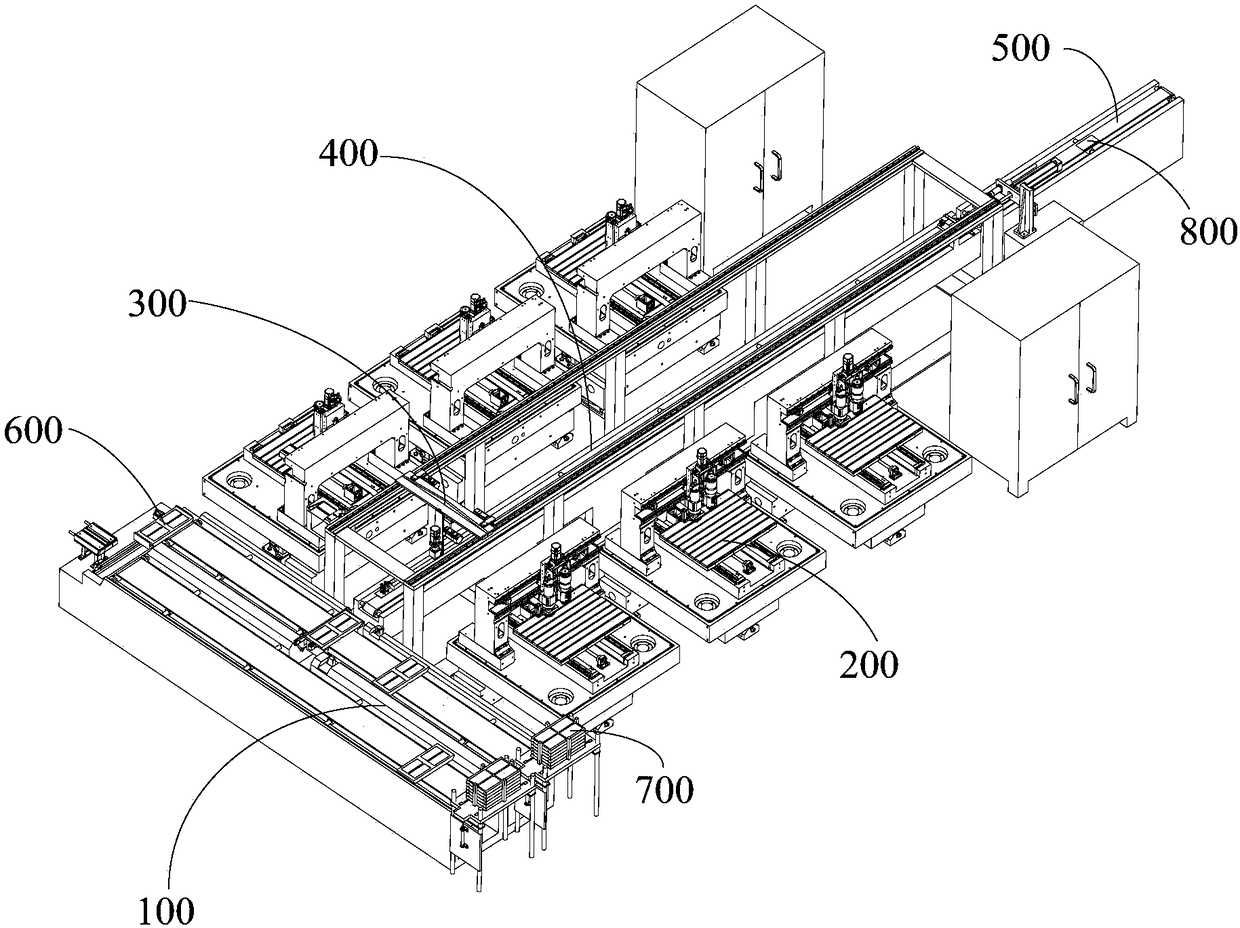

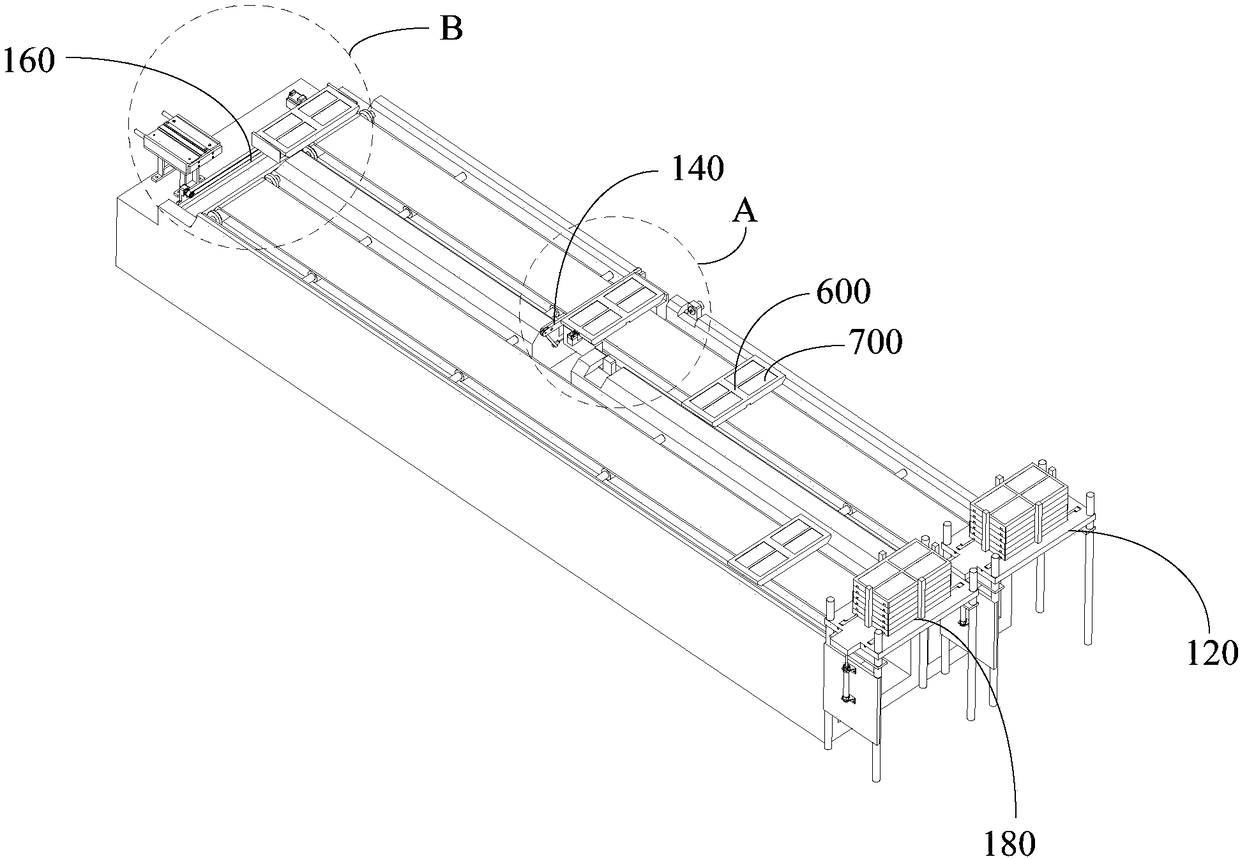

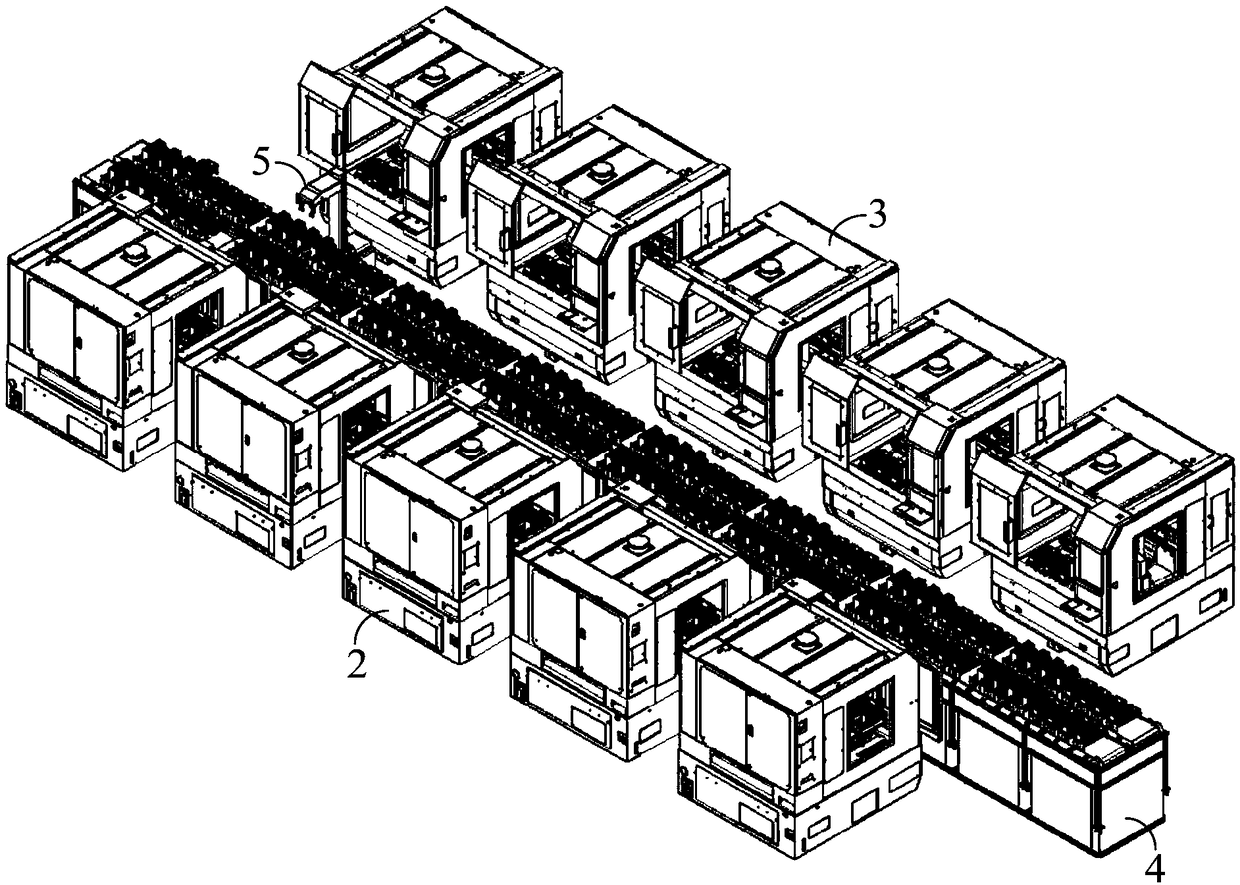

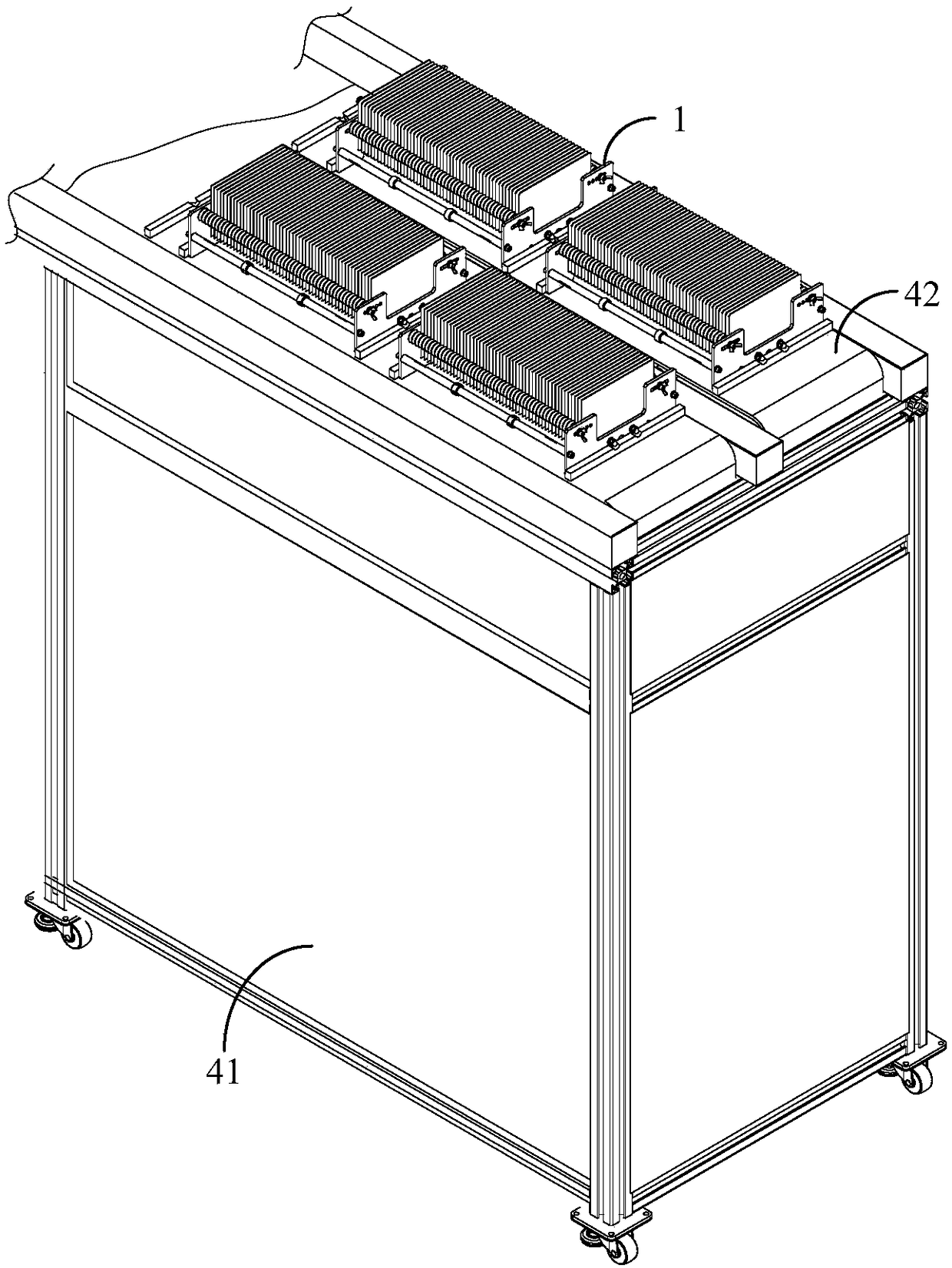

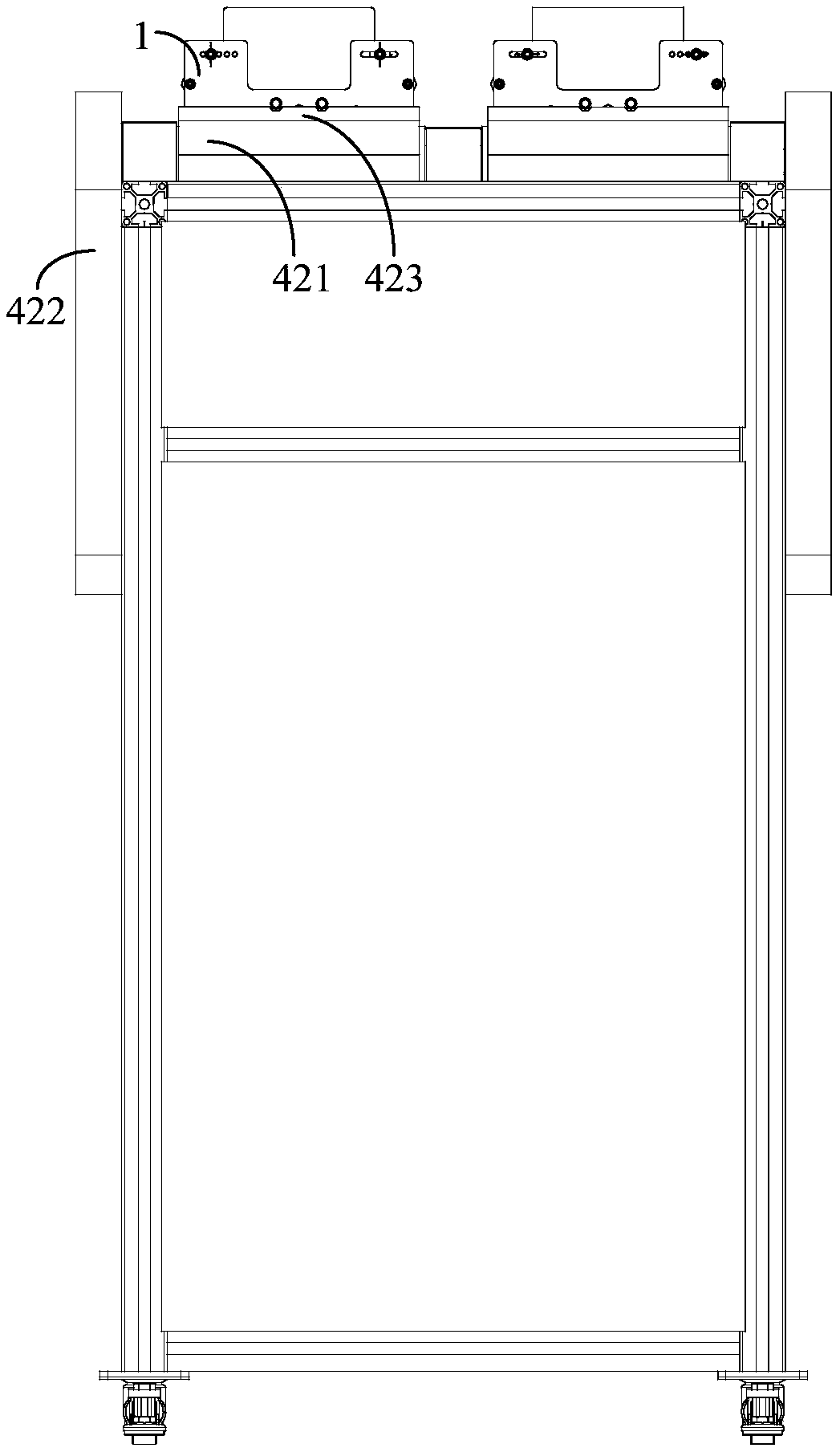

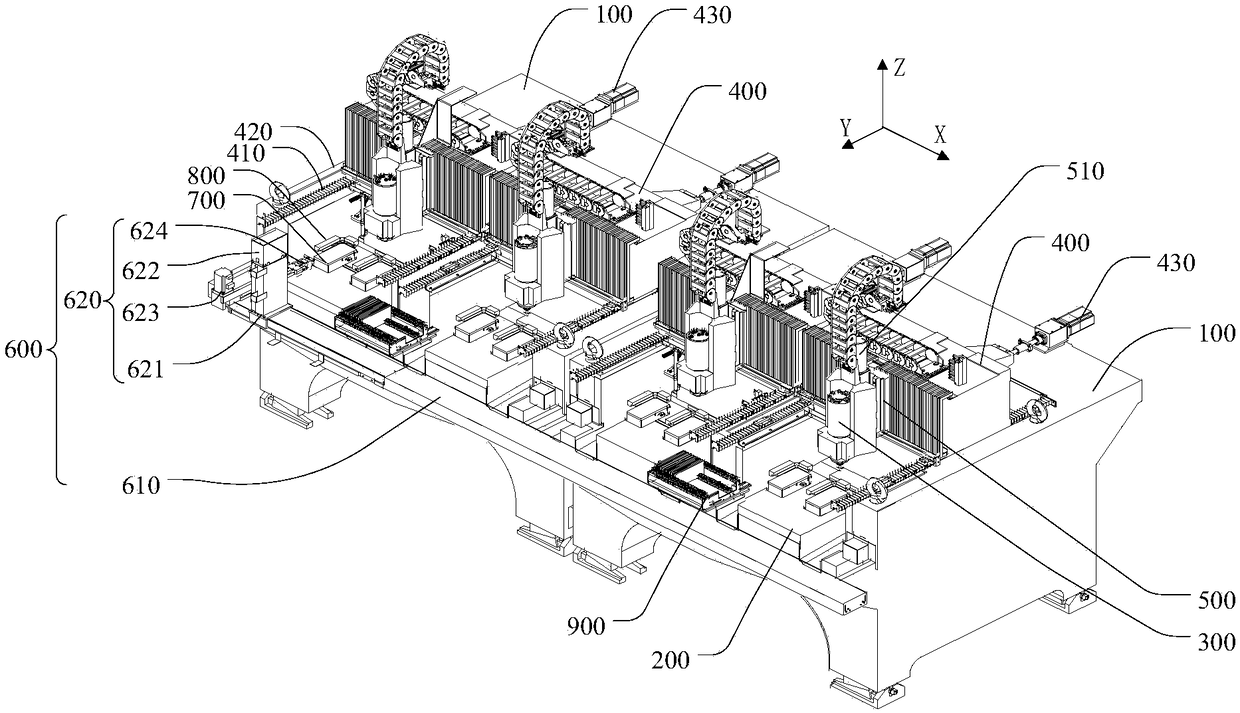

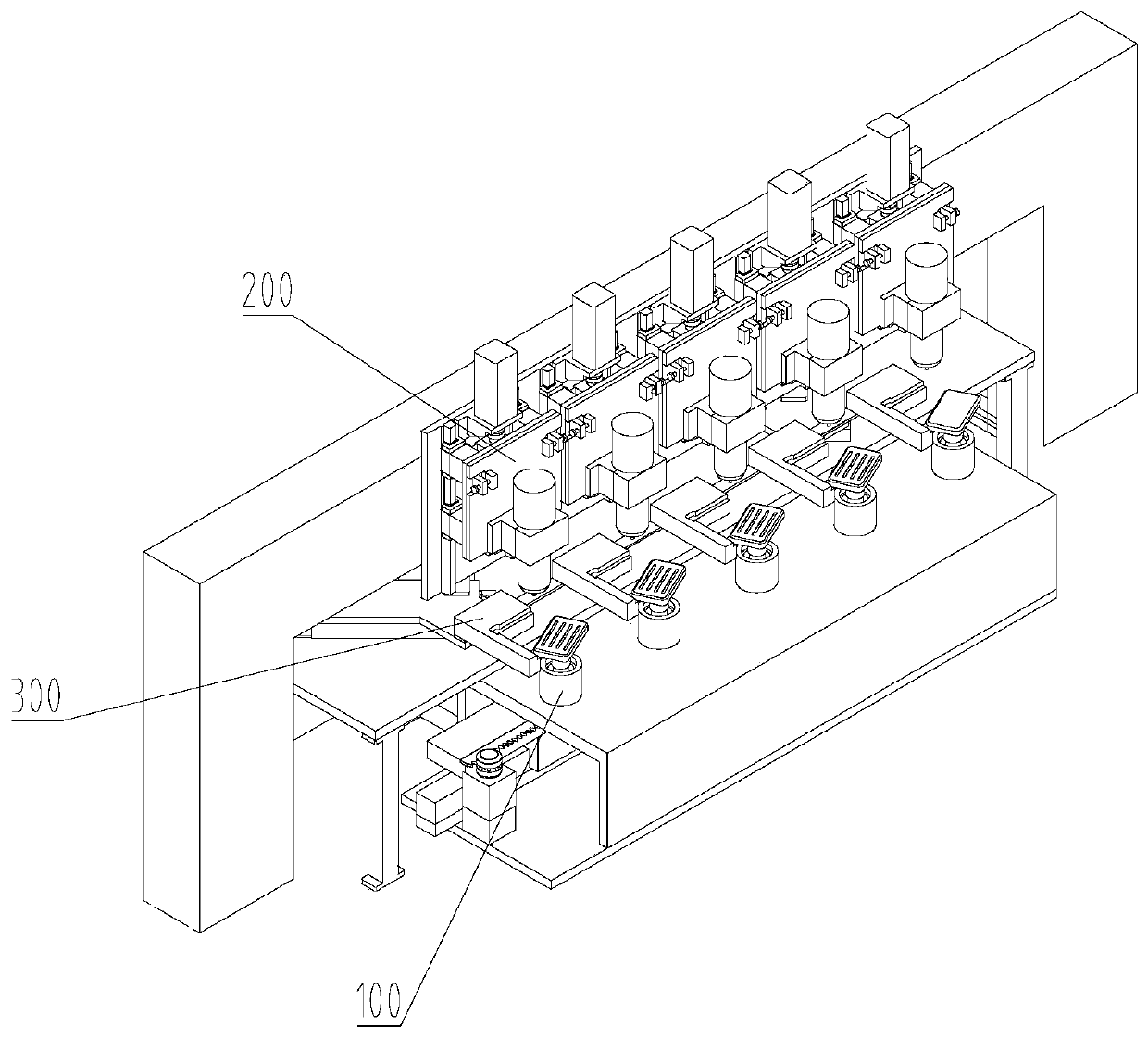

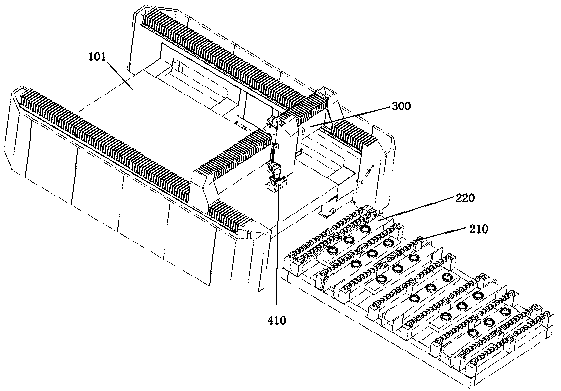

Automatic production line based on glass engraving and milling machines

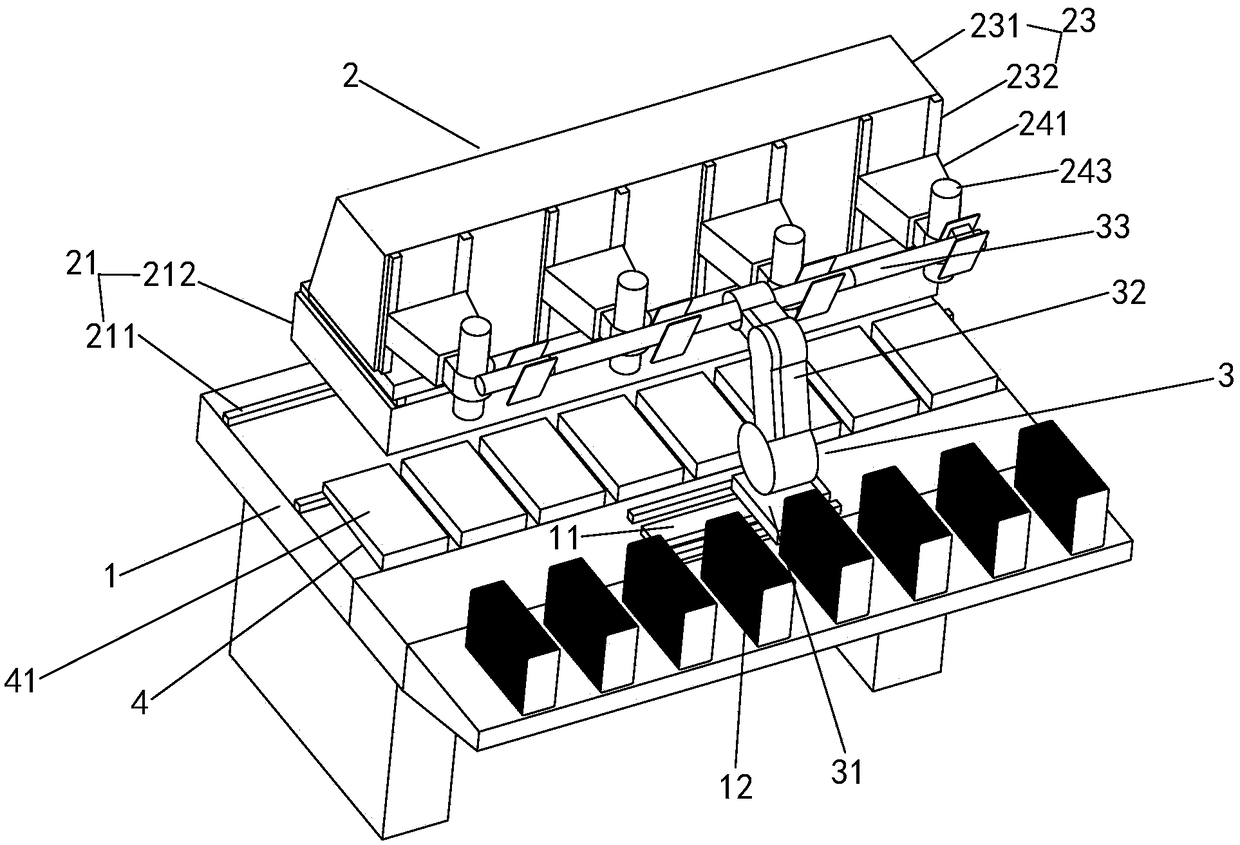

PendingCN108583113ARealize automatic supplyRealize automatic feeding processModel makingProduction lineEngineering

The invention discloses an automatic production line based on glass engraving and milling machines. The automatic production line based on the glass engraving and milling machines comprises a feedingdevice, a feeding and blanking device, multiple dual-channel glass engraving and milling machines, and a cleaning device, wherein the feeding device is located on one side of the tail end of the feeding and blanking device, and is used for taking out glass materials in trays and providing the glass materials to the feeding and blanking device; the feeding and blanking device stretches across the multiple dual-channel glass engraving and milling machines, and is used for placing the glass materials provided by the feeding device onto the multiple dual-channel glass engraving and milling machines; the multiple dual-channel glass engraving and milling machines are arranged under the feeding and blanking device at intervals, and are used for processing the glass materials into glass finished products; the feeding and discharging device is further used for taking out the glass finished products from the dual-channel glass engraving and milling machines and providing the glass finished products to the cleaning device; and the cleaning device is located at the tail end of the feeding and blanking device, is connected with the feeding and blanking device, and is used for cleaning the glassfinished products.

Owner:SHENZHEN CREATE CENTURY MACHINERY

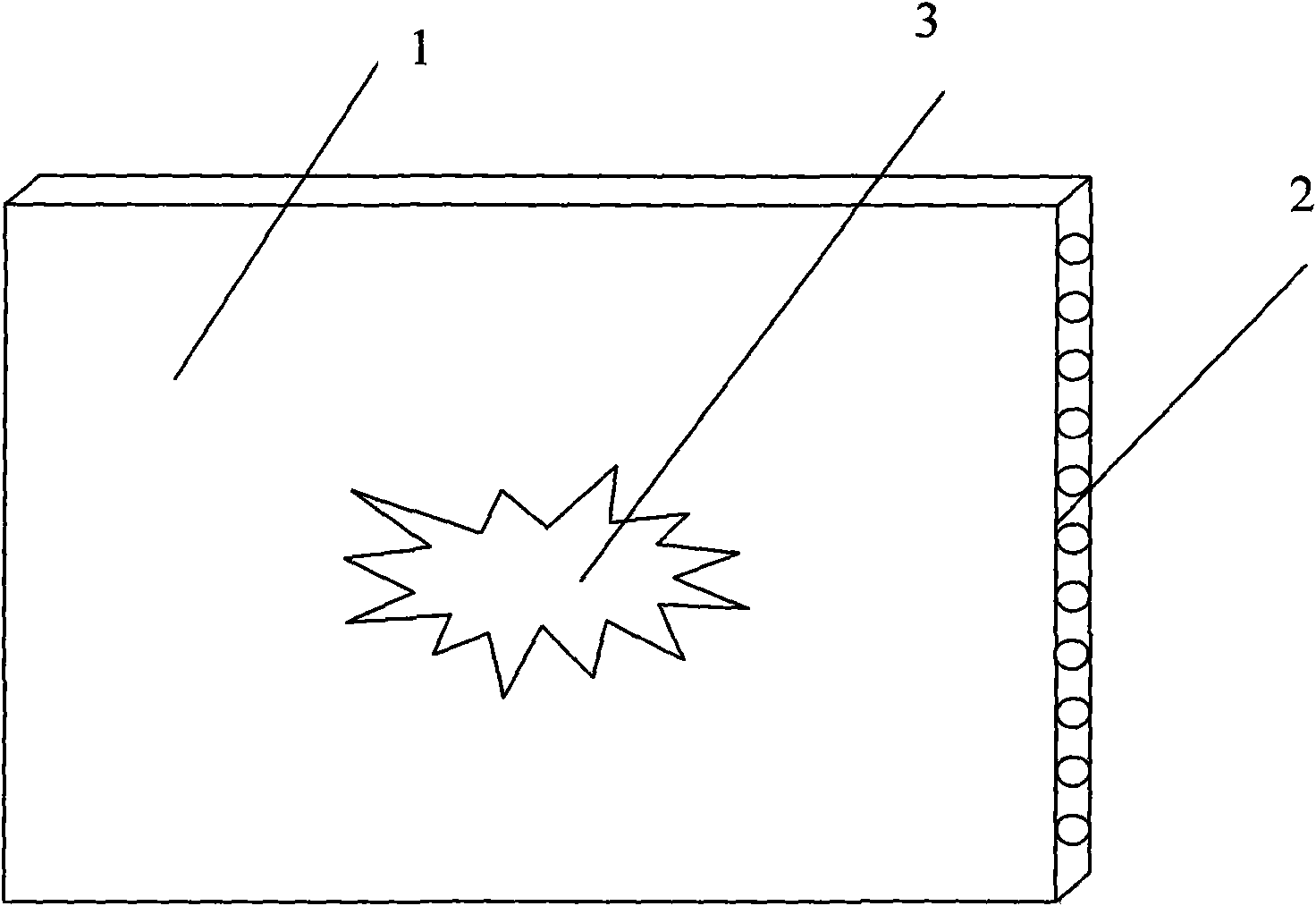

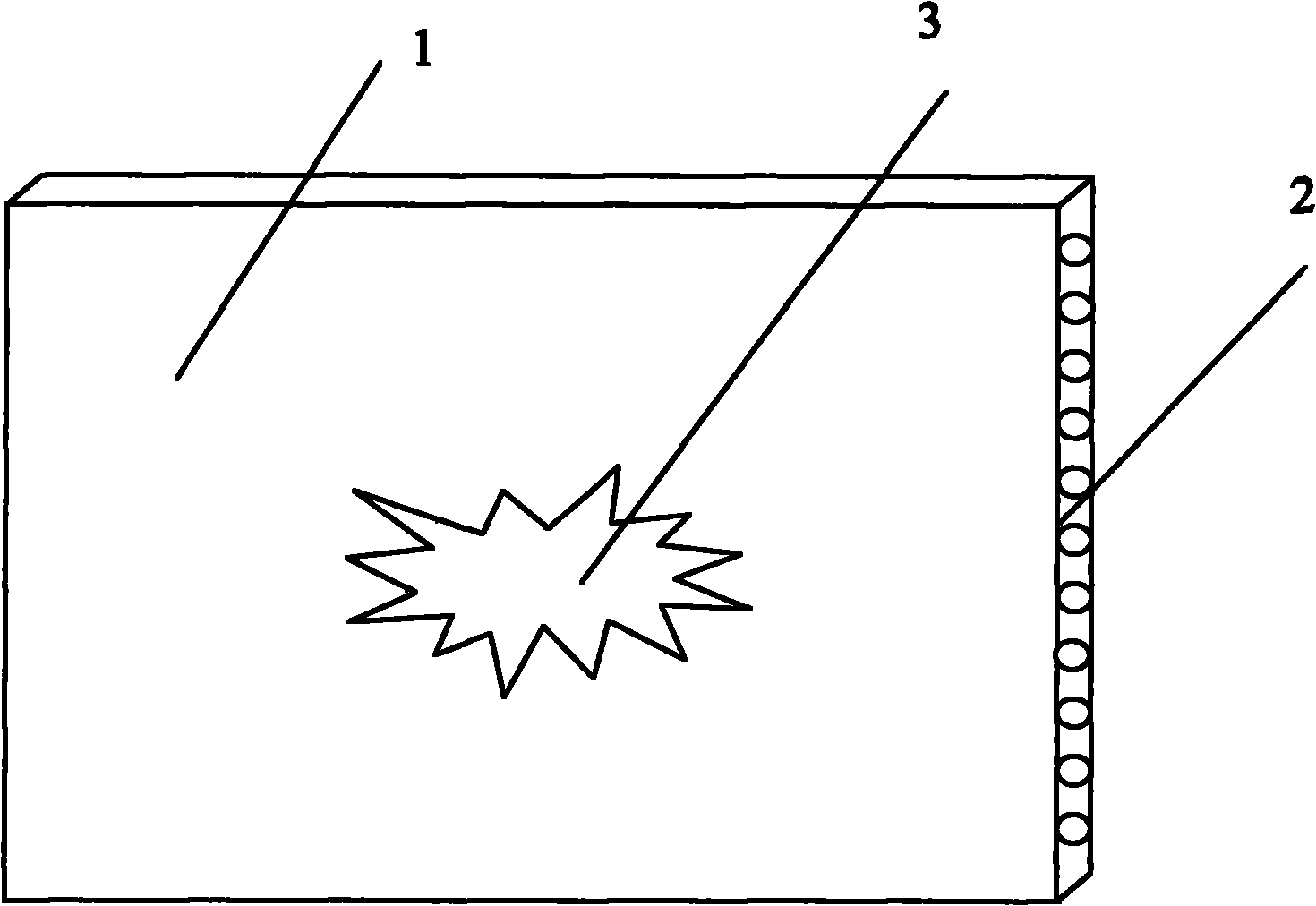

Laser engraving device adopting LED light source

