Method for making glass rear cover of organic electroluminescence display

A production method and display technology are applied in the production field of the glass back cover of organic electroluminescent displays, which can solve the problems of thin glass deformation, complex process, low production efficiency, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

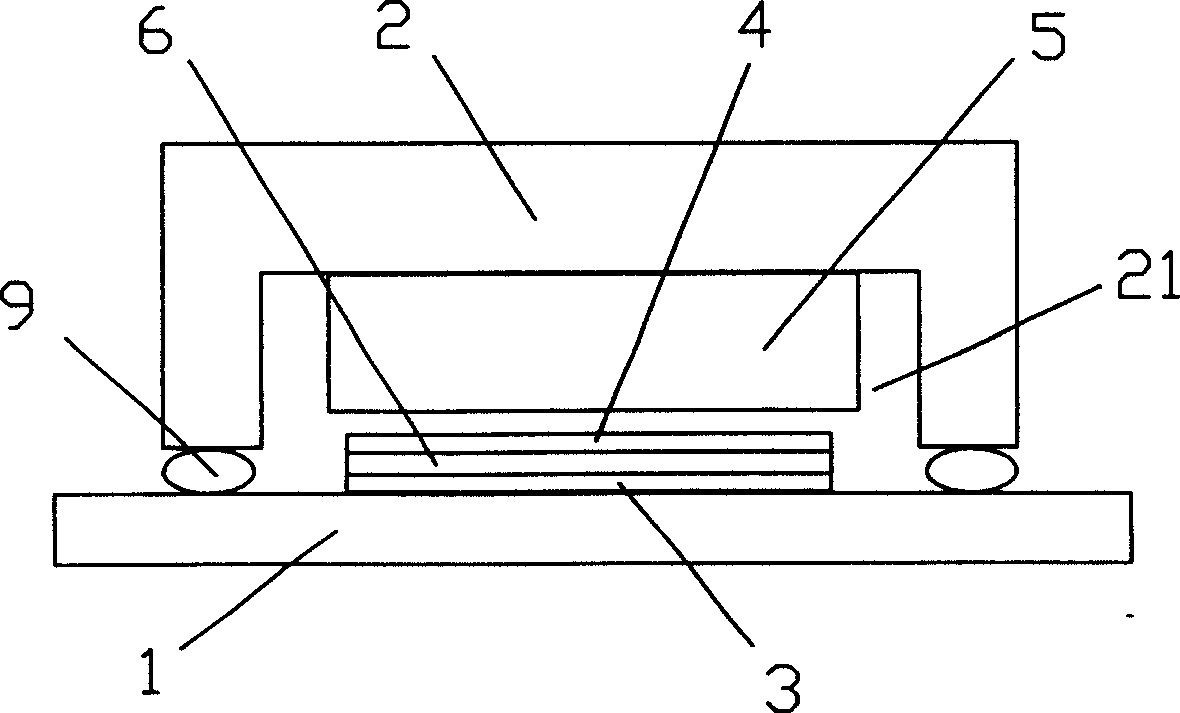

[0025] Such as image 3 As shown, the organic electroluminescence display is composed of a flat glass front cover 1 and a glass back cover 2 with a groove 21 sealed and connected through a sealing glue 9, and the groove 21 forms a sealed inner cavity, and the The groove 21 is provided with a desiccant 5, and the front of the desiccant 5 is provided with positive and negative electrodes 3 and 4, and a thin layer of organic light-emitting material layer 6 is coated between the two electrode interlayers, and the positive and negative electrodes 3 and 4 Direct current is applied to the organic luminescent material layer 6 to drive it to emit light. The process of etching grooves on flat glass to form the glass back cover of the present invention, that is, the method for making the glass back cover of an organic electroluminescent display comprises the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com