Glass engraving fabricating technique

A production process and glass technology, which is used in the process of producing decorative surface effects, decorative arts, special decorative structures, etc., to achieve high artistic appreciation, scientific material selection, and good artistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

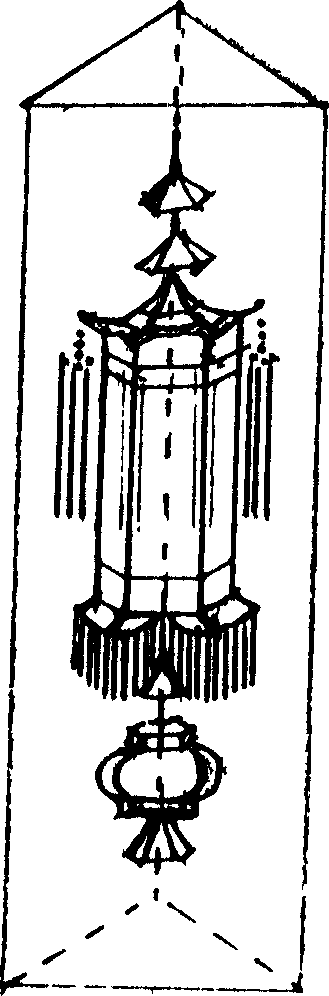

[0009] Embodiment 1, the production of palace lantern table screen and flower and bird table screen. Use plexiglass or crystal glass with a thickness of 2 cm to make a regular triangular prism with a height of 75 cm, polish it brightly, and use a computer engraving machine and assorted small files to carve a pattern 1 (all kinds of palace lanterns, vases, flowers and birds) on one of the edges. ), take this as a unit, select 5 according to the production target as a group, and embed them in the prepared table screen frame, package and install the bracket.