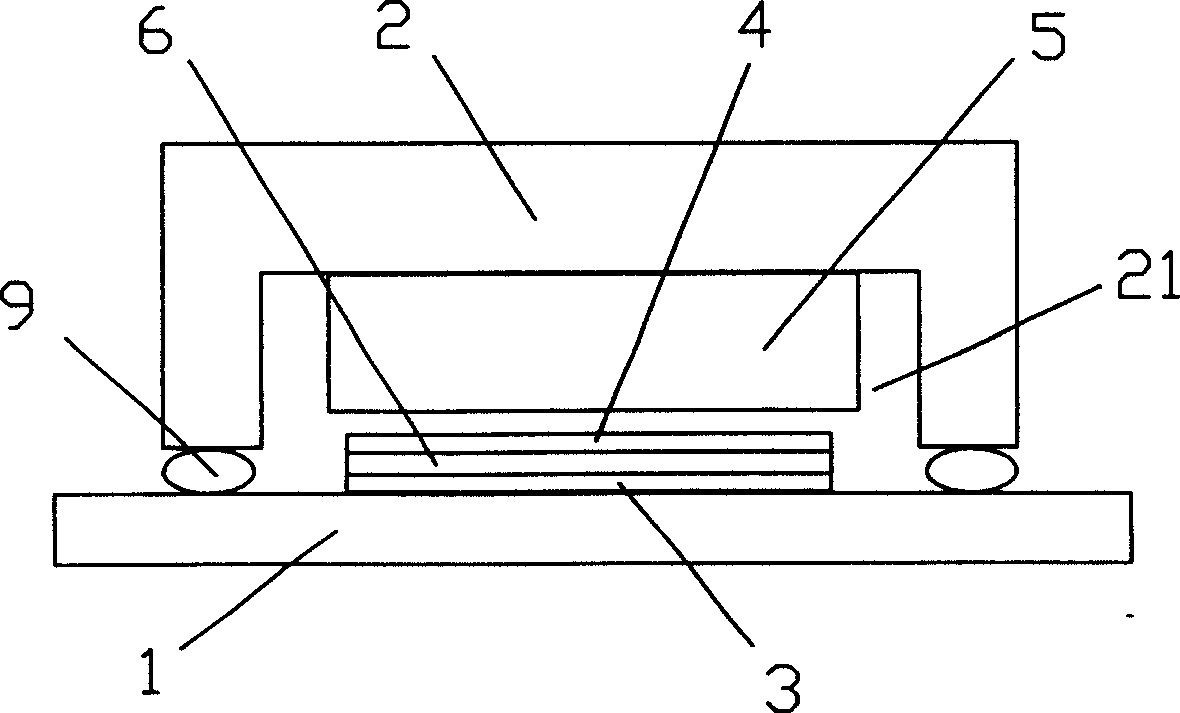

InactiveCN101905626ABroad application marketQuality is not affectedNon-electric lightingPoint-like light sourceFlat glassLaser engraving

The invention relates to a laser engraving device adopting an LED light source, which comprises a transparent board, the edge of the transparent plate is provided with an LED light source, rupture points are engraved inside the transparent board, and the LED light source is bonded to the transparent board through a sealant. The LED light source is connected with an external power source. The transparent board is a piece of plate glass, or an organic plate or an acrylic plate. The LED light source comprises more than two LEDs. A great number of rupture points are engraved inside the transparent board through a laser glass engraving technology, and the LEDs are arranged at the edge of the transparent board. Under the irradiation of LED rays, the rupture points inside the transparent board can emit a large amount of light rays to form a plurality of small light-emitting sources, and the light-emitting sources can form a pattern. The laser engraving device can achieve any illumination effect, is suitable to being used indoors and outdoors and has no abrasion, no pollution, low power consumption, environment protection, energy saving and long service life.

Owner:上海镭立激光科技有限公司

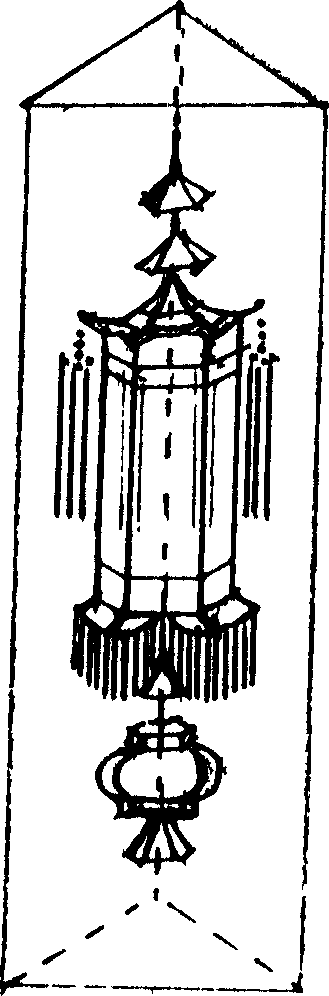

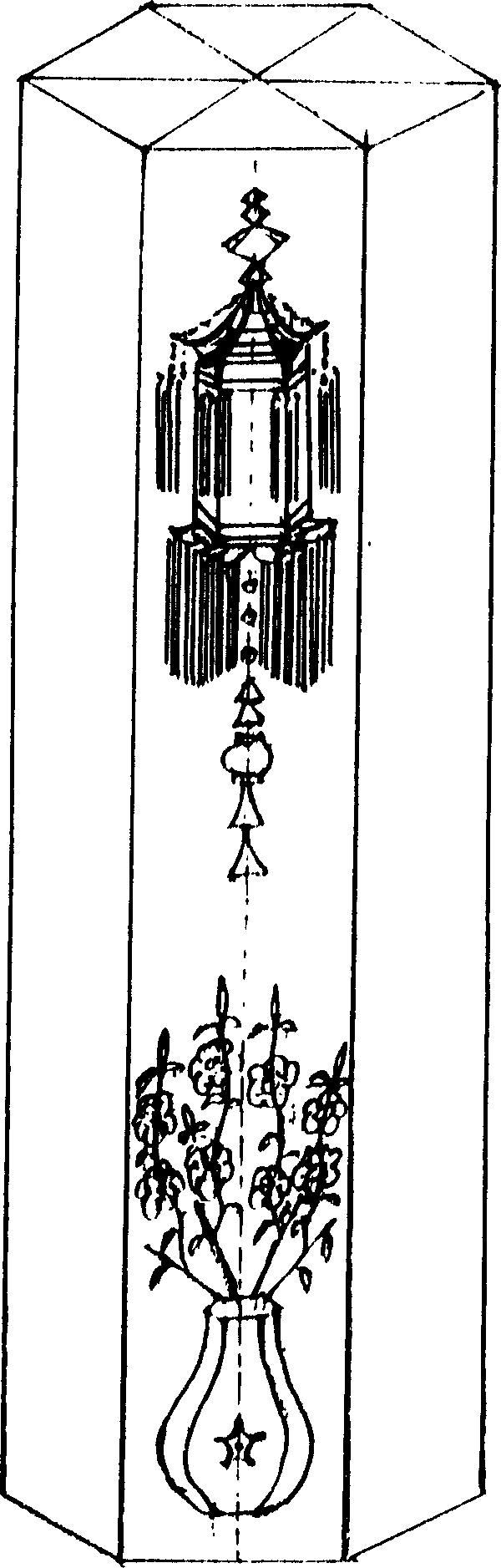

Glass engraving fabricating technique

InactiveCN1565869AConducive to carry forwardAdvanced technologyDecorative surface effectsSpecial ornamental structuresEngineeringPrism

Disclosed is a process of carving patterns on a regular three prism includes preparing a transparent regular three prism made of organic glass or crystal glass, carving symmetric patterns on one arris of the prism, carving patterns matchable to the symmetric patterns on the two side surfaces relative to the carved arris, then making the carved three prism into a craftwork. The invented process is advanced, simple, and the carved three prism has beautiful appearance and can be used widely.

Owner:丁志富

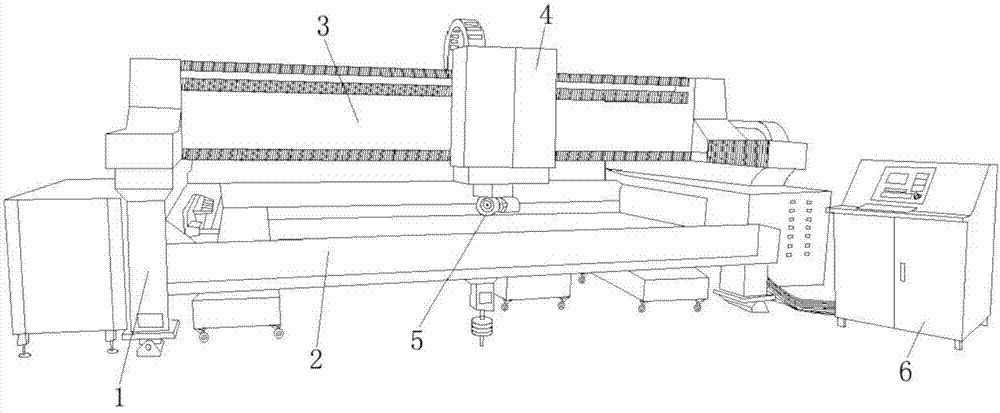

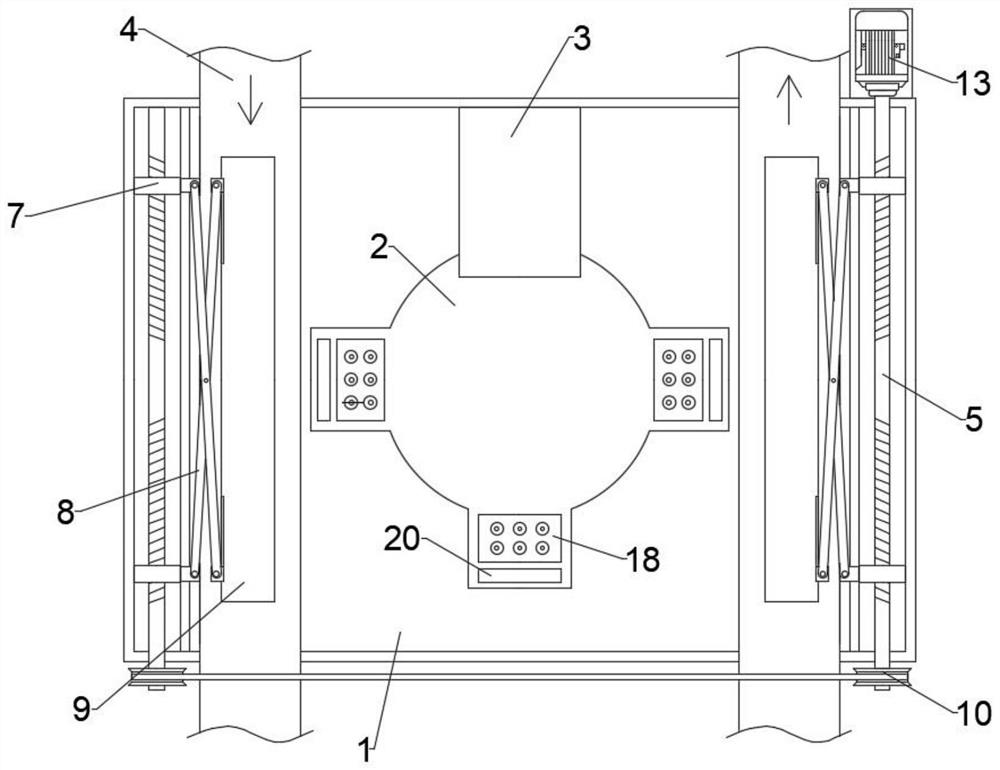

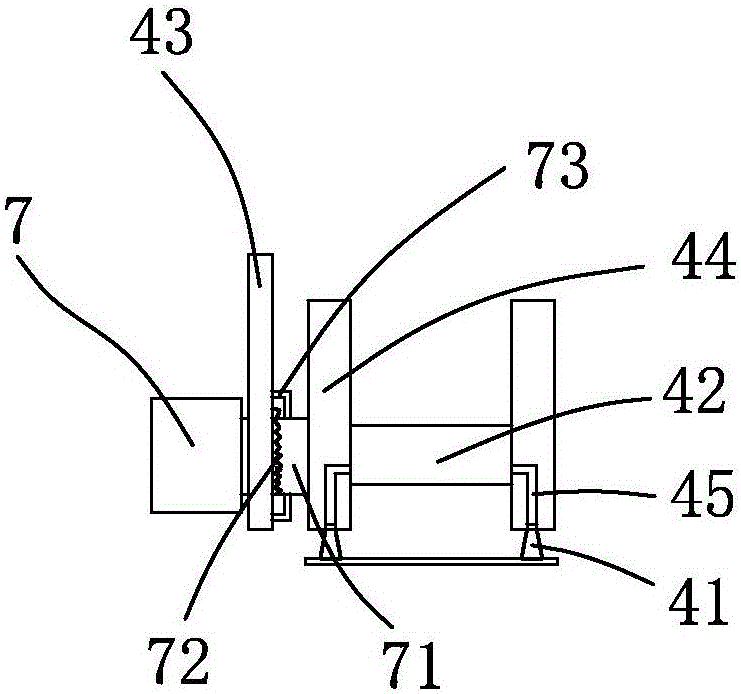

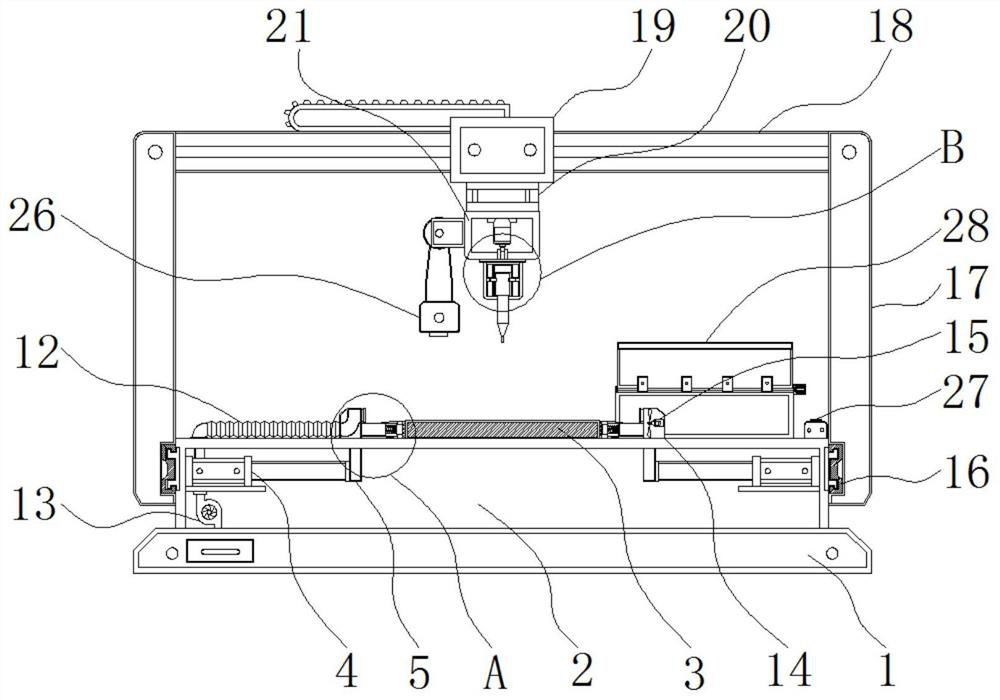

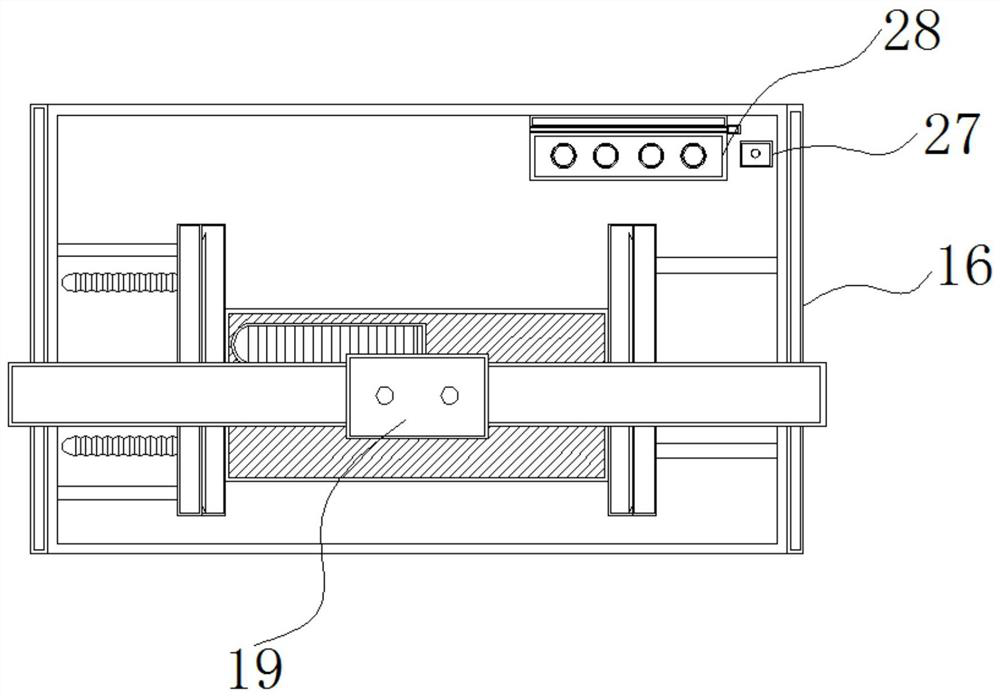

Large glass engraving machine

ActiveCN106394094AAchieve entryAffect normal workOther artistic work equipmentsEngravingGlass engraverEngineering

The invention provides a large glass engraving machine. The large glass engraving machine comprises a rack, an engraving table arranged on the rack for placing glass, a glass loading device arranged at the front side of the engraving table, and an engraving device positioned above the engraving table; the engraving device is driven by a translation mechanism to transversely translate and longitudinally translate; an engraving tool is fixedly arranged on the engraving device; a vertical drive device is arranged on the engraving tool to drive the engraving tool to operate up and down; and a cooling system is further fixedly arranged on the engraving device. The large glass engraving machine can meet engraving work of large boards, is wide in applicability, can realize functions of automatic loading, automatic cutting and the like; and moreover, the service life of the tool and the service lives of related cutting devices are long, and maintenance is easy.

Owner:百能数控设备(福建)有限公司

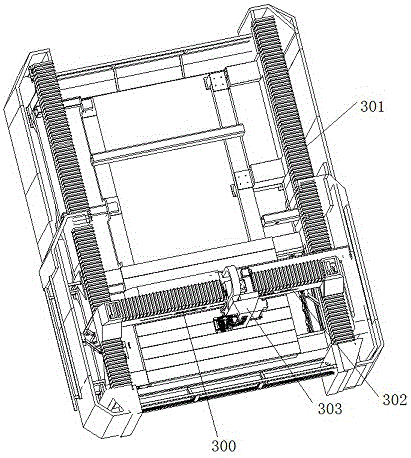

Glass engraving and milling machine

The invention provides a glass engraving and milling machine. The glass engraving and milling machine comprises a gantry frame, a bed body, a workbench, a processing spindle, a material frame, and a mechanical hand, the gantry frame is arranged on the bed body, the processing spindle is located on the front face of the gantry frame, a Y-axis guiding rail on the bed body extends to the area corresponding to the back face of the gantry frame from the area corresponding to the front face of the gantry frame, the material frame is arranged at the back part of the bed body relative to the back faceof the gantry frame, the workbench is arranged above the Y-axis guiding rail, and the arraying directions of the workbench and the material frame are parallel to the Y-axis; and the mechanical hand is located on the back face of the gantry frame, the material changing between the workbench and the material frame is achieved, the material frame comprises a picking material frame and a storing material frame, and the arraying directions of the picking material frame and the storing material frame are parallel to the Y-axis. According to the glass engraving and milling machine, the material frame and the mechanical hand are placed in the rear of the gantry frame, so that the feeding and discharging areas are away from the processing area, the fact that the cutting fluid splashes the workpiece in the material frame in the machining process is avoided, and the adhesion of the two or multiple workpieces due to the water vapor is prevented.

Owner:SHENZHEN CREATE CENTURY MACHINERY

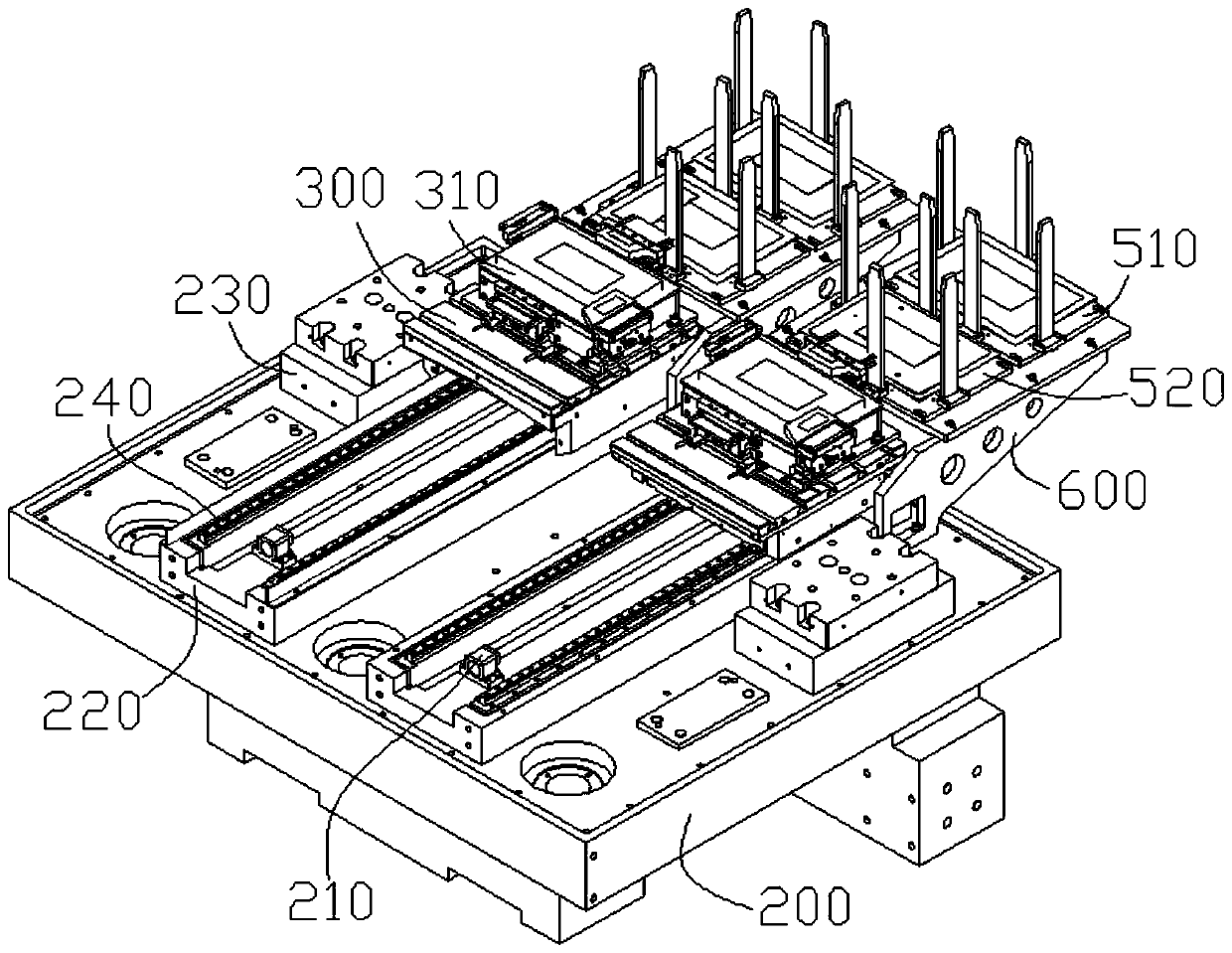

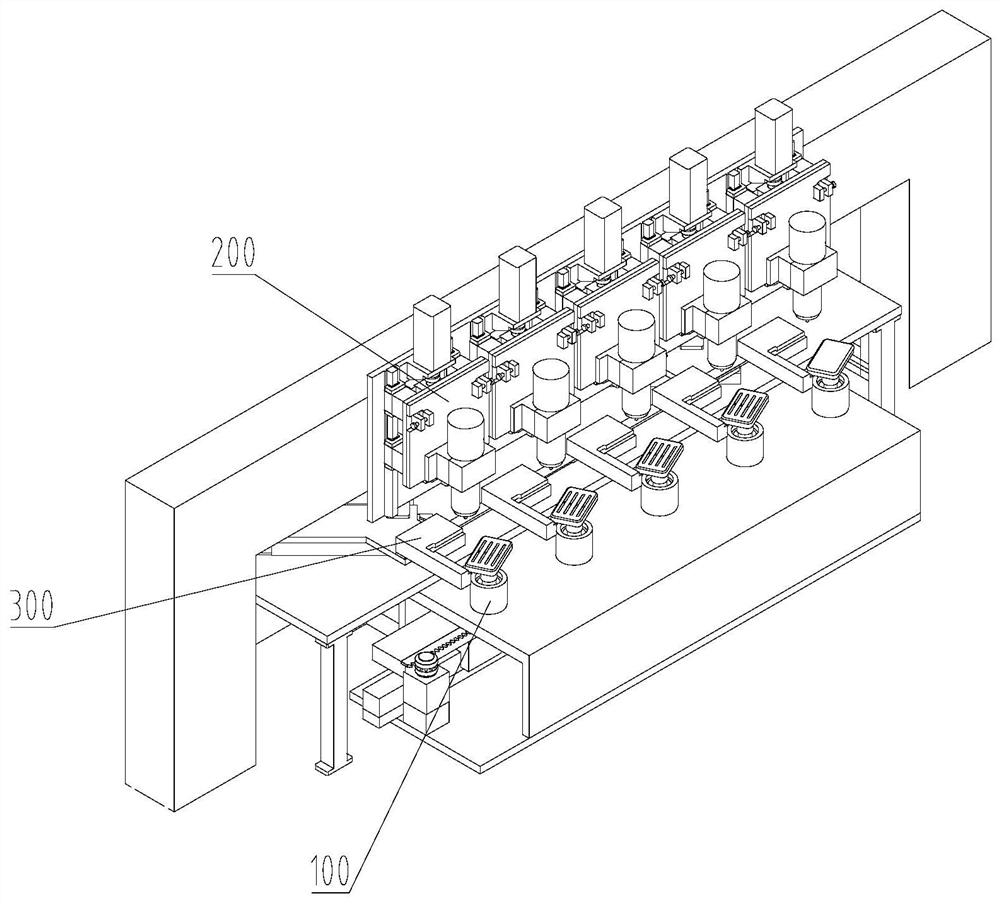

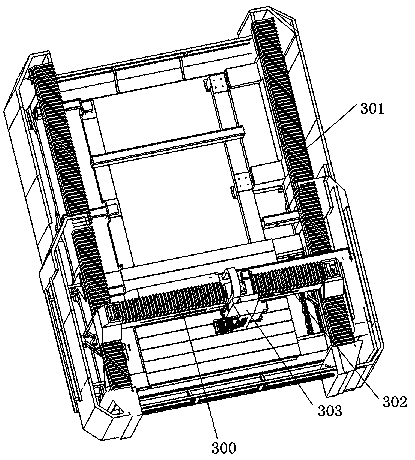

Glass engraving and milling machine based automatic production line

PendingCN108583112ARealize automatic supplyRealize automatic loading and unloadingCharge manipulationFlexible article cleaningProduction lineEngineering

The invention discloses a glass engraving and milling machine based automatic production line. The glass engraving and milling machine based automatic production line comprises a supplying device, glass engraving and milling machines, a fix-axis driving type manipulator, a finished product conveying device and a washing device, wherein the supplying device is arranged at one end of the finished product conveying device and is used for conveying and positioning a material tray; the glass engraving and milling machines are arranged at two sides of the finished product conveying device and are used for processing glass materials into glass products; the five-axis driving type manipulator is arranged above the finished product conveying device and is used for picking the glass materials from the material tray, positioning the glass materials on the corresponding glass engraving and milling machine, picking the glass product from the corresponding glass engraving and milling machines and positioning the glass product on the finished product conveying device; the finished product conveying device is used for conveying the glass product to the washing device; and the washing device is used for washing the glass product. According to the technical scheme, the glass engraving and milling machine based automatic production line has the advantages that the glass materials are prepared into the glass product in a complete automatic manner, so that the labor cost is effectively decreased while the production efficiency is effectively improved.

Owner:SHENZHEN CREATE CENTURY MACHINERY

Full-automatic glass engraving machine

InactiveCN103084945AReasonable structureEasy to operatePlane surface grinding machinesGrinding/polishing safety devicesSynchronous motorMechanical engineering

The invention discloses a full-automatic glass engraving machine which comprises a lathe bed, a working table-board, a beam, a grinding head box, a grinding head mechanism and an electronic control cabinet, wherein the working table-board is arranged on the lathe bed, the beam is arranged on the working table-board through two Y-axis screw rod guide rail transmission mechanisms, the grinding head box is connected with the beam through an X-axis screw rod guide rail transmission mechanism and a Z-axis screw rod guide rail transmission mechanism, and the grinding head mechanism is connected with the lower end of the grinding head box through a grinding head rotation synchronous belt transmission mechanism. The X-axis screw rod guide rail transmission mechanism is driven by an X-axis drive synchronous motor. The two Y-axis screw rod guide rail transmission mechanisms are driven by two Y-axis drive synchronous motors. The Z-axis screw rod guide rail transmission mechanism is driven by a Z-axis drive synchronous motor. The grinding head rotation synchronous belt transmission mechanism is driven by a grinding head rotation drive servo motor. The full-automatic glass engraving machine has the advantages of being reasonable in structure, easy to operate, long in serve life, high in machining accuracy, capable of automatically engraving the surface of glass.