Embodiment 2

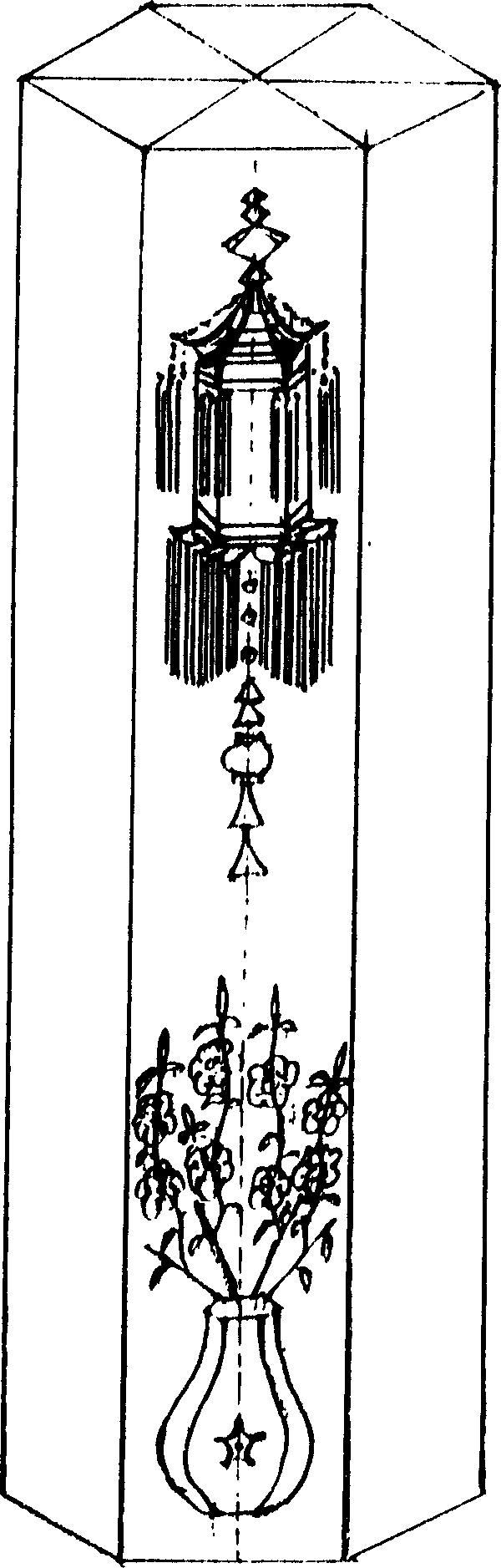

[0010] Embodiment 2, the making of palace lamp vase type desk lamp. Use organic or crystal glass blanks with a thickness of 2 cm to make regular three-branched columns with a height of 75 cm, polish them brightly, and use the method in Example 1 to carve palace lanterns and vases, select 6 as a group, and inlay the edges with patterns inwards Put it into a hollow hexagonal prism frame made of plastic, use the hexagonal prism as a lamp post, and match the lamp holder, lampshade and base. And put on the light bulb, open it, and connect it with wires.

Embodiment 3

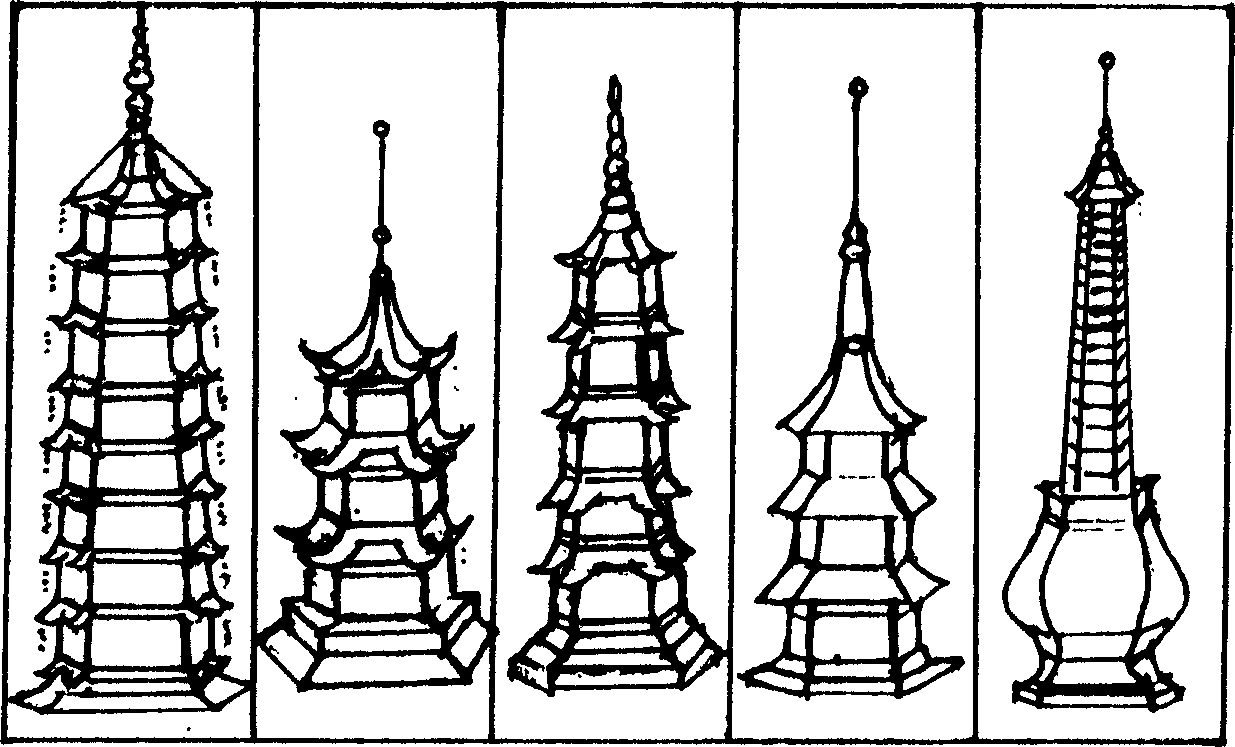

[0011] Embodiment 3, the making of pagoda columnar desk lamp, make the regular triangular prism of the same size as example 2 engraved with well-known pagoda patterns in various places in China by the same method as above, polish it brightly, and insert the edges engraved with patterns into the hollow made of plastic In the hexagonal prism frame, use it as a lamp post, add a lamp holder, a lampshade and a base, install a light bulb, a switch, and wires to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com