Owner:上海依我玻璃制品有限公司

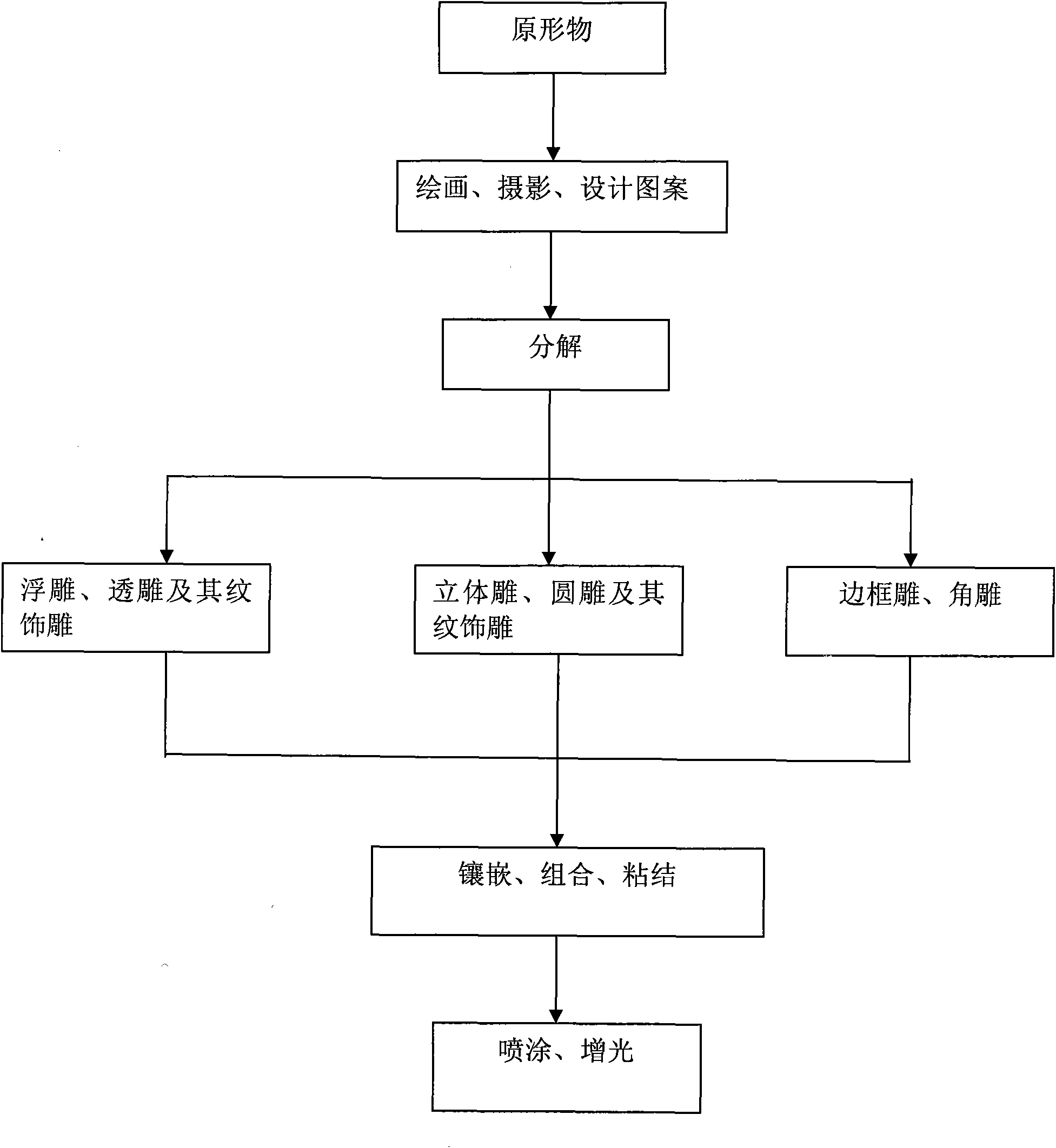

Method for carving and embedding chromatic organic glass

InactiveCN101648482AOver timeAchieve steeringDecorative surface effectsOrnamental structuresOrganic glassGlass engraving

The invention relates to method for carving and embedding chromatic organic glass, which can effectively solve the engraving and embedding problems of chromatic organic glass with different shapes. The method has the technical solution that chromatic patterns are designed and created on articles with different shapes by drawing or photographing, and the chromatic patterns are decomposed into a plurality of parts according to different colors and positions, and then organic glass having the same color with the discomposed parts is selected to be respectively carved. The method comprises the following steps: relief carving, openwork carving or emblazonry carving; three-dimensional carving or emblazonry carving; rim and corner ornamental carving; putting, combining and adhering the created chromatic patterns on each carved part according to the original drawing, photographing or design; lustre adding: spraying environment-friendly polyurethane paint of a lustre adding material to the surface of the pattern after a whole carved and embedded pattern is completed. The method is advanced, scientific and unique and is effectively used for carving and embedding the chromatic organic glass,and thereby, the chromatic organic glass is solid and durable and is resistant to erosion and dampness. Therefore, the method is an innovation on organic glass carving.

Owner:袁兴华

Method for fabricating organic electroluminescent display and back cover made from glass

The processing method includes following steps: at first to clean glass plate and plate thin transitional layer and paint photonasty anti-corrosion pretecting layer at the obverse side, to remove the transitional and pretecting layers in pattern to make corrosion pattern by photoetching, to fit two glass plates with etched flute pattern together back to back and seal the around edge, then to etch it till required deep by etching solution, to remove the protecting layer and transitional layer at surface of the glass plates and separate the two glass plates, the glass rear lid of organic electroluminescence display is produced.

Owner:TRULY SEMICON

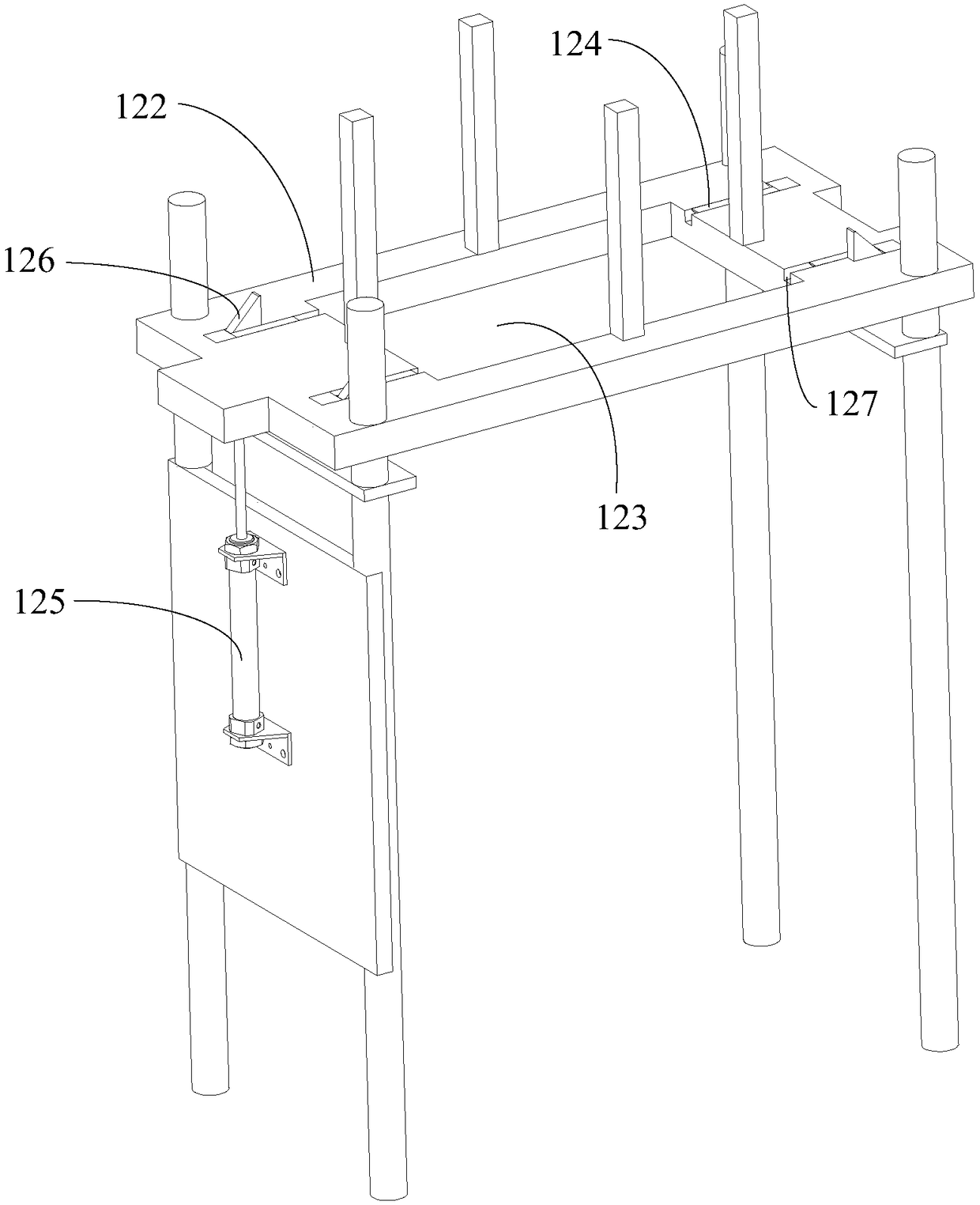

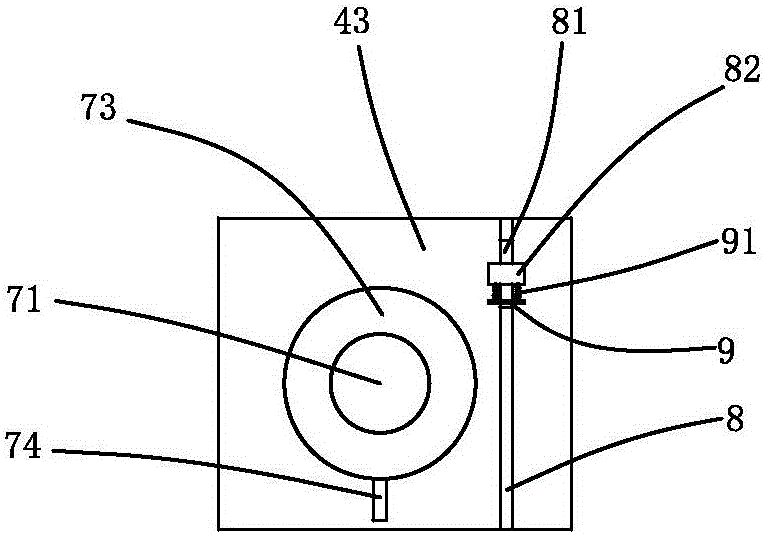

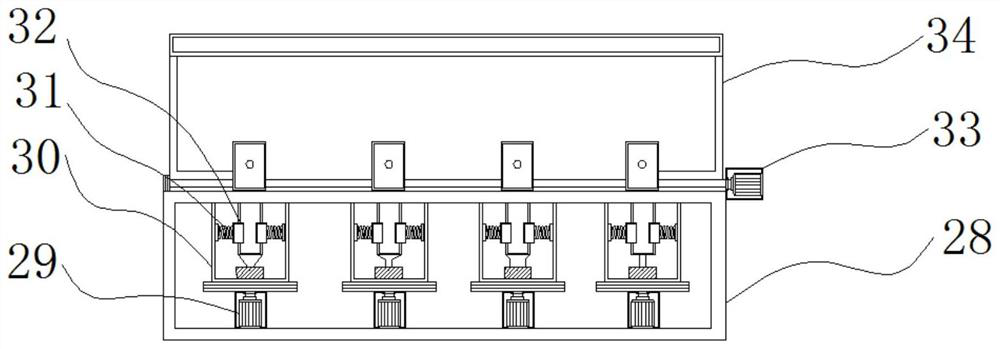

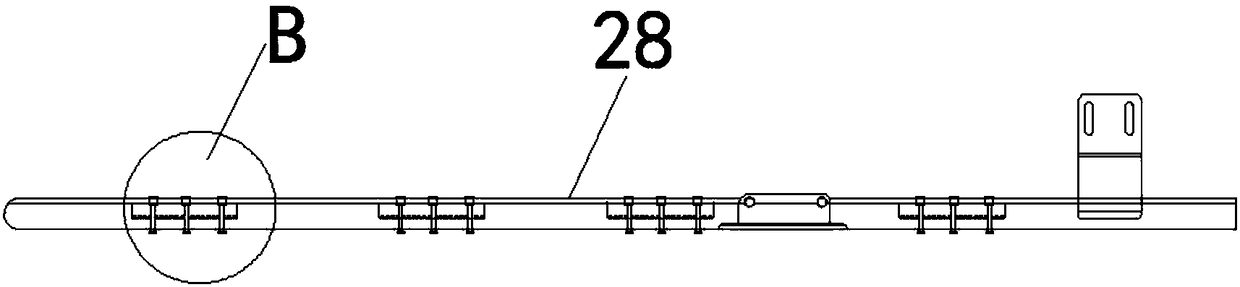

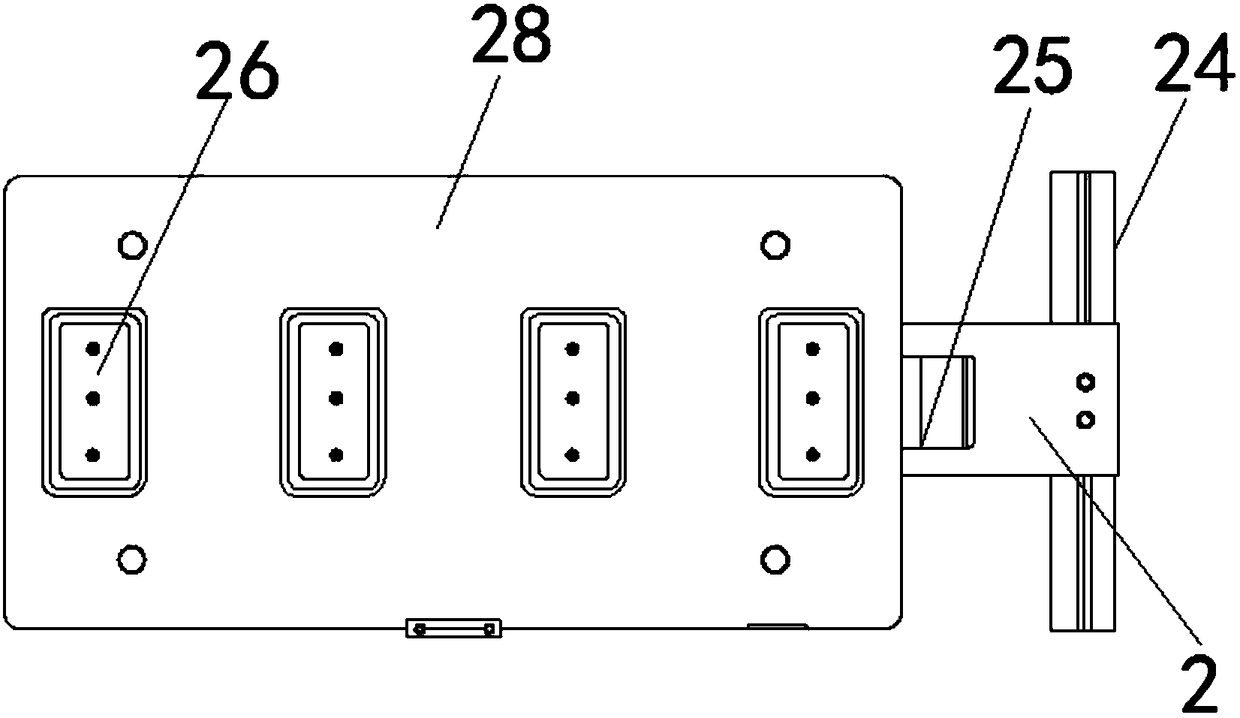

Automatic material taking and placing mechanism of engraving and milling machine

The invention relates to the technical field of glass engraving and milling machines, in particular to an automatic material taking and placing mechanism of an engraving and milling machine. According to the technical scheme, a box body is arranged, an inner cavity is formed in the box body, conveying mechanisms used for conveying workpieces are arranged on the left portion and the right portion of the inner cavity correspondingly, auxiliary feeding mechanisms are arranged on the cavity walls of the left end and the right end of the inner cavity correspondingly, a rotating column is arranged on the lower portion of the inner cavity, and a machining rotating disc is rotationally arranged on the top of the rotating column; a hollow sleeve is arranged on the bottom wall of the machining rotary disc, a bevel gear ring is arranged at the outer end of the hollow sleeve, and limiting mechanisms used for positioning workpieces are evenly arranged on the machining rotary disc. Through cooperation of the machining rotating disc, the conveying mechanism, the bidirectional lead screw, the suction cup mechanism, the connecting rod, the bevel gear, the bevel gear ring, the positioning plate, the cam and the abutting rod, the engraving and milling machine can conduct feeding and discharging at the same time through the simple structure, shutdown for material replacement is not needed, material taking or discharging is conducted through the conveying mechanism, and the production efficiency is improved. And the working efficiency of the engraving and milling machine is effectively improved.

Owner:东莞市友鸿机电设备有限公司

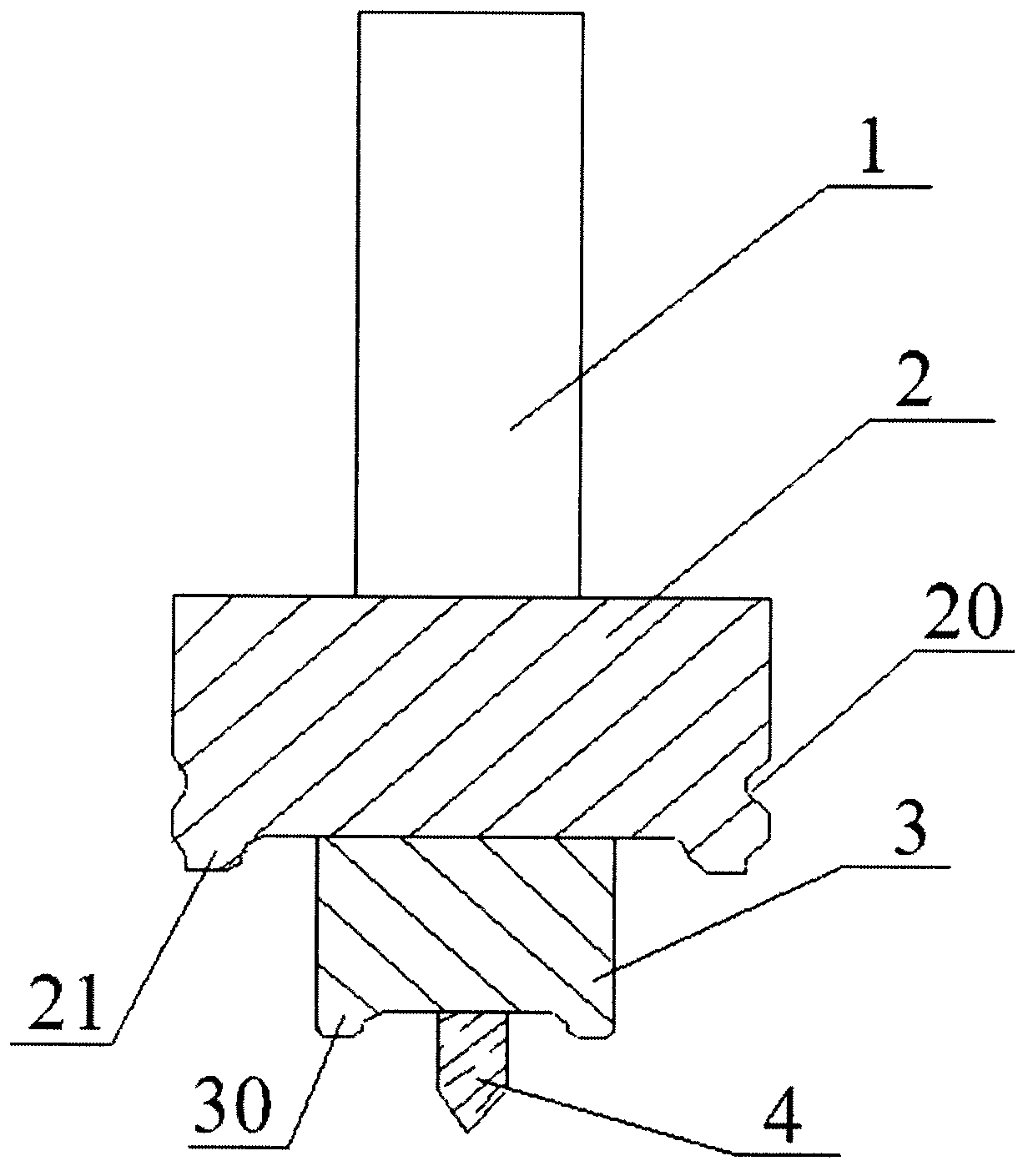

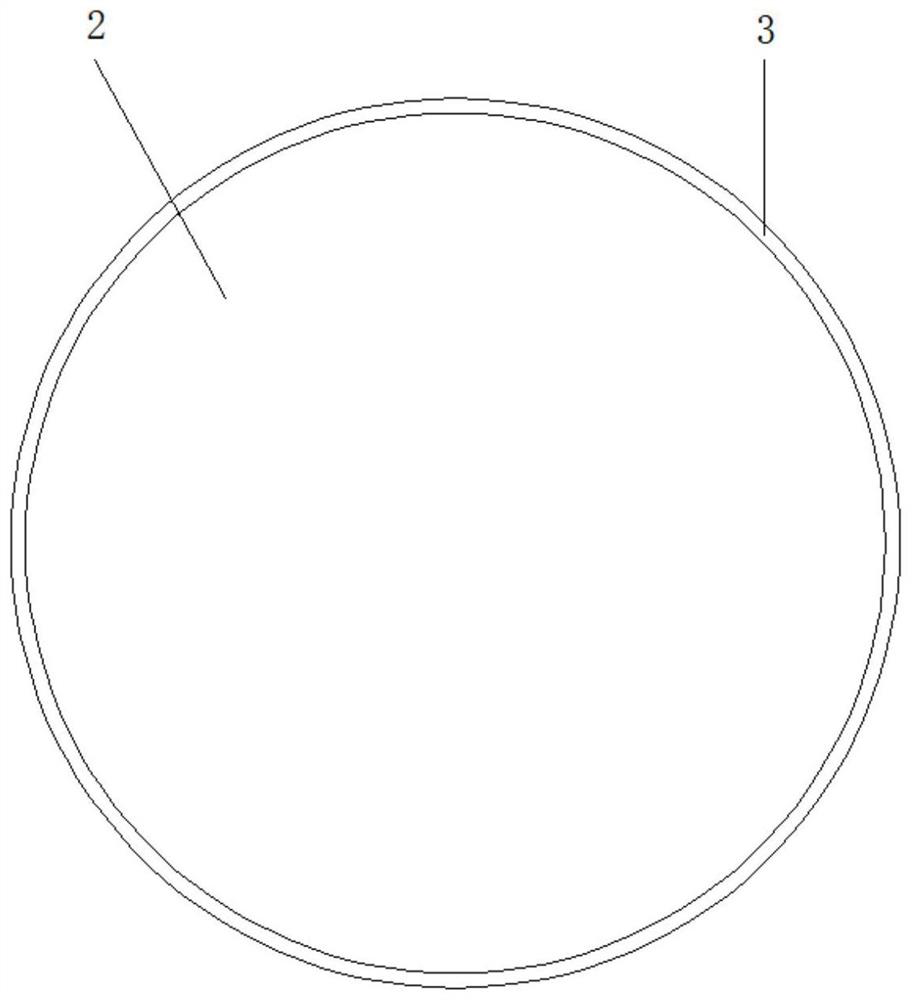

Integrated grinding wheel of glass engraving machine

InactiveCN103663952AIncrease productivityImprove yield rateGrinding machine componentsGlass severing apparatusEngineeringGrinding wheel

The invention discloses an integrated grinding wheel of a glass engraving machine. The integrated grinding wheel comprises a rough grinding wheel, a fine grinding wheel, a drill bit and a grinding wheel shaft, wherein the bottom of the drill bit is shaped like an inverted cone, and the drill bit is arranged below the rough grinding wheel and at the center of the rough grinding wheel; a circle of bulge is arranged below the rough grinding wheel, and the rough grinding wheel is arranged below the fine grinding wheel; the lower edge of the fine grinding wheel is provided with a circle of bulge, and a circle of groove is formed below the fine grinding wheel; the grinding wheel shaft is arranged above the fine grinding wheel and located on central shafts of the rough grinding wheel and the fine grinding wheel. The grinding wheel of the glass engraving machine, disclosed by the invention, is simple and convenient in operation of a processing mode in production and capable of increasing the production efficiency in glass processing and improving the glass processing yield.

Owner:KUSN GUANYI GLASS

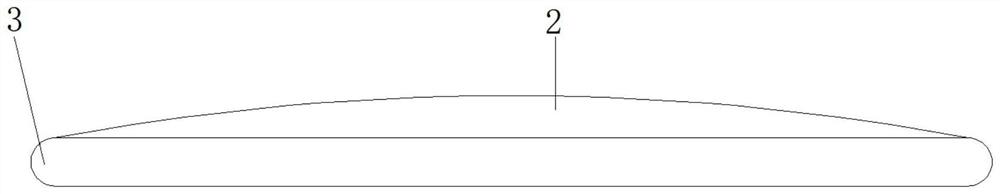

Special optical lens for mobile phone and processing method thereof

InactiveCN111913240AHigh surface finishSimple process conditionsTelephone set constructionsOptical elementsGlass engraverEngineering

The invention discloses a special optical lens for a mobile phone, and relates to the technical field of optical lenses. An optical lens special for a mobile phone comprises a lens body, the lens bodyis of a cylindrical structure, a top arc part is integrally formed at the top of the lens body, side arc parts are integrally formed on the periphery of the lens body, and the lens body, the top arcpart and the side arc parts are all made of glass. The processing method comprises the following steps: S1, cutting an optical lens blank material A from a glass raw material by using a glass engraving machine according to the size of the optical lens; s2, grinding a top arc part and a side arc part to obtain a semi-finished product B by using an edge grinding machine according to the designed shape of the optical lens; according to the invention, through the arrangement of the strengthening furnace strengthening process, the pressure stress layer is formed on the surface of the optical lens after the optical lens is subjected to the heat treatment process, the optical lens has a special fragment state, and when the optical lens is subjected to external force, the pressure stress layer cancounteract part of tensile stress.

Owner:中山北方晶华精密光学有限公司

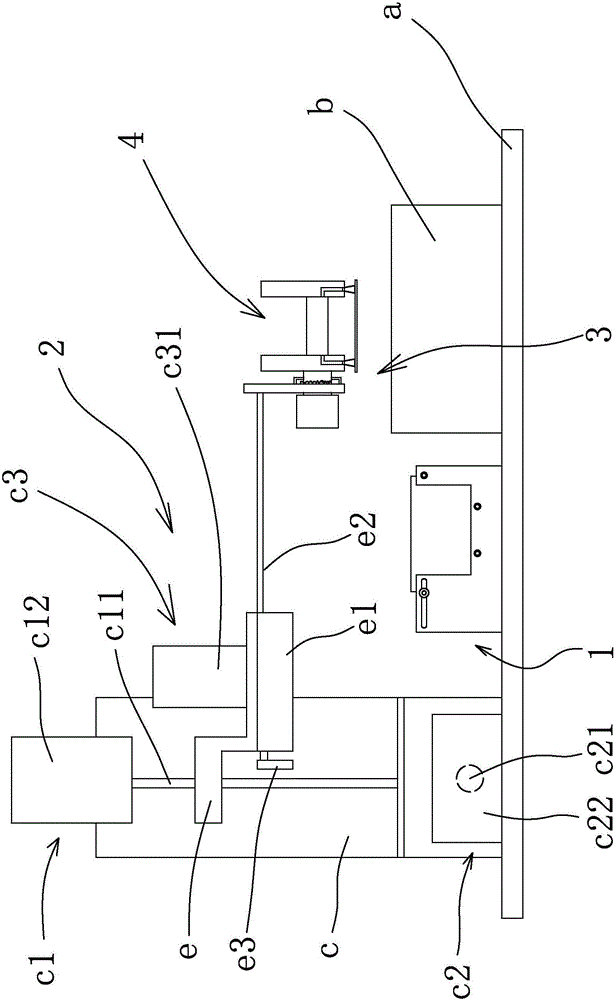

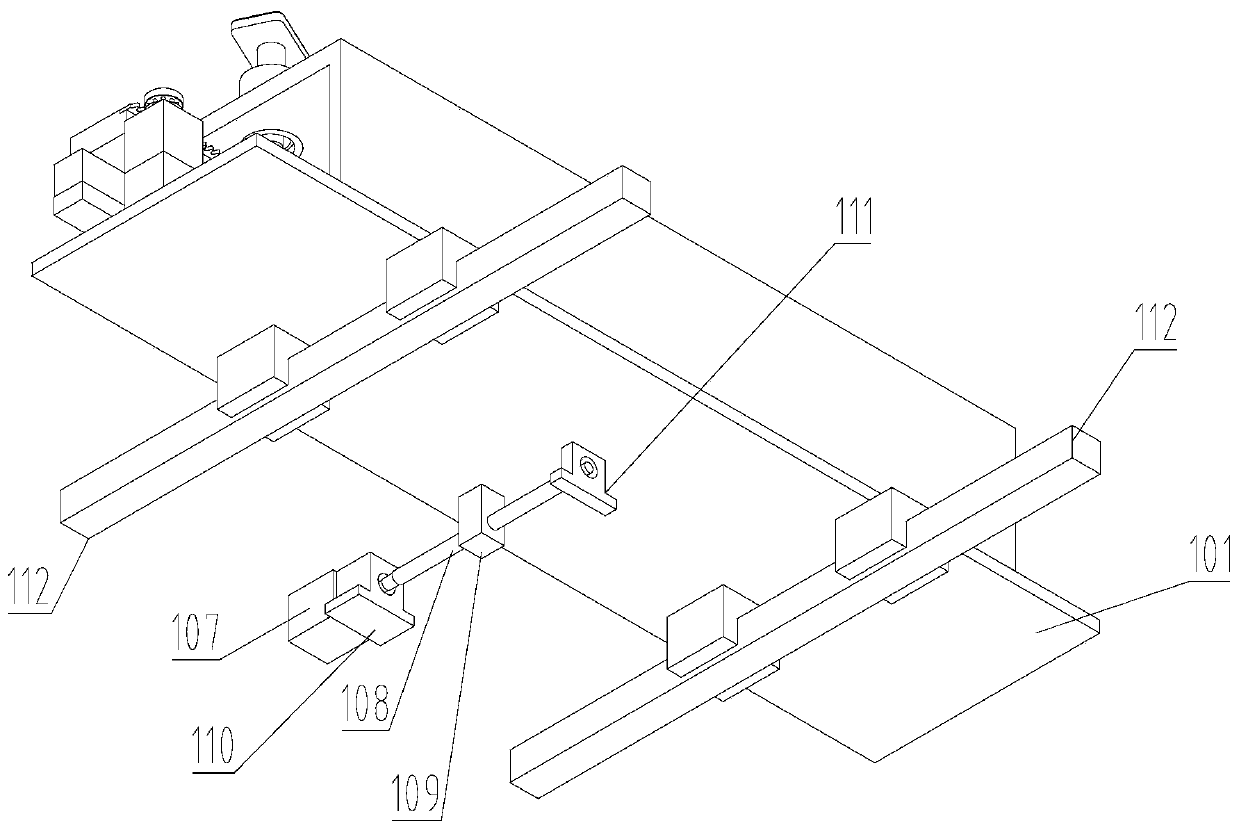

Glass engraving device and glass production method adopting glass engraving device

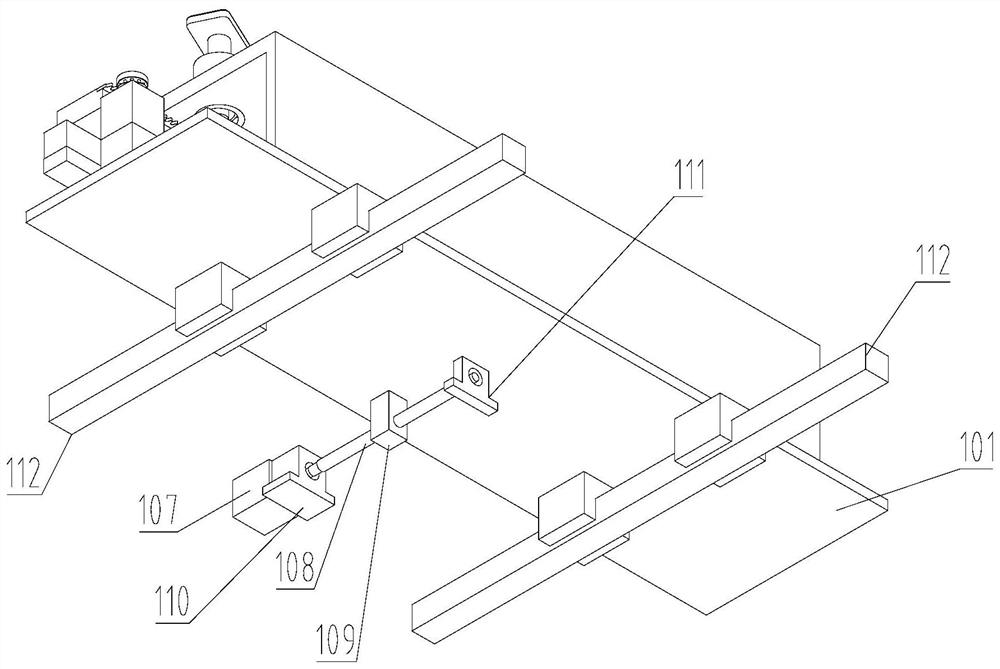

ActiveCN106218288AGuaranteed interval distributionEasy to take outOther artistic work equipmentsModel makingEngineeringTransfer mechanism

The invention provides a glass engraving device and a glass production method adopting the glass engraving device. The glass engraving device comprises a work platform. The work platform is provided with at least one empty glass shelf and at least one glass shelf holding glass to be machined. The work platform is provided with a glass transferring mechanism capable of transferring the glass between a processing platform and the glass shelves. A rotating shaft is provided with a buffering structure preventing the situation that because the rotation speed is excessively high, materials on a fetching assembly fall. The buffering structure comprises a buffering spring which is circumferentially arranged on the rotating shaft. One end of the buffering spring acts on the installation seat, and the other end of the buffering spring acts on the rotating shaft. The rotating shaft is sleeved with a locating sleeve capable of rotating along with the rotating shaft. The locating sleeve is provided with a stop rod limiting the rotation angle of the rotating shaft. The installation seat is provided with a limiting structure, and when the limiting structure is in contact with the stop rod, the rotating shaft can be prevented from rotating. The buffering spring is arranged in the locating sleeve. The glass engraving device and the glass production method adopting the glass engraving device have the advantages that the production efficiency is high, and the materials are not prone to falling off.

Owner:广东顺德晶纬玻璃制品有限公司

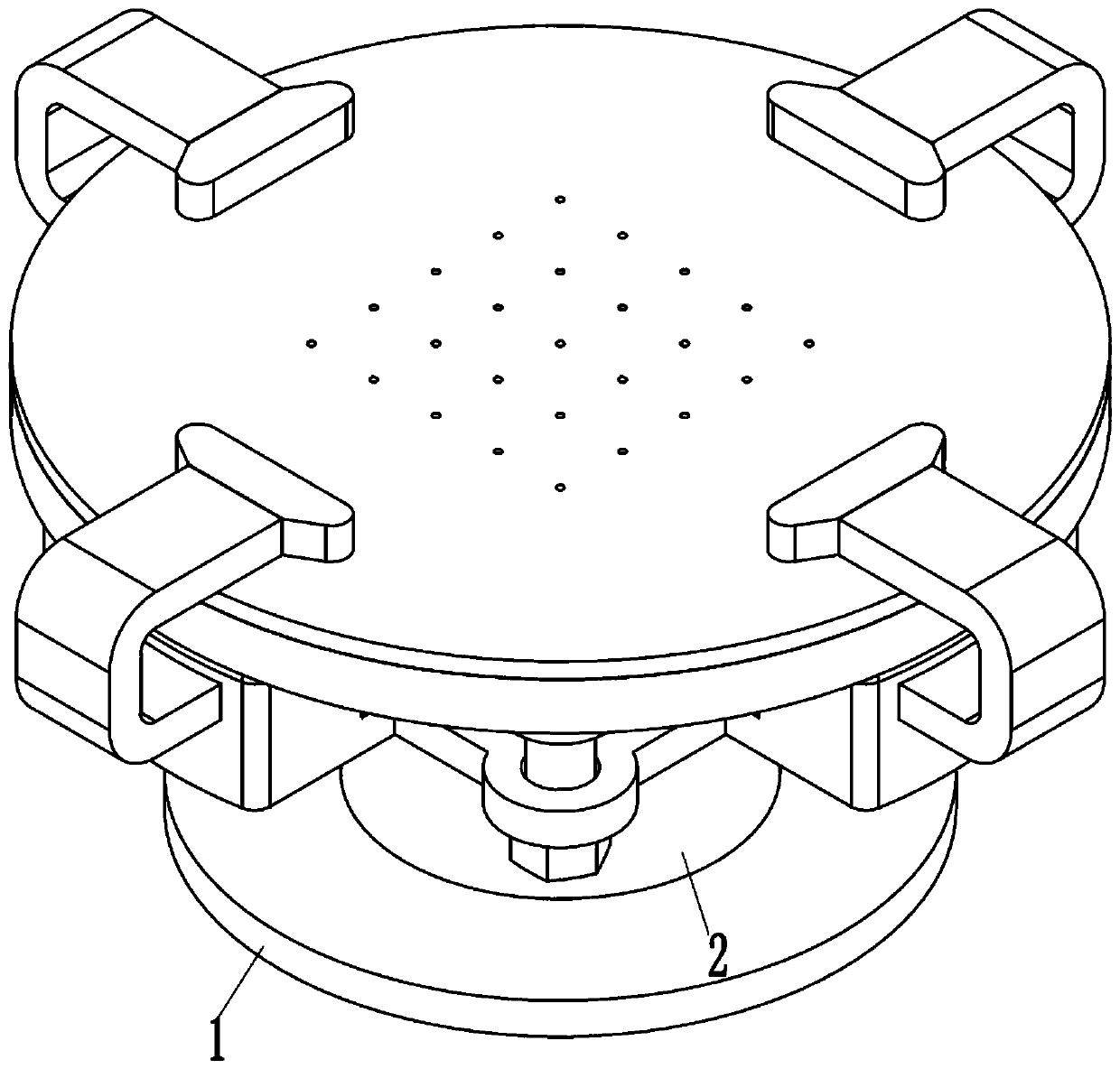

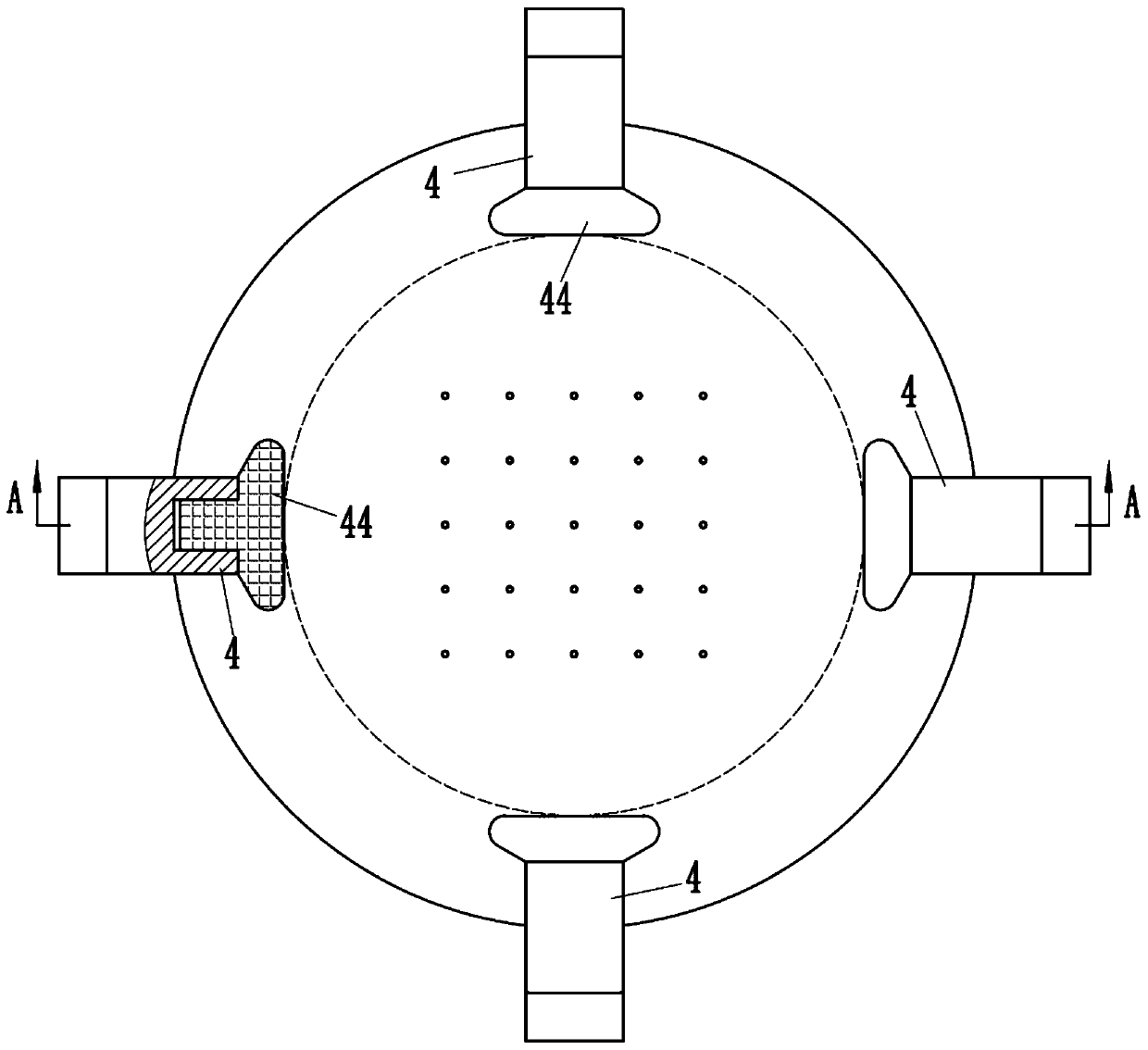

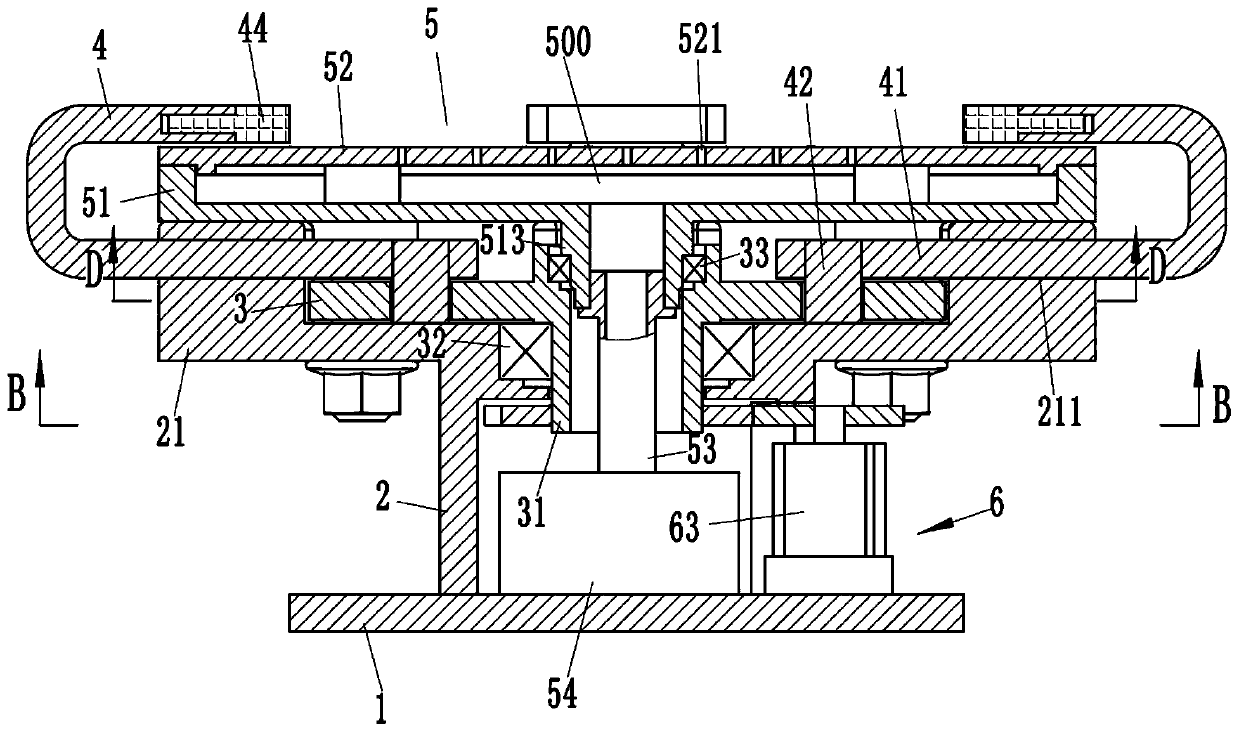

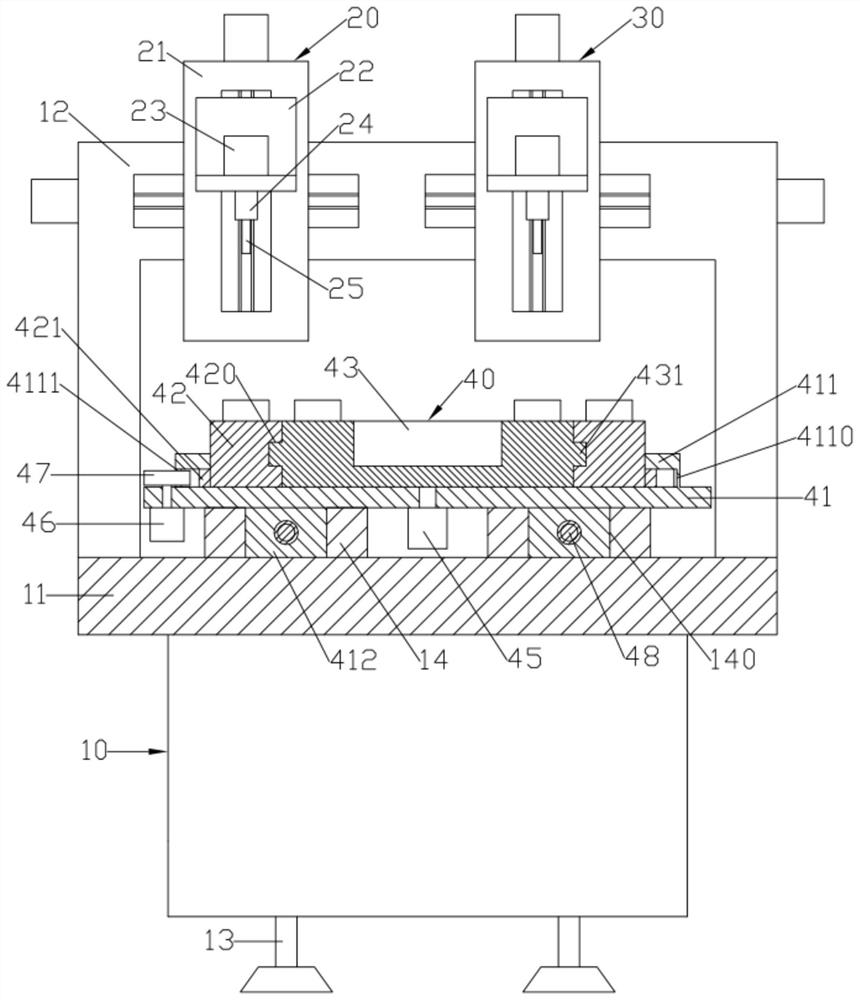

Processing table for glass engraving machine

InactiveCN111216254AEasy to fixReduce manufacturing costWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention discloses a processing table for a glass engraving machine. The processing table comprises a bottom plate, wherein a base is fixed to the bottom plate, a driving disc is hinged to the upper end of the base, and four eccentrically arranged arc grooves uniformly distributed on the circumference are formed on the driving disc; four connecting arms uniformly distributed on the circumference are fixed to the outer wall of the upper end of the base, rectangular grooves are formed in the outer ends of the connecting arms, each rectangular groove is in fit connection with a lower rectangular plate of a corresponding U-shaped clamping plate, the lower rectangular plates penetrate through inner extending ends of the rectangular grooves to be sleeved and fixed with driving rods, and thedriving rods are inserted in the corresponding arc grooves in a sleeved manner; and an adsorption platform is fixed to upper ends of the four connecting arms, and upper rectangular plates of the U-shaped clamping plates are located above the adsorption platform. Circular glass can be centrally positioned and clamped by the four U-shaped clamping plates which can move synchronously; and fixing ofthe circular glass can be further strengthened by the adsorption platform, so that the production cost can be effectively reduced.

Owner:东莞市嘉宏机电科技有限公司

Glass workpiece production line

PendingCN108996231AReduce processing timeIncrease productivityCharge manipulationConveyor partsProduction lineEngineering

The invention discloses a glass workpiece production line which comprises a first processing unit, a second processing unit opposite to the first processing unit, a feed box conveying line arranged between the first processing unit and the second processing unit, and automatic guided vehicle AGV manipulators arranged on two sides of the feed box conveying line. The first processing unit and the second processing unit comprise a plurality of glass engraving and milling machines arranged side by side; the feed box conveying line comprises a machine table and at least one feed box conveying device arranged on the machine table; and the AGV manipulators are used for picking and placing feed boxes between the feed box conveying device and the glass engraving and milling machines. According to the glass workpiece production line provided by the invention, the production efficiency of glass workpieces can be effectively improved, and meanwhile, the manufacturing cost of the glass workpieces is reduced.

Owner:SUZHOU TAIKAN MACHINERY CO LTD

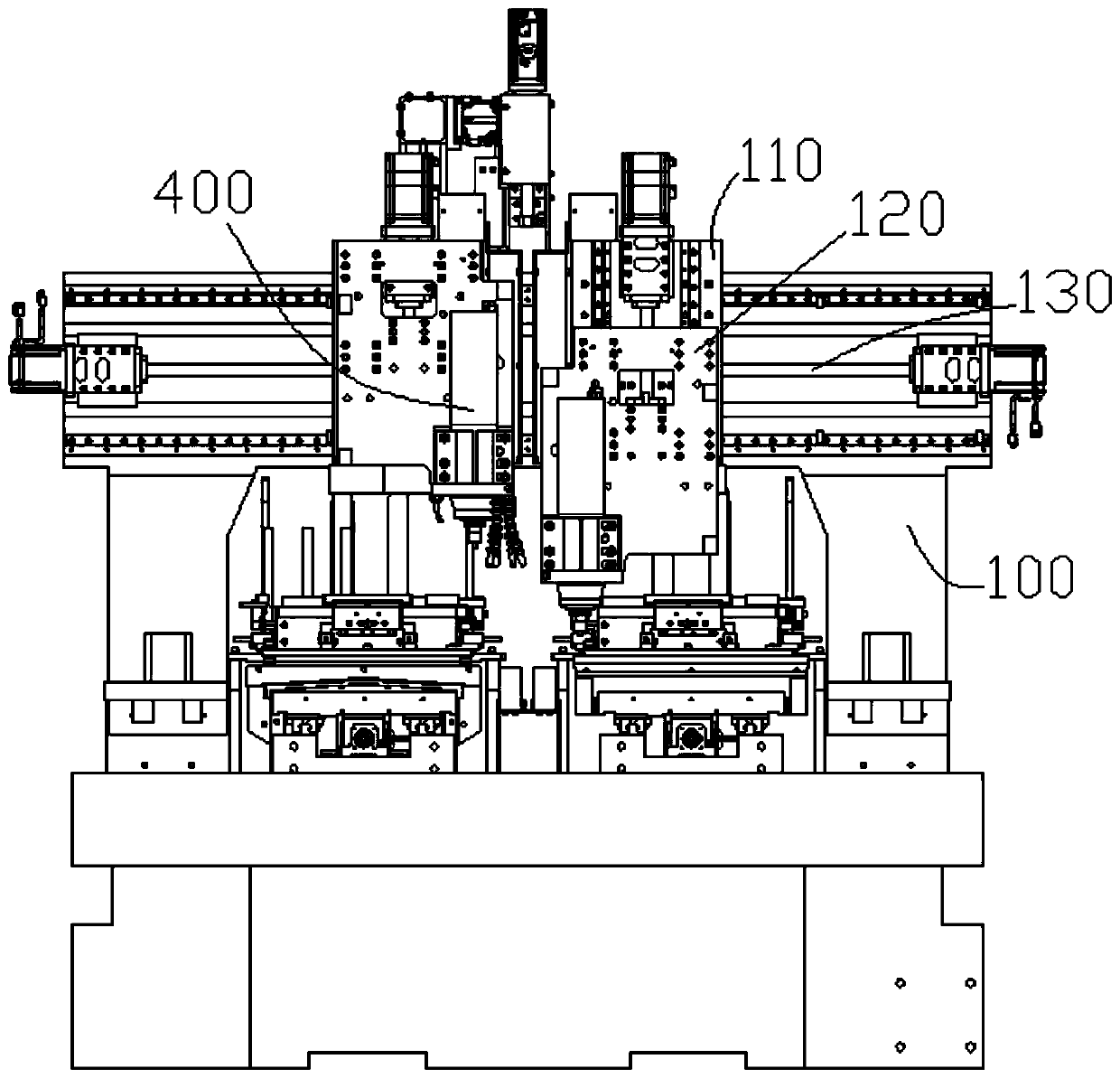

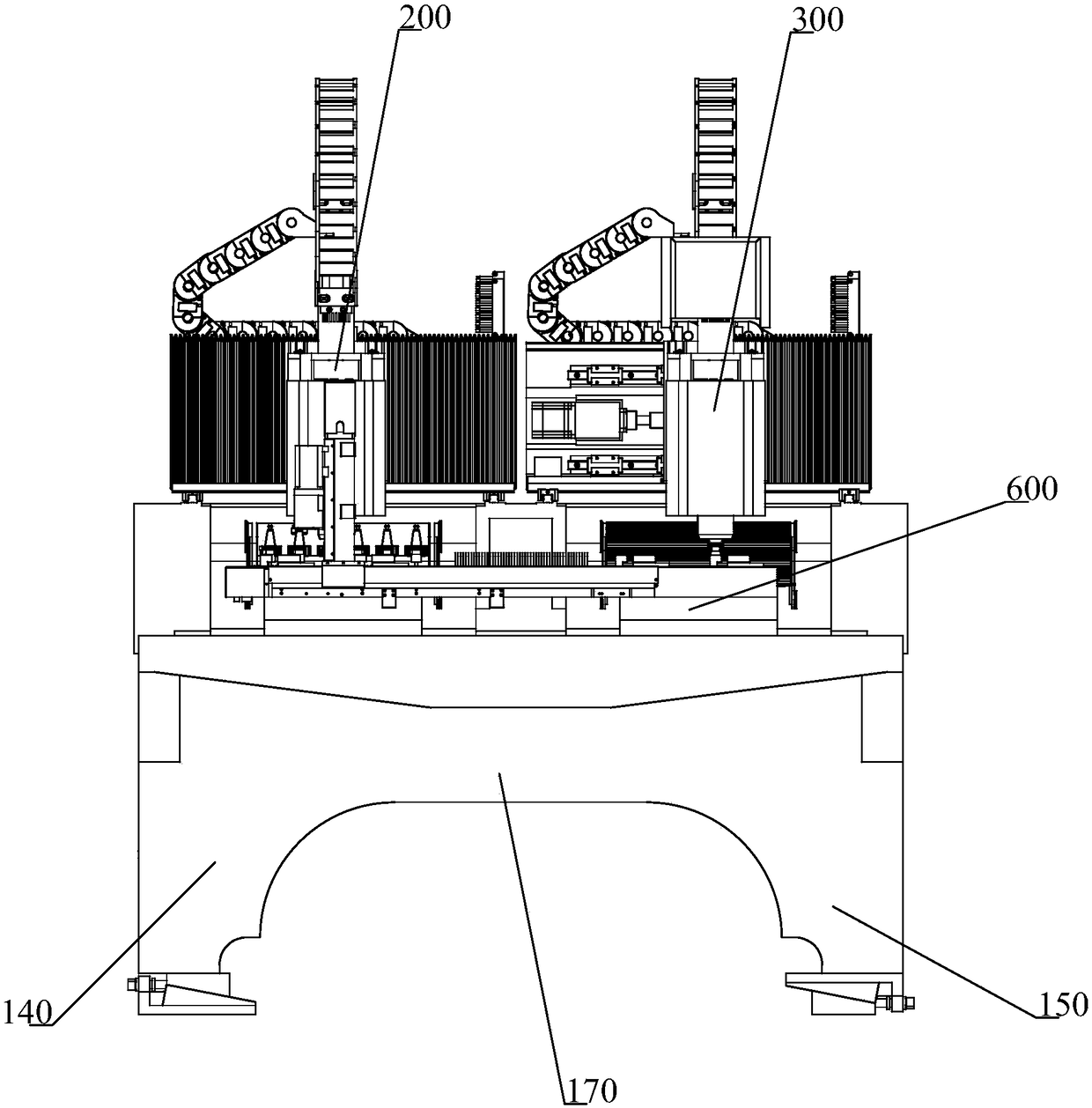

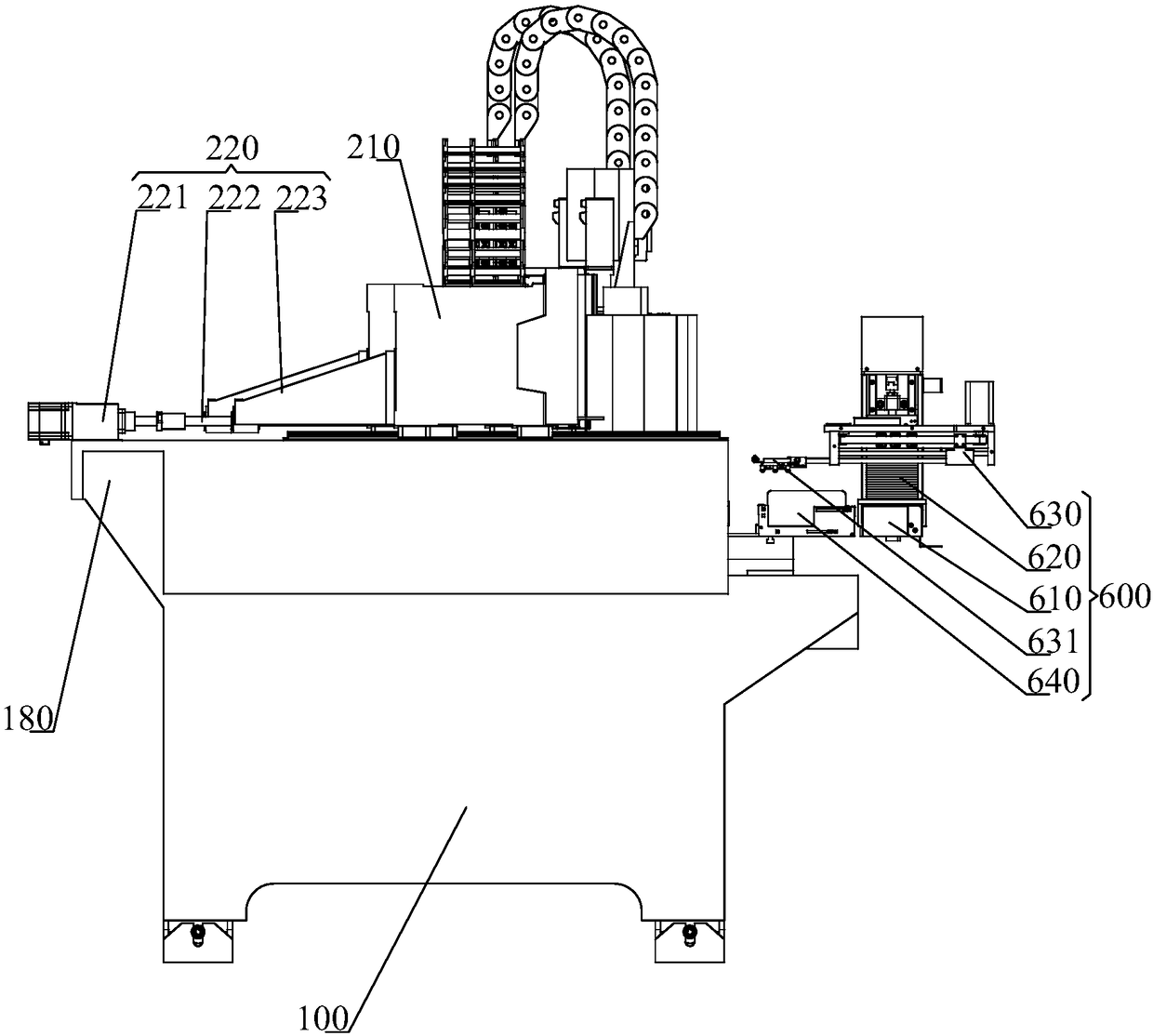

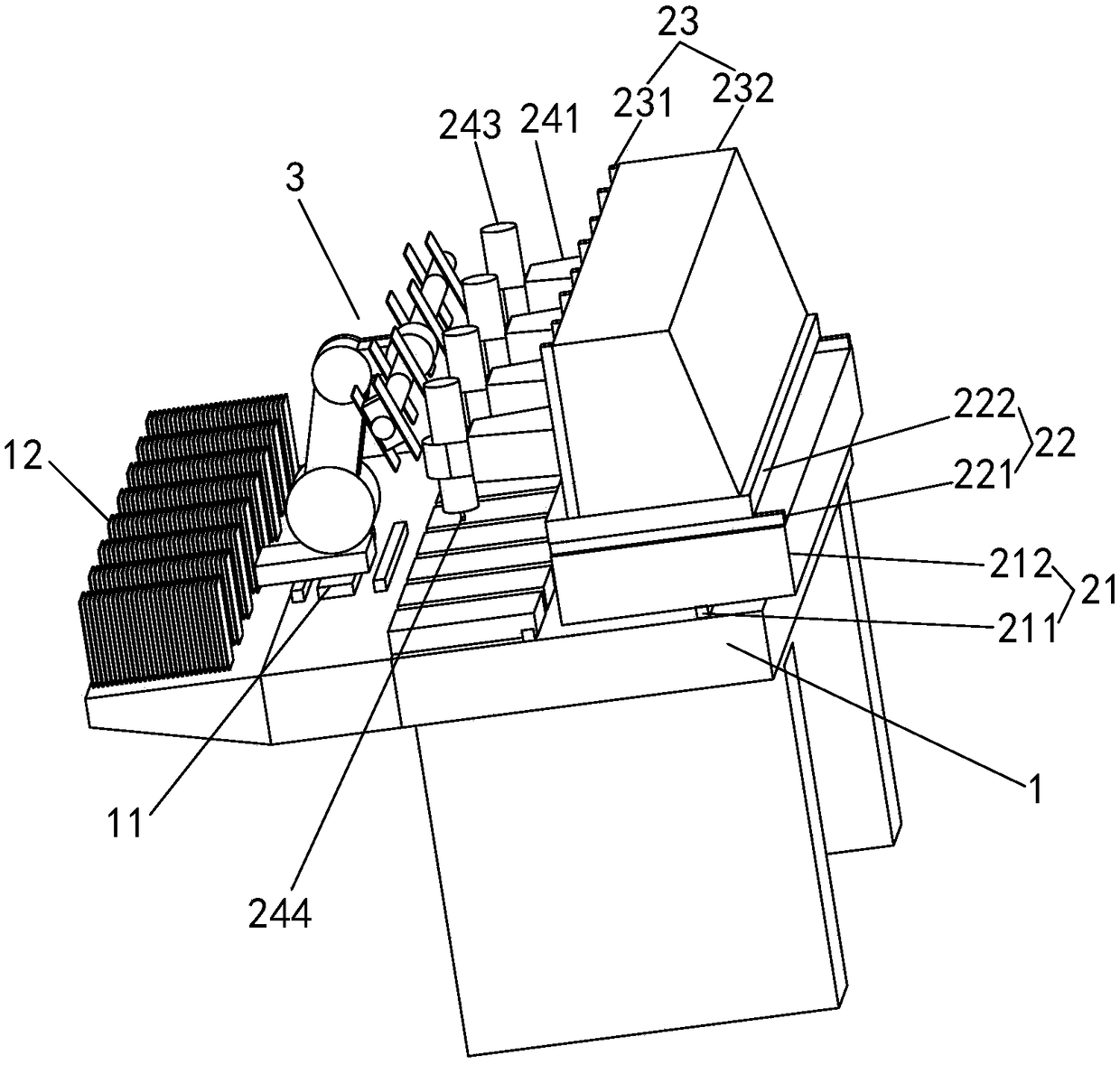

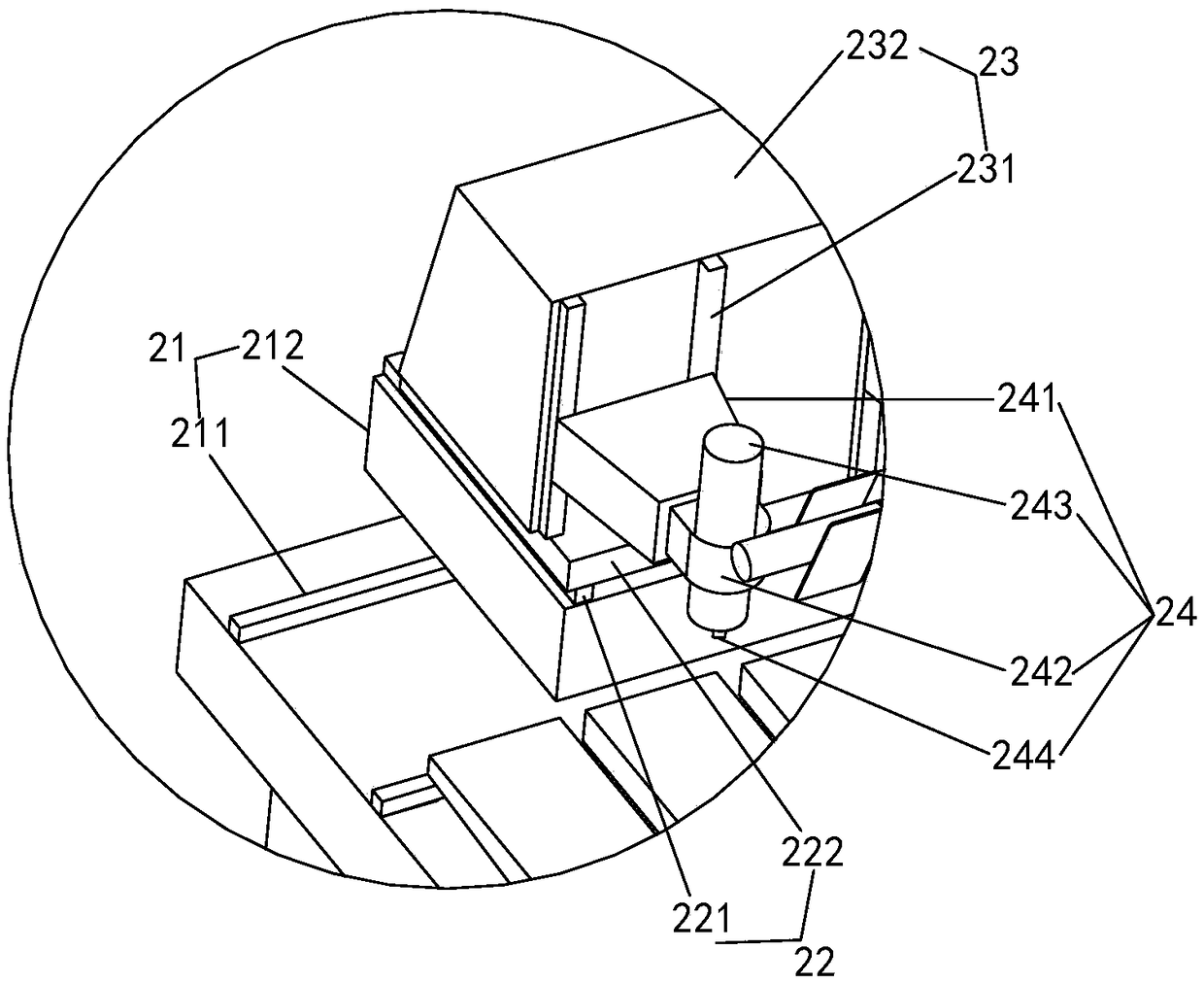

Glass engraving and milling machine with double processing heads

PendingCN108382111APrecise positioningReduce difficultyProgramme-controlled manipulatorOther artistic work equipmentsEngineeringGlass engraving

The invention discloses a glass engraving and milling machine with double processing heads. The glass engraving and milling machine comprises a base, a first cross beam assembly and a second cross beam assembly. The base is provided with a mounting table. The first guide rail assembly and the second guide rail assembly are arranged on the mounting table. The first guide rail assembly and the second guide rail assembly are arranged in an extending manner in parallel front and back. The first cross beam assembly comprises a first movable cross beam part, a first front-back driver, a first left-right movement mechanism, a first up-down movement mechanism and a first processing main shaft. The first movable cross beam part is spanned on the mounting table in the left-right direction, and is movably mounted on the first guide rail assembly. The first front-back driver is connected with the base and the first movable cross beam part. The first left-right movement mechanism is mounted on thefirst movable cross beam part. The first up-down movement mechanism is mounted on the first left-right movement mechanism and is positioned on the front side of the first movable cross beam part. Thefirst processing main shaft is fixedly mounted on the first up-down movement mechanism. The second cross beam assembly has a corresponding structure of the first cross beam assembly. The second guiderail assembly has a corresponding structure of the first guide rail assembly. The second cross beam assembly is movably mounted on the second guide rail assembly. The glass engraving and milling machine has the effect of improving the processing efficiency.

Owner:SHENZHEN CREATE CENTURY MACHINERY

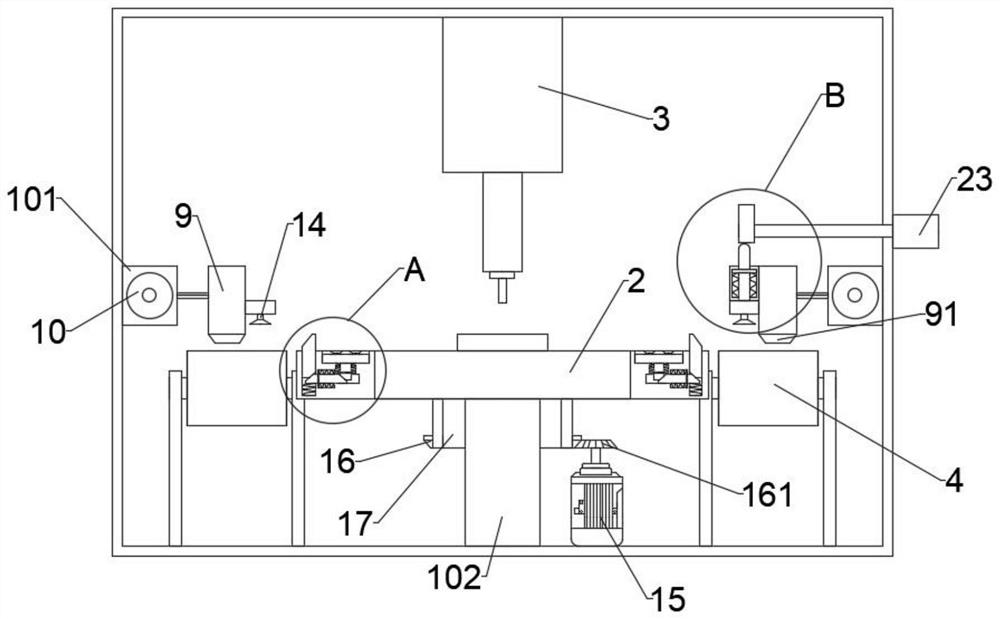

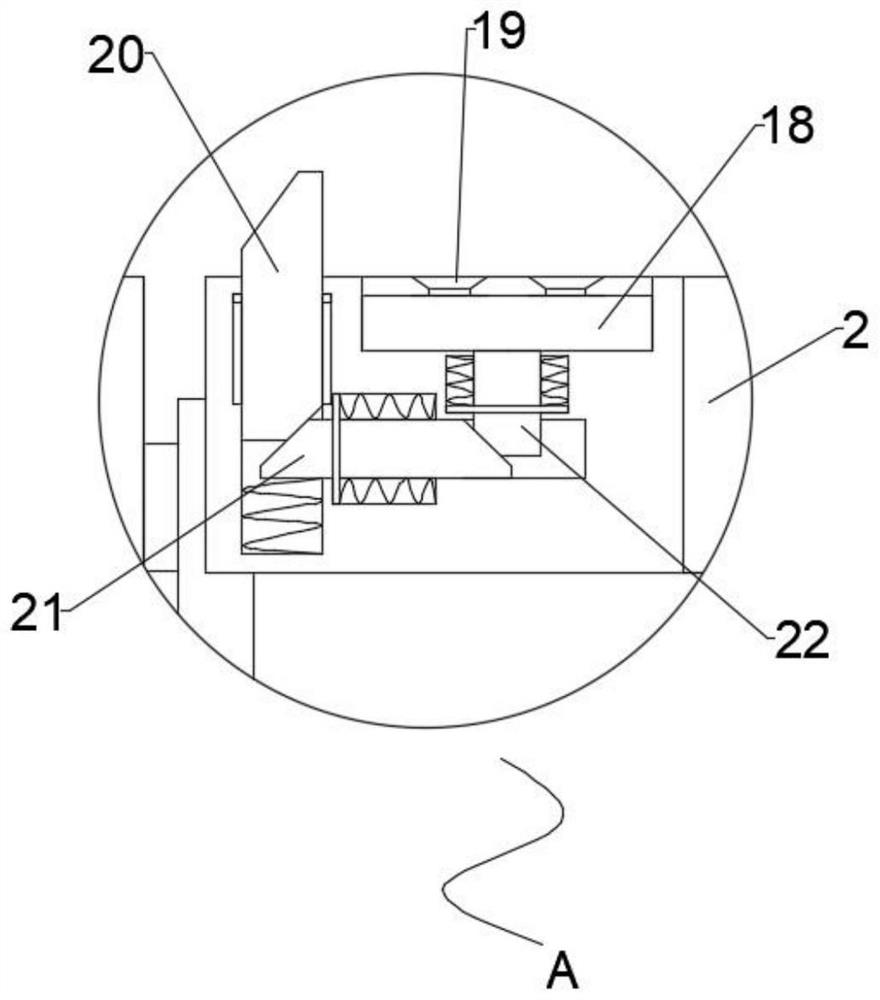

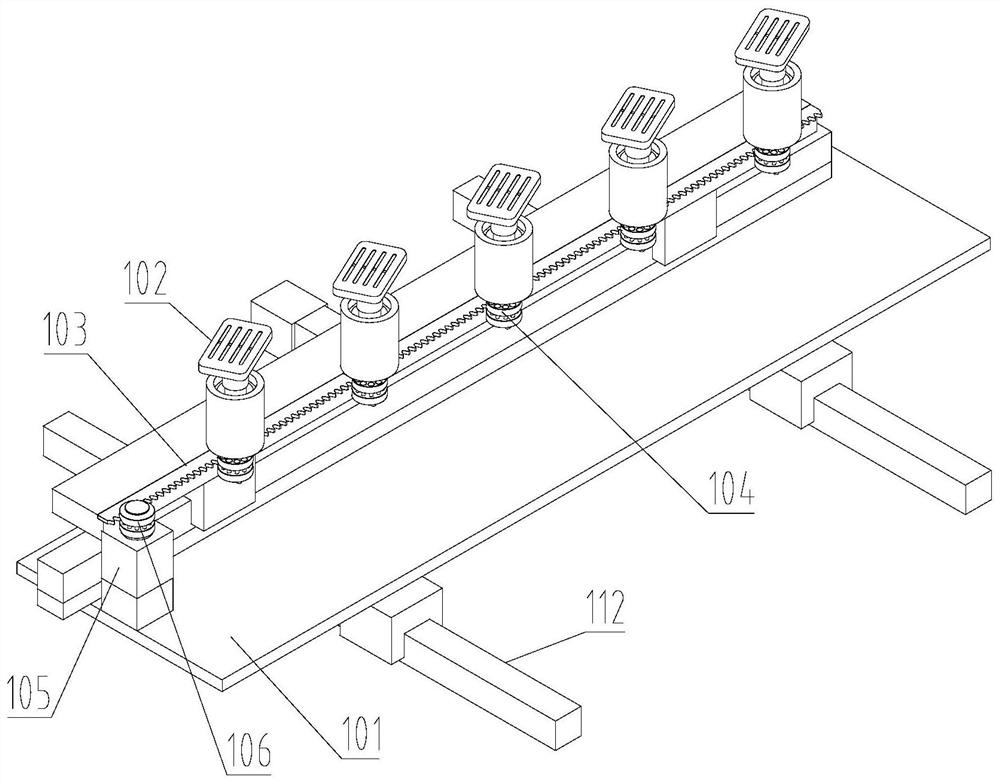

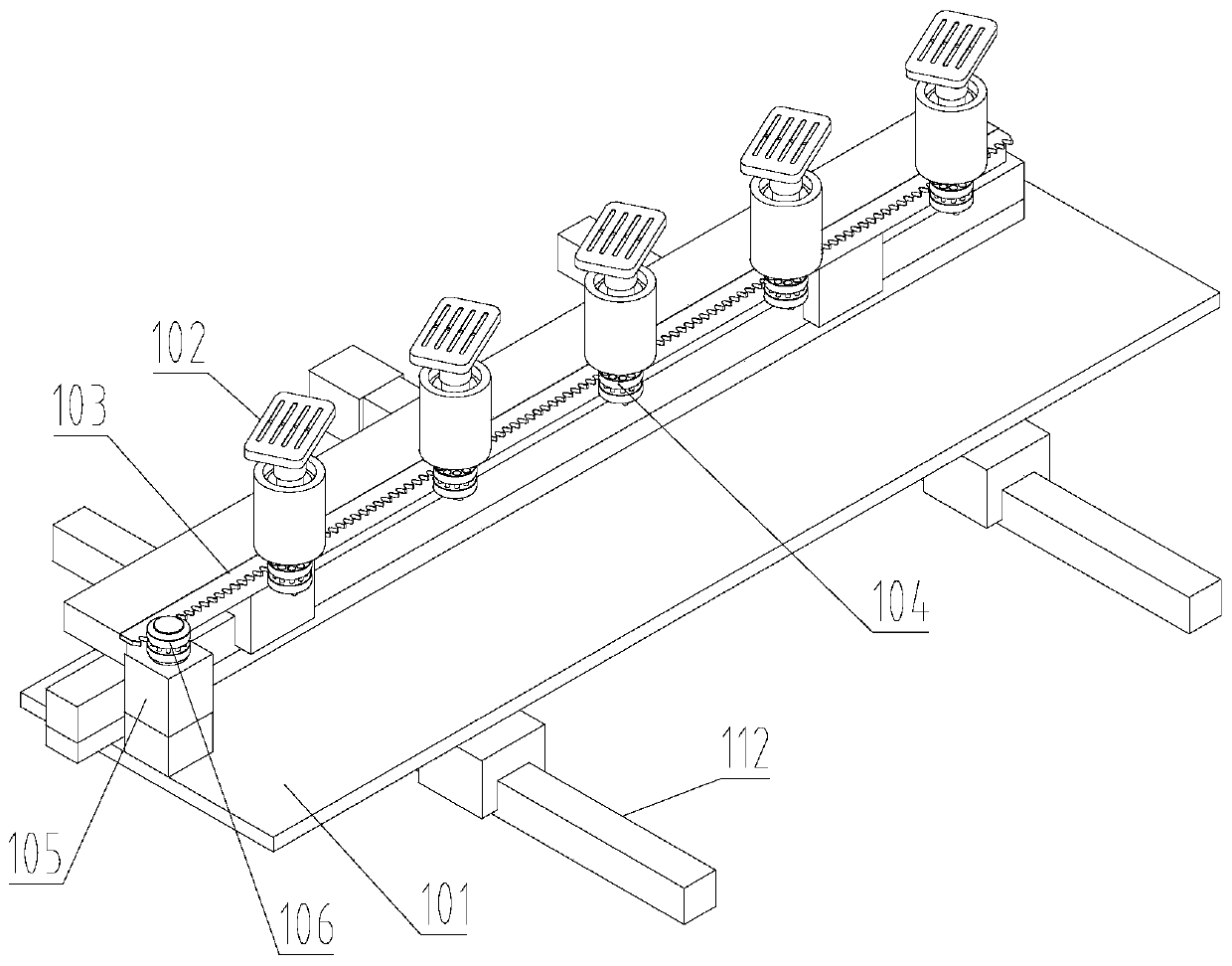

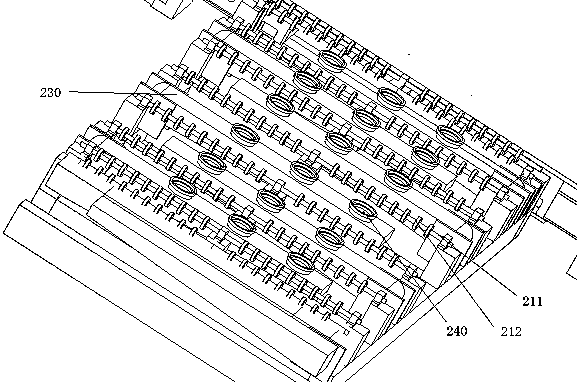

glass engraving machine

The invention discloses a glass engraving machine. The glass engraving machine comprises a rotating device (100) and a grinding head device (200), the rotating device (100) comprises an adsorption platform (102) for storing the to-be-processed glass, the adsorption platform (102) is configured to be capable of rotating around the axis arranged in the vertical direction, and the grinding head device (200) comprises a cutter head (201) for processing the glass. The glass engraving machine is high in whole machine rigidity, high in processing efficiency and high in processing quality.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

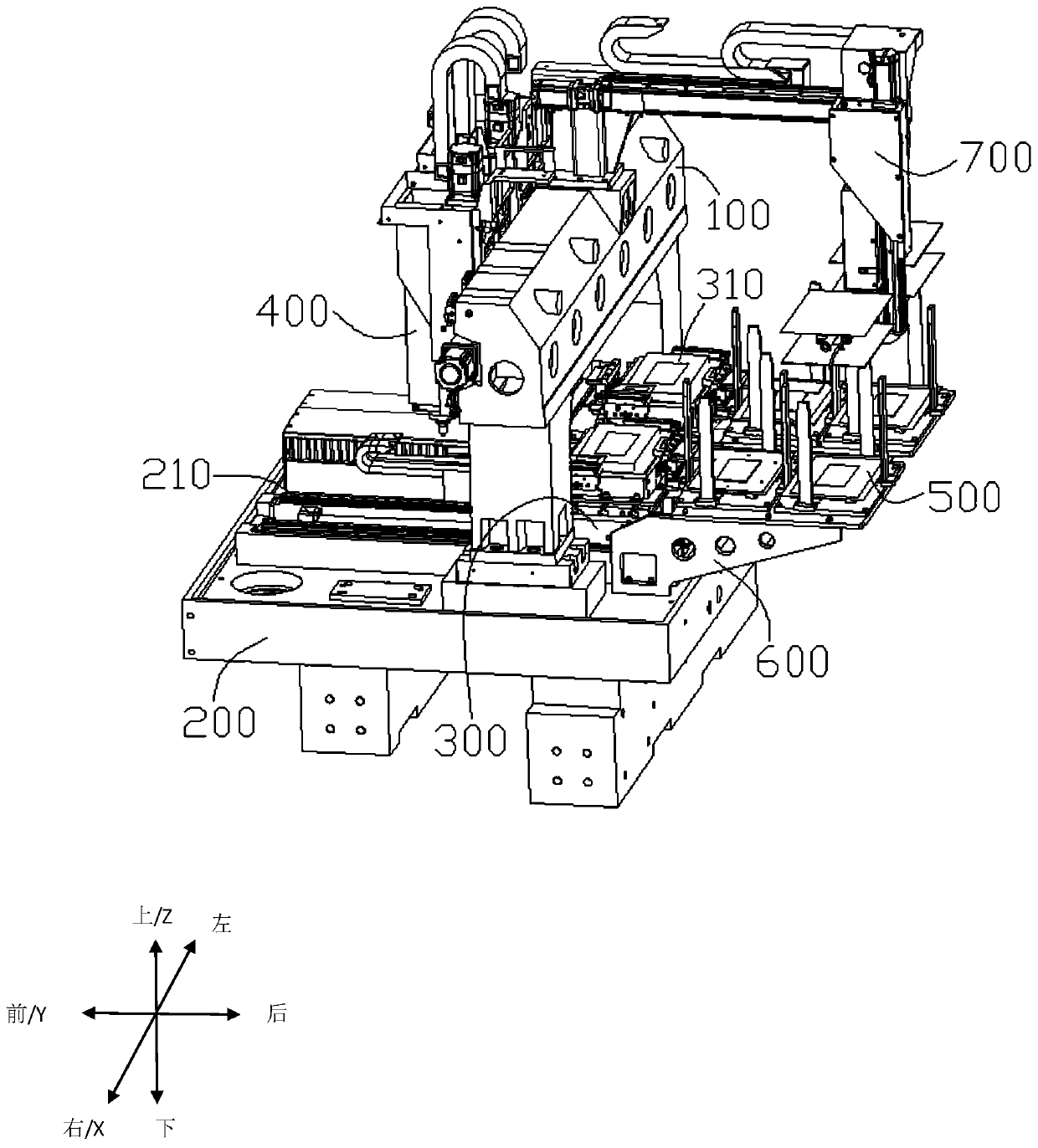

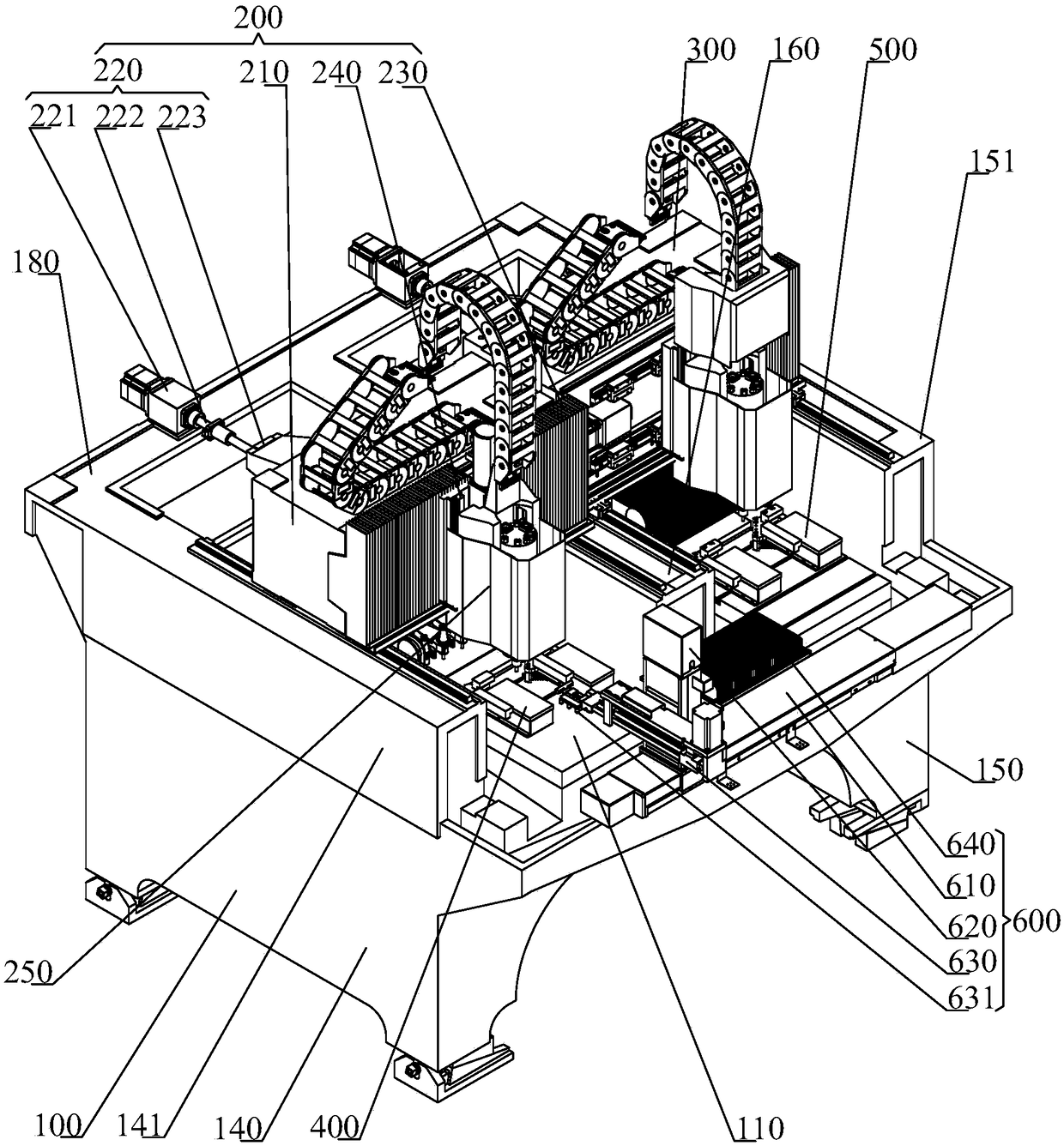

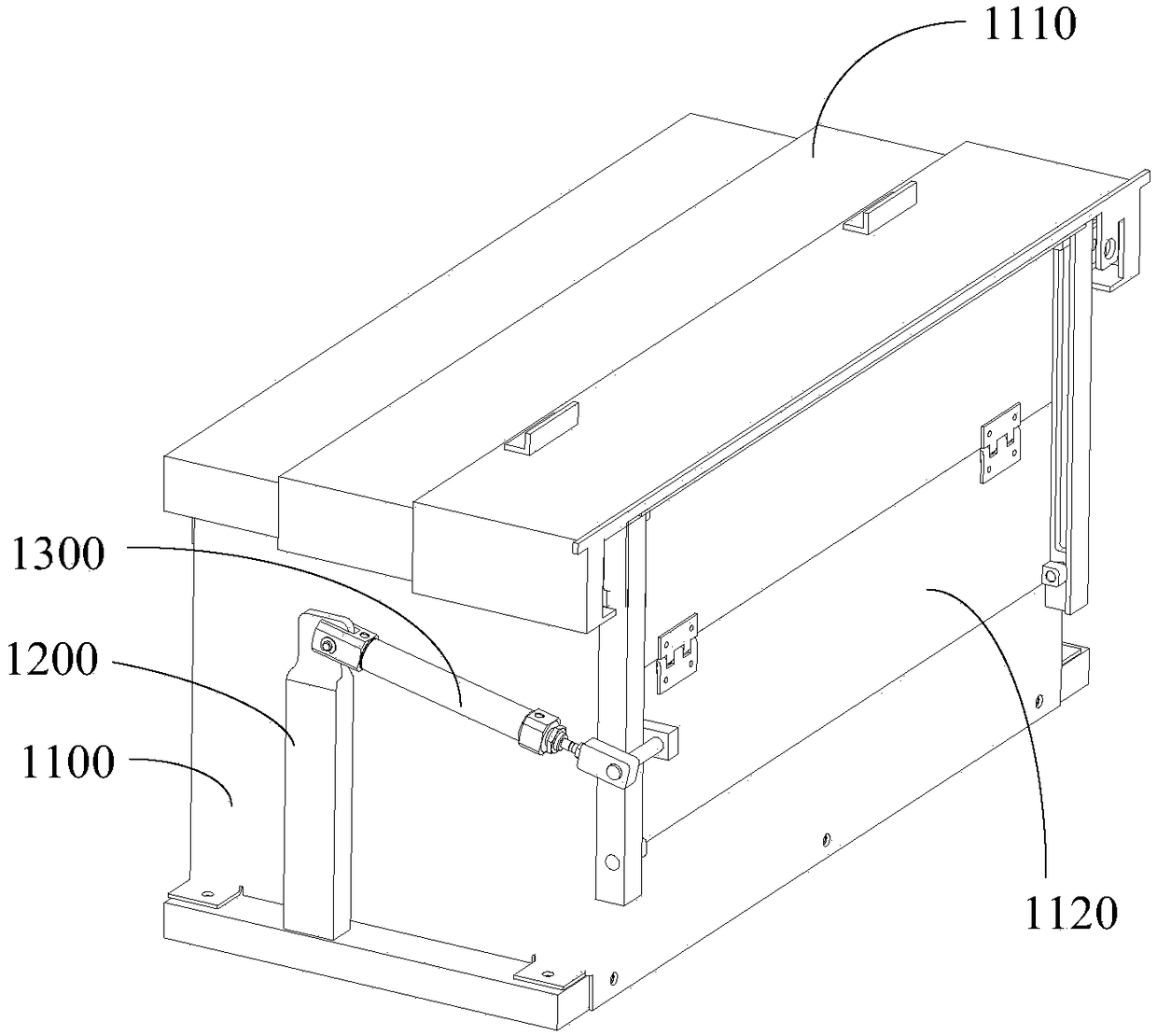

Movable column type automatic feed and discharge glass engraving and milling machine and working method thereof

PendingCN109228767ASimple structureSmall footprintGripping headsOther artistic work equipmentsEngineeringSmall footprint

The invention discloses a movable column type automatic feed and discharge glass engraving and milling machine and a working method thereof. The glass engraving and milling machine comprises a base, amachining mechanism for machining materials, a feed and discharge mechanical hand for taking and placing the materials, and a working table. The working table and the machining mechanism are both arranged on the base. One end of the feed and discharge mechanical hand is slidingly connected to the base. The other end of the feed and discharge mechanical hand can take and place the materials. The glass engraving and milling machine can continuously take, place and machine the materials without being halted, machining efficiency is improved, the glass engraving and milling machine is simple in structure, small in occupied area and easy to maintain, and production cost is reduced.

Owner:深圳市通快机电有限公司

A rotary displacement glass engraving machine

The invention discloses a rotating and shifting glass engraving machine, which comprises a case and a workbench unit; a manipulator is arranged on the front side of the case; a manipulator is arranged on the front side of the case; The end is provided with a "凵"-shaped rear support frame with the opening facing downward; the front end surface of the horizontal part of the rear support frame is equipped with an external engraving device and an internal engraving device; The base of the workbench; a ring-shaped outer workbench and an inner workbench are arranged on the base of the workbench; the inner workbench is located in the outer workbench and the two are coaxially arranged; the inner workbench and the outer workbench are respectively provided with a number of circular Evenly distributed workpiece fixtures; the outer engraving device is used to process the workpiece on the outer table; the inner engraving device is used to process the workpiece on the inner table.

Owner:信丰尚玻建材有限公司

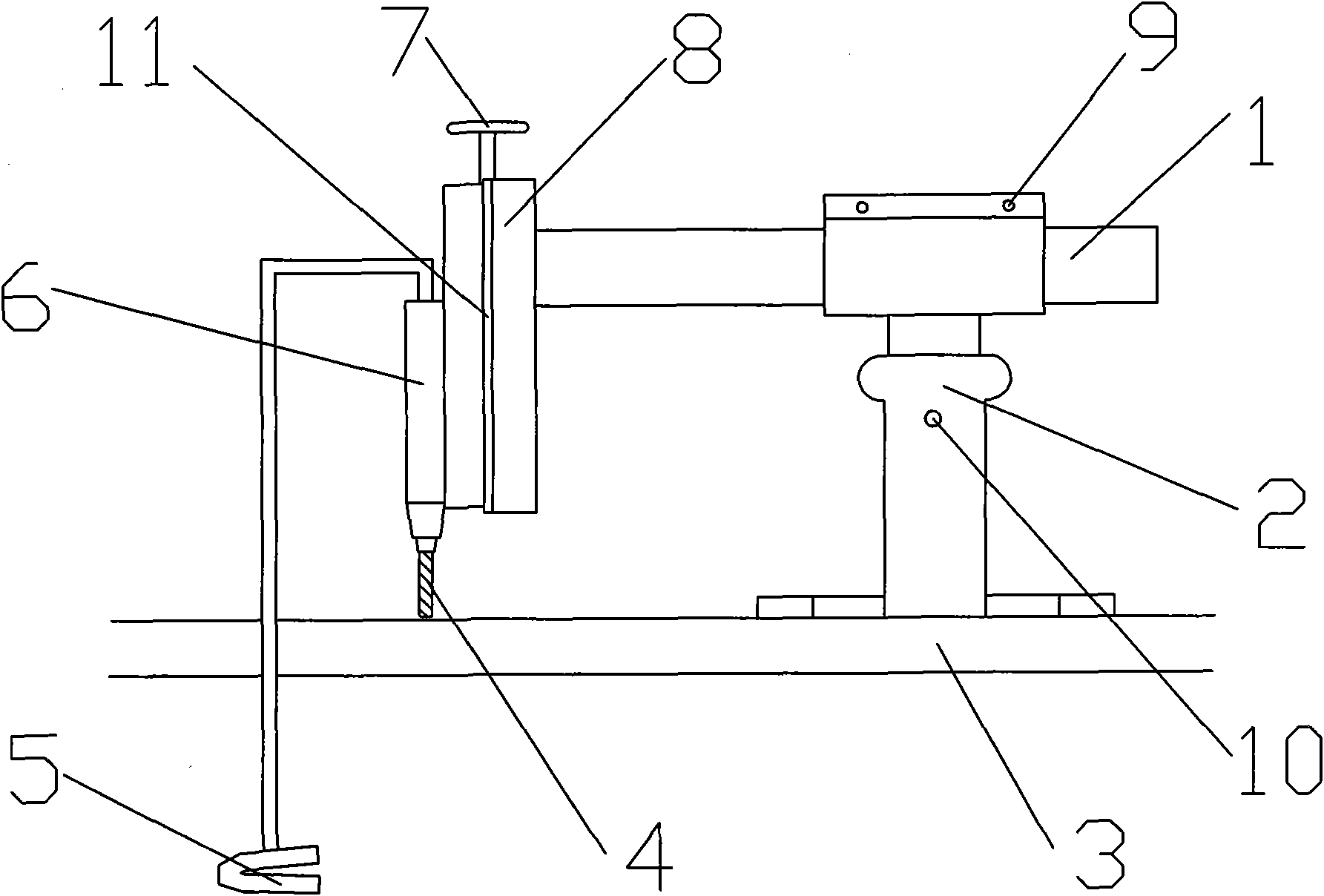

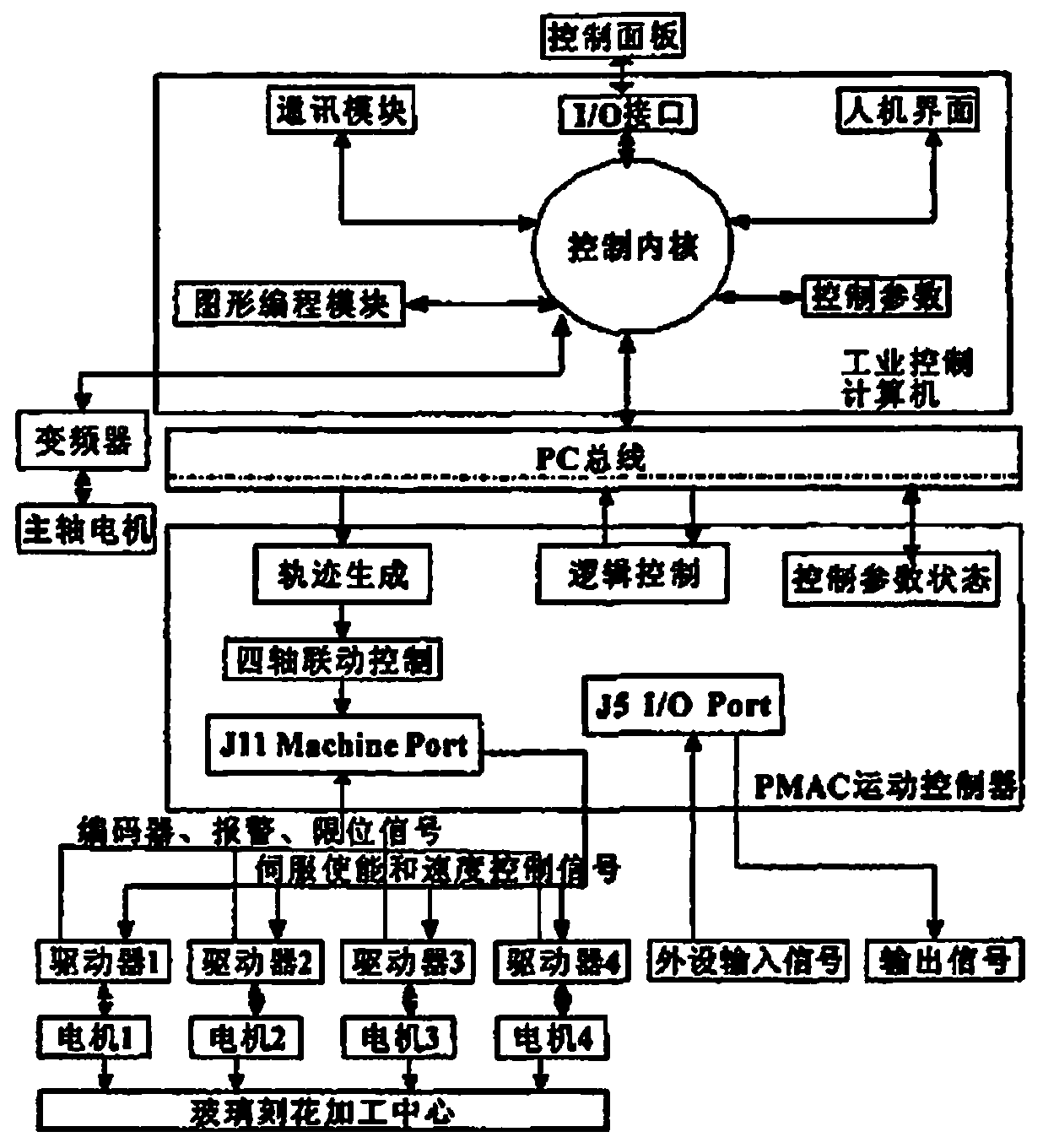

Four-axis linkage numerical control glass carving processing center control system

InactiveCN107783499AImprove flexibilityImprove adaptabilityNumerical controlControl mannerSystems management

A four-axis linkage CNC glass engraving machining center control system adopts the control mode of PC+PMAC open multi-axis motion controller, inserts the PMAC motion control card into the standard slot of the PC for real-time control, and the PC acts as The upper computer of the man-machine interface and system management. Through modular design, the control system establishes a unified reconfigurable system platform, which enhances the flexibility and adaptability of the CNC system, and enables my country's glass machining industry to further develop and continuously improve, catching up with or even surpassing foreign equipment.

Owner:许亚夫

Efficient CNC engraving and milling machine with dust collection structure for glass processing

ActiveCN112572035AImprove extraction efficiencyGuaranteed processing effectLaser beam welding apparatusModel makingProcess engineeringAir blower

The invention discloses an efficient CNC engraving and milling machine with a dust collection structure for glass processing, and relates to the technical field of glass processing. The efficient CNCengraving and milling machine specifically comprises a base and a switching mechanism shell, a workbench is fixed to the upper surface of the base, a glass main body is arranged on the upper surface of the workbench, an electric telescopic rod is arranged in the workbench, the tail end of the electric telescopic rod is connected with a push plate, and a first chuck is fixed to the upper end of thepush plate. According to the efficient CNC engraving and milling machine with the dust collection structure for glass processing, a dust suction port is formed, so that in the clamping process of clamping plates, the dust suction port sucks chippings generated during glass engraving through suction of a dust suction pipeline and an exhaust fan, and the chippings are stored in a waste box in the base; and an air blower is arranged in a second chuck on the right side of the glass main body, chippings can be blown to the dust suction port to be sucked, the chipping suction efficiency is greatlyimproved through pairwise cooperation, the glass surface machining effect is effectively guaranteed, and a production workshop is cleaner and more sanitary.

Owner:HULUNBUIR UNIV +1

Combined production line of glass accurate engraving machines

The invention discloses a combined production line of glass accurate engraving machines. Each accurate glass engraving machine comprises a base, worktables, machine heads, cross beams and saddles; thecross beams are arranged at the upper ends of the bases in a sliding manner and slide in the direction of the Y axis, the worktables are fixed to the bases, the saddles are in sliding connection withthe cross beams and slide in the direction of the X axis, the machine heads are located above the worktables and are arranged on the saddles in a sliding manner, the machine heads slide in the direction of the Z axis, and the combined production line of the glass accurate engraving machines comprises a mechanical arm and multiple glass accurate engraving machines; the mechanical arm is shared bythe multiple glass accurate engraving machines; the mechanical arm comprises a sliding rod crossing all the glass accurate engraving machines and a workpiece grabbing mechanism which is arranged on the sliding rod in a sleeving manner and in sliding connection with the sliding rod; the workpiece grabbing mechanism is used for feeding and discharging. The combined production line has the beneficialeffects that workers can conveniently carry out unified control and management, meanwhile, the number of mechanical arms is reduced, and the production cost is reduced.

Owner:SHENZHEN CREATE CENTURY MACHINERY

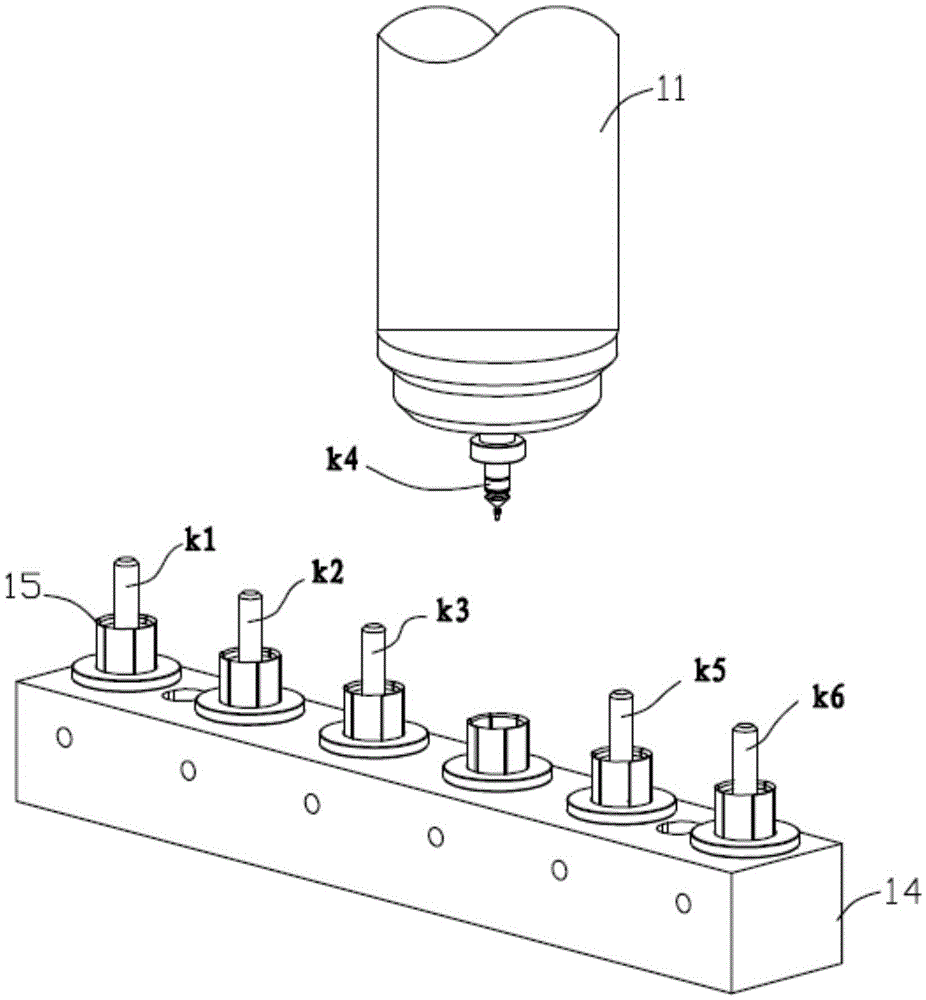

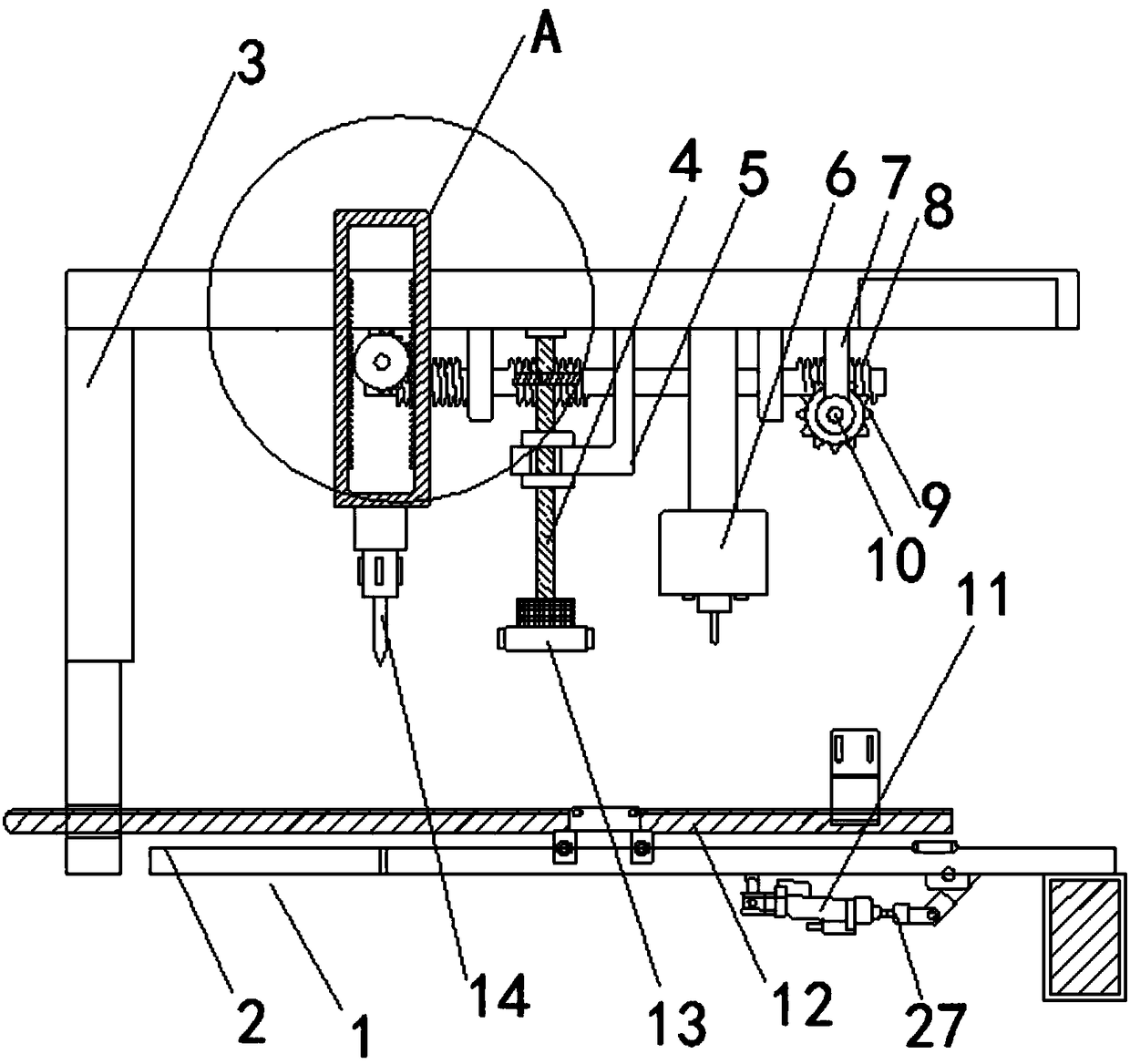

Positioning device of CNC engraving and milling machine

ActiveCN108177472AImprove engraving qualityNovel structureEdge grinding machinesGrinding feed controlGear wheelEngineering

The invention discloses a positioning device of a CNC engraving and milling machine. The positioning device comprises a device body, wherein a base is arranged on the bottom end of the device body, abearing frame is arranged on the top end of the device body, a frame is arranged on the bearing frame, a lifting gear is installed in the frame, a plurality of lifting teeth are arranged on the innerwall of the frame, an engraving mechanism is arranged on the bottom end of the frame, a worm is arranged on one end of the lifting gear, a connecting rod is installed on one end of the worm, a drivinggear is arranged on the bottom end of the connecting rod, a motor is arranged on one end of the driving gear, and a CNC engraving and milling mechanism, a fixed rod and a lifting rod are installed between the frame and the connecting rod. The positioning device has the advantages of novel structure and simplicity and convenience in operation, air pressure in an air tap is changed by virtue of anair cylinder which is externally connected with an air pipe, so that glass is adsorbed, and an infrared signal of an infrared induction lamp is received by an infrared receiver, so that engraving, grinding and CNC engraving and milling are performed in the glass, the operating errors are reduced, the glass engraving quality is increased, defective products are reduced, and the production cost is reduced.

Owner:江苏瑞苏科技有限公司

Glass engraving machine

The invention discloses a glass engraving machine. The glass engraving machine comprises a rotating device (100) and a grinding head device (200), the rotating device (100) comprises an adsorption platform (102) for storing the to-be-processed glass, the adsorption platform (102) is configured to be capable of rotating around the axis arranged in the vertical direction, and the grinding head device (200) comprises a cutter head (201) for processing the glass. The glass engraving machine is high in whole machine rigidity, high in processing efficiency and high in processing quality.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

A large glass engraving machine

ActiveCN106394094BAchieve entryAffect normal workOther artistic work equipmentsEngravingGlass engraverEngineering

Owner:百能数控设备(福建)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